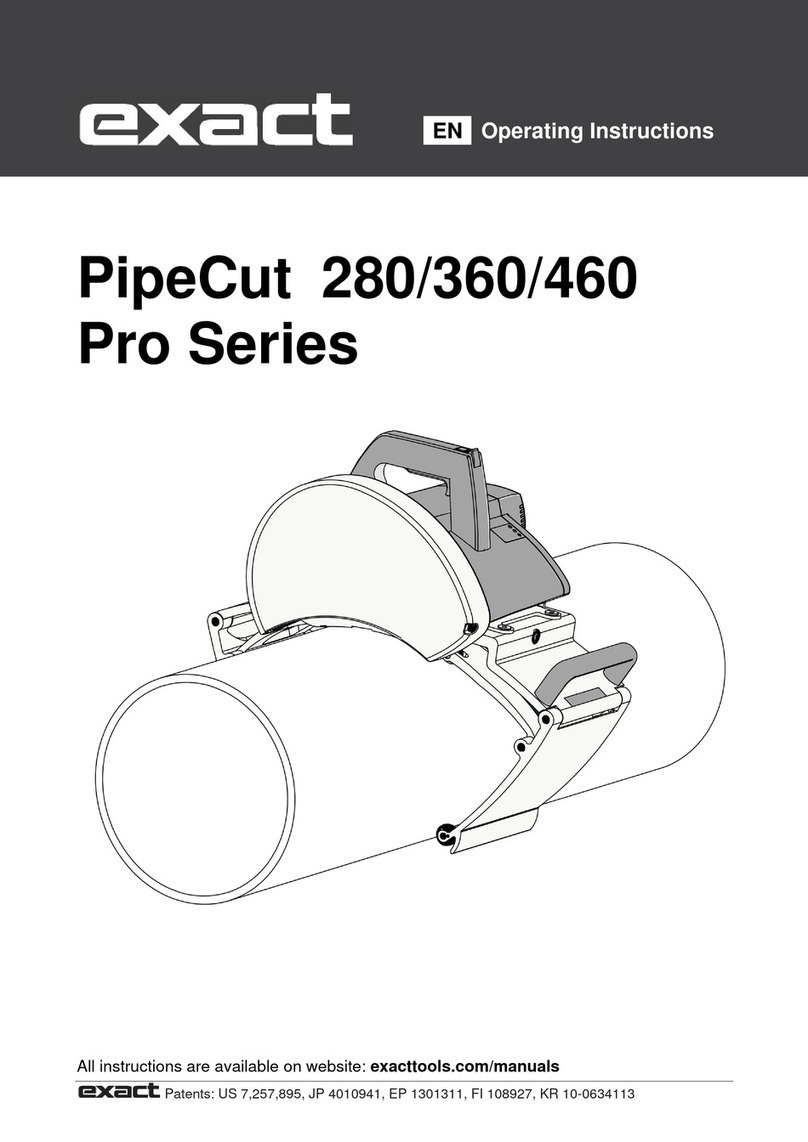

eXact PipeCut 360 AIR User manual

PipeCut 360 AIR

patents: US 7,257,895, JP 4010941, EP 1301311, FI 108927, KR 10-0634113

FI Käyttöohje x–xx

US Manual xx–xx

FI Espanja xx–xx

FI Ranska xx–xx

23

english english

Blade information for

Exact 360 AIR pipe saws

Exact 360 AIR pipe saws use the

following blades:

