Evolution Controls 1 Series User manual

©Evolution Controls Inc.

22-Nov-2019

Evolution

Automation Interface ..CONTROLS INC. .EVO™/ECM-ACU+

San Diego, CA USA http://www.gotoevo.com/ Voice (858)748-7359

Made in USA Fax (858) 679-3365

EC Motor Series 1

Application

The EVO/ECM-ACU+ allows industry standard 0V to

+10V automation signals to adjust and monitor EC

Motors. These are fractional horsepower air moving

motors featuring an internal microprocessor based

drive. The design provides exceptional efficiency,

performance and motor life. The motor may be

factory configured to provide constant mass airflow

or constant torque over the configured control range.

The ACU+ provides remote adjustment of the motor

output from 0 to 100% of the motor’s programmed

control range. A signal lamp on the control

continuously flashes out the flow index

1

. Instruments

are not required to read the flow index. A 0V - +10V

signal connects RPM to the automation control.

Jumpers allow the ACU+ to be configured for 0V to

+10V automation signal, +2V to +10V automation

signal, and manual/override control. The ACU+ can

also be used for stand-alone manual control.

Signal Lamp

The green lamp continuously indicates the flow

index. After a pause, the lamp flashes out the tens

digit, then the units digit of a number between 1 and

99. Long flashes represent the tens digit, and short

flashes represent the units digit. For example, a

flow index of 23 flashes two longs, then three shorts.

Two extra long flashes indicate a flow index of 0. An

extra long flash and ten short flashes indicates a

flow index of 100. The lamp flashes the signal that

was present when the flash sequence started.

Turning Adjust controls the EC motor to the

manually adjusted setting. The manual setting has

authority for 15 minutes.

Ordering

EVO/ECM-ACU+ Control without metal plate

EVO/ECM-ACU+ -MP Control mounted to a single

gang (US) metal plate.

1

Flow Index = percent of the programmed control range.

Manual Override

•Temporary local Adjust for air balance.

•Manual control without any 0 - +10V signal.

•Local Default

•Startup mode keeps control in Manual until

automation is connected.

When local adjust is turned, Vspd is set by Adjust.

Vspd remains at the Adjust value for 15 minutes

after the last Adjust movement is detected allowing

time to make airflow measurements.

With the “M” jumper in place, Adjust controls the

motor when a +0.1-+10V control is not detected.

This feature allows the ACU+ to be used as a

manual control. And it provides a local default for

critical applications by providing a safe operating

speed should the +0.1-+10V signal fail.

The ACU+ is provided new with startup mode

enabled. The control behaves like the “M” jumper is

in place, even if it is not. This allows the mechanical

equipment to be tested and used before automation

is installed. After automation is installed, the startup

mode can be disabled by starting/stopping the motor

five times with a +0.1-+10V signal present. The

motor start/stop event may be performed by cycling

~24V

2

power to the control with the control signal

above +0.1V, or by raising and lowering the +0.1 -

+10V signal with the “P” jumper installed.

2

~24V = 24Vac

Equipment manufacturer:

Please use the model above

as your part number, or in

your description.

©Evolution Controls Inc.

22-Nov-2019

Series 1 EVO/ECM-ACU+

San Diego, CA USA http://www.gotoEVO.com Page 2of 6

Jumpers

“P” The "P" jumper provides

ON/OFF control by switching

the motor's "GO" control line

off when the signal drops

below +1 (2mA) volt and on

when the signal exceeds

+2V (4mA). Adjust turns the

motor On/Off with the “P”

jumper installed.

Without the jumper, turn ACU+ power

On/Off to control motor On/Off.

“M” The “M” jumper enables manual override. In

manual override, the fan speed is controlled

by the local Adjust when the automation

signal is below +0.2V. It controls the motor

before automation is installed, or when

automation fails. It returns to automation

control when the signal is above +0.2V.

Without the “M” jumper, manual override is

enabled whenever Adjust is turned. It

remains enable for 15 minutes and then

returns to automation control.

“S”The “S” jumper reverses Adjust rotation so

adjustment is correct from the component

side of the board (sometimes marked “R”).

“Opt” The Opt. space has no function. The space

may be used to store an unused jumper.

