EWC Controls ULTRA-ZONE ST2E Series Service manual

CONTROLS INC.

Excellence Without Compromise

WARNING: THESE PANELS ARE DESIGNED

FOR USE WITH 24 VOLTS. DO NOT USE

ANY OTHER VOLTAGE! USE CAUTION TO

AVOID ELECTRIC SHOCK OR EQUIPMENT

SPECIFICATIONS

Power Requirements: 24V 60Hz 40VA

Wiring Connections: Screw Terminal blocks

for Thermostat gauge wire connections.

Mounting: Mounts with 4 screws and

mollies (included).

Panel Dimensions: Length: 10” (254mm);

Width: 9 7/8" (251mm); Depth: 1 9/16” (40mm).

TABLE OF CONTENTS

PAGE

1

2

5

6

7

8

Introduction & Specifications

Application Notes

Typical 5 zone control panel diagram

Thermostat Requirements (See Notes)

Checkout Procedures

EWC-ST-3E Wiring Diagram

EWC-ST-2E

Models EWC-ST-2E & EWC-ST-3E

T E C H N I C A L B U L L E T I N

Model EWC-ST-2E ZONE2

T’STAT

ZONE1

T’STAT

C

W

Y

R

C

W

Y

R

R1

O

B

G

O

R

C

+

_

ADDITIONAL

ZONE PANEL

CAUTION

PLEASE read all

instructions carefully

before starting the

installation

procedures.

J1

SYSTEM

24VAC

T’FORMER

2

1

ZONE2

MOTOR

ZONE1

MOTOR

M6

M4

M2

M1

M6

M4

M2

M1

SW1

SW2

OPEN

CLOSE

OPEN

CLOSE

EWC

CONTROLS INC.

Englishtown, NJ

ULTRA-ZONE

CONTROL SYSTEM

Y

W

G

R

B

O

X

CB1

Congratulations on purchasing the ST2E/ST3E series

ULTRA-ZONE Control Panel. The ST series of zone control

panels are still the same popular, field proven zone control

panels that have been in use for the last seventeen years! The

new “E” series revision has a few upgrades to enhance the

reliability, protection and operation of the board.

First and most important is the replacement of the old 3 amp

slo-blo fuse, with an integrated Thermal Circuit breaker or

Polyfuse. This means no more running to the electronics store

to buy a fuse, after the spare fuse that was provided has blown.

The Polyfuse protects the panel against shorts in the thermostat

or damper field wiring. It does not protect against shorts in the

HVAC equipment field wiring. See page 2.

The location of the J1 jumper on the panel has also changed, and

there is now an arrow pointing to it. The J1 jumper enables

fan operation in Heat mode as well as Cooling mode.

With the exception of the Polyfuse and the J1 jumper, all

other changes have no direct bearing on the wiring,

installation, or operation of the control panel.

The ST series zone control panels are the most versatile

and rugged relay based logic control systems in use today.

The Master/Slave circuitry of these panels can be utilized

to satisfy numerous control applications and job specifications.

The heating/cooling changeover operation is still controlled by a

changeover subbase on the zone 1 thermostat, or a separate

remote selector switch can be used instead. This allows

for inexpensive standard 2 or 3 wire thermostats to be used in all

zones depending on the field application.

The table on Page 6 shows the types of digital programmable

thermostats that are compatible with the ST2E or ST3E panels.

The diagrams included with this bulletin are based upon the

most frequently asked questions regarding the wiring of these

panels. There are additional diagrams available through the

Technical Support Hotline@ 1-800-526-4048.

Contact the Hotline if you find yourself on the job site and

unsure of the exact wiring for your ST Series Control Panel.