• Diamond X 180 and X 165 Discs, for

cutting cast iron only

• Exact ALU 180 and 165, for cutting

aluminum and all kinds of plastics

• Exact Cermet 180 and 165, for cutting

steel and stainless steel

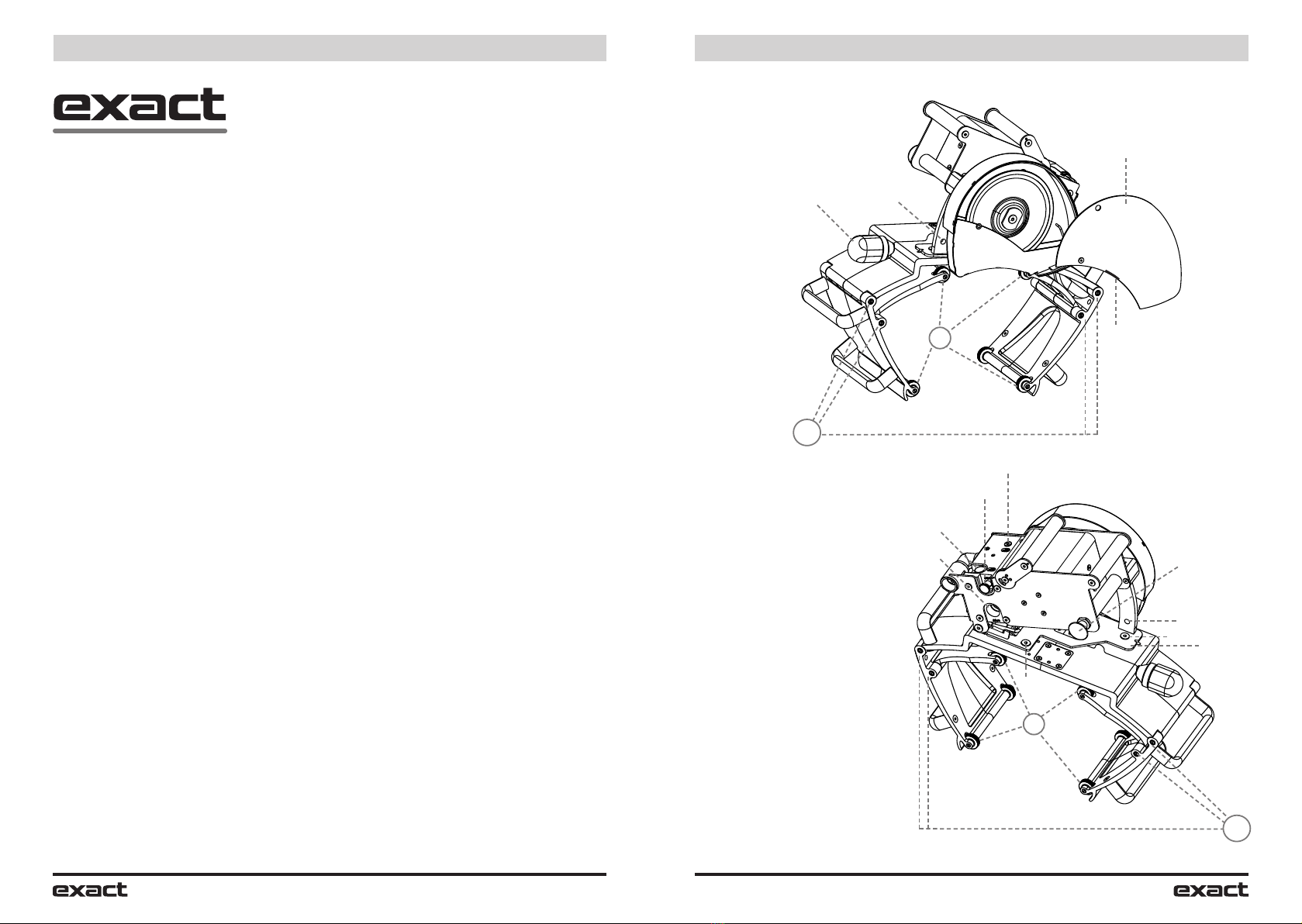

PipeCut 360 AIR

A1 START button

A2 STOP button

(air current shutoff switch)

A3 Locking pin

A4 Gripper adjustment lock

A5 Blade guard

A6 Locking pin hole

A7 Gripper’s wheels and

ball bearings

A8 Adjustment screw

A9 Adjustment screw

A10 Adjustment pointer

A11 Inlet coupling

A12 Measuring edge

A13 Oil tank cap

A14 Gripper’s joints

A4 A6

A5

A12

A14

A7

A13

A6

A3

A9

A8 A10

A1

A11

A2

A7

A14

PICTURE A

45

english english

SafetyIntroduction

Safety information

Personal protective equipment

WARNING

Intoxicants:

Drugs, alcohol, and medications may

weaken attention, judgement, and/or the

ability to concentrate. Impaired reexes,

unsteady balance, hallucinations, and

miscalculations may cause serious work-

place accidents such as personal injuries,

damage to tools and property, or death.

Never use the tool if you are under

the inuence of alcohol, intoxicating

medications, and/or drugs.

If you know about, or notice someone

using alcohol, drugs, or intoxicating

medications, make sure that he or she

is not using the tool.

WARNING

Danger of being caught in moving parts

Do not wear loose jewelry, clothing,

or uniforms. Make sure that possible

shirtsleeves, shoelaces, and/or pants

cuffs cannot be caught by the machine’s

moving parts or become entangled

with any other object or natural feature

at the job site.

To minimize the danger of choking,

make sure that any collar, tie, or hood

cannot become entangled with the

device, cords, or accessories.

To minimize the danger of entanglement,

make sure that hair and headgear

cannot be caught by the device’s

moving parts, cords, or accessories.

Personal protective equipment must conform

to the applicable health and safety require-

ments. Always use the following personal

protective equipment:

• Hard hat conforming to occupational safety

requirements.

• Sufcient hearing protection.

• Safety goggles or visor for eye protection.

• Cut-resistant safety gloves.

• Non-skid safety shoes conforming to

occupational safety regulations.

• Breathing mask.

Installation, use, and

maintenance:

precautionary measures

WARNING

Explosives and flammable materials,

liquids, and gases: Danger of explosion

If used in explosive atmospheres, the tool

may cause an explosion and/or re.

Explosions are dangerous and may cause

extremely serious accidents, injuries, or

death. Because the tool often creates

sparks while sawing, it must never be used

near any kind of potentially explosive or

highly ammable material, liquid, or gas.

Thoroughly familiarize yourself with the

national, state-specic, and local safety

instructions related to working near or

among, explosive materials.

Never use the tool near explosives or

highly ammable materials, liquids, or

gases.

Never work in highly ammable or

explosive atmospheres.

Make sure that your work area has

no hidden gas sources or explosives.

If there are explosives, highly ammable

materials, liquids, or gases at your job

site, make sure that they do not pose

a danger and cannot come into contact

with sparks created by the saw.

Operating, safety, and

servicing instructions

You now have the use of a completely new

type of tool. Developed as a safe alterna-

tive to dangerous tools used to cut round

pipes, the extremely effective Exact 360

AIR has been designed to cut various types

of metals and plastics. It is absolutely

essential that you carefully read and under-

stand these operating, safety, and servicing

instructions before using the pipe saw.

Keep this manual conveniently within reach

of all pipe saw users. Make sure that all

persons using the saw have read and

understood the dangers and operating

instructions specied in this manual, and

always follow the rules and regulations

provided by occupational safety agencies.

The Exact 360 AIR pipe saw is for profes-

sional use only.

Personal safety precautions

and requirements

Make sure that the job site where you are

working complies with all national, local,

and state-specic occupational safety

regulations. Only trained persons familiar

with all general safety regulations, as well

as the possible dangers occurring at job

sites, may use this tool. Failure to follow

the instructions specied in this manual

may cause serious personal injury, damage

to the tool, or a hazardous situation.

Installation, storage,

maintenance, and disposal

This tool may be installed, stored, main-

tained, and disposed only by persons who:

• are physically able to handle the size,

weight, and power of the device.

• are familiar with all relevant national,

state-specic, and local safety regula-

tions, as well as precautionary measures

aimed at accident prevention.

• have read and understood these

operating instructions.

• have not ingested alcohol, drugs, or

medications impairing alertness or

the ability to work.

Use

Only professionally capable persons may

use this tool.

Users are capable if they:

• are able to handle the size, weight, and

power of the device.

• are trained to use this device according

to national, state-specic, and local

instructions.

• are familiar with, and understand, all

national, state-specic, and local safety

regulations, as well as precautionary

measures aimed at accident prevention.

• have read and understood this manual.

• have not ingested alcohol, drugs, or

medications impairing alertness or the

ability to work.

67

english english

Safety Safety

WARNING

Electric shock

If the device comes into contact with electric

circuits or other power sources, it may

cause serious injury or death. Always make

sure there are no cables, wires, or circuits

running inside or near the pipe to be cut

that could conduct electricity to the device

or user.

Do not work near electrical circuits or

other sources of electric currents.

Make sure that your working area has

no hidden electrical circuits and that

the pipe to be sawn is not in contact

with any kind of electrical circuit, power

source, cable, wire, or transformer.

Make sure that any water coming

from inside the pipe or existing at the

job site does not cause the danger of

electric shock, and that no water comes

into contact with any kind of electrical

circuit, power source, cable, wire, or

transformer.

WARNING

Compressed air can cause serious injuries.