Specifications

Power NEC Class II or equal

~24V ± 20% 50/60 Hz

2W, 4VA + 1VA/Motor

Control

Signal no "P" jumper

0V to +10V = 0%-100% pwm

"P" Jumper

+2 to +10V = 0%-100% pwm

4-20mA = 0%-100% pwm

ON/OFF Control Between

+1V & +2V (2 & 4 mA)

RPM

Signal 0V to +10V, 5 mA max.

= 0 to 2,000 RPM in 10 RPM steps

Outputs

Go & VSpd +22V ±2V @ 20 mA

2 motor loads

RPM from 1 motor only

Vspd Supports Autoswitch Function

Thermal

Stability>0.01%/oF

Operating 0oF to 130oF (-18oC to 55oC)

Environment 10-80% rh

Connections 1/4 Tabs

Signal

“P” Jumper Out “P” Jumper In

P

S

M

©Evolution Controls Inc.

22-Nov-2019

Series 1 EVO/ECM-ACU+

San Diego, CA USA http://www.gotoEVO.com Page 3of 6

0.265"

ø

0

.

1

8

7

5

"Use#8Flathead Use4mmFlathead

1.133"

1.429" 36.30mm

1.793" 45.54mm

64.01mm 2.520"

28.78mm

6.73mm

2

1

.

3

9

m

m0

.

8

4

2

"

4

4

.

4

5

m

m1

.

7

5

0

"

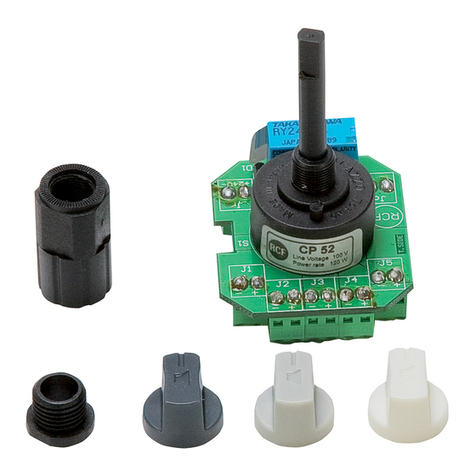

Mounting

Mount the ACU+ inside a metal control cabinet or

enclosure. Fasten the mounting posts to an earthed

metal surface.

Mount the ACU+ with clearance for the ~24V power

wires, automation wires and control cable connector.

Mount the control so the Signal and Status lamps are

visible. Make Adjust accessible if it is used in your

application.

The control may be surface mounted, or reverse

mounted so the lamps and Adjust are visible through

the enclosure wall.

The ACU+-MP is a reverse mounted control on an

aluminum single gang US electrical plate. The plate may

be mounted in a single gang electrical box cutout often

used to mount a PSC motor speed control. Mount it to

a single gang handy box to provide separation from

high voltage wiring, or to provide RFI shielding.

The plate is drilled to accommodate most single gang

rectangular outlet trim plates. This plate may be

attached to provide a gasketed seal when mounted in a

weatherproof box, where door is needed to hide Adjust,

or where the ACU+ needs to be wall mounted in an

occupied space.

For manual control, use knob EVO/ACC-Knb3.

For surface mount, remove the shaft and place it into

the Adjust on the component side of the board. A silver

or white surface under the LEDs makes them more

visible from the component side of the ACU+.

©Evolution Controls Inc.

22-Nov-2019

Series 1 EVO/ECM-ACU+

San Diego, CA USA http://www.gotoEVO.com Page 4of 6

IIUSA

Wiring

Power the EVO/ECM-ACU+ with a ~24V NEC Class

power limited transformer

3

. Observe all code

requirements and follow all safety practices regarding

low voltage power supplies and circuits to insure a

safe, reliable installation.

Some applications may require an isolated power

supply or alternative earthing scheme. Follow

applicable code requirements and carefully observe all

safety practices concerning earthing and safety

requirements for low voltage circuits.

Earth one lead of the ~24V side of the power

transformer

4

. Connect the earthed lead to the ACU+

Xfmr neutral connection.

Connect the hot lead of the ~24V side of the power

transformer to the ACU+ Xfmr ~24V connection.

~24V Aux and Neutral are convenience connections.

Up to 20 VA loads may be connected to Aux.

