Ex-baltic BA444DF-P PROFIBUS PA User manual

Issue: 2

23

rd

June 2011

BA444DF-P

PROFIBUS PA

Intrinsically safe

Field mounting

8 variable

Fieldbus Indicator

Issue 2

2

1. Description

1.1 Documentation

2. Operation

2.1 Error messages

3. Intrinsic Safety Certification

3.1 ATEX certificate

3.2 Zones, gas groups and T rating

3.3 Fieldbus connection

3.4 Certification Iabel Information

4. System Design for Hazardous Area

4.1 FISCO Systems

4.2 Non-FISCO Sysems

5. Installation

5.1 Location

5.2 Installation procedure

5.3 EMC

6. Configuration

6.1 Configuration menus

6.2 Node configuration menu

6.2.1 Enter fieldbus address

6.2.2 Access code

6.2.3 Change from node to listener

6.2.4 Reset to node factory defaults

6.3 Listener configuration menu

6.3.1 Access

6.3.2 Summary of configuration

functions.

6.4 Description of listener menu functions

6.4.1 Scan fieldbus segment

6.4.2 List configured input

parameters.

6.4.3 Enter address & display

parameters.

6.4.4 Enable selected input

6.4.5 Enter source address

6.4.6 Enter destination address

6.4.7 Enter Index

6.4.8 Decimal point position

6.4.9 Configuration of bargraph

6.4.10 Scale numeric display

6.4.11 Access code for listener

configuration menu.

6.4.12 Change from fieldbus listener to

fieldbus node.

6.4.13 Reset to listener factory

defaults.

7. Maintenance

7.1 Fault finding during commissioning

7.2 Fault finding after commissioning

7.3 Servicing

7.4 Routine maintenance

7.5 Guarantee

7.6 Customer comments

8. Accessories

8.1 Scale and Tag marking

8.2 Tag plate

8.3 Pipe mounting kits

Appendix 1

ATEX dust certification

Appendix 2

FM Approval for use in the USA and

cFM Approval for use in Canada.

Appendix 3

IECEx certification

CONTENTS

The BA444DF-P is CE marked to show compliance with the European Explosive Atmospheres

Directive 94/9/EC and the European EMC Directive 2004/108/EC

3

1. DESCRIPTION

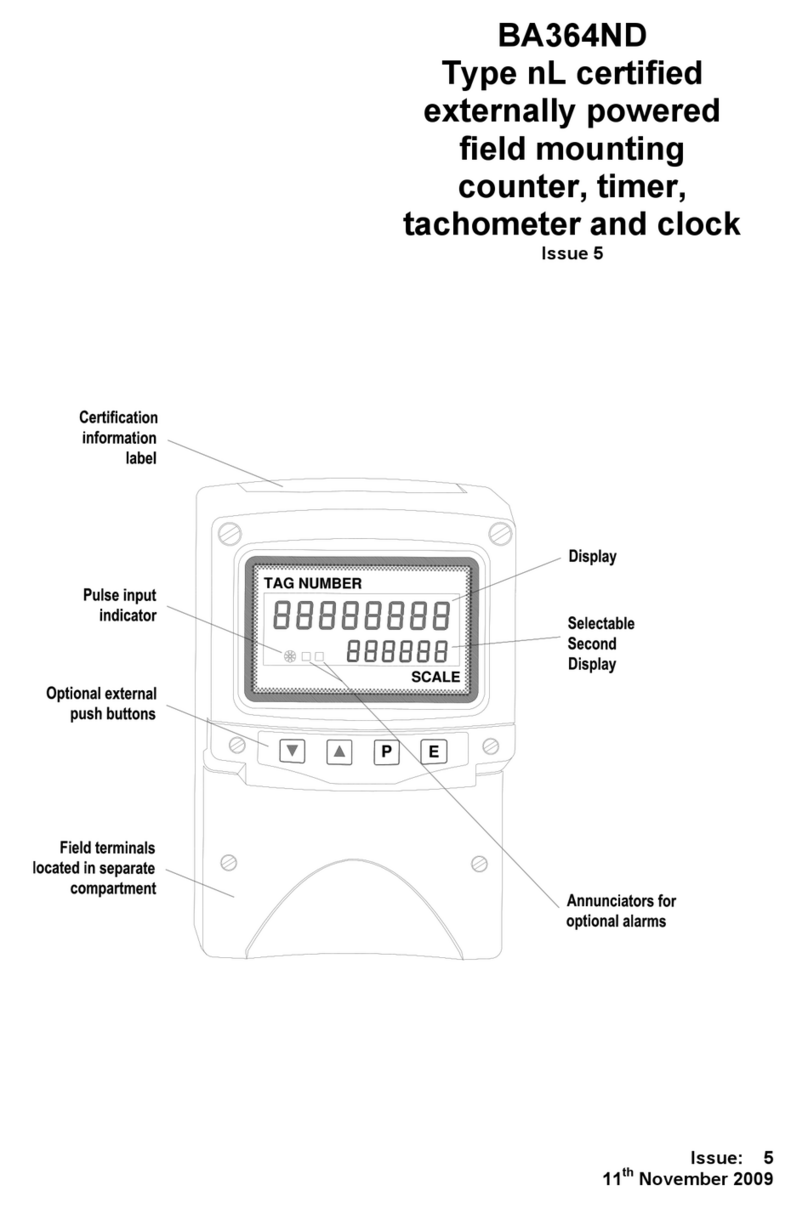

The BA444DF-P fieldbus indicator is an

intrinsically safe, PROFIBUS PA instrument, that

may be configured as a fieldbus node or as a

fieldbus listener. It can display up to eight fieldbus

process variables on a five digit LCD and a 31

segment analogue bargraph. The instrument is

bus powered so no additional power supply is

required and has PROFIBUS PA User

Organisation approval, certificate Z01505.

Fieldbus node configuration may be performed by

either a User PRM data download or by a DPV1

configurator, and if required, the instrument

address may be entered via the front panel push

buttons.

When configured as a fieldbus listener, the

BA444DF-P is not visible to the fieldbus host and

can only be configured using the push buttons on

the front of the instrument.

Housed in a robust IP66 glass reinforced polyester

(GRP) enclosure with a toughened glass window,

the BA444DF-P is surface mounting, or may be

pipe mounted using one of the accessory kits.

The instrument is intrinsically safe and has been

certified by European Notified Body Intertek

Testing and Certification Ltd (ITS) to the ATEX

Directive 94/9/EC for use in explosive gas and

combustible dust atmospheres. ATEX dust

certification is an option – see Appendix 1.

For use in the USA and Canada, the BA444DF-P

is available with intrinsic safety and nonincendive

FM and cFM Approval – see Appendix 2.

For international applications, all versions of the

BA444DF-P PROFIBUS PA indicator have IECEx

intrinsic safety approval allowing installation in

explosive gas atmospheres. IECEx dust

certification is available as an option – see

Appendix 3.

The instrument’s communication protocol is shown

on a label inside the terminal cover. The ‘-P’ order

code suffix also indicates the protocol but is not

shown on the instrument certification label.