DAMAGE

(DISPONIBLE EN ESPAÑOL EN EWCCONTROLS.COM)

ewccontrols.com/acrobat/090375a0248.pdf

TB-115

P/N 090375A0115 REV. N 11.5.20

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- [email protected] 1

Copyright ©2009 EWC Controls All Rights Reserved

rol Panel

CONTROL SYSTEM

K6

K7

R6

R7

C7 +

C6 +

D11

D12

D10

D6

D4

D9

D5

D3

D21

D22

D20

D19

D24

D23

D25

D26

C

W

Y

R

ZONE 2

T'STAT

C

W

Y

R

R1

0

B

G

ZONE 1

T'STAT

CAUTION

0

R

C

+

-

ADDITIONAL

ZONE PANEL

#1: WIRING DIAGRAM

HEATING ONLY INSTALLATION

rol Panel

K6

K7

R6

R7

C7 +

C6 +

D11

D12

D10

D6

D4

D9

D5

D3

D21

D22

D20

D19

D24

D23

D25

D26

C

W

Y

R

ZONE 2

T'STAT

C

W

Y

R

R1

0

B

G

ZONE 1

T'STAT

CAUTION

0

R

C

+

-

ADDITIONAL

ZONE PANEL

#2: WIRING DIAGRAM

COOLING ONLY INSTALLATION

AP PL ICA TIO N NO TES

OPERATION

To operate the system in the heat mode,

the "B" terminal has to be made to the "R1"

terminal on the zone 1 terminal block. This

allows any zone thermostat to call for heat.

When a zone calls for heat, the control

panel closes the circuit from "R" to "W"

activating the furnace. The zone damper

calling for heat remains open and zones

satisfied will close. The fan and limit control

in the furnace will operate the fan.

1. HEAT MODE:

2. COOL MODE:

To operate the system in the cool mode,

the "O" terminal has to be made to the "R1"

terminal on the zone 1 terminal block. This

allows for any thermostat to call for cooling.

On call for cooling, terminals "R", "G" and

"Y" are made to bring on the fan and

compressor. The dampers for zones calling

will remain open; the dampers satisfied will

close.

3. OFF POSITION:

When the subbase on zone 1 is in the

"OFF" position the entire system is disabled.

4. CONTINUOUS FAN:

When placing the fan switch on the

subbase from "AUTO" to "ON" position, the

panel closes the circuit between "R" and "G"

terminals to energize the fan relay.

5. OPEN-CLOSE SWITCHES:

If left in the open position when all zones

satisfy, the damper will drive to open

position. If left in closed position, when all

zones satisfy , the damper will remain

closed unless it is the last zone to satisfy;

then it will remain open.

NOTE: The last zone to satisfy will always

be open regardless of position of switch.

WIRING

1. HVAC SYSTEM:

Wiring the HVAC system to the EWC-ST-2E

or EWC-ST-3E is typical of wiring a subbase

to a heating/cooling system. (4 wires

required.)

The following terminals are on the system

terminal block:

R-

Y-

W-

G-

Wire to the RH heating transformer

and/or the RC cooling transformer.

Wire to the Compressor Relay.

Wire to Heat Control (gas valve, oil

burner relay) on system terminal block.

Wire to Fan Relay.

2. TRANSFORMER 24V 40VA:

A separate 24V 40VA transformer is required

to be wired to terminals 1 and 2 of the

terminal block labeled "T-Former". (2 wires

required.) This transformer powers the panel

board, thermostats and damper motors. It

does not power the furnace or the air

conditioner. The board is now protected by

aThermal Polyfuse at the transformer input.

When the polyfuse trips it will get quite hot. To

reset the breaker, remove the 24 VAC for

approximately 30 seconds. Check the damper

motors and field wiring for shorts. If adding two

panels together, be sure of wiring in (+ and - )

circuit.

3. ZONE DAMPER MOTORS:

Use 3 conductor wire from each set of MAN

or RDN zone damper terminals or 2

conductor wire on "SR" dampers to the

panel. See diagrams #4 and 5 when wiring

more than one damper per zone.

ZONE 1: Thermostats that have subbases

with "B" and "O" terminals are required to

enable system changeover. These include

mechanical and battery operated

thermostats (6 wires required - terminals W,

Y, G, R, B and O), and electro-mechanical

and programmable digital thermostats (24

VAC, 7 wires required - terminals C, W, Y,

G, R, B and O).

