Evolution Controls EVO/ECM-Modbus User guide

©Evolution Controls Inc.

10-Sept-2020

EVO/ECM-Modbus RTU Series 2

Application Guide

©2001 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Contents

DESCRIPTION................................................................................................................................... 1

Mounting ........................................................................................................................................ 3

Enclosure ........................................................................................................................................ 4

WIRING........................................................................................................................................... 5

Power Connection ...........................................................................................................................................5

Trunk Connection............................................................................................................................................5

Motor Connection ...........................................................................................................................................6

PWM Motor Output...................................................................................................................................................6

0-10 VDC Motor Output ............................................................................................................................................7

PROTOCOL ...................................................................................................................................... 8

Register Usage ................................................................................................................................................8

Dynamic Registers .......................................................................................................................................................8

Read Only Registers.....................................................................................................................................................8

Default Registers .........................................................................................................................................................9

Configuration Registers................................................................................................................................................9

RPM Alarm Limit Registers ...........................................................................................................................................9

Register Assignments.....................................................................................................................................10

Register 1 - On/Off Control and Status.........................................................................................................................10

Register 2 - Motor 1 - % Out .......................................................................................................................................11

Register 3 - Motor 2 - % Out .......................................................................................................................................12

Register 4 - Motor 3 - % Out .......................................................................................................................................12

Register 5 - Motor 4 - % Out .......................................................................................................................................12

Register 6 - Motor 1 –RPM.........................................................................................................................................12

Register 7 - Motor 2 - RPM .........................................................................................................................................12

Register 8 - Motor 3 - RPM .........................................................................................................................................12

Register 9 - Motor 4 - RPM .........................................................................................................................................12

Register 10 - Motor 1 –Default % Out .........................................................................................................................13

Register 11 - Motor 2 –Default % Out .........................................................................................................................13

Register 12 - Motor 3 –Default % Out .........................................................................................................................13

Register 13 - Motor 4 –Default % Out .........................................................................................................................13

Register 14 - Configurations........................................................................................................................................13

Register 15 - Group1 Address .....................................................................................................................................16

Register 16 - Group 2 Address.....................................................................................................................................16

Register 17 - Unit Address ..........................................................................................................................................17

Register 18 - Baud Rate ..............................................................................................................................................17

Register 19 - Motor 1 Low RPM Limit...........................................................................................................................17

Register 20 - Motor 2 Low RPM Limit...........................................................................................................................17

Register 21 - Motor 3 Low RPM Limit...........................................................................................................................17

Register 22 - Motor 4 Low RPM Limit...........................................................................................................................18

Register 23 - Motor 1 High RPM Limit..........................................................................................................................18

Register 24 - Motor 2 High RPM Limit..........................................................................................................................18

Register 25 - Motor 3 High RPM Limit..........................................................................................................................18

Register 26 - Motor 4 High RPM Limit..........................................................................................................................18

EVO/ECM-Modbus RTU protocol ....................................................................................................................19

Read Registers Command (03) ....................................................................................................................................19

Write Single Register Command (06) ...........................................................................................................................20

©Evolution Controls Inc.

10-Sept-2020

EVO/ECM-Modbus RTU Series 2

Application Guide

©2001 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Write Multiple Registers Command (16) ......................................................................................................................21

Read Multiple Coil Registers Command (01).................................................................................................................22

Write Single Coil Register Command (05) .....................................................................................................................23

ADDRESSING.................................................................................................................................. 24

INTEGRATION ................................................................................................................................ 26

BACnet IP......................................................................................................................................................26

Modbus to BACnet Gateway.......................................................................................................................................27

BACnet Mapping .......................................................................................................................................................28

Babel Buster SPX Gateway Setup Procedure.................................................................................................................29

Modbus to BACnet Integration Procedure....................................................................................................................40

CONFIGURATION............................................................................................................................ 45

Configuration Tool.........................................................................................................................................45