There is an alternative version of the fieldbus

display, order code BA444DF-F for use on

FOUNDATION™ fieldbus networks.

1.1 Documentation

This instruction manual describes ATEX system

design and installation of the BA444DF-P

PROFIBUS PA indicator.

System design information for non-ATEX and dust

approvals is shown in appendices to this manual.

2. OPERATION

The BA444DF-P indicator can display up to eight

pre-configured PROFIBUS PA process variables

designated in-1 to in-8. The operator can select

which variable is displayed using the ▼and ▲

push buttons which scroll the display through the

eight inputs. A numeric annunciator on the left

hand side of the display shows which of the eight

inputs is currently being displayed.

2.1 Error messages

‘no ConF’ No inputs have been

configured or are enabled.

‘no dAtA’ No data is being received

with the current configuration.

3. INTRINSIC SAFETY CERTIFICATION

3.1 ATEX certificate

The BA444DF-P has been issued with an EC-Type

Examination Certificate by Notified Body Intertek

Testing and Certification Ltd (ITS) confirming

compliance with the European ATEX Directive

94/9/EC for Group II, Category 1 gas

atmospheres, Ga Ex ia IIC T4 and for dust

atmospheres Ex iaD 20 T100ºC IP66. The

BA444DF-P is also FISCO compliant. The

instrument bears the Community Mark and, subject

to local codes of practice, may be installed in any

of the European Economic Area (EEA) member

countries. ATEX certificates are also acceptable

for installations in Switzerland.

This manual describes ATEX installations in

explosive gas atmospheres which conform with

EN 60079:Part 14 Electrical Installation in

Hazardous Areas. When designing systems for

installation outside the UK, the local Code of

Practice should be consulted.

For use in the presence of combustible dust,

please refer to Appendix 1 that describes ATEX

installations complying with EN 61241: Part 14.

4

3.2 Zones, gas groups and T rating

The BA444DF-P has been issued with EC Type

Examination certificate ITS06ATEX25313

confirming that it complies with the requirements

for Group II Category 1G Ga Ex ia IIC T4

Tamb = –40 to 70ºC specified in the ATEX

Directive. When connected to a suitable certified

system the BA444DF-P may be installed in:

Zone 0 explosive gas air mixture

continuously present.

Zone 1 explosive gas air mixture

likely to occur in normal

operation.

Zone 2 explosive gas air mixture not

likely to occur, and if it does will

only exist for a short time.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

Having a temperature classification of:

T1 450ºC

T2 300ºC

T3 200ºC

T4 135ºC

At an ambient temperature between –40 & +70ºC.

Note: minimum guaranteed operating temperature

is –20ºC.

This allows the BA444DF-P PROFIBUS PA

indicator to be installed in all Zones and to be used

with most industrial gases.

3.3 Fieldbus connection

The BA444DF-P Indicator is powered and receives

data via the H1 fieldbus, which is connected to

terminals 1 and 2. These terminals are non-

polarised, comply with the Fieldbus Intrinsically

Safe Concept (FISCO) defined in IEC 60079 Part

27 and also have separate entity parameters as

shown below:

FISCO Entity

Ui = 17.5V dc 22.0V dc

Ii = 380mA dc 250mA dc

Pi = 5.32W 1.2W

The maximum equivalent capacitance and

inductance at terminals 1 & 2 is:

Ci = 0nF

Li = 8µH

3.4 Certification Label Information

The certification information label is fitted in a

recess on the top outer surface of the enclosure. It

shows details of the ATEX certification, a

statement that the instrument is a FISCO Field

Device, plus BEKA associates name and location.

IECEx approval information is also included. The

label for some versions of the instrument will also

contain non-European certification information.

The instrument serial number and year of

manufacture are recorded on a separate label

inside the terminal compartment.

4. SYSTEM DESIGN FOR HAZARDOUS

AREAS

4.1 FISCO Systems

The BA444DF-P PROFIBUS PA indicator may be

connected to any ATEX certified FISCO compliant

fieldbus segment, providing the segment can

supply the additional 13mA required to operate the

instrument.

