Excel Tire Gauge SC05SS/VAC User manual

SC05SS/VAC

Manual

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 (401)384-6157

www.exceltiregauge.com

Air/Vac Combo

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

22

Table of Contents

IMPORTANT SAFETY INFORMATION � � � � � � � � � � � � � � � � � � � � 3

DIMENSIONS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

TECHNICAL SPECIFICATIONS � � � � � � � � � � � � � � � � � � � � � � � � � 6

SITE PREPARATION� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

INSTALLATION � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

COMPONENTS� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

ZW500D2 SPECIFICATIONS � � � � � � � � � � � � � � � � � � � � � � � � � � 19

HI FLOW TRUCK COMPRESSOR � � � � � � � � � � � � � � � � � � � � � � � 20

ELECTRONIC HEAD � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

OPERATING INSTRUCTIONS � � � � � � � � � � � � � � � � � � � � � � � � � 23

WIRING DIAGRAMS � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

TROUBLESHOOTING� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

WARRANTY � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

APPENDIX A - CREDIT CARD ONLY VACUUM � � � � � � � � � � � � � � 28

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 33

IMPORTANT SAFETY INFORMATION

1. Read all instructions.

2. Care must be taken as burns can occur from touching hot parts.

3. Do not operate equipment with a damaged cord or if equipment has been

dropped or damaged - utility must have been examined by a qualified service

person.

4. To reduce the risk of fire, do not operate equipment in the vicinity of open

containers of flammable liquids (gasoline).

5. Keep hair, loose clothing, fingers, and all parts of body away from moving parts.

6. To reduce risk of electric shock, disconnect power from machine before

servicing.

7. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

“SAVE THESE INSTRUCTIONS”

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

44

DIMENSIONS

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 55

Air/VAC

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

66

TECHNICAL SPECIFICATIONS

SC05SS

NO COMPRESSOR

SC05SS

ZW500D2-30/7Y(3)

SC05SS HIGH FLOW

TRUCK COMPRESSOR

Electrical

Requirement

110 VAC +/- 10% 110 VAC +/- 10% 110 VAC +/- 10%

Electrical

Frequency

60Hz 60Hz 60Hz

Electrical

Consumption

3 AMPS 13 AMPS 21 AMPS

Recommended

Circuit Breaker

20 A - Class C 20 A - Class C 30 Amp - Class C

Air Pressure

Default Setting

35 PSI 35 PSI 35 PSI

Air Calibration

Range

4 - 80 PSI 4 - 80 PSI 4 - 120 PSI

Average Air

Flow

Dependant on

connected air supply

3.4 - 2.5 CFM 5.3 - 4.2 CFM

Max Pressure

Output

80 PSI 80 PSI 120 PSI

Operational

Temp Range

*with Optional

Heater

-30 ° - 140 °F -30 ° - 140 °F -30 ° - 140 °F

Air Relative

Humidity w/o

Condensation

0 - 95% 0 - 95% 0 - 95 %

Weight 90 lbs 110 lbs 125 lbs

THE MOST COMMON APPLICATION OF THIS UNIT IS TO CALIBRATE TIRES

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 77

SITE PREPARATION

**IMPORTANT NOTES**

- DO NOT install this equipment where its use cannot be observed and/or

supervised. Unobserved equipment invites vandalism and theft.

- If installing on a raised curb/walkway, Excel Tire Gauge, LLC, recommends that the

curb/walkway cannot be more that 6 inches in height and the unit must be

installed no more than 10 inches away from the curb/walkway in order to meet

ADA compliance.

- The Excel equipment must be installed to meet all federal and local regulations,

inclusive of electrical, zoning, and applicable ADA standards.

Excel Tire Gauge, LLC. recommends units to be mounted on a 30” X 30” X 6” concrete

pad constructed to not create a trip hazard and in compliance with ADA standards.

Utility Requirements:

Refer to electrical specification information on specific machine

installation requirements.

Water Option:

- Water line for water service units equipped with ¼” FPT connection

- Use city water line pressure only

- Install a ¼” Ball valve prior to connecting water line to the machine water line

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

88

UNPACKING

Immediately inspect your unit for concealed loss or damage, which occurred in

transit. If any such condition is found contact the carrier’s agent and file a claim

immediately. There is a specific time limit for requesting a claim.

Excel strongly recommends that you save the original factory packaging. For some

models warranty service requires that you return the unit to the factory via UPS. Factory

packaging should prevent damage in shipment. If you require new packaging contact

the factory.

INSTALLATION CHECK LIST:

1. Prepare site in accordance with Site Preparation

2. Install proper electrical service a per the National Electrical & Local Codes

3. Run supply line (water) if needed

4. Mount unit

5. Connect electricity and/or water

6. Check operation. Pre-set pressure and connect hose chuck to the tire

**Warning**

This equipment incorporates parts such as switches, motors, or the like that tend to

produce arcs or sparks that can cause an explosion. When located in gasoline-dispensing

and service stations, install and use at least 20 feet (6m) horizontally from the exterior

enclosure of any dispensing pump and at least 18 inches (450mm) above a driveway or

ground level.