EVO/ECM-ModBus Registers Coils............................................................................................. 47

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 1

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

DESCRIPTION

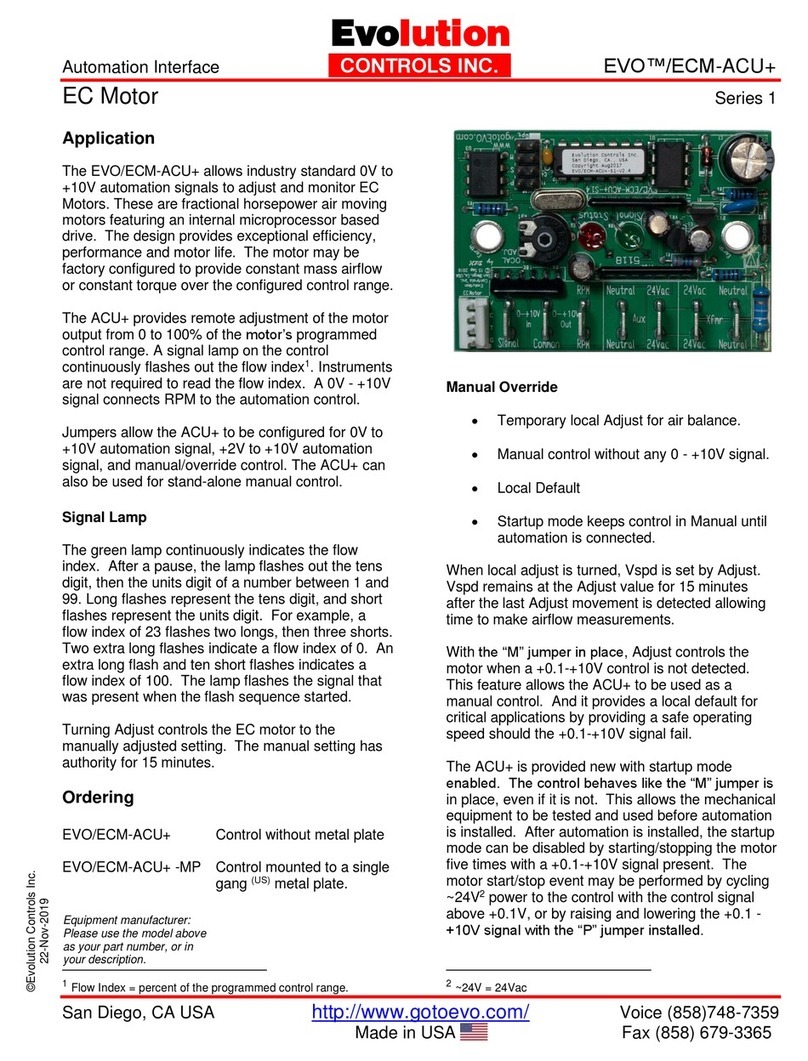

EVO/™ECM-Modbus

The EVO/ECM-Modbus RTU (Remote Terminal Unit)

allows an industrial or building automation system to

monitor and control Electronically Commutated

Motors (ECM) over an industry standard Modbus

RTU serial data link. Each RTU connects to four ECM

Motors.

ECM motors are fractional horsepower blower motors featuring an internal microprocessor to

provide exceptional efficiency, performance, and motor life. The motor may be programmed for

constant airflow or constant torque.

Modbus is an industry standard communications protocol allowing connection to most industrial

and building automation systems.

The EVO/ECM-Modbus RTU allows the automation system to control each motor's output and

on/off; monitor each motor's RPM and control status; and set default values used during power

up and communications interruptions.

A four-conductor low voltage control cable connects each motor to the RTU. Low voltage on/off

control is provided over the control cable by direct connection to the motor. External relays or

starters are not required for ECM Motors.

The EVO/ECM-Modbus RTU allows adjustment of the motor output from 0% to 100% of the

programmed control range. The ECM motor sends a signal from its commutator circuit to the RTU.