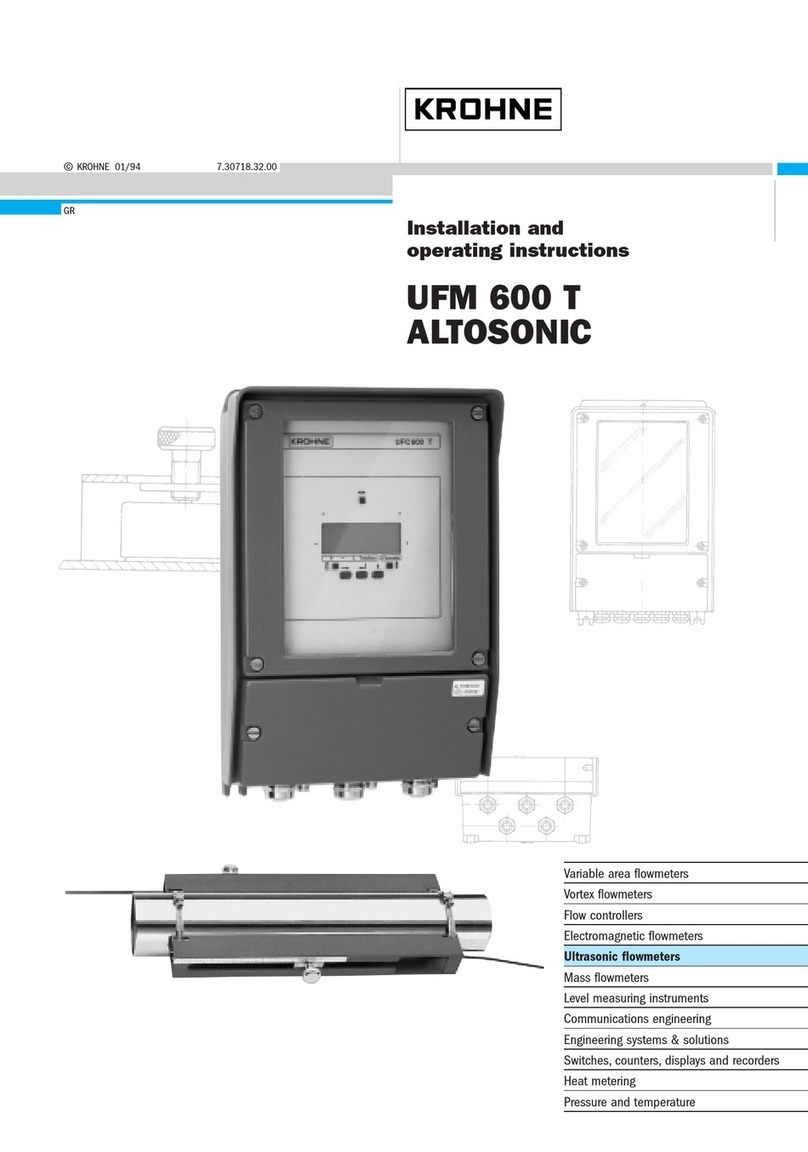

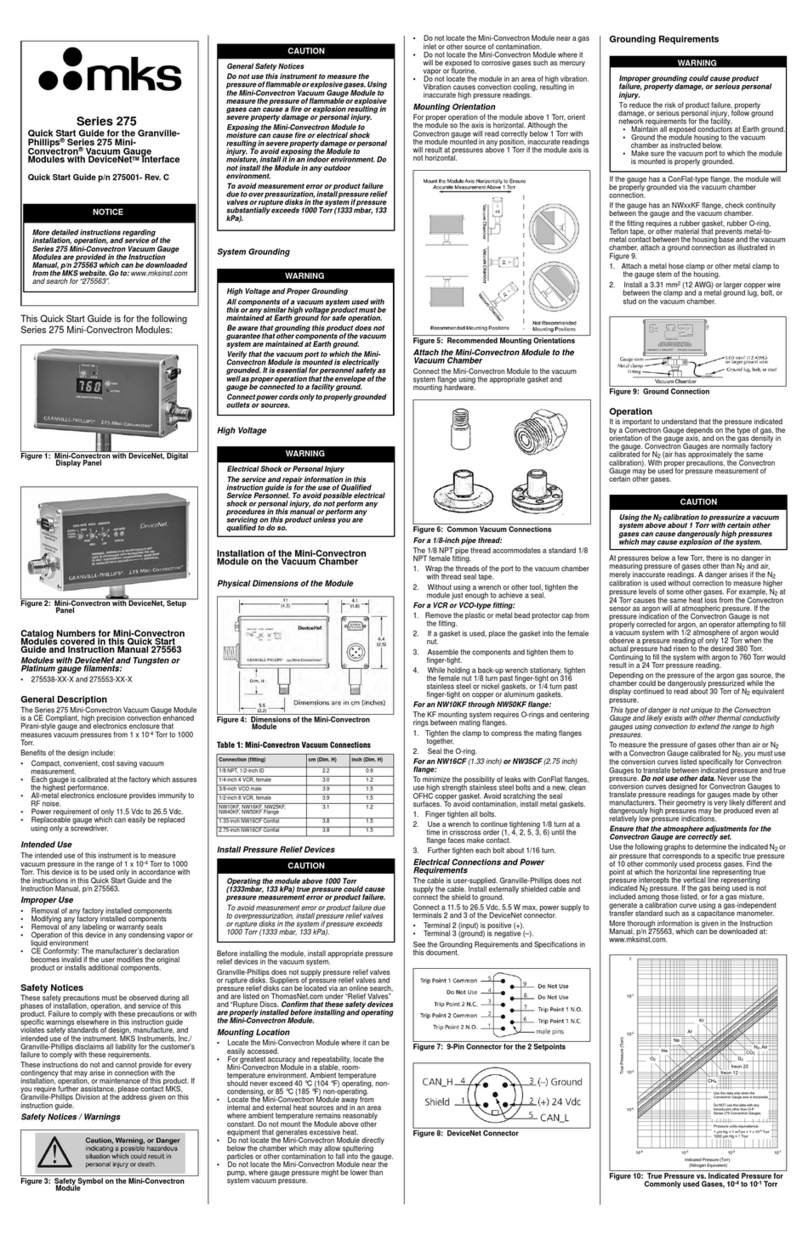

Fig 1 shows a typical fieldbus segment. To comply

with FISCO requirements, the power supply,

terminators, field devices and the interconnecting

cables must conform with IEC60079 part 27.

Fig 1 FISCO fieldbus system

5

4.2 Non-FISCO Systems

For non-FISCO applications the BA444DF-P

PROFIBUS PA indicator has a higher voltage

entity intrinsic safety input parameter allowing

connection to a wide range of fieldbus segments.

The BA444DF-P may be connected to any

intrinsically safe segment providing:

The device powering the fieldbus segment is

ATEX certified and has output parameters

equal to or less than:

Uo = 22V dc

Io = 250mA dc

Po = 1.2W

The segment can provide an additional 13mA

to power the BA444DF-P PROFIBUS PA

indicator.

The equivalent internal capacitance Ci of the

BA444DF-P PROFIBUS PA indicator is zero and

the equivalent internal inductance is insignificant.

Therefore these BA444DF-P parameters do not

need to be considered.

5. INSTALLATION

5.1 Location

The BA444DF-P PROFIBUS PA indicator is

housed in a robust IP66 glass reinforced polyester

(GRP) enclosure incorporating an armoured glass

window and stainless steel fittings. It is suitable for

exterior mounting in most industrial environments,

including offshore and wastewater treatment

installations. Please consult BEKA associates if

high vibration is anticipated.

The BA444DF-P enclosure is surface mounting.

Accessory kits described in sections 8.3 of this

manual enable the instrument to be mounted onto

a vertical or horizontal pipe.

The field terminals and the two mounting holes are

located in a separate compartment with a sealed

cover allowing the instrument to be installed

without exposing the display assembly.

The BA444DF-P earth terminal is connected to the

carbon loaded GRP enclosure. If this enclosure is

not bolted to a post or structure connected to the

plant potential equalising network, the instrument’s

earth terminal should be connected to the

potential equalising network as recommenced in

EN 60079-14.

The BA444DF-P enclosure is supplied with a

bonding plate to ensure electrical continuity

between the three conduit / cable entries.