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 99

ELECTRICAL CONNECTIONS & GROUNDING

This product should be connected to a grounded, metallic, permanent wiring

system or an equipment grounding terminal lead on the product. Each air tower should

have a dedicated GFCI protected branch circuit as below. Improperly sized circuits risk

compressor damage.

SC05SS 1 HP requires a GFCI protected 110 volt 20 amp dedicated circuit at the

installation location.

SC05SS HIGH OUTPUT (Truck unit) requires a GFCI protected 110 volt 30 amp

dedicated circuit at the installation location. Consult the National Electrical Code and

local autorities having jurisdiction for appropriate guidance.

1. Open lower side panel by removing all screws

(Tamper proof T27 bit required)

2. Ensure the air tower is plumb and level

3. Bolt unit to the concrete base

4. Two 7/8” knockouts are provided in the rear of unit to accept 1/2” electrical

fittings

5. Connect the power wires

a. Connect Phase (hot/black wire) to phase on power source

b. Connect Neutral (white wire) to neutral on power source

c. Connect ground wire (green wire) to ground on power source

6. Turn breaker inside the store on

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

1010

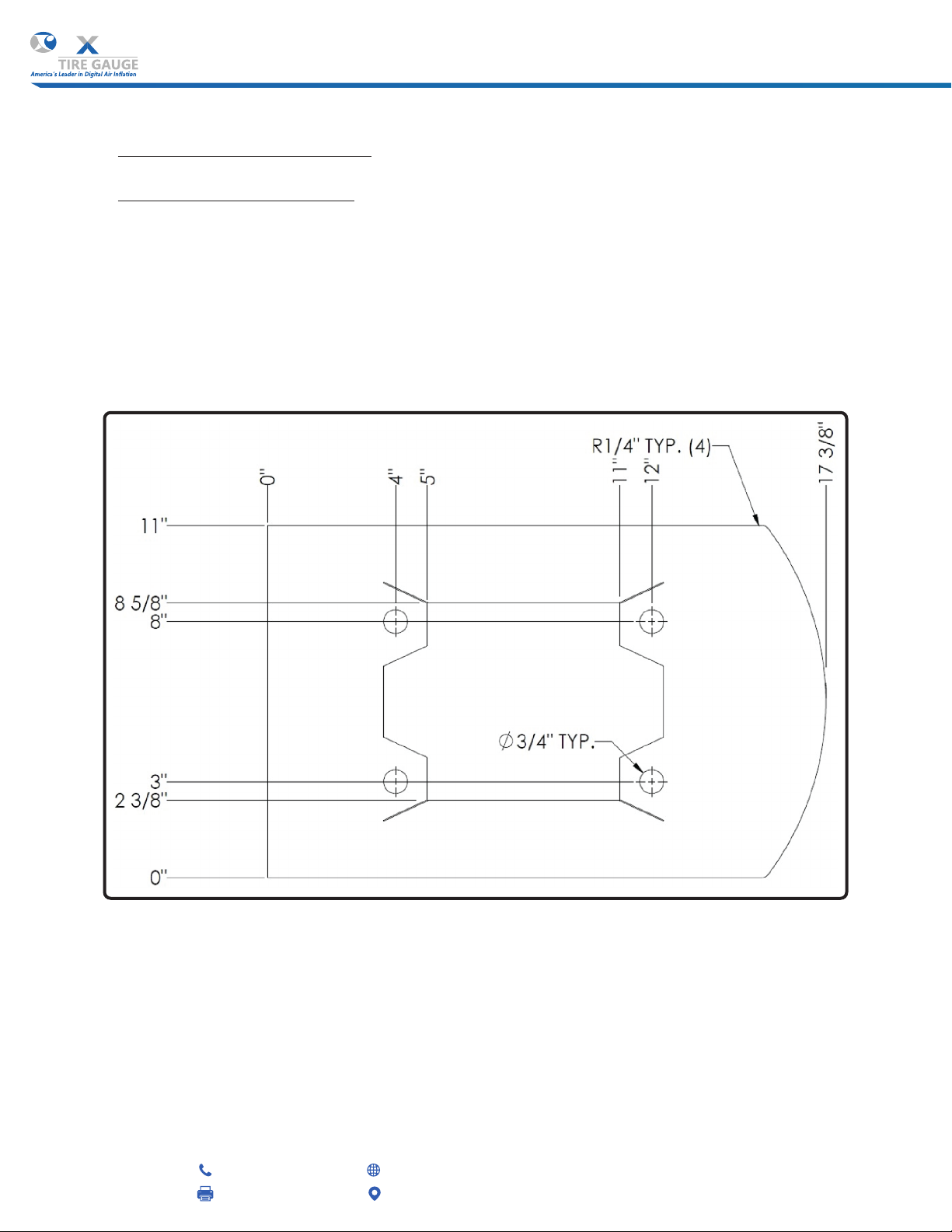

BASE PLATE DIMENSIONS

SECURING THE CABINET

The construction of a concrete base is recommended whenever possible.