Always close the air feed, release the

pressure from the piping, and detach

the tool from the air feed when it is

not being used, repaired, or adjusted,

for example when blades are being

replaced.

Never change blades or service the

tool while it is still connected to the

compressed air source. Always make

sure the device is detached from

the compressed air source when

performing an inspection or servicing

operation. Make sure that the motor

is completely shut off and that the

hoses are not pressurized.

WARNING

Danger of vibration

Avoid exposure to vibration; it can damage

the nervous system as well as hinder blood

circulation in hands and arms. This may

in turn cause pain in sensitive joints and

possible old injuries.

Always use sharp blades whose

condition has been checked. A faulty

or damaged blade must never be used

for sawing, and should be replaced

with an intact blade. Dull, damaged, or

faulty blades may intensify vibration.

Avoid exposure to vibration. Long-term

exposure to vibration may cause

injuries to the user’s joints and/or

nervous system.

Only professional technicians may test

the Exact 360 AIR pipe saw. The pipe saw

may not be tested or serviced by persons

untrained in the servicing of pneumatic

tools. Servicing personnel must be autho-

rized to test these kinds of tools and use

a pneumatic system according to national,

state-specic, and local regulations.

Safety information

• Overspeed caused by excessive air

pressure should be avoided with the

pressure regulators. Recommended

pressures and air quantities must not

be exceeded when using the machine.

Excessive pressure or air quantities may

cause the breakage of the machine,

blade, and accessories, or a hazardous

situation resulting in serious personal

injury or damage to the equipment.

• Couplings and air hoses must be in good

condition. Check the couplings, air hoses,

and compressor before use. Never work

with a damaged coupling, air hose, or

compressor.

WARNING

Only use blades displaying

the Exact brand name:

Exact ALU 180

Exact ALU 165

Exact Diamond X 180

Exact Diamond X 165

Exact Cermet X 180

Exact Cermet X 165

Do not use other manufacturers’

blades. Exact Tools blades are high

quality and have been designed

specically for the Exact 360 AIR

pipe saw.

See the manual’s Operating Instructions,

page 17.

WARNING

Failure to comply with these operating

instructions may result in serious injuries

or death.

Make sure that the pipe being cut is

correctly supported, and that each end

of the pipe on both sides of the sawing

point cannot collapse uncontrollably as

the pipe is being cut.

Make sure that sparks do not endanger

people or materials. Sparks may cause

accidents if they come into contact with

ammable materials, liquids, or gases.

See the section Explosives and

Flammable Materials, Liquids and Gases,

page 5.

Personal protection equipment must

be used as described in the chapter

Personal Protection Equipment, page 5.

Slipping, stumbling, or falling must be

indicated as the reason for a serious

accident or fatality. Watch out for exces-

sively long hoses left at the job site.

Work carefully in unfamiliar locations.

For example, hidden electrical cables

may cause a danger.

Maintain a balanced position and a

steady foothold.

If an improperly installed or damaged

tool vibrates excessively, react quickly.

Shut off the device or cut off the air

pressure if possible.

Stay clear of spinning blades; the rotary

motion may continue for several seconds

after the air feed has been shut off. Do

not detach the pipe saw from the pipe

before the spinning motion has stopped.

Note that compressed air left in the

hose can cause an unintentional

startup. Always empty the hose care-

fully after use. Never detach a

pressurized hose.

If there is a fault in the energy feed,

press the STOP button (Picture A2).

89

english english

General safety regulations

To reduce the risk of personal injuries, any-

one who uses, installs, repairs, or services

this tool, replaces its parts or works in its

vicinity, must have read and understood

these instructions.

Our objective is to manufacture tools that

enhance working safety and efciency. The

most important safety factor for this and

any other tool is ITS USER. Your diligence

and judgement are the best protection

against accidents and injuries. Because

all possible risk factors cannot be treated

in this manual, only the most important

are mentioned. Only professionally trained

users may install, adjust, or use this com-

pressed air tool. This tool or its parts may

not be altered in any way. Do not use this

tool if it has been damaged. If the rating

plate displaying the nominal speed or

operational pressure, or stickers warning

of dangers, are no longer legible or have

become detached, they must be replaced

immediately.

Consult the following sources for further

occupational safety-related information:

• Other guidelines and bulletins provided

with the tool.

• Your employer, professional association,

and/or labor union

• “Safety Code for Portable Air Tools”,

(ANSI B186.1), at the time of publication

available from the Global Engineering

Documents organization at:

http://global.ihs.com/ or telephone

number 1 800 854 7179. If procuring

the ANSI standards is difcult, contact

the ANSI organization at:

http://www.ansi.org/

• Additional information concerning

occupational health and safety is

available from the following websites:

Safety Safety

http://www.osha.gov (USA)

http://europe.osha.eu.int (Europe)

Dangers related to the compressed air

feed and couplings

• Compressed air can cause serious injuries.

Always check the condition of the cou-

plings, compressor, and hoses before use.

• Always turn off the air feed, release the

pressure from the pipes and/or hoses,

and detach the tool from the air feed

source when it is not being used, repairs

are being made, or parts are being

changed. After the shutoff, the hose is

emptied by pushing the START button

(Picture A1) to cut off the compressed

air ow. The machine will run for a few

seconds, after which the hose will be

emptied of air. Watch out for the spinning

blade and make sure that nothing has

been caught in the saw’s blade or other

parts. Open the coupling only when you

are sure that the hose is unpressurized.

• Never point a compressed air hose at

yourself or anyone else. Always make

sure that the compressed air cannot

send objects or materials ying

dangerously towards yourself or others.

• Compressed air hoses waving around

uncontrollably are extremely dangerous

and can cause serious injuries to people,

as well as damage to equipment,

materials, and the surroundings. Always

check that the hoses and couplings are

intact and tightly closed. Make sure that

couplings are always secured with a

durable safety wire. Check the safety

wire’s condition and durability before use.

• If you use a quick coupling, always make

sure that the couplings are intact. Always

use a safety wire loop to prevent the

hoses’ uncontrolled loosening if the

coupling breaks. Check the use of the

couplings with the applicable safety

instructions provided by the manufacturer.

Read the installation instructions carefully.

• If general purpose threaded couplings are

used, locking pins must also be installed.

• The air pressure must not exceed 6.3

bar (90 PSI) or the pressure specied on

the tool’s rating plate. Exceeding the

pressure recommendation can result in

the machine’s breakage or a hazardous

situation.

• Check the hose’s condition before

installation. A broken or worn out hose

may cause a hazardous situation.