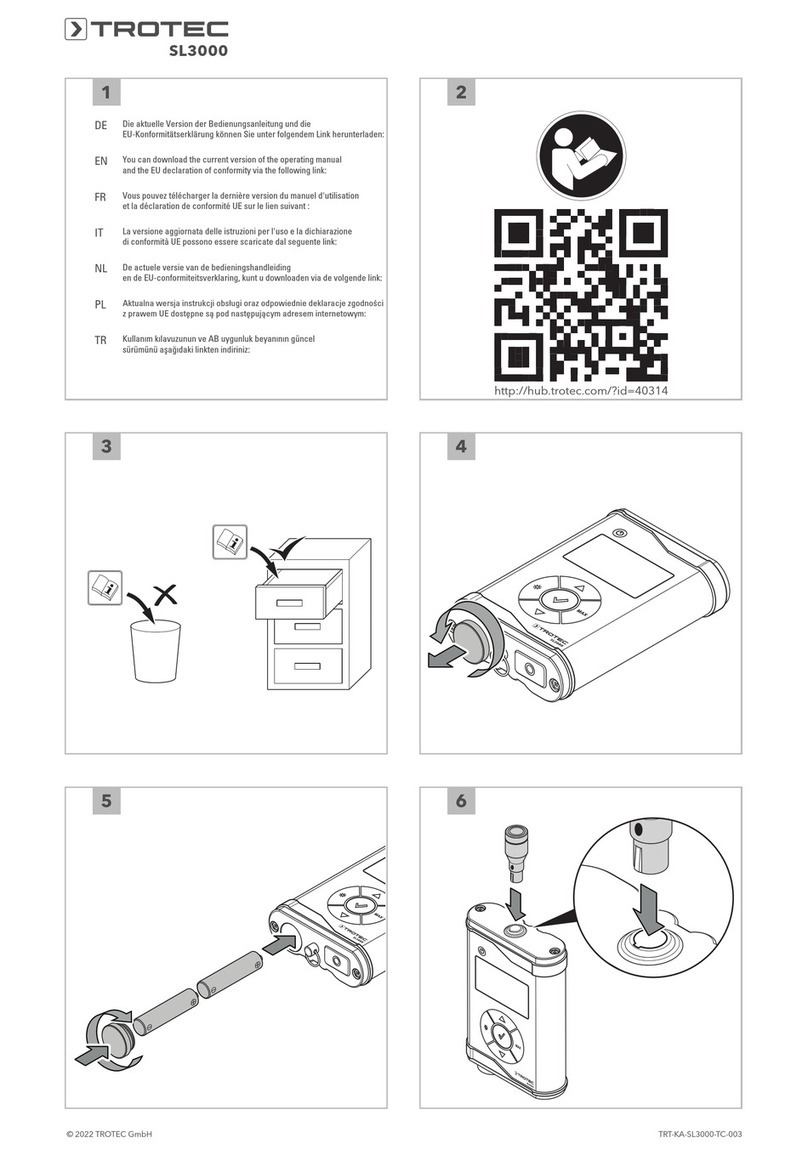

5.2 Installation Procedure

Fig 2 illustrates the instrument installation

procedure.

a. Remove the instrument terminal cover by

unscrewing the two captive 'A' screws.

b. Mount the instrument on a flat surface and

secure with two M6 screws through the 'B'

holes. Alternatively use one of the mounting

kits described in section 8.3

c. Remove the temporary dust seals from the

three cable entries and install the required

glands, conduit fittings or blanking plugs.

Note: The temporary dust seals fitted for

transit do not maintain the IP66 protection of

the BA444DF-P enclosure.

Cable glands, conduit fittings, blanking plugs

and cables must be suitable for continuous

use at the maximum operating temperature

of the instrument.

d. Connect the field wiring to the terminals as

shown in Fig 3.

e. Replace the instrument terminal cover and

evenly tighten the two 'A' screws.

Fig 2 BA444DF-P installation procedure

6

5.3 EMC

The BA444DF-P complies with the requirements of

the European EMC Directive 2004/108/EC. For

specified immunity, all wiring should be in

screened twisted pairs with the screens earthed at

one point in the safe area.

Fig 3 Dimensions and terminal connections

6. CONFIGURATION

The BA444DF-P 8 variable PROFIBUS PA PA

indicator may be configured as a fieldbus node or

as a fieldbus listener. When used as a fieldbus

node the indicator is configured via the fieldbus

host although the instrument address may be

entered via the front panel push buttons using the

menu shown in Fig 4. For detailed node

conditioning information please refer to the BEKA

PROFIBUS PA Display – Fieldbus Interface Guide

which may be downloaded from the BEKA website

www.beka.co.uk

As a fieldbus listener, the BA444DF-P is not visible

to the fieldbus host and can only be configured via

the front panel push buttons using the menu

shown in Fig 6.

Throughout this manual the four BA444DF-P push

buttons are identified P E ▼▲and legends

displayed by the instrument are shown within

inverted commas e.g. ‘CodE’ and ‘Enb’.

6.1 Configuration menus

The configuration menus are separated into two

sections, fieldbus node and fieldbus listener. Both

contain the ‘tYPE’ function that enables transfer

between the two. Unless otherwise requested

when ordered, all PROFIBUS PA BA444DF-P

instruments are supplied as a fieldbus node with

default configuration but can easily be reconfigured

on-site.

6.2 Node configuration menu

The node configuration menu is shown in Fig 4.

Access to the menu is obtained by operating the P

and Ebuttons simultaneously. If the BA444DF-P

is not protected by an access code the first

parameter 'Addr’ will be displayed. If the

instrument is protected by an access code, ‘CodE’

will be displayed first. Pressing Pwill allow the

four digit security code to be entered digit by digit

using the ▼or ▲button to adjust the flashing digit

and Pto move control to the next digit. When the

correct code has been entered, pressing Ewill

cause the first parameter ‘Addr’ to be displayed.

If an incorrect code is entered, or no button is

pressed for ten seconds, the BA444DF-P will

automatically return to the display mode.

6.2.1 Enter fieldbus address ‘Addr’

This function enables the fieldbus address of the

BA444DF-P to be entered via the push buttons.

Select ‘Addr’ in the node menu using the ▼or ▲

button and press Pto enter the function. This will

reveal the existing three digit decimal address with

the left hand digit flashing which may be changed

by operating the ▼or ▲button. When set as

required operating the Pbutton will transfer control

to the next digit that may be adjusted in the same

way. When all digits are set as required operating

the Ebutton will enter the new address and the

indicator will restart in the display mode after

completing the initialisation sequence. If the

address is not changed, operating the Ebutton will

return the display to the ‘Addr’ prompt in the node

configuration menu.

6.2.2 Access code for configuration menu

‘CodE’

Access to the node configuration menu may be

protected by a four digit security code which must

be entered to gain access. New instruments are

supplied configured with the default code 0000

which disables this protection and allows

unrestricted access to the configuration menu.

7

To enter a new access code select ‘CodE’ in the

node configuration menu by operating the ▼or ▲

button. To enter the function press Pwhich will

reveal the current access code with one digit

flashing. The code may be changed using the ▼or

▲button to adjust the flashing digit and the P

button to move control to the next digit. When the

required code has been selected, press Eto enter

the selection and return to the ‘CodE’ prompt in the

configuration menu. The revised access code will

be activated when the transmitter is returned to the

display mode.

If the access code is lost please contact BEKA

associates.

6.2.3 Change from node to listener ‘tYPE’

This function enables the instrument to be

changed from a fieldbus node to a fieldbus listener.

Select ‘tYPE’ in the node configuration menu using

the ▼or ▲button. To enter the function press P

which will show that the instrument is configured

as a fieldbus node, to change to a fieldbus listener

press the ▼or ▲button which will toggle the

display to ‘LStnr’ To prevent accidental changes

this request must be confirmed by operating the P

button and entering ‘5urE’. The instrument will

display ‘0000’ with the first digit flashing, using the

▼or ▲button set the flashing digit to ‘5’ and press

the Pbutton to move control to the next digit which

should be set to ‘u’. When the four letters of ‘5urE’

have been entered, operating the Ebutton will

cause the instrument to restart as a fieldbus

listener in the display mode.

CAUTION

All the instrument’s node configuration

information will be lost when it is

changed from a fieldbus node to a

fieldbus listener.

Please refer to the quick set-up procedure in the

BEKA PROFIBUS PA Display – Fieldbus Interface

Guide.