The RTU translates this signal to a 0-1500 RPM value.

During operation, the automation system may dynamically change motor outputs, and turn

motors on and off to meet current operating needs. Should communications from the

automation system fail, the EVO/ECM-Modbus RTU can be set to hold the last commanded values

from the automation system or revert to defaults stored in the RTU's non-volatile memory.

Defaults are invoked on power up. Defaults are overridden when communication is established,

and dynamic values sent to the RTU.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 2

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Notes…

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 3

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Mounting

Mount the EVO/ECM-Modbus RTU inside a metal control cabinet or enclosure. Make sure the

enclosure is earthed. When mounting the low voltage power transformer in the same enclosure,

be sure to separate the high and low voltage sections of the enclosure, as required by good safety

practice, and building codes.

To reduce EMI (electro-magnetic interference), tightly fasten the control mounting posts to an

earthed metal surface of the enclosure. Ensure good electrical contact between the mounting

posts and electrical ground.

Low voltage communications and motor control wiring can be routed into the low voltage section

of the metal enclosure or be plugged into opening in the side of the enclosure. All external

connections are made to one side of the board. Make a rectangular cutout in the side of the

enclosure when the application requires external plug in of motor and communication cables.

2.69"

2.48"

1.78”

0.34”

3.83”

3.62"

1.79”

0.42”

Board Dimensions

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 4

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Enclosure

These drawings detail the minimum inside floor and face dimensions for a suitable enclosure.

1.20”

2.20” 3.58”

4.25”

1.00”

0.20"

0.61”

0.90”

0.12”

0.38”

3.36”

Inside Face

3.58”

0.90”

2.75”

2.20”

0.38”Ø 0.25”

0.21”2.34”

Inside Floor

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 5

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

WIRING

POWER CONNECTION

Power the EVO/ECM-Modbus RTU with a ~24V 50/60 Hz 10 VA low voltage

power source. Connect the hot side of the power source to the ~24V

connection. Connect the neutral side of the power source to the neutral

connection. Observe all building and electrical code requirements

concerning low voltage power sources and wiring to insure a safe, reliable

installation. In most jurisdictions the neutral must be earthed.

TRUNK CONNECTION

A single trunk routes from one EVO/ECM-Modbus RTU to the next, connecting up to 31 RTUs to

the Modbus RTU master. The trunk may be up to 4000 feet long. Connect a 120-ohm 1/4-Watt

terminating resister at each end of the trunk. The most common connection places the Modbus

RTU master at one end of the trunk. Many Modbus RTU masters have a non-removeable built in

terminator or use an impedance altering means to provide line bias. These masters must be

placed at the end of the line.

When possible, placing the Modbus RTU master in the center of the trunk improves application

versatility, often reduces installation costs, and improves communications reliability.

The trunk cable field terminates to a plug-in connector at each RTU. Use a twisted pair cable with

an overall foil shield. Recommend the use of EIA RS-485 cable 22-24 AWG twisted and balanced,

with an impedance of 100-130 ohms, a capacitance below 100 pF per meter (30 pF per foot), with

a braided shield. Connect the shield to the Shield/Common terminal at each RTU as shown in the

picture below. Do not ground the shield at the RTUs. The shield must be chassis grounded at the

master only.

The shield wire is usually not insulated. Keep the shield leads short between the cable sheath and

the shield connection. Let the other wires be longer!

EVO/ECM-Modbus EVO/ECM-Modbus EVO/ECM-Modbus EVO/ECM-ModbusEVO/ECM-Modbus

Modbus Master EVO/ECM-Modbus

EVO/ECM-Modbus EVO/ECM-Modbus EVO/ECM-Modbus EVO/ECM-Modbus EVO/ECM-Modbus EVO/ECM-ModbusModbus Master

Neutral

24Vac 50/60 Hz

Ground

EVO/ECM-Modbus

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 6

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Traditionally, a Modbus trunk requires a pair of external resistors to pull up and pull down the two

trunk wires to maintain the trunk at a known biasing voltage when no device is communicating.