Danger of catching

• Stay clear of spinning grinding disks or

blades. Note that the blade will continue

to spin after the closing of the START valve

and it may continue spinning for several

seconds.

• Entangled clothes, gloves, jewelry, ties,

scarfs or long hair in the tool or its acces-

sories can cause choking, scalp injuries,

and/or deep wounds.

Never open the blade guard (Picture A5) if

you are not sure if the blade or grinding disk

has stopped spinning.

Danger caused by flying objects

• The machining of steel and other materials

can quickly generate ying debris. Even

small objects can injure the eyes and

cause blindness.

• Always use impact-resistant protective

goggles and a safety mask when operating

the tool, working nearby in repair and

servicing areas, or changing parts.

• Make sure that other users in the same

area are also wearing protective goggles

and safety masks.

• Make sure that the pipe to be cut is rmly

supported. A weakly or improperly supported

pipe may cause a hazardous situation.

• Make sure that the sparks generated by

the machine can never, under any circum-

stances, come into contact with ammable

and/or potentially explosive materials or

liquids.

• Make sure that sparks or shavings pose

no danger to other persons at the job site.

Equipment-related risk factors

• Before changing a blade, always shut off

the air feed, release the air pressure from

the hose and detach the tool from the air

feed source.

• Use only the recommended sizes and

types of blades.

• Never use a damaged blade. Always check

the blade’s condition before use.

• Check the blade’s attachment before use.

For more detailed instructions, see the

Changing Blades section, page 18.

Operational risks

• Users and servicers must be able to

physically handle the tool’s size, weight,

and power.

Safety information

• Hold the tool properly: be ready to react

to any abnormal or sudden movement –

keep both hands ready.

• Never use the tool unless the blade is

aligned with the material to be cut.

• The Exact 360 AIR is designed to be used

with a blade guard that must always be in

place to provide protection from shavings

and other debris. Never operate a pipe

saw if the blade guard is improperly

attached.

• Never move the machine while the motor

is running or the blade is rotating.

• Do not use the tool if you are tired or your

alertness has become impaired for health

reasons.

• Do not start working if your foothold or

balance is unsteady. Falling while holding

a saw can cause a hazardous situation.

10 11

english english

Dangers caused by repetitive movements

• When operating the tool, the user may

experience discomfort in hands, arms,

shoulders, the neck, and other parts of

the body.

• Work with a comfortable but secure

stance and avoid an awkward or un-

balanced working position. Varying your

position during longer tasks can minimize

discomfort and fatigue.

• Do not ignore symptoms such as

continuous or periodic discomfort, pain,

anxiety, ache, tingling, numbness, a

burning sensation, or stiffness. Stop

using the tool, inform your employer,

and contact a doctor.

Dangers of noise and vibration

• Loud noises can cause permanent hearing

defects and other problems such as

tinnitus. Use the hearing protectors

recommended by the employer or occupa-

tional health and safety regulations.

• Exposure to excess vibration can cause

crippling injuries to the nervous system,

as well as the blood circulation in hands

and arms. Dress warmly and keep your

hands warm and dry. If you experience

numbness, tingling, pain or paleness of

the skin, stop using the tool, inform your

employer, and contact a doctor.

• Hold the tool correctly without excess

effort; the risks caused by vibration gener-

ally increase if you grip the tool too tightly.

Avoidance of unnecessarily high noise and

vibration levels:

• Use and service the tool and select,

maintain, and change the equipment and

accessories according to these operating

instructions.

• Use sound attenuation materials to

minimize the noise generated by the

sawed pipe’s resonance.

Job site-related dangers

• Do not use the saw in areas or on terrain

where there is the danger of falling or slip-

ping. Make sure that your working position

is as steady as possible and that you have

a secure foothold.

• Always make sure that the ditch or shaft

in which you are working is properly rein-

forced and that its edges are not in danger

of collapsing. Make sure that the terrain is

not in danger of giving way or settling.

• If the cutting operation is in a ditch or

trench, access to the STOP button may be

limited. Always have a co-worker be ready

to turn off the air feed to the tool in the

event of an emergency. A separate air feed

with a shutoff device can also be used

for emergency situations.

• Make sure that there are no underground

electrical cables, gas sources, ammable

materials, or other potentially dangerous

objects that could cause a hazardous

situation.

• Slipping, stumbling, or falling can result in

a serious accident or death. Watch out for

hoses at the job site or working platform.

• Avoid the inhalation of dust and vapors, as

well as the handling of job site waste that

could cause health hazards such as, for

example, cancer, birth defects, asthma,

and/or dermatitis. Use dust extraction

equipment and a breathing mask when

the material to be cut releases airborne

particles.

• Some sawing generates dust containing

chemicals that, according to the state of

California, can cause cancer, birth defects,

and other reproductive harm.

Examples of these kinds of chemicals include:

• lead from lead-based paints,

• crystalline silica from bricks, cement, and

other masonry products,

• arsenic and chromium from chemically-

treated rubber.

Your risk from these exposures will vary

depending on how often you do this type

of work.

Safety Environment

Environment

Separate collection. When your Exact 360

AIR machine is worn out, do not dispose of

it with normal household waste; the product

must be recycled separately. The separate

collection and recycling of used products

and packaging facilitates the recovery of

materials, reduces environmental pollution,

and decreases the demand for raw

materials. Local regulations allow the

delivery of households’ pipe saws to

municipal waste dumps or a dealer when

buying a new product.

To reduce your exposure to these chemicals,

work in a well ventilated area and use

approved protective equipment such as dust

masks specically designed to lter out

microscopic particles. Working without

the appropriate protective equipment is

prohibited.

• Be extremely careful when working in

unfamiliar work surroundings; there may

be hidden dangers such as electrical

cables, as well as gas, water, or other

pipes.

• This tool is not intended for use in poten-

tially explosive atmospheres, nor is it

insulated to provide protection from

electric shock if it comes into contact

with an electrical power source.

DO NOT DESTROY – GIVE TO THE USER

Rating plate and stickers

The product is furnished with a rating plate

and stickers displaying important safety

and product information.

Rating plate with following information:

Exact PipeCut 360 AIR

Serial number ………

Pressure max. 6.3 BAR (90 PSI)

Air ow max. 3.9 m3 / min (140 cfm)

Blade 180 mm or 165 mm (7” or 6.6 inch)

Max no-load speed 4000 rpm

Exact Tools Oy

Särkiniementie 5 B 64

FI-00210 Helsinki

Finland

www.exacttools.com

12 13

english english

Guarantee Operational instructions

Operational instructions

Pipe saws are designed with a gripper unit

that ensures the saw’s secure attachment

to the pipe. The saw is attached by turning

the gripper adjustment lock (Picture A4)

and by tightening it securely to the pipe.