6.2.4 Reset the instrument to node factory

defaults ‘rESEt’

The BA444DF-P may be reset to the factory

defaults that are shown below:

Security Code 0000 (disabled)

Device address 126

For each of the eight inputs:

Decimal point XXX.XX

Bar Type Left

Bar lower limit 0.0

Bar Upper limit 100.0

Gain 1.0

Offset 0.0

To reset the BA444DF-P select ‘rESEt’ in the

configuration menu by operating the ▼or ▲

button. To enter the function press Pwhich will

reveal ‘0000’ with the left hand digit flashing. To

prevent accidental use of this function, ‘5urE’ must

be entered to confirm that the instrument is to be

reset.

Using the ▼or ▲button set the flashing digit to ‘5’

and press the Pbutton to move control to the next

digit which should be set to ‘u’. When the four

letters of ‘5urE’ have been entered operating the E

button will reset the BA444DF-P to the factory

defaults. Any existing configuration and

addresses will be lost when the instrument is reset.

FIG 4 Node configuration menu

8

6.3 Listener configuration menu

When used as a fieldbus listener the BA444DF-P

is not visible to the fieldbus host and can only be

configured using the front panel push buttons

shown in Fig 3.

The listener configuration menu is separated into

three sections, ‘SCAn’, ‘LISt’ and ‘Edit’, plus three

housekeeping functions ‘CodE’, ‘tYPE’ and ‘rESEt’

as shown in Fig 6.

‘SCAn’ is the simplest method of configuration if

the addresses of the data sources to be displayed

by the BA444DF-P listener are not known.

In the ‘SCAn’ function pressing the Pbutton

causes the BA444DF-P listener to search the

fieldbus segment to which it is connected for all

data sources. The hexadecimal device

addresses for each data source are displayed as

shown in Fig 5.

The ▼and ▲push buttons scroll the display

through all the data sources on the segment

showing the source and destination address for

each one. To aid identification, operating the P

button will preview the value of the data at the

selected addresses with a zero index i.e. the first

five bytes in the data string. If the format of the

data is not DS-33 (status + float) ‘no dAt’ will be

displayed. The selected source and destination

addresses may be allocated to one of the eight

BA444DF-P listener inputs in-1, to in-8. Operating

the Pbutton will reveal the current listener input

which may be changed using the ▼or ▲push

button, when set as required, operating the Epush

button will enter the allocation. If the process

variable to be displayed is located further along the

data stream i.e. has an index greater than 5, the

required index must be entered via the index ‘ind’

function in the edit sub-menu.

A worked configuration example illustrating this

procedure is contained in the Quick Set-up section

of the PROFIBUS PA Interface Guide.

Fig 5 Device Addresses

If the source and destination addresses and index

of the process variable to be displayed by the

BA444DF-P listener are known, they may be

directly entered via the edit sub-menu. This sub-

menu also provides full control of both the numeric

and bargraph display parameters.

9

10

6.3.1 Access

Access to the listener configuration menu is

obtained by operating the Pand Ebuttons

simultaneously. If the BA444DF-P listener

configuration menu is not protected by an access

code the first parameter 'SCAn’ will be displayed.

If the BA444DF-P is protected by an access code,

‘CodE’ will be displayed first. Pressing Pwill allow

the four digit security code to be entered digit by

digit using the ▼or ▲button to adjust the flashing

digit and Pto move control to the next digit. When

the correct code has been entered, pressing Ewill

cause the first parameter ‘SCAn’ to be displayed.

If an incorrect code is entered, or no button is

pressed for ten seconds, the indicator will

automatically return to the display mode.

Section 6.3.2 contains a summary of each

configuration function including a cross reference

to a more detailed description.

6.3.2 Summary of listener configuration

functions

Instrument Summary

display of function

‘SCAn’ Scan fieldbus segment

Identifies all data sources on the

fieldbus segment to which the listener is

connected and enables selected data to

be allocated to one of the eight listener

inputs in-1 to in-8.

See section 6.4.1

‘LiSt’ List configured input parameters

For each of the eight BA444DF-P

listener inputs, in-1 to in-8 shows if the

input is enabled, Source Address,

Destination Address and the Index

which have been allocated.

Parameters can not be changed from

within this function.

See section 6.4.2

‘Edit’ Enter addresses and display

parameters

Sub-menu which allows known fieldbus

device addresses to be entered and all

display parameters adjusted for each of

the eight fieldbus listener inputs.

See section 6.4.3

‘Enb’ Enable selected input

Enables each of the eight

listener inputs in-1 to in-8 to

be enabled or disabled

without affecting any

parameters.

See section 6.4.4

‘SrC’ Enter Source Address

Allows hexadecimal fieldbus

device source address for

each of the eight listener

inputs in-1 to in-8 to be

entered.

See section 6.4.5

‘dSt’ Enter Destination Address

Allows hexadecimal fieldbus

device destination address for

each listener input in-1 to in-8

to be entered.

See section 6.4.6

‘ind’ Enter Index

Allows hexadecimal index for

specified fieldbus source

address to be entered for

each listener input in-1 to in-

8.

See section 6.4.7

‘dP’ Decimal point position

Defines position of displayed

decimal point for each listener

input in-1 to in-8.

See section 6.4.8

‘bAr’ Configuration of bargraph

Defines the bargraphs

justification and the digital

display at which the bargraph

is zero and full scale for each

listener input in-1 to in-8.

See section 6.4.9

‘SCALE’ Scale numeric display

Applies zero offset and scale

factor to the numeric display

for each listener input in-1 to

in-8.

See section 6.4.10

‘CodE’ Access code for listener

configuration menu

Enters a four digit security access

code for configuration menu. Default

code 0000 disables this function.

See section 6.4.11

‘tYPE’ Change from listener to node

Enables the instrument to be

conditioned as a fieldbus listener or a

fieldbus node.

See section 6.4.12

‘rESEt’ Reset to listener factory defaults

Returns the BA444DF-P listener to

factory defaults.

See section 6.4.13

11

6.4 Description of listener menu functions

This section contains a detailed description of each

function in the listener configuration menu. It

should be read in conjunction with Fig 6.

6.4.1 Scan fieldbus segment ‘SCAn’

If the Device Addresses of a data source are not

known, the ‘SCAn’ function provides a simple way

to identify them. This function scans the fieldbus

segment to which the BA444DF-P listener is

connected and identifies all the data sources. To

aid identification the value of the process variable

with a zero index i.e. the first five bytes in the data

string at the address may be pre-viewed.

The BA444DF-P listener only supports DS-33

formatted data (status+float) which is the usual

format for analogue process variables. The

‘SCAn’ function will identify, irrespective of format,

all data sources on the segment whose destination

address is five bytes long. When pre-viewed, non

DS-33 formatted data will produce a ‘no dAt’ error

message.

‘SCAn’ is the first function displayed when entering

the configuration menu, or it may be selected from

within the menu by operating the ▼or ▲button.

To scan the fieldbus segment to which the listener

is connected for all data sources press Pwhich will

reveal the hexadecimal source address and

destination address of the first data source found

as shown in Fig 5. If there is more than one data

source, operating the ▼or ▲button will scroll

though all of them.

If there are no data sources on the fieldbus

segment the BA444DF-P listener will display

‘noSrC’.