If model MCS-DXB remote selector switch is

used, it will be wired to the zone 1 terminal

block in place of the changeover subbase

(7 wires required total: 4 on the MCS-DXB -

B, G, O and R1; 3 on the thermostat - W,

Y and R). See diagram #3.

OTHER ZONES: 3 wires are required for

mechanical and battery operated

thermostats - terminals W, Y and R. 4 wires

are required for electro-mechanical and 24

VAC digital thermostats - terminals C, W, Y

and R. No subbases required.

See page 6 for specific types of

thermostats required.

4. THERMOSTATS:

5. HEAT ONLY OR COOL ONLY

Zone 1 no longer requires a subbase or

remote switch. All zones need only a two

or three wire thermostat to operate in either

heat or cool.

APPLICATIONS:

2

CONTROL SYSTEM

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 •FAX 732-446-5362

R

GYW

OB

ZONE 2 THERMOSTAT

R

GYW

OB

ZONE 1 THERMOSTAT

FIELD

INSTALLED

JUMPER

R

GYW

OB

ZONE 2 THERMOSTAT

R

GYW

OB

ZONE 1 THERMOSTAT

FIELD

INSTALLED

JUMPER

Panel

K6

K7

C

W

Y

R

ZONE 2

T'STAT

C

W

Y

R

R1

0

B

G

ZONE 1

T'STAT

CAUTION

0

R

C

+

-

PLEASE read all

instructions carefully

before starting the

installation procedures.

ADDITIONAL

ZONE PANEL

CONTROL SYSTEM

GREEN

BROWN

RED

ORANGE

RED

HEAT

OFF

COOL

FAN

ON AUTO

Front of Plate

Back of Plate

#4: TYPICAL TANDEM

DAMPER WIRING

3

#3: EWC-ST-2E WITH MCS-DXB

REMOTE SELECTOR SWITCH

#5: CONTROL OF UP TO FOUR DAMPERS PER ZONE

USING EXTERNAL RELAY

K9

K8

X

R

G

W

Y

B

O

1

2

K4

SW1

24V

T'FORMER

K2

K1

K5

OPEN

CLOSE

OPEN

CLOSE

SW2

M1

M2

M4

M6

ZONE2

M1

M2

M4

M6

ZONE1

MOTOR

MOTOR

Model

CONTROLS

Englishtown

MA-ND4 TYPE MOTORS ON

ND OR URD TYPE DAMPERS

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 • FAX 732-446-5362

CB1

RED

RED

BROWN

ORANGE

GREEN

1

6

4

1

6

4

1

6

4

1

6

4

24VAC TRANSFORMER

40 - 60VA RATING

MAX. NUMBER OF 4 DAMPERS

PER ZONE.

Multiple Damper Wiring on a Single Zone, using a Separate Transformer

and an Isolating Relay. Maximum of 4 dampers per 40 va transformer.

M1

M2

M4

M6

ZONE

MOTOR

46

1

46

1

46

1

2

1

3

COIL

24 vac

NC

NO

C

R1 Isolation Relay

SPDT action with 24 vac coil

Relay is shown de-energized.

All dampers are closed.

To Line Voltage

Provide over current

protection

46

1

Separate 24 vac

Transformer

TYPICAL FEEDER CONDUCTOR

TYPICAL JUNCTION POINT

L1

L2

H

C

One relay coil=One motor.

Don’t overload your power

transformer, by connecting

too many relays.

R

GYW

OB

ZONE 2 THERMOSTAT

R

GYW

OB

ZONE 1 THERMOSTAT

#6: TYPICAL FAN CENTER AND OIL

BURNER WITH ISOLATION RELAY #7: TYPICAL GAS FURNACE

#8: FAN CONTROL

WITH HOT WATER COIL

#9: ZONING IN HEATING ONLY

NO ZONE CONTROLLED COOLING

4

LAY

RELAY

T

T

rol Panel

CONTROL SYSTEM

K6

K7

R6

R7

C7 +

C6 +

D11

D12

D10

D6

D4

D9

D5

D3

D21

D22

D20

D19

D24

D23

D25

D26

C

W

Y

R

ZONE 2

T'STAT

C

W

Y

R

R1

0

B

G

ZONE 1

T'STAT

CAUTION

0

R

C

+

-

PLEASE read all

instructions carefully

before starting the

installation procedures.