Make sure that all of the gripper’s wheels

turn freely and that there is no sand or

debris between the joints. If debris or sand

is present, the gripper must be cleaned

before beginning the work. If a fault is

detected in the gripper unit’s mechanism,

the saw cannot be used.

Guarantee

The guarantee’s terms became effective

on 1 January 2017. If Exact 360 AIR saw

becomes unusable due to material or

manufacturing faults during the guarantee’s

period of validity, we will repair the Exact

360 AIR pipe saw or supply a new or

factory-reconditioned Exact 360 AIR saw

free of charge according to our discretion.

Guarantee period

The Exact Tools guarantee is valid 12

months from the date of purchase.

The guarantee is valid only if:

1. a dated purchase receipt is furnished to

the authorized servicing company or it is

downloaded on our website in connection

with the registration of the guarantee.

2. the Exact 360 AIR saw has not been

misused.

3. no attempt has been made by non-

approved persons to repair the saw.

4. the Exact 360 AIR saw has been used

according to these operating, safety,

and servicing instructions.

5. the Exact 360 AIR saw has been

delivered to an authorized servicing

company during the guarantee’s period

of validity.

Note:

The Exact 360 AIR saw should be

furnished to an authorized repair shop

with delivery expenses paid. If the Exact

360 AIR saw is repaired within the scope

of the guarantee, the product will be

returned with the delivery expenses paid.

If the Exact 360 AIR saw is not repaired

within the scope of the, guarantee, the

delivery expenses will be the customer’s

responsibility.

Guarantee’s limitations:

The guarantee does not the cover following

parts, services, or damages:

- Saw blades and diamond blades

- Gripper unit’s wheels.

- Blade ange.

- Attachment ange.

- Pulling ange washer.

- Normal wear.

- Misuse or faults and damages resulting

from accidents.

- Water, re, and physical damages.

- Motor breakage or other damage caused

by dirt or an unsuitable grade of oil.

- Damages resulting from the use of

air whose purity level falls below its

reference value.

- Damages resulting from the use of air

volumes or air pressures exceeding their

reference values.

As a result of continuous product develop-

ment, the information in this manual

may change. Changes are not announced

separately.

Before using the pipe saw, check that:

• the sliding lower blade guard slides freely.

• the motor unit’s locking mechanism

functions perfectly.

• the gripper unit’s wheels turn freely.

• the compressed air’s pressure and out-

put comply with the manual’s recommen-

dations.

• the pipe to be cut is rmly supported on

both sides of the cutting point.

• the compressed air hoses have been

attached properly.

• the safety wire preventing the hose’s

detachment from the machine is securely

in place.

• you have the right type of blade,

specically designed to cut the material

to be sawed, installed in the machine.

• the blade is in good condition and is tight.

PICTURE A

A1 START button

A2 STOP button

(air current shutoff switch)

A3 Locking pin

A4 Gripper adjustment lock

A5 Blade guard

A6 Locking pin hole

A7 Gripper’s wheels and ball bearings

A8 Adjustment screw

A9 Adjustment screw

A10 Adjustment pointer

A11 Inlet coupling

A12 Measuring edge

A13 Oil tank cap

A14 Gripper’s joints

A13

A6

A3

A9

A8 A10

A1

A4 A6

A11

A2

A7

A5

A12

A14

A7

• you have the proper personal protection

equipment as specied in the operational

safety section of this manual.

• there is enough oil in the oil tank.

NOTE: the motor will not start if there is

not enough oil in the oil tank. If the oil

starts to run low during the sawing, the

motor will shut off and not start before

the oil tank has been lled.

Start the motor by pushing the START

button (Picture A1). Make sure that STOP

button (Picture A2) has been pulled to its

out-position. If the STOP button is at its

in-position, the motor will not start. Begin

sawing as soon as possible after the

motor has been turned on to avoid running

the motor unloaded or at overspeed.

14 15

english english

Determination of pipe’s sawing point

Mark the sawing point on the pipe to be cut

in a way that deducts one inch from the

required measurement. The blade’s point of

contact with the wall of the pipe is one inch

from the measuring edge in the direction of

the saw’s gripper unit. Always keep in mind

that the measuring edge is set one inch

more than, or correspondingly less than,

the required measurement depending from

which direction the required dimension is

being calculated.

Attachment of pipe saw to pipe

Place the pipe saw above the pipe to be

sawn, ensuring that the gripper encloses the

pipe to be sawn. The diameter of the pipe

saw’s gripper can be adjusted with the gripper

adjustment lock (Picture A4). Place the pipe

saw at the desired position by using the

measuring edge part of the blade guard.

(Picture A 12). Adjust the gripper unit ac-

cording to the pipe’s diameter by turning the

pipe saw’s gripper adjustment lock (Picture

A4) and tightening the saw against the pipe.

Make sure that the compressed air hose or

any other object is not caught between the

gripper and the pipe to be cut. Never begin

sawing if your ngers, or any other improperly

placed clothes or other tools, are between

the gripper and the pipe. Also remove any

possible sand and/or other debris from

under the gripper. Make sure that the saw

travels freely. If the saw is not moving proper-

ly, detach the saw from the pipe and check

the gripper’s wheels and ball bearings, (Picture

A7) cleaning and oiling them if necessary. If

the saw’s gripper unit has been damaged, the

machine cannot be used until it is repaired.

Piercing and sawing of pipe wall

Make sure that all persons working near

the pipe saw have the appropriate personal

protection equipment.

Firmly grip the saw’s operating handle

(Picture D1) with your right hand and hold

the gripper adjustment lock (Picture A4)

with your left hand.

Pierce the pipe’s wall by gently pushing

the pipe saw’s operating handle directly

downwards with an even pressure until

the blade has cut through the pipe’s wall

and the motor unit has locked in the

sawing position. You will feel the locking

when the locking pin (Picture A3) snaps

into the slot designed for it (Picture A6)

and moves slightly to the right.

Now that the pipe saw is locked in the

sawing position and you can safely begin

the pipe’s circular sawing. Never feed the

saw in the wrong direction.

Filling of oil tank

When the oil tank’s piston is visible in the

oil level sight glass, and the motor is not

running other than by pressing the Start

button, oil should be added to the oil tank.

The piston must always be pressed down-

wards when oil is being added.