The EVO/ECM-Modbus is equipped with internal failsafe biasing so no external biasing is required.

EVO™/ECM-Modbus communications is half-duplex. All devices contain a transmitter and a

receiver. Only one transmitter on a trunk can be transmitting at a time. All other devices on

the trunk (Master and RTU slaves) must be in receive.

When a Master finishes sending, it must

quickly "turn-around" so it is ready to

receive a reply from the RTU.

The EVO™/ECM-Modbus reply is very fast. Some Masters, especially those where turn-around is

controlled over a higher-level network (server architecture) cannot turn around fast enough to

receive the RTU's reply. The Reply Delay flag in register 14 can be set to

delay the RTU's reply.

MOTOR CONNECTION

PWM Motor Output

A four-conductor cable connects each motor to

the EVO/ECM-Modbus RTU output connector.

Plug the motor end of the cable into the motor

and plug the circuit board end into motor

connection 1, 2, 3, or 4 on the RTU.

The motor control cable may be up to 150 meters

(500’) long.

Motor cables are prefabricated, with an

ECM Motor connector on one end, and a

small 4-pin circuit board connector on the

other.

Order

Motor Cable ECM-CBL_ _

Custom Lengths substitute the length in feet

for the last two digits.

Order connectors from

Digikey PN ED1702-ND

http://www.digikey.com

Communications

Motor

4

Motor

3

Motor

2

Motor

1

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 7

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Some applications may not be suitable for prefabricated cables. Cut a short cable in half, and

splice cable in between as needed for the application. Cables can be field fabricated using the

parts and tooling identified on the cable drawing. (The pneumatic bench tool can be used in the

field and is preferred over a hand-operated tool.)

0-10 VDC Motor Output

The length of the 0-10 VDC motor control cable is more limited by the line loss and the amount of

electrical noise interference. The ECM-Modbus RTU’s 0-10 VDC is rated at 10 mA. The rough

guideline for maximum cable length is 45 meters (150’) for 22 awg wire and 90 meters (300’) for

18 awg wire.

Depending on the programming of the motor, the RPM and Go signals may not be used for a 0-10

VDC controlled motor. If that the case, only the Red and Green wires of the EVO/ECM-CBL-?? are

used.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 8

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

PROTOCOL

The EVO/ECM-Modbus RTU communicates RS485 using baud rates from 1200 to 38400 bauds, no

parity and 1 stop bit.

The EVO/ECM-Modbus RTU responds to three Modbus master commands to address data

registers 1 through 26. Registers 1 through 16 and 19 through 26 are directly addressed.

Registers 17 and 18 can only be accessed using the service address 255.

Each Modbus register is 16 bits long. These bits are organized as two bytes (8 bits). Each byte

contains two nibbles (4 bits). A Modbus register can hold one piece of information, or multiple

pieces of information. A piece of information can use both bytes, or multiple information can be

stored in each byte, nibble, or bit.

Register 1, Register 14 and two additional bits are also organized as 34 coil registers. Each coil is a

bit that can be accessed individually. The two additional bits are for setting the controller to write

defaults to dynamic registers and to reset the controller.

The chart below describes the data stored in each register.

Command 03 reads multiple registers

Command 16 writes multiple registers

Command 06 writes to a single register

Command 01 read multiple coil registers

Command 05 write a single coil register

REGISTER USAGE

Dynamic Registers

Registers 1 through 5 contain dynamic operating data. The EVO/ECM-Modbus RTU uses this

information to turn the motors on/off, and to set each motor's airflow. These registers may be

written by the Modbus RTU Master, or set to values stored in the default registers. The defaults

are restored on RTU power up, on RTU reset, or when a communications timeout occurs. The

Modbus master should read these registers on each scan of the trunk.