ADDITIONAL

ZONE PANEL

K9

K8

X

R

G

W

Y

B

O

1

2

K4

SW1

24V

T'FORMER

K2

K1

K5

OPEN

CLOSE

OPEN

CLOSE

SW2

M1

M2

M4

M6

ZONE2

M1

M2

M4

M6

ZONE1

MOTOR

MOTOR

Model

CONTROLS

Englishtown

K9

K8

X

R

G

W

Y

B

O

1

2

K4

SW1

24V

T'FORMER

K2

K1

K5

OPEN

CLOSE

OPEN

CLOSE

SW2

M1

M2

M4

M6

ZONE2

M1

M2

M4

M6

ZONE1

MOTOR

MOTOR

Model

CONTROLS

Englishtown

K9

K8

X

R

G

W

Y

B

O

1

2

K4

SW1

24V

T'FORMER

K2

K1

K5

OPEN

CLOSE

OPEN

CLOSE

SW2

M1

M2

M4

M6

ZONE2

M1

M2

M4

M6

ZONE1

MOTOR

MOTOR

Model

CONTROLS

Englishtown

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 • FAX 732-446-5362

CB1

CB1

CB1

ISOLATION RE

HEATING

Y

C

Y

C

W

C

Y

R

G

Y

C

C

Y

R

G

RELAY

T

T

ISOLATION

RELAY

HEATING

Y

C

Y

C

C

Y

R

G

JUMPERS

CUT

**CUT ‘J1’ JUMPER**

FAN

CENTER

OUTDOOR

CONDENSING

UNIT

GAS

FURNACE

OUTDOOR

CONDENSING

UNIT

OUTDOOR

CONDENSING

UNIT

AIR

HANDLER

R

GYW

OB

ZONE 2 THERMOSTAT

R

GYW

OB

ZONE 1 THERMOSTAT

FIELD

INSTALLED

JUMPER

5

#10: WIRING DIAGRAM

INTERCONNECTION OF TWO PANELS FOR ADDITIONAL ZONES

MASTER PANEL

SLAVE PANEL

PANELS MAY BE

DAMAGED IF NOT

WIRED EXACTLY

AS SHOWN

0 to 0

R to R

C to C

+ to +

- to -

K9

K8

C9

C8

Z9

Z8

D19

D20

D21

D22

D26

D25

D24

D23

Z7

C6

C7

D17

D18

D12

D11

D10

D9

D3

D4

D5

D6

D13

D14

D15

D16

Z6

K3

K5

K4

K2

K1

K6

K7

C3

C2

C1

C5

C4

Z5

Z4

Z2

Z1

Z3

D8

D7

D1

D2

SW2

SW1

Y

W

R

C

ZONE-3

C

C

R

R

W

W

Y

Y

ZONE-2

ZONE-1

OPEN

OPEN

CLOSE

CLOSE

OPEN

CLOSE

M1

M2

M4

M6

ZONE3

M1

M1

M2

M2

M4

M4

M6

M6

ZONE2

ZONE1

T'STAT

T'STAT

T'STAT

MOTOR

MOTOR

MOTOR

-

+

R

O

C

G

B

O

R1

X

R

G

W

Y

B

O

1

2

24V

T'FORMER

Model EWC-ST-3E

CONTROL SYSTEM

CONTROLS INC.

Englishtown, NJ

CAUTION

PLEASE read all

instructions

carefully before

starting the

installation

procedures.