When the source and destination addresses of a

data source are displayed, to aid identification the

value of the process variable with a zero index i.e.

the first five bytes in the data string may be pre-

viewed by operating the Pbutton. If this confirms

that it is the required address, it may be allocated

to one of the eight BA444DF-P listener inputs in-1

to in-8. To select the required listener input, press

Pwhich will display the first input in-1. Operating

the ▼or ▲button will scroll the display through

the other inputs. When the required input is

displayed pressing Ewill allocate the selected data

source address to the selected input and return the

display to the source and destination addresses

from which another data source address may be

selected. When a data source address is allocated

to a listener input any previous allocation will be

overwritten.

If the required process variable has an index

above 5 i.e. it is not the first five bytes in the data

string, the required index should be entered via the

‘ind’ function in the Edit sub-menu which is

described in section 6.4.7

6.4.2 List configured input parameters ‘LiSt’

The ‘LiSt’ function enables the Source Address,

Destination Address and Index allocated to each

listener input to be viewed without danger of it

being accidentally changed.

The ‘LiSt’ function may be selected from within the

menu by operating ▼or ▲button. To enter the

function press Pwhich will display the listener

input currently selected in the display mode, other

inputs may be selected using the ▼or ▲button.

Operating the Pbutton will cause the following

parameters for the selected input to be displayed

sequentially:

Display Explanation

‘Enb:Y or N’ Input Enabled yes or no

‘SrC:00’ Source Address

‘dSt :00’ Destination Address

‘ind :00’ Index

The display then automatically returns to the

selected BA444DF-P listener input from where

another input may be selected.

If one of the eight BA444DF-P Listener’s inputs in-

1 to in-8 has not had a Source Address,

Destination Address and Index allocated to it, ‘LiSt’

will show both addresses as ‘FF’ and the index

‘ind’ as ‘00’.

6.4.3 Enter address & display parameters

‘Edit’

The ‘Edit’ sub-menu may be selected from within

the menu by operating ▼or ▲button. To enter the

function press Pwhich will display the listener

input currently selected in the display mode, other

listener inputs may be selected using the ▼or ▲

button. When the required input has been

selected operating the Pbutton will enter the edit

sub-menu at ‘Enb’ for the selected input.

6.4.4 Enable selected input ‘Enb’

‘Enb’ turns the listener input selected in the Edit

function on or off without affecting the conditioning.

To enter the function press Pwhich will reveal

whether the selected input is ‘on’ or ‘oFF’.

Operating the ▼or ▲buttons will toggle between

the two conditions. When set as required

operating the Ebutton will enter the selection and

return to the ‘Enb’ prompt in the edit sub-menu.

12

6.4.5 Enter source address ‘SrC’

This function allows a known fieldbus device

source address to be entered and allocated to the

listener input selected in the edit function. To enter

the function press Pwhich will reveal the existing

two digit hexadecimal address with one digit

flashing which may be changed by operating the ▼

or ▲button. When set as required operating the

Pbutton will transfer control to the second digit

that may be adjusted in the same way. When both

digits are set as required operating the Ebutton

will enter the selection and return to the ‘SrC’

prompt in the edit sub-menu.

6.4.6 Enter destination address ‘dSt’

This function allows a known fieldbus device

destination address to be entered and allocated to

the listener input selected in the Edit function. To

enter the function press Pwhich will reveal the

existing two digit hexadecimal address with one

digit flashing which may be changed by operating

the ▼or ▲button. When set as required operating

the Pbutton will transfer control to the second digit

that may be adjusted in the same way. When both

digits are set as required operating the Ebutton

will enter the selection and return to the ‘dSt’

prompt in the edit sub-menu.

6.4.7 Enter Index ‘ind’

Index defines the location of the required process

variable in the data string. The ‘ind’ function allows

a known Index for the selected fieldbus Source

Address to be entered and allocated to the

BA444DF-P listener input selected in the Edit

function. The data location is manufacturer specific

and can not be automatically determined; the

device documentation should therefore be

consulted. To enter the function press Pwhich will

reveal the existing two digit hexadecimal address

with one digit flashing which may be changed by

operating the ▼or ▲button. When set as required

operating the Pbutton will transfer control to the

second digit that may be adjusted in the same

way. When both digits are set as required

operating the Ebutton will enter the selection and

return to the ‘ind’ prompt in the edit sub-menu.

6.4.8 Decimal point position ‘dP’

This defines the position the decimal point in the

numeric display. To enter the function press P

which will reveal the existing decimal point

position. Operating the ▼or ▲button will move

the decimal point to the required position, omit it,

or activate all the decimal points which

automatically provides maximum resolution in the

display mode irrespective of the numeric value.

When positioned as required, operating the E

button will enter the selection and return to the ‘dP’

prompt in the edit sub-menu.

6.4.9 Configuration of bargraph display ‘bAr’

This function contains three sub-functions that

enable the bargraph, justify its position and define

the relationship between the bargraph and the

instrument’s numeric display.

Sub-function ‘b.tYPE’ enables the bargraph to be

left, centre or right justified, or to be turned off.

Sub-functions ‘bArLo’ and ‘bArhi’ define the

listener’s numeric display at which the bargraph

starts and is at full scale.

The ‘bAr’ function may be selected from within the

edit sub-menu by operating the ▼or ▲button.

To enter the function press Pwhich will display the

‘b.tYPE’ sub-function, pressing Pagain will reveal

the existing bargraph justification. The ▼or ▲

button will scroll through the four options, when the

required justification is displayed, pressing Ewill

enter the selection and return the display to the

‘b.tYPE’ prompt in the edit sub-menu from which

‘bArLo’ may be selected using the ▼or ▲button.

‘bArLo’ defines the listener’s numeric display at

which the bargraph starts, to enter the function

press Pwhich will reveal the existing setting. The

display may be changed using the ▼or ▲button

to adjust the flashing digit and the Pbutton to

move control to the next digit. When the required

starting display has been selected, press Eto

return to the ‘bArLo’ prompt in the edit sub-menu

from which the ‘bArHi’ function may be selected.

‘bArHi’ defines the listener’s numeric display at

which the bargraph is full scale, to enter the

function press Pwhich will reveal the existing

setting. The display may be changed using the ▼

or ▲button to adjust the flashing digit and the P

button to move control to the next digit. When the

required display has been selected, press Etwice

to enter the new values and return to the ‘bAr’

prompt in the edit sub-menu.

Note: If the ‘dP’ function has been set to provide

automatic maximum resolution irrespective of the

displayed value, it may be necessary to manually

position the decimal point before adjusting ‘bArLo’

or ‘bArHi’. This can be achieved by repeatedly

operating the Pbutton until the activated decimal

point flashes, the decimal point can then be

positioned using either the ▼or ▲button.

Pressing the Pbutton again will return control to

one of the digits.

6.4.10 Scale numeric display ‘SCALE’

A scaling factor ‘Gain’ and an offset ‘oFFSt’ may

be applied to the fieldbus process variable using

this function, thus allowing the listener to display

the fieldbus process variable in alternative units.