Read Only Registers

Registers 6 through 9 only respond to a read command from the Modbus Master. These registers

contain each motor's RPM. The Modbus master should read these registers on each scan of the

trunk.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 9

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Default Registers

Registers 10 through 14 contain default operating data. The EVO/ECM-Modbus RTU stores this

data in non-volatile E2PROM, so the data is available when the RTU is powered up. Default values

are copied to their respective dynamic registers on RTU power up, on RTU reset, or when a

communications timeout occurs.

Configuration Registers

Registers 15 through 18 store EVO/ECM-Modbus RTU configuration information in non-volatile

E2PROM.

RPM Alarm Limit Registers

Registers 19 through 26 store high and low alarm limits for each motor. These values are stored in

E2PROM only. There are no associated dynamic registers for RPM limits.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 10

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

REGISTER ASSIGNMENTS

Register 1 - On/Off Control and Status

Low Byte

Motor Enable/Disable Nibble

Each of the 4 bits in this nibble represents the associated motor enable command. If the

associated bit is set (1), and the associated flow index is greater than "0" the motor runs. If the

bit is clear (0), the motor stops regardless of the associated flow index. The Modbus RTU Master

writes to this nibble to enable/disable motors and reads the nibble to retrieve the motor

enable/disable status.

Bit 0 = Motor 1, Bit 1 = Motor 2, Bit 2 = Motor 3, and Bit 3 = Motor 4.

RPM Alarm Nibble

Each of the 4 bits in this nibble represents the associated motor alarm status. If the associated bit

is set (1), the motor RPM is not between the low and high RPM limits. If the associated bit is clear

(0), the associated motor RPM is between the low and high RPM limits. When a motor is turned

off, the RPM Alarm bit is cleared. The alarm bit is held clear for 20 seconds after a starting a

motor. When an RPM alarm bit is set, the alarm clears when the associated motor RPM is at least

50 RPM or 100 RPM inside the low and high RPM limits depending on the hysteresis selection bit

(Coil 29) in Register 14.

Bit 4 = Motor 1, Bit 5 = Motor 2, Bit 6 = Motor 3, and Bit 7 = Motor 4.

High Byte

External Command Flag

A Modbus RTU Master may use the EC flag to mark that it has read default values from the

EVO/ECM-Modbus RTU. The EC flag is cleared if a configuration tool or global command changes

default values. Resetting the RTU also clears the EC flag.

Use of this flag is optional. Using the EC flag increases communications throughput. If the EC flag

is not set, the Modbus RTU Master reads registers 1 through 26, then sets the EC flag. If the EC

flag is set, the Modbus RTU Master only needs to read registers 1 through 9.

Bit 0 = External Command Flag

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 11

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Reserved Flags

These flags reserved for future use

Bits 1, 2, 3, 4, & 5 = Reserved Flags

Communications Timed Out Flag

If valid communications cease for three minutes, the controller sets the CTO flag. When

communications resumes, the Modbus master should report "Communications Restored" then

reset the CTO flag.

Bit 6 = CTO Flag

Reset Flag

When the Modbus RTU Master sets the reset flag, the EVO/ECM-Modbus RTU acknowledges the

command, then resets. The reset clears (0) the Reset Flag, and sets the Motor On/Offs and Motor

% Outs to their default values

Register 1, High Byte, bit 7 = Reset Flag

Register 2 - Motor 1 - % Out

The equipment manufacturer programs the ECM Motor to operate between a minimum airflow

(or torque) and a maximum airflow. A flow index between 1 and 100 (percent) in this register

controls ECM Motor 1 to the associated airflow.

V = Vindex * (Vmax -Vmin) + Vmin

A zero flow index stops the motor. The motor speed can be disabled by clearing the associated

bit in the enable/disable nibble of Register 1.

Integer value from 0 to 100

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 12

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Register 3 - Motor 2 - % Out

…See Register 2 description

Register 4 - Motor 3 - % Out

…See Register 2 description

Register 5 - Motor 4 - % Out

…See register 2 description.