Make sure that the pressure has been dis-

connected from the saw and that the intake

hose is detached. Unscrew the oil tank’s

cap. Use a clean tool such as a screwdriver

to press the oil tank’s piston into the down-

ward position. This pressing is done through

the hole in the oil cap. While pressing, make

sure that the threading inside the hole

remains undamaged. After pressing, the

piston will no longer be visible in the oil level

sight glass. The best way to ll the oil tank

is with a hypodermic syringe. The volume

of the tank is approximately 0.05 liters, or

about 3 cubic inches. After the lling, screw

the oil tank cap back in place. Any possible

oil spillage should be carefully wiped away.

NOTE! The level of the oil, for example at

the halfway mark, may be visible in the

tank’s oil level sight glass. This does not,

however, indicate the actual level of the oil.

The position of the piston, also visible in the

oil level sight glass, provides the only true

indication of the amount of oil in the tank.

When the piston has been pushed down it is

no longer visible in the oil level sight glass.

D1 D2

D3

D6

D4

D5

PICTURE D (Pipe cutting)

D1 Handle 1

D2 Handle 2

D3 Handle 3

D4 Handle 4

D5 Handle 5

D6 Handle 6

1. 2. 3. 4.

Release the motor unit to the upper posi-

tion by pulling the locking pin (Picture A3)

and press the STOP (Picture A2) button

immediately to turn off the motor. Always

avoid using the motor without loading.

Operational instructions Operational instructions

The feeding speed is selected according to

the pipe’s material and wall thickness. An

excessive feeding speed can damage the

blade, overload the pipe saw, and cause

a poor sawing result. Control the feeding

speed during the entire duration of the

cutting. Never completely let go of the saw

while cutting.

The pipe’s circumferential sawing

consists of four steps:

1. Begin the sawing by feeding the pipe

saw forward while gripping the handles

(Picture D1 and D2) until you have

sawed approximately one-fourth of

the pipe’s circumference.

2. Change your grip on the handles:

(Picture D4 and D5) now the pipe saw’s

own weight helps the feeding motion

and you can also slightly brake the

feeding speed.

3. When the pipe saw is under the pipe,

change the position of your grip on the

handles (Picture D2 and D3) and pull

the pipe saw forward and upwards until

you have sawed approximately three-

fourths of the pipe’s circumference.

4. Once again change the position of your

grip on the handles (D1 and D6) and

feed the pipe saw until the cutting is

completed.

16 17

english english

If problems, unusual noises, or excessive

vibrations occurring during the piercing or

sawing process require the sawing to be

interrupted before the pipe has been cut,

turn off the motor by pushing the STOP

button (Picture A2) and release the blade

by pulling the locking pin out (Picture A3).

When the problem that caused the interrup-

tion has been claried and xed, resume

sawing after checking that the saw or blade

has not been damaged. Never start the

motor when the motor unit is locked in its

sawing position or when the teeth of the

blade are in contact with the pipe to be sawn.

Underwater sawing

If the pipe to be cut is partially or completely

underwater, or it is possible that water coming

from within the pipe will raise the water level

at the cutting location so high that the saw

will remain submerged during the cutting

period, an additional hose should be used

in the air exhaust opening. The length of the

additional hose should enable it to reach

above the water surface during the entire

duration of the cutting. Connect the additional

hose by threading a ¾ inch thread to the

opening on the rear section of the pipe saw

(Picture A11). Make sure that the hose cannot

wave around uncontrollably, which could

cause a hazardous situation. If necessary,

use a safety wire to support the additional

hose, which should always be intact.

An exhaust pipe attached to the machine

can detrimentally affect sawing efciency,

particularly if the pipe is long or has a

small diameter. When carrying out under-

water sawing, the participation of at least

two workers is recommended. One worker

supervises the progress of the work, and

is close to the compressed air shutoff

valve in case a possible emergency shut-

down of the machine is necessary. The

other worker performs the actual sawing.

Use in cold conditions

WARNING: Use warm safety gloves when

handling the saw in cold conditions. Cold

metal may cause skin injuries.

In cold conditions, note the possible develop-

ment of brittleness in the material to be cut.

Check the blade screw’s tightness before

cutting by using the open-end wrench

(Picture B3) and hex socket key (Picture B2).

Check before use that there is no moisture or

ice inside the compressed air hose you are

using. Possible excess moisture and pieces

of ice may damage the hose, resulting in

personal injuries or damage to the materials.

Make sure that you use oil that suits the

operation of compressed air machines in

cold conditions. When the temperature falls

under –5°C (23°F), make sure that the

pour point of the machine’s lubrication oil

is lower than –25°C / –13°F.

Because moisture remaining in the pipe

saw’s motor, lubrication system, and other

channels may freeze, the pipe saw should

be stored and maintained in a warm

location. To remove any condensate water

that has entered with the compressed air,

a dry cutting should be made with the pipe

saw indoors and in dry conditions. The

stream of warm and dry compressed air fed

through the pipe saw’s motor, lubrication

system, and air vents will remove possible

moisture and reduce the risk of freezing.

Do not use solvent-borne de-icing uids

that could damage the lubrication system.

Storage

Store the pipe saw in a dry location shielded

from direct sunlight. Do not store the pipe

saw on weak structures or a wobbly shelf.

Make sure that the storage location can sup-

port the weight of the pipe saw. Protect the

pipe saw and its parts from possible dents.

Recommendation

Before connecting the Exact 360 AIR to the

compressed air hose, always run the com-

pressor until it reaches its operating tempera-

ture. When the compressor has reached its

operating temperature, blow compressed air

out of the hose to remove any possibly accu-

mulated water or debris. Connect the com-

pressed air hose to the machine only after

the hose has been cleaned.

Technical data

Technical data

While blowing air, be particularly careful

when handling the compressed air hose;

the end of a hose waving around

uncontrollably may injure the user.

• Exact PipeCut 360 AIR

• Minimum Pipe OD 60 mm (2 inch)

• Maximum Pipe OD 355 mm (14 inch)

• Weight 26.8 kg (59 lbs)

• Pressure max. 6.3 bar (90 PSI)

• Free air volume max. 3.9 m3/min

(140 cfm)

• Blade 180 mm or 165 mm (7” or 6.5”)

• Max no-load speed 4000 rpm

• Air intake and exhaust couplings ¾ NPT

inside thread

• Air quality requirement, 40 microns/m3

or better

• Operating temperature + 40°C – –20°C /

104°F – –4°F

NOTE! If the recommended pressure and

air quantity are not attained, the machine

can be used normally, but the machine’s

efciency and working speed will decrease

correspondingly. The machine is not recom-

mended for use in conditions where the

recommended pressure and air volume are

less than half of the recommended values.