ADDITIONAL

ZONE PANEL

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 • FAX 732-446-5362

CB1

K9

K8

C9

C8

Z9

Z8

D19

D20

D21

D22

D26

D25

D24

D23

Z7

C6

C7

D12

D11

D10

D9

D3

D4

D5

D6

Z6

K5

K4

K2

K1

K6

K7

C2

C1

C5

C4

Z5

Z4

Z2

Z1

D8

D7

D1

D2

SW2

SW1

C

C

R

R

W

W

Y

Y

ZONE-2

ZONE-1

OPEN

OPEN

CLOSE

CLOSE

M1

M1

M2

M2

M4

M4

M6

M6

ZONE2

ZONE1

T'STAT

T'STAT

MOTOR

MOTOR

-

+

R

O

C

G

B

O

R1

X

R

G

W

Y

B

O

1

2

24V

T'FORMER

CONTROL SYSTEM

CONTROLS INC.

Englishtown, NJ

CAUTION

PLEASE read all

instructions

carefully before

starting the

installation

procedures.

ADDITIONAL

ZONE PANEL

CB1

Model EWC-ST-2E

1

6

4

1

6

4

1

6

4

1

6

4

1

6

4

DAMPER MOTORS

DAMPER MOTORS

TRANSFORMER

C

Y

G

Y

W

C

R

HVAC

EQUIPMENT

R

GYW

OB

ZONE 3 THERMOSTAT

R

GYW

OB

ZONE 2 THERMOSTAT

R

GYW

OB

ZONE 1 THERMOSTAT

R

GYW

OB

ZONE 5 THERMOSTAT

R

GYW

OB

ZONE 4 THERMOSTAT

PANELS MAY BE

DAMAGED IF NOT

WIRED EXACTLY

AS SHOWN

6

THERMOSTAT REQUIREMENTS

K6

K7

R6

R7

C7 +

C6 +

D11

D12

D10

D6

D4

D9

D5

D3

D21

D22

D20

D19

C

W

Y

R

ZONE 2

T'STAT

C

W

Y

R

R1

0

B

G

ZONE 1

T'STAT

CAUTION

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 • FAX 732-446-5362

ZONE 1

C

R

BY

W/E

ZONE 1 THERMOSTAT – MODEL EWT-725

G

W2

O

C

RC

BYW

ZONE 2 THERMOSTAT – MODEL EWT-601-2

G

RH

O

If the application is heat only, cool only or using the MCS-DXB

remote system selector switch, all thermostats must be set

to the same mode of operation at all times.

Zone 2 and Zone 3 thermostats must be in the same mode

(Heat or Cool) as the Zone 1 thermostat.

3

The Zone 1 (Master) thermostat must be set to heat or cool mode,

in order for Zone 2 or Zone 3 to function! If Zone 1 is turned “OFF”

Zone 2 and Zone 3 cannot function.

6 WIRES REQUIRED

MANUFACTURER

DIGITAL NON-

PROGRAMMABLE

THERMOSTATS

(Battery Operated)

DIGITAL

PROGRAMMABLE

THERMOSTATS

(Battery Operated)

EWT-725

Not Available

Not Available

EWC

CONTROLS

EMERSON

HONEYWELL Not Available Not Available

EWT-601-2

ZONES 2 & HIGHER

3WIRES REQUIRED

DIGITAL NON-

PROGRAMMABLE

THERMOSTATS

(Battery Operated)

DIGITAL

PROGRAMMABLE

THERMOSTATS

(Battery Operated)

EWT-725

EWC

CONTROLS

EMERSON

HONEYWELL Not Available Not Available

EWT-601-2

MANUFACTURER

WiFi

Thermostats

(Hardwired)

Not Available

Not Available

Not Available

NOTES

Not Available Not Available

4Manufacturers have been phasing out thermostat designs with

separate O & B terminals for many years now. Thermostats that are

compatible with the ST series controller are increasingly difficult

to find. As a result, the ST series zone control will soon phase out

as well. We suggest upgrading to our model NCM300 zone control,

which is compatible with 99% of the thermostats available

in today’s market. Including popular WiFi thermostats.