13

The ‘SCALE’ function may be selected from within

the edit sub-menu by operating the ▼or ▲button.

To enter the function press Pwhich will display the

‘GAin’ sub-function, pressing Pagain will reveal

the existing gain with one digit flashing. This

flashing digit may be changed by operating the ▼

or ▲ button; when adjusted the Pbutton will move

control to the next digit or to the decimal point

which can be positioned using the ▼or ▲button.

When ‘GAin’ has been set to the required value

operating the Ebutton will enter the selection and

return to the ‘GAin’ prompt in the sub-menu from

where the ‘oFFSt’ function can be selected using

the ▼or ▲button.

To enter the ‘oFFSt’ function press Pwhich will

reveal the existing offset with one digit flashing.

Again the flashing digit may be changed by

operating the ▼or ▲button and the Pbutton will

move control to the next digit or to the decimal

point. When ‘oFFSt’ has been set to the required

value operating the Ebutton will enter the selection

and return to the ‘oFFSt’ prompt in the sub-menu.

Three operations of the Ebutton will return to the

‘Edit’ function in the main configuration menu.

6.4.11 Access code for listener configuration

menu ‘CodE’

Access to the listener configuration menu may be

protected by a four digit security code which must

be entered to gain access. New instruments are

supplied configured with the default code 0000

which disables this protection and allows

unrestricted access to the configuration menu.

To enter a new access code select ‘CodE’ in the

configuration menu by operating the ▼or ▲

button. To enter the function press P,this will

reveal the current access code with one digit

flashing. The code may be changed using the ▼or

▲button to adjust the flashing digit and the P

button to move control to the next digit. When the

required code has been selected, press Eto enter

the selection and return to the ‘CodE’ prompt in the

configuration menu. The revised access code will

be activated when the transmitter is returned to the

display mode.

If the access code is lost please contact BEKA

associates.

6.4.12 Change from fieldbus listener to

fieldbus node ‘tYPE’

This function enables the BA444DF-P to be

conditioned as a fieldbus node or as a fieldbus

listener. To change the function of the instrument

select ‘tYPE’ in the listener configuration menu

using the ▼or ▲button and press Pto enter

which will show that the instrument is configured

as a fieldbus listener.

To change to a fieldbus node press the ▼or ▲

button which will toggle the display to ‘nodE’. To

prevent accidental changes this request must be

confirmed by operating the Pbutton and entering

‘5urE’. The instrument will display ‘0000’ with the

first digit flashing, using the ▼or ▲button set the

flashing digit to ‘5’ and press the Pbutton to move

control to the next digit which should be set to ‘u’.

When the four letters of ‘5urE’ have been entered,

operating the Ebutton will result in the instrument

restarting in the display mode as a fieldbus node.

CAUTION

All the instrument’s listener configuration

information will be lost when it is

changed from a fieldbus listener to a

fieldbus node.

6.4.13 Reset the listener to factory defaults

‘rESEt’

The BA444DF-P listener may be reset to the

factory defaults that are shown below:

Security Code 0000 (disabled)

For each of the eight inputs:

Decimal point XXX.XX

Bar Type Left

Bar lower limit 0.0

Bar Upper limit 100.0

Gain 1.0

Offset 0.0

To reset the BA444DF-P listener select ‘rESEt’ in

the configuration menu by operating the ▼or ▲

button. To enter the function press P,this will

reveal ‘0000’ with the left hand digit flashing. To

prevent accidental use of this function, ‘5urE’ must

be entered to confirm that the instrument is to be

reset.

Using the ▼or ▲button set the flashing digit to ‘5’

and press the Pbutton to move control to the next

digit which should be set to ‘u’. When the four

letters of ‘5urE’ have been entered operating the E

button will reset the BA444DF-P to the factory

defaults. Any existing configuration and

addresses will be lost when the listener is reset.

14

7. MAINTENANCE

7.1 Fault finding during commissioning

If a BA444DF-P fails to function during

commissioning the following procedure should be

followed:

Symptom Cause Check:

No Display Instrument not

correctly

connected or

powered.

9 to 22V between

terminals 1 & 2.

Displays

‘no ConF’ No inputs are

enabled. Configuration of

each input.

Displays

‘no dAtA’ No data being

received with the

current

configuration.

Addresses and

Index are correct.

That data has

DS-33 format.

Display shows

‘9.9.9.9.9’ with all

decimal points

flashing; all

bargraph

segments

activated and

bargraph scale

flashing.

Value

over-range Configuration.

and

decimal point

position.

Display shows

‘-9.9.9.9.9’ with

all decimal points

flashing; no

bargraph

segments

activated and

bargraph scale

flashing.

Value

under-range Configuration

And

Decimal point

position.

Display

alternates

between value

and the word

‘bAd’. Bargraph

flashes.

Status of fieldbus

variable has a

quality of ‘BAD’

or a fault state is

active.

Fieldbus

configuration.

Bargraph scale

flashes. Process variable

is outside the

limits defined for

the bargraph.

Bargraph

configuration.

All display

segments

activated.

Display is

initialising. This is normal

operation, after a

few seconds the

model number

followed by the

firmware version

will be displayed

prior to entering

the display

mode.

7.2 Fault finding after commissioning

ENSURE PLANT SAFETY BEFORE

STARTING MAINTENANCE

Live maintenance is permitted on

intrinsically safe equipment installed in a

hazardous area, but only certified test

equipment should be used unless a gas

clearance certificate is available.

If a BA444DF-P fails after it has been

functioning correctly, the table shown in section

7.1 may help to identify the cause of the failure.

If this procedure does not reveal the cause of the

fault, it is recommended that the instrument is

replaced.

7.3 Servicing

We recommend that faulty BA444DF-P PROFIBUS

PA Indicators are returned to BEKA associates or

to our local agent for repair.

7.4 Routine maintenance

The mechanical and electrical condition of the

instrument should be regularly checked. Initially

annual inspections are recommended, but the

inspection frequency should be adjusted to suit the

environmental conditions.

7.5 Guarantee

Instruments which fail within the guarantee period

should be returned to BEKA associates or our local

agent. It is helpful if a brief description of the fault

symptoms is provided.

7.6 Customer comments

BEKA associates is always pleased to receive

comments from customers about our products and

services. All communications are acknowledged

and whenever possible, suggestions are

implemented.

15

8. ACCESSORIES

8.1 Scale and tag marking

BA444DF-P PROFIBUS PA Indicators are fitted

with a blank escutcheon around the liquid crystal

display. If specified when the instrument is

ordered, this can be supplied printed with units of

measurement and tag information, plus a scale for

the horizontal bargraph. Alternatively, information

may be added on-site via an embossed strip, dry

transfer or a permanent marker.

To gain access to the display escutcheon remove

the terminal cover by unscrewing the two 'A'

screws which will reveal two concealed 'D' screws.

Unscrew all four 'D' screws and carefully lift off the

front of the instrument. The location of these

screws is shown in Fig 2.