Recommended motor lubrication oil

MOBIL DTE 24 ISO VG32 Temperature range

of this oil is +5°C up to +40°C (41°F up

to 104°F) If the temperature is lower than

+5°C (41°F) a thinner oil must be used.

The Exact 360 AIR machine cuts all

known pipe grades and with the following

blades:

• Diamond X 180 and X 165 Discs, for

cutting cast iron only.

• Exact ALU 180 and 165, aluminum and

all kinds of plastics.

• Exact Cermet 180 and 165, for cutting

steel and stainless steel.

Servicing, changing saw blades,

and the machine’s straightness

sawing adjustment

The motor’s interior parts should be

washed with cleaning uids, not blown

clean with air jets. Do not use strong

solvents.

Only professionally capable technicians

can test the Exact 360 AIR pipe saw.

The pipe saw cannot be tested or serviced

by persons who have not been trained

in the servicing of pneumatic tools. They

must be authorized to test these kinds

of tools and use pneumatic systems

according to national, state-specic, and

local regulations.

150/6 33.7/1.35 26.2/1.03

200/8 35.8/1.40 28.3/1.11

250/10 39.0/1.55 31.5/1.24

300/12 42.3/1.70 34.8/1.37

350/14 45.0/1.80 37.5/1.47

Cutting depths

Cutting depth mm/inch

blade 165 mm/6.5”

Pipe diameter

DN mm/inch

Cutting depth mm/inch

blade 180 mm/7”

Operational instructions

18 19

english english

WARNING

Never change the blade if the machine

is connected to a compressed air

source or you are not sure if the motor

has completely stopped.

Always use undamaged tools when changing

blades. Damaged tools will not necessarily

achieve the required tightness for the blade’s

attachment components, which may cause

loosening while sawing.

Do not use other manufacturers’ blades.

Do not use an unchecked blade.

Check the condition of the blade. Cutting

with a dull blade causes extra strain on

the machine and can lead to a signicantly

poorer sawing result. A dull or damaged blade

must be immediately replaced by a new or

sharpened blade. Sawing with a dull or

damaged blade can cause extra sparking,

detached saw teeth, and thus a hazardous

situation to persons and/or materials.

Never saw with a bent or damaged blade.

The tools used to change blades are

supplied with the machine. A blade can

also be changed with other correctly-sized

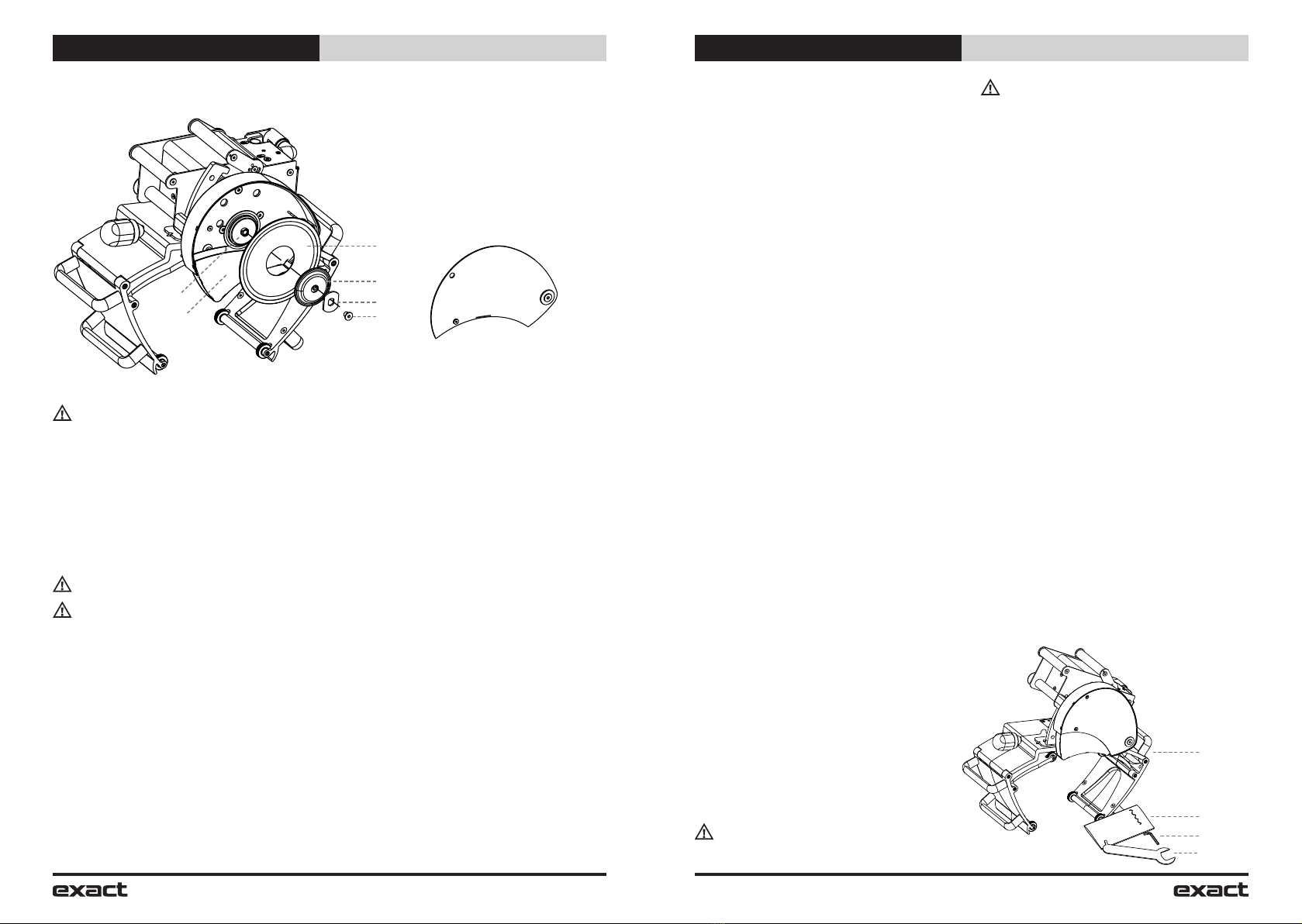

PICTURE C

Picture B

(overview and tools)

Changing blades

hex socket keys and open-end wrenches.