7

#12: SYSTEM CIRCUIT

#11: THERMOSTAT CIRCUIT

CH ECK OU T PROCEDUR E

#13: DAMPER CIRCUIT

K6

K7

R6

R7

C7 +

C6 +

D11

D12

D10

D6

D4

D9

D5

D3

D21

D22

D20

D19

D24

D23

D25

D26

C

W

Y

R

ZONE 2

T'STAT

C

W

Y

R

R1

0

B

G

ZONE 1

T'STAT

CAUTION

0

R

C

+

-

PLEASE read all

instructions carefully

before starting the

installation

procedures.

ADDITIONAL

ZONE PANEL

D15

D16

D18

D17

C

W

Y

R

ZONE 3

T'STAT

HEATING MODE OFF MODE COOLING MODE

STAT

DAMPER

CALLING

OPEN

NOT CALLING

CLOSED

24 VOLTS

24 VOLTS

COMMON COMMON

O VOLTS

O VOLTS

O VOLTS

O VOLTS

O VOLTS

24 VOLTS

24 VOLTS

24 VOLTS

24 VOLTS

24 VOLTS

INPUT TO PANEL:

COMMON

24 VOLTS

NOTE: Conditions shown are with at

least one thermostat always calling.

When all thermostats satisfy, damper

position will depend on position of

"OPEN-CLOSED" switch. In "OPEN"

position, damper will drive to open

position. In "CLOSED" position, all

voltage is removed from damper motor;

motor will remain in whatever position it

was in when all thermostats satisfied.

If 24 volts is present from M1 to M4 and

M1 to M6, damper motor may either be

turning or stuck between open and

closed postions.

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 • FAX 732-446-5362

K9

K8

K3

K5

K4

K2

K1

SW2

SW1

OPEN

OPEN

CLOSE

CLOSE

OPEN

CLOSE

M1

M2

M4

M6

ZONE3

M1

M1

M2

M2

M4

M4

M6

M6

ZONE2

ZONE1

MOTOR

MOTOR

MOTOR

X

R

G

W

Y

B

O

1

2

24V

T'FORMER

EWC-ST-3E

CONTROLS

Englishtown

K9

K8

K3

K5

K4

K2

K1

SW2

SW1

OPEN

OPEN

CLOSE

CLOSE

OPEN

CLOSE

M1

M2

M4

M6

ZONE3

M1

M1

M2

M2

M4

M4

M6

M6

ZONE2

ZONE1

MOTOR

MOTOR

MOTOR

X

R

G

W

Y

B

O

1

2

24V

T'FORMER

EWC-ST-3E

CONTROLS

Englishtown

O VOLTS 24 VOLTS

COMMON COMMON

24 VOLTS 24 VOLTS

COMMON COMMON

24 VOLTS 24 VOLTS

CB1

CB1

8

#14: WIRING DIAGRAM

MODEL EWC-ST-3E CONTROL PANEL

CONTROLS INC.

Excellence Without Compromise Technical . . . . . . . 800-446-3110

Sales . . . . . . . . 800-446-3110

Fax . . . . . . . . .

EWC Controls Inc. • 385 Highway 33 • Englishtown, NJ 07726 • 800-446-3110 • FAX 732-446-5362

K9

K8

C9

C8

Z9

Z8

D19

D20

D21

D22

D26

D25

D24

D23

Z7

C6

C7

D17

D18

D12

D11

D10

D9

D3

D4

D5

D6

D13

D14

D15

D16

Z6

K3

K5

K4

K2

K1

K6

K7

C3

C2

C1

C5

C4

Z5

Z4

Z2

Z1

Z3

D8

D7

D1

D2

SW2

SW1

Y

W

R

C

ZONE-3

C

C

R

R

W

W

Y

Y

ZONE-2

ZONE-1

OPEN

OPEN

CLOSE

CLOSE

OPEN

CLOSE

M1

M2

M4

M6

ZONE3

M1

M1

M2

M2

M4

M4

M6

M6

ZONE2

ZONE1

T'STAT

T'STAT

T'STAT

MOTOR

MOTOR

MOTOR

-

+

R

O

C

G

B

O

R1

X

R

G

W

Y

B

O

1

2

24V

T'FORMER

Model EWC-ST-3E

CONTROL SYSTEM

CONTROLS INC.