After adding the required legends, or fitting a new

pre-printed self-adhesive escutcheon, ensure that

the gasket is correctly positioned before

reassembling the instrument enclosure.

8.2 Tag plate

The BA444DF-P can be supplied with a blank or

custom laser marked stainless steel plate secured

by two screws to the front of the instrument

enclosure. This plate can accommodate:

1 row of 9 alphanumeric characters 10mm high

or 1 row of 11 alphanumeric characters 7mm high

or 2 rows of 18 alphanumeric characters 5mm

high.

or 8 cells each containing units of measurement or

identification for one of the 8 inputs.

8.3 Pipe mounting kits

Two pipe mounting kits are available for securing

the BA444DF-P to a horizontal or vertical pipe.

BA392D Stainless steel bracket secured by two

worm drive hose clips for 60 to 80mm

outside diameter pipes.

BA393 Heavy-duty stainless steel bracket

secured by a single 'V' bolt. Will clamp

to any pipe with an outside diameter

between 40 and 80mm.

16

APPENDIX 1

ATEX dust certification

A1.0 ATEX dust certification

In addition to ATEX certification permitting

installation in explosive gas atmospheres which is

described in the main section of this instruction

manual, the BA444DF-P is available with optional

ATEX certification permitting use in the presence

of combustible dusts. If ATEX dust certification is

required it must be requested when the BA444DF-

P PROFIBUS PA indicator is purchased.

WARNING

Before installing a BA444DF-P

PROFIBUS PA indicator in the presence

of a combustible dust, ensure that the

certification information label, which is

located on the top of the instrument,

specifies dust certification – see section

A1.2

A1.1 Zones and Maximum Surface

Temperature

The BA444DF-P has been ATEX certified as

Group II, Category 1D Ex iaD 20 T100

o

C IP66

apparatus Tamb = -20 to 60

o

C. When installed

as specified by EN 61241-14 ‘Electrical apparatus

for use in the presence of combustible dust –

Selection and installation’, the BA444DF-P

PROFIBUS PA indicator may be installed in:

Zone 20 explosive atmosphere in the

form of a cloud of

combustible dust in air is

continuously present, or for

long periods or frequently.

Zone 21 explosive atmosphere in the

form of a cloud of

combustible dust in air is

likely to occur occasionally

in normal operation.

Zone 22 explosive atmosphere in the

form of a cloud of

combustible dust in air is not

likely to occur in normal

operation, but if it does

occur, will only persist for a

short period.

Be used with dusts having a Minimum Ignition

Temperature of:

Dust cloud 150

o

C

Dust layer on BA444DF-P 175

o

C

up to 5mm thick

Dust layer on BA444DF-P Refer to

over 5mm thick. EN 61241-14

At an ambient temperature between –20 and

+60

o

C

A1.2 Certification Label Information

The certification label is fitted in a recess on the

top outer surface of the enclosure. It shows details

of the ATEX dust certification including the

maximum surface temperature and ingress

protection plus BEKA associates name and

location. IECEx dust approval information is also

shown, non-European certification information may

also be included.

The instrument serial number and date of

manufacture are recorded on a separate label

inside the terminal compartment.

A1.3 Installation & maintenance

The ATEX dust certification relies on the

BA444DF-P PROFIBUS PA enclosure being dust-

tight. Therefore the terminal cover should only be

removed when dust can not enter the instrument

enclosure. Before replacing the terminal cover

ensure that the sealing gaskets are undamaged

and are free from foreign bodies.

17

APPENDIX 2

FM Approval for use in the USA and

cFM Approval for use in Canada

A2.0 Factory Mutual Approval

For installations in the USA and Canada, a version

of the BA444DF-P is available with FM and cFM

intrinsic safety and nonincendive approval, project

identifications 3027031 and 3027031C. Copies

of the Certificates of Compliance are available

from BEKA associates sales office and

www.beka.co.uk

The FM and cFM Approved version is identical to

the ATEX version except the three M20 x 1,5

tapped cable entries are replaced by three plain

unthreaded 22.25mm diameter entries. Approved

hubs and glands are listed in note 6 of Intrinsically

Safe Control Drawing CI410-12 and note 5 of

Nonincendive Control Drawing CI410-13. The

certification label on the FM and cFM Approved

version includes ATEX gas certification information

so that the BA444DF-P PROFIBUS PA indicator

may be used in systems covered by either

authority.

A2.1 Intrinsic safety approval

The BA444DF-P is approved to FM Class 3610

intrinsic safety standard for use in indoor and

outdoor hazardous (classified) locations.

Installations must comply with BEKA associates

Control Drawing CI410-12, which is attached to

this Appendix, ANSI/ISA RP12.06.01 ‘Installation

of Intrinsically Safe Systems for Hazardous

(Classified) Locations’ and with the National

Electrical Code ANSI/NFPA70.

The BA444DF-P has a T4 rating at ambient

temperatures up to +70

o

C and may be used with

the following gases and dusts:

Intrinsic Safety

Division 1 or 2

Class I Group A & B

Group C

Group D

Class II Group E, F & G

Class III

Zone 0, 1 or 2

Class 1 Group IIC

Group IIB

Group IIA

Canadian installations must comply with the

Canadian Electrical Code C22.2 and with BEKA

associates Control Drawing CI410-12, which is

attached to this Appendix.

The FM and cFM entity parameters are identical to

the ATEX parameters and, like the ATEX

certification, confirm that the BA444DF-P complies

with the FISCO Field Device requirements

specified in IEC60079-27. The intrinsically safe

system shown in Fig 1 of this manual may

therefore be used for installations in the USA and

Canada, providing the fieldbus power supply,

terminators, Zener barriers and galvanic isolators

are FM Approved for US installations and cFM or

CSA Approved for Canadian installations. All

installations must comply with BEKA associates

Control Drawing CI410-12 .

FM and cFM Approvals also allows the BA444DF-

P to be connected to non-FISCO systems using

the entity concept – see section 3.2 of this manual.

A2.2 Nonincendive approval

The BA444DF-P is FM Class 3611 nonincendive

approved allowing it to be installed in Division 2

indoor and outdoor hazardous (classified) locations

without the need for Zener barriers or galvanic

isolators. US installations must comply with the

BEKA associates Control Drawing CI410-13, which

is attached to this Appendix, and with the National

Electrical Code ANSI/NFPA70.

Canadian nonincendive installations must comply

with the Canadian Electrical Code C22.2 and with

BEKA associates Control Drawing CI410-13, which

is attached to this Appendix.

The FM and cFM Nonincendive Approvals also

allow the BA444DF-P PROFIBUS PA indicator to

be connected to any appropriately certified FNICO

compliant fieldbus segment.

The BA444DF-P has a T4 rating at ambient

temperatures up to +70ºC and may be used with

the following gases and dusts:

Nonincendive

Division 2

Class I Group A & B

Group C

Group D

Class II Groups E, F & G

Class III

Zone 2

Class I Group IIC

Group IIB

Group IIA

18

19

20

Table of contents

Other Ex-baltic Measuring Instrument manuals