With the “P” jumper out, you may interrupt the Xfmr

connection as a means to stop the motor. Most

automation controllers will power the ACU+ directly

from a ~24V on/off output, eliminating the fan relay.

Automation controllers that switch neutral may require

a fan relay.

The signal input is single-ended, so the ACU+ internally

connects neutral and signal common.

Connect the 0V to +10V control signal to the Signal

connection. Connect the control signal common to the

Common connection.

The input presents a 21K ohm load to the signal

source. Include this resistance when calculating a

dropping resistor for 4-20 Ma operation. A 511 ohm

1% resistor

5

provides a 500 ohm dropping resistance.

Connect to the motor using an EVO/ECM-CBL motor

control cable. The control’s motor cable connector is

small so it may be carefully pulled through an empty

3/4” conduit.

Keep high voltage wiring away from the ACU+ circuitry

or wiring. Follow electrical code requirements for

separation of high and low voltage wiring and

components.

3

See NECUSA 725.41

4

NECUSA 250.20.a.

5

www.Mouser.com pn. 271-511-RC

©Evolution Controls Inc.

22-Nov-2019

Series 1 EVO/ECM-ACU+

San Diego, CA USA http://www.gotoEVO.com Page 5of 6

During Construction

The equipment manufacturer may have set Adjust to allow heating equipment to operate during construction. If

not, Adjust can be set on site to provide a flow to safely operate heating.

Automation Air Balance

If Automation is already installed, air balance can be achieved using automation tools. Please notice that a

control signal less than +0.2V may put the ACU+ into manual override. Avoid setting the automation signal to

less than +0.2V. Caution: turning Adjust locks out the automation signal for 15 minutes.Cycle power for

faster lockout removal.

Manual Air Balance

The ACU+ can be manually adjusted before automation is available. The balancer’s manual adjustment has

authority until automation is connected.

Air Balancer:

1. Use Adjust to set the air flow. This adjustment will have authority for at least 15 minutes.

2. Read the flashing green lamp and record the flow index on the air balance report.

Automation Integrator:

1. Set the Signal to 0V to invoke manual override.

2. Record the RPM on the air balance report.

3. Enter the flow index from the air balance report.

4. Observe the RPM is at or near the RPM observed in step 2.

5. Cycle the motor on/off 5 times.

6

This clears the manual override function unless the “M” jumper is in

place.

Factory Setup

6

Signal must be greater than +0.1V for 0V to +10V applications.

Automation

Permanent Manual Override?

Y Install the “M” jumper

N Remove the “M” jumper

On/Off control using the +2V to +10V Signal?

Y Install the “P” jumper

N Remove the “P” jumper

Manual Adjust from the component side?

Y Install the “S” jumper

N Remove the “S” jumper

Manual Adjust

Manual Adjust Only?

Y Install the “M” jumper

N Remove the “M” jumper

On/Off control using the Manual Adjust?

Y Install the “P” jumper

N Remove the “P” jumper

Manual Adjust from the component side?

Y Install the “S” jumper

N Remove the “S” jumper

©Evolution Controls Inc.

22-Nov-2019

Series 1 EVO/ECM-ACU+

San Diego, CA USA http://www.gotoEVO.com Page 6of 6

EVO/ECM-4Spd Controls 1 Motor &

EVO/ECM-ACU+ Automation RPM Monitor

Optional 2nd Control Monitors Motor 2

Cabling Details

2 Motor Control EVO/ECM-MXC2

The EVO/ECM-MXC2 connects one EVO/ECM-ACU+ to control 2 motors. The master control sets the speed of

both motors. A second control may be connected to monitor the 2nd motor rpm.

Parts:

EVO/ECM-CBL-? Control cable for Genteq 2.3 & 5.0 motor

EVO/USM-CBL-? Control cable for US Motor Perfect Speed

EVO/ECM-PIG-? Control cable with unterminated motor end

EVO/ECM-JMP ? Jumper cable for use with EVO/ECM-MXC2

EVO/ACC-KNB-0 Standard ACU+ Adjust shaft

EVO/ACC-KNB-1 Extended ACU+ Adjust shaft

EVO/ACC-KNB-3 Extended ACU+ Adjust shaft with knob

2.54 mm Shunt Standard ACU+ Option header shunt

This manual suits for next models

2

Table of contents

Other Evolution Controls Recording Equipment manuals