Englishtown, NJ

CAUTION

ADDITIONAL

ZONE PANEL

CB1

732-446-5362

1

6

4

DAMPER MOTORS

1

6

4

1

6

4

24VAC

TRANSFORMER

C

Y

HVAC

EQUIPMENT

G

Y

W

C

R

C

RC

BYW

ZONE 2 THERMOSTAT – MODEL EWT-601-2

G

RH

O

C

RC

BYW

ZONE 3 THERMOSTAT – MODEL EWT-601-2

G

RH

O

C

R

BY

W/E

ZONE 1 THERMOSTAT – MODEL EWT-725

G

W2

O

This manual suits for next models

3

Table of contents

Popular Control Panel manuals by other brands

Electronics Line

Electronics Line Commpact Quick start installation guide

CAME

CAME Z Series instructions

Vaillant

Vaillant sensoHOME VRT 380 Operating and installation instructions

Panasonic

Panasonic AG-RCP30P operating instructions

GHM

GHM GREISINGER GIR 300 Mounting and operating manual

DSC

DSC PowerSeries PC1616 installation guide

Infinova

Infinova V2110 Installation & operation instructions

ELECRAFT

ELECRAFT K-Pod owner's manual

Belden

Belden Grass Valley NV9604 user guide

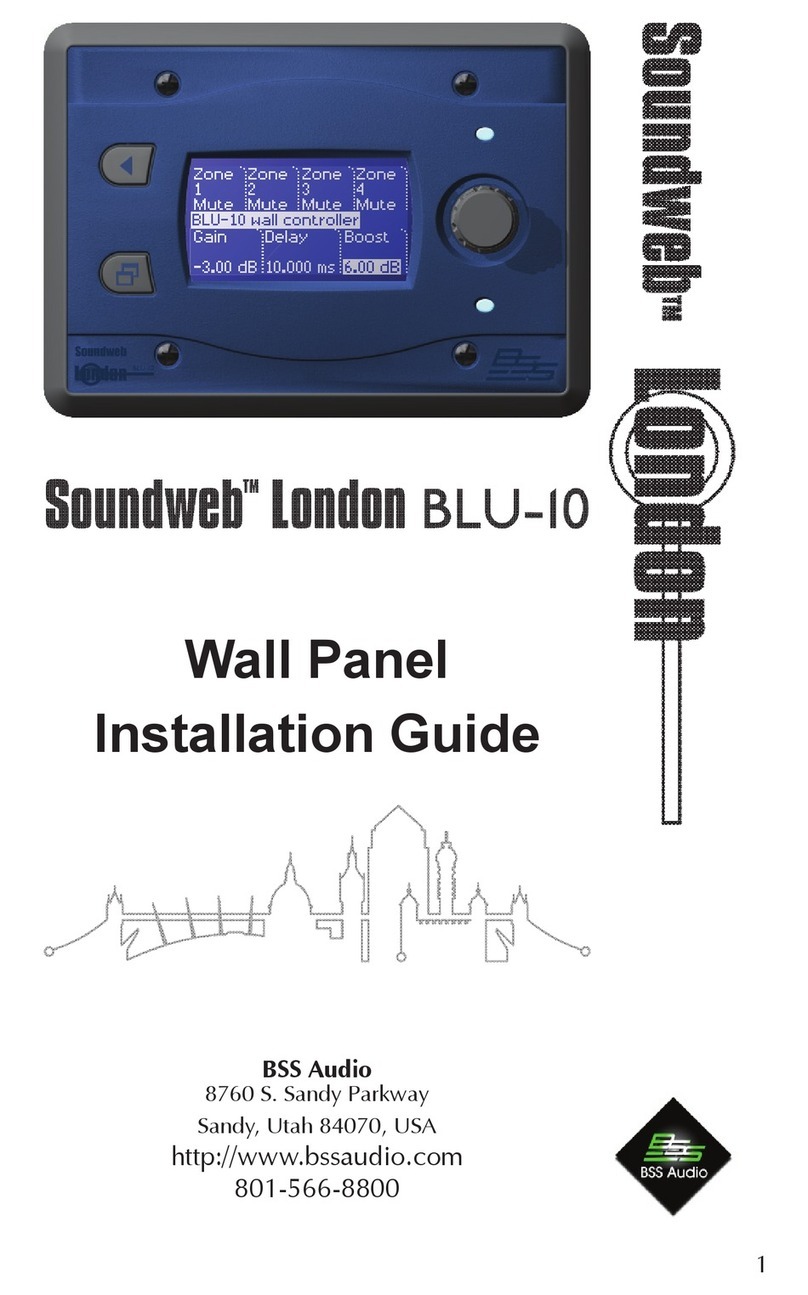

BSS Audio

BSS Audio Soundweb London BLU-10 installation guide

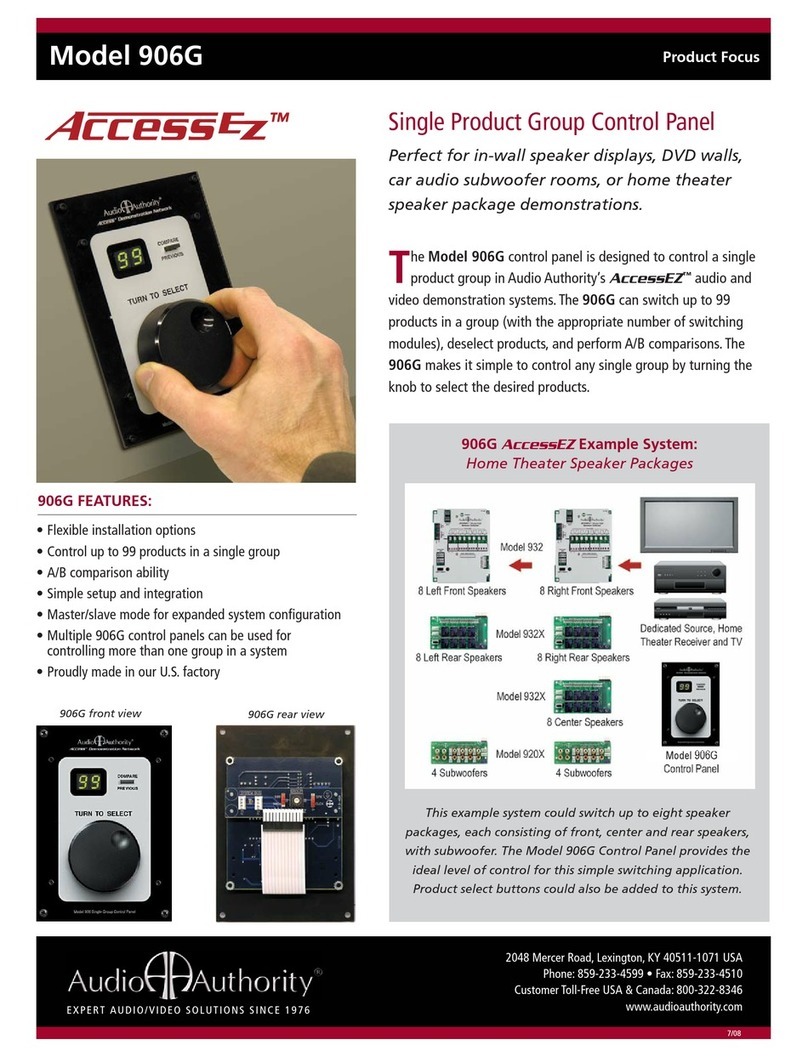

Audio Authority

Audio Authority AccessEZ Control Panel 906G Features

Kongsberg

Kongsberg Simrad Mk3 installation manual