Contents

Notes on using these operating instructions

099-003412-EW501

09.08.2023

1 Contents

1Contents .......................................................................................................................................... 3

2For your safety ............................................................................................................................... 4

2.1 Notes on using these operating instructions .......................................................................... 4

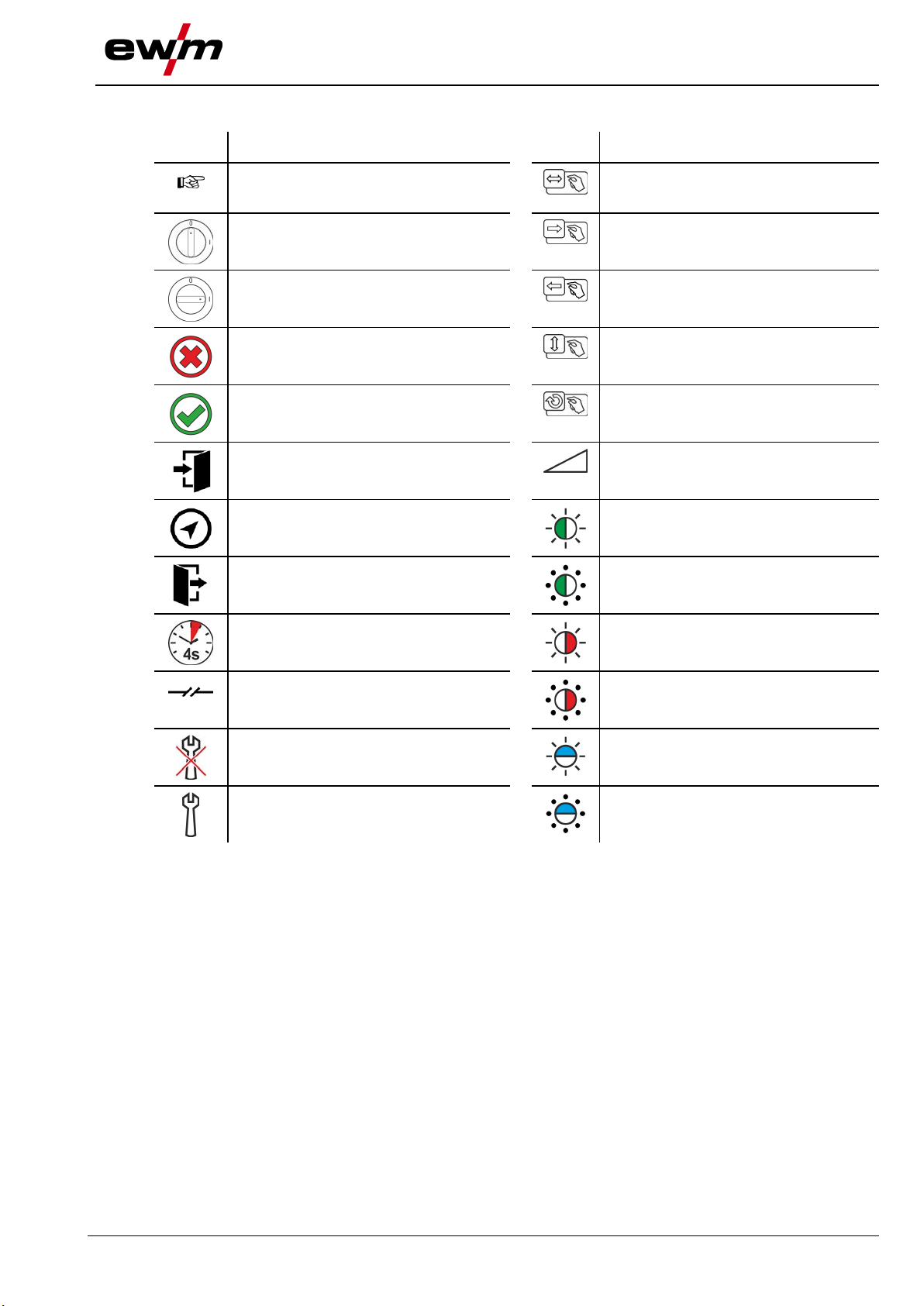

2.2 Explanation of icons ............................................................................................................... 5

2.3 Safety instructions .................................................................................................................. 6

2.4 Transport and installation ...................................................................................................... 9

3Intended use ................................................................................................................................. 11

3.1 Applications .......................................................................................................................... 11

3.2 Documents which also apply ............................................................................................... 11

3.2.1 Warranty ............................................................................................................... 11

3.2.2 Declaration of Conformity ..................................................................................... 11

3.2.3 Service documents (spare parts) ......................................................................... 11

4Machine description – quick overview ...................................................................................... 12

4.1 TGM 40230 Handy ............................................................................................................... 12

5Design and function ..................................................................................................................... 13

5.1 Transport and installation .................................................................................................... 13

5.1.1 Ambient conditions ............................................................................................... 14

5.1.2 Mains connection .................................................................................................. 15

5.1.2.1 Mains configuration ............................................................................... 15

5.2 Presets ................................................................................................................................. 15

5.2.1 Selecting the grinding track .................................................................................. 15

5.2.2 Preparing electrodes for the grinding process ..................................................... 16

5.2.3 Setting the grinding angle of the tungsten electrode ............................................ 17

5.2.4 Setting the speed .................................................................................................. 18

5.2.5 Guideline values for speed controller setting ....................................................... 18

5.3 Inserting the electrode ......................................................................................................... 19

5.4 Grinding the electrode.......................................................................................................... 19

5.5 Changing the filter ................................................................................................................ 20

5.6 Replacing the grinding disk .................................................................................................. 22

6Maintenance, care and disposal ................................................................................................. 24

6.1 Cleaning ............................................................................................................................... 24

6.2 Disposing of equipment ....................................................................................................... 25

7Technical data .............................................................................................................................. 26

7.1 TGM 40230 Handy ............................................................................................................... 26

8Replaceable parts ........................................................................................................................ 27

8.1 TGM 40230 Handy ............................................................................................................... 27

9Appendix ....................................................................................................................................... 28

9.1 Searching for a dealer.......................................................................................................... 28