The Exact 360 AIR pipe saw’s blades can

be changed in job site conditions.

Open the blade guard (Picture C1) with the

hex socket key (Picture B2). After setting

the blade guard aside, open the blade

screw (Picture C2) with the hex socket key

and open-end wrench (Picture B3). Use

the open-end wrench as a counterforce

to prevent a turning motion by setting the

pulling ange washer securely in the place

designed for it, after which the blade screw

will open by turning the hex socket key.

Use force if the screw is tight. Remove the

pulling ange washer (Picture C3) and the

attachment ange (Picture C4), after which

you can set the blade (Picture C5) in place.

Make sure that the blade ange located

under the blade (Picture C6) is securely

in place and that there are no shavings,

debris, sand or other functionally detri-

mental materials between the blade ange

and the newly installed blade. Also check

that there are no shavings, debris, sand, or

other functionally detrimental materials in

the attachment ange, screws, or pulling

ange washer. If there is unwanted matter

in the blade or other parts, the parts must

be cleaned before their installation. When

the new blade has been securely placed

over the blade ange, set the attachment

ange carefully over the blade, then re-

attach the pulling ange washer and screw.

Tighten the screw with the open-end wrench

by using the pulling ange washer as a

counterforce.

Blade guard

Always clean the blade guard’s inside

surfaces (Picture C1), if you have sawed

plastic and are now sawing metal pipes.

The warming of the metal shavings and

blade from the sawing may cause the plastic

to melt or smolder, possibly releasing toxic

gases. Clean the blade guard regularly and

pay particular attention to the functioning

of the lower blade guard (Picture C7). The

lower blade guard should move freely, and

make sure that there is no debris, shavings,

or sand in its mechanism’s moving parts

that could impair its functioning.

Cleaning of gripper unit

Clean the gripper unit regularly with clean

compressed air. Lubricate the gripper’s

trapeze screw, transfer nuts, wheels, hinges

(Picture A14), and ball bearings with the

applicable oil. Check that there is no

debris, chips, or other materials that

could hinder its functioning in the gripper.

Straightness sawing adjustment

Open the adjustment screws (Picture A8) and

(Picture A9) turn the tool in the adjustment

pointer (Picture A10) as shown in the picture:

if you want that sawing to go more to the

left, turn the entire motor unit to the right.

Filling of oil tank

WARNING:

Use only the correct type of oil

specied for this purpose.

Keep debris, sand, or shavings from

passing into the oil tank. Unwanted

materials in the oil tank can damage

the lubrication system or the device’s

other precision mechanics.

Open the oil tank cap (Picture A13) by using

the hex socket key (Picture B2). Use appro-

priate effort to press the piston inside the

oil tank down by using a clean stick-like tool

such as a screwdriver. You will feel the

downward motion of the piston when it

clicks in place. Pour oil into the oil tank

using a suitable dosing feeder or funnel

to avoid spillage. When the oil tank is full,

screw the oil tank cap rmly in place. The

piston inside the oil tank will snap back to

its initial position when the motor is started.

Wintertime use

When the temperature falls under –5°C (23°F),

make sure that the pour point of the machine’s

lubrication oil is lower than –25°C / –13°F

Delivery content

- Exact 360 AIR

- Blade key/straightness sawing adjustment

key

- Operating Instructions

Note: Additional hose not included

C1 Blade guard

C2 Blade screw

C3 Pullingangewasher

C4 Attachmentange

C5 Blade

C6 Bladeange

C7 Lower blade guard

B1 Exact 360 AIR

B2 Hex socket key

B3 Open-end wrench

B4 Operating

instructions

C1

C2

C3

C4

C5

C6

C7

B3

B2

B1

B4

Operational instructions Technical data

Exact Tools Oy

Särkiniementie 5 B 64

00210 HELSINKI

FINLAND

Tel + 358 9 4366750

FAX + 358 9 43667550

www.exacttools.com

Table of contents

Other eXact Saw manuals

eXact

eXact PipeCut P400 User manual

eXact

eXact PipeCut 170 User manual

eXact

eXact PipeCut P400 User manual

eXact

eXact Pipecut 280 Pro Series User manual

eXact

eXact PipeCut V1000 User manual

eXact

eXact Pipecut 360 INOX Series User manual

eXact

eXact PipeCut 220E User manual

eXact

eXact PipeCut 220 Pro Series User manual

eXact

eXact Pro Series User manual

eXact

eXact PipeCut 280E System User manual

Popular Saw manuals by other brands

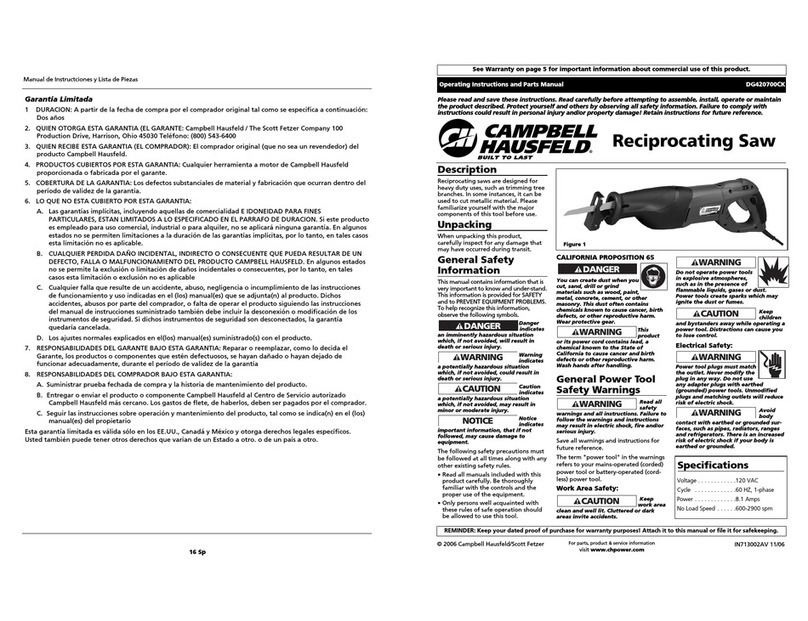

Campbell Hausfeld

Campbell Hausfeld DG420700CK Operating instructions and parts manual

Rockwell

Rockwell LithiumTech RK2516 Operation manual

Ryobi

Ryobi SC164VS Operator's manual

REMS

REMS Turbo K instruction manual

Elektra Beckum

Elektra Beckum BAS 316G DNB operating instructions

Makita

Makita LS1018LN instruction manual