Register 6 - Motor 1 –RPM

The EVO/ECM-Modbus RTU reads commutator pulses from ECM motor 1. The RTU integrates

these pulses and calculates the motor's RPM.

2 byte Integer Value

Register 7 - Motor 2 - RPM

…See register 6 description.

Register 8 - Motor 3 - RPM

…See register 6 description.

Register 9 - Motor 4 - RPM

…See register 6 description.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 13

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Register 10 - Motor 1 –Default % Out

When the EVO/ECM-Modbus RTU is reset, the value stored in register 10 is transferred to register

2. Register 2 sets the airflow (torque) for motor 1. The motor operates at this airflow until the

Modbus RTU Master changes the value in register 2. Defaults may also be selectively invoked

during loss of communications with the Modbus RTU Master.

Lower Byte, Integer value from 1 to 100

Register 11 - Motor 2 –Default % Out

…See register 10 description.

Register 12 - Motor 3 –Default % Out

…See register 10 description.

Register 13 - Motor 4 –Default % Out

…See register 10 description.

Register 14 - Configurations

Low Byte

Motor Enable/Disable Defaults Nibble

This nibble sets the default enable/disable state for each ECM Motor. When the EVO/ECM-

Modbus RTU resets, the value stored in this nibble is transferred to the enable/disable nibble in

register 1. This causes each motor to be enabled or disabled to the associated default value. The

Modbus RTU Master changes the value in register 1 enable/disable nibble when communication is

established. Defaults may also be selectively invoked during a loss of communications with the

Modbus Master.

Bit 0 = Motor 1, Bit 1 = Motor 2, Bit 2 = Motor 3, and Bit 3 = Motor 4.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 14

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Configuration Flags Nibble

Flags may be set or cleared to modify the behavior of the EVO/ECM-Modbus RTU. The upper

nibble of the lower byte of register 14 contains 4 flags.

Communication Timeout Flag (Register 14, Bit 4)

If the EVO/ECM-Modbus RTU loses communication, it will continue to operate at the last values

set by the Modbus Master. If the communications timeout flag is set (1), and the RTU does not

receive a valid communication for 3 minutes, a reset will occur, and the default values will be

loaded into their respective dynamic registers.

Reserve Flag (Register 14, Bit 5)

Bit 5 is reserved for future use.

Group 1 Reply Flag (Register 14, Bit 6)

Group addressing allows a write register (16) or write multiple registers (06) command to be

issued to a group of EVO/ECM-Modbus RTUs. None of these RTUs issue a reply to the Modbus

Master, since all RTUs in the group would try to reply at the same time. Some Modbus Masters

can be configured so they do not need a reply. Others will generate a communication error if they

do not receive a reply.

When the Group 1 Flag is set (1), this RTU will provide a reply when the Group 1 address is polled.

Only set this flag for one of the RTUs in the group.

Group 2 Reply Flag (Register 14, Bit 7)

Group addressing allows a write register (16) or write multiple registers (06) command to be

issued to a group of EVO/ECM-Modbus RTUs. None of these RTUs issue a reply to the Modbus

Master, since all RTUs in the group would try to reply at the same time. Some Modbus Masters

can be configured so they do not need a reply. Others will generate a communications error if

they do not receive a reply.

When the Group 2 Flag is set (1), this RTU will provide a reply when the Group 2 address is polled.

Only set this flag for one of the RTUs in the group.

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 15

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

High Byte …delays

Reply Delay

The RTU may reply to a poll from the master before the master is turned around and

ready to receive. Setting these bits inserts a delay before the RTU replies to a poll. Set

this value as low as possible.

0=0ms, 1=8ms, 2=12ms, 3=16ms, 4=20ms, 5=24ms,6=28ms, 7=32ms

Bit 0 - 2

Next Message Delay

At the end of a transaction, the RTU immediately listens for new data. In some

applications, the line may ring, or have other noise. Setting this bit causes the RTU to

wait for three-byte times before receiving data. Leave this bit clear if possible.

Bit 3

RPM Alarm Hysteresis

RPM Alarm hysteresis is the tolerance band to avoid alarm chattering.

0 = 50 RPM, 1 = 100 RPM

Bit 4

Pilot Pulse

Some EC motors detect Pilot Pulse (Autoswitch) from the controller. Pilot Pulse provides a

49us pulse at a minimum and maximum signal, so the motor knows the controller is

connected.

Bit 5

Lock

Set this bit to lock address & baud rate registers out from modification

Bit 6

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 16

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Register 15 - Group1 Address

Group1 Address

Group addressing allows a write register (16) or write multiple registers (06) command to be

issued to a group of EVO/ECM-Modbus RTUs. This feature allows logical grouping of EVO/ECM-

Modbus RTUs to fit building floor plans and ease interactive control with other automated

systems within the facility.

The group address can be any address from 200 to 247. A group address should not be the same

as the unit address, or the unit address of any other RTU connected to the same trunk.

When the Modbus RTU Master writes to a group address, no RTU sharing the same Group 1

address should respond. Some Modbus Masters will generate communication error if they do not

receive a reply. In such case, the Group 1 Reply Flag in Register 14 in one RTU in the group should

be set to provide the reply.

Each RTU may have two group addresses, allowing overlap of group functions.

Register 16 - Group 2 Address

Group addressing allows a write register (16) or write multiple registers (06) command to be

issued to a group of EVO/ECM-Modbus RTUs. This feature allows logical grouping of EVO/ECM-

Modbus RTUs to fit building floor plans and ease interactive control with other automated

systems within the facility.

The group address can be any address from 200 to 247. A group address should not be the same

as the unit address, or the unit address of any other RTU connected to the same trunk.

When the Modbus RTU Master writes to a group address, no RTU sharing the same Group 1

address should respond. Some Modbus Masters will generate communication error if they do not

receive a reply. In such case, the Group 2 Reply Flag in Register 14 in one RTU in the group should

be set to provide the reply.

Each RTU may have two group addresses, allowing overlap of group functions.

Alarm Type Select

Select the Alarm type

0 = RPM Alarms, 1 = Contact Alarms

Bit 7

©Evolution Controls Inc.

10-Sept-2020

EVO/™ECM-Modbus RTU Series 2 Page 17

Application Guide

©2020 All Rights Reserved

Evolution Controls Inc.

San Diego, CA USA

Register 17 - Unit Address

Unit Address

The Modbus RTU Master uses the unit address when communicating with a specific EVO/ECM-

Modbus RTU. Each RTU connected on the same trunk must have a unique unit address in the

range of 1 to 199.

The Modbus Master should NEVER write to this register during normal operation! Only write this

register using the Modbus Configuration software. See the configuration section of this manual

for more information.

Register 18 - Baud Rate

Baud Rate

The EVO/ECM-Modbus RTU can be configured to one of six different baud rates.

The Modbus Master should NEVER write to this register during normal operation! Only write this

register using the Modbus Configuration software. See the configuration section of this manual

for more information.

0=1.2 kb, 1=2.4 kb, 2 = 4.8 kb, 3 = 9.6 kb, 4 = 19.2kb, 5 = 38.4kb

Register 19 - Motor 1 Low RPM Limit

Register 20 - Motor 2 Low RPM Limit

Register 21 - Motor 3 Low RPM Limit

When Motor 1 RPM drops below this limit, and the motor has been commanded on for at

least 20 seconds, the corresponding alarm flag (Register 1) is set. The flag is cleared

when the RPM exceeds this limit by 50 RPM or 100 RPM depending on the hysteresis

selection bit (Coil 29) in Register 14.

…See Register 19

…See Register 19

Table of contents

Other Evolution Controls Recording Equipment manuals