The following schematic drawing shows the correct position of the bolt

holes and the distance between them.

Water Option: Water ball valve must be installed. Use 1/4” water pipe/tubing.

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 1111

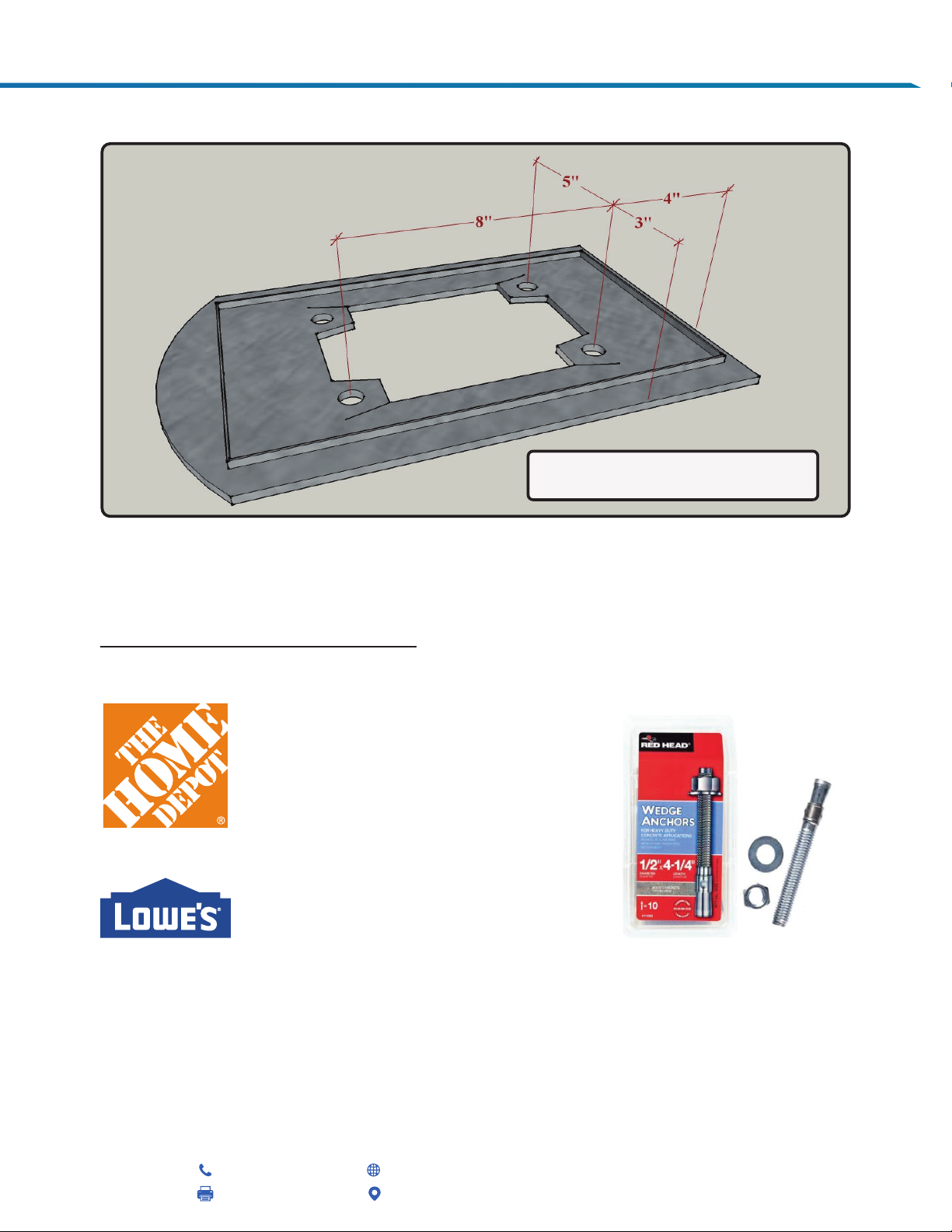

PREFERRED ANCHORS:

1/2” WEDGE ANCHOR BOLTS

SC05SS

BASE PLATE

RECOMMENDED ANCHORS:

Red Head Model # 11020

Internet # 100151116

Store Sku # 703131

1/2 in. x 4-1/4 in. Steel Hex-Nut-Head

Concrete Wedge Anchors (10-Pack)

Red Head Model # 11020

10-Pack 1/2 in. x 4-1/4 in.

Wedge Anchors

Item # 55603

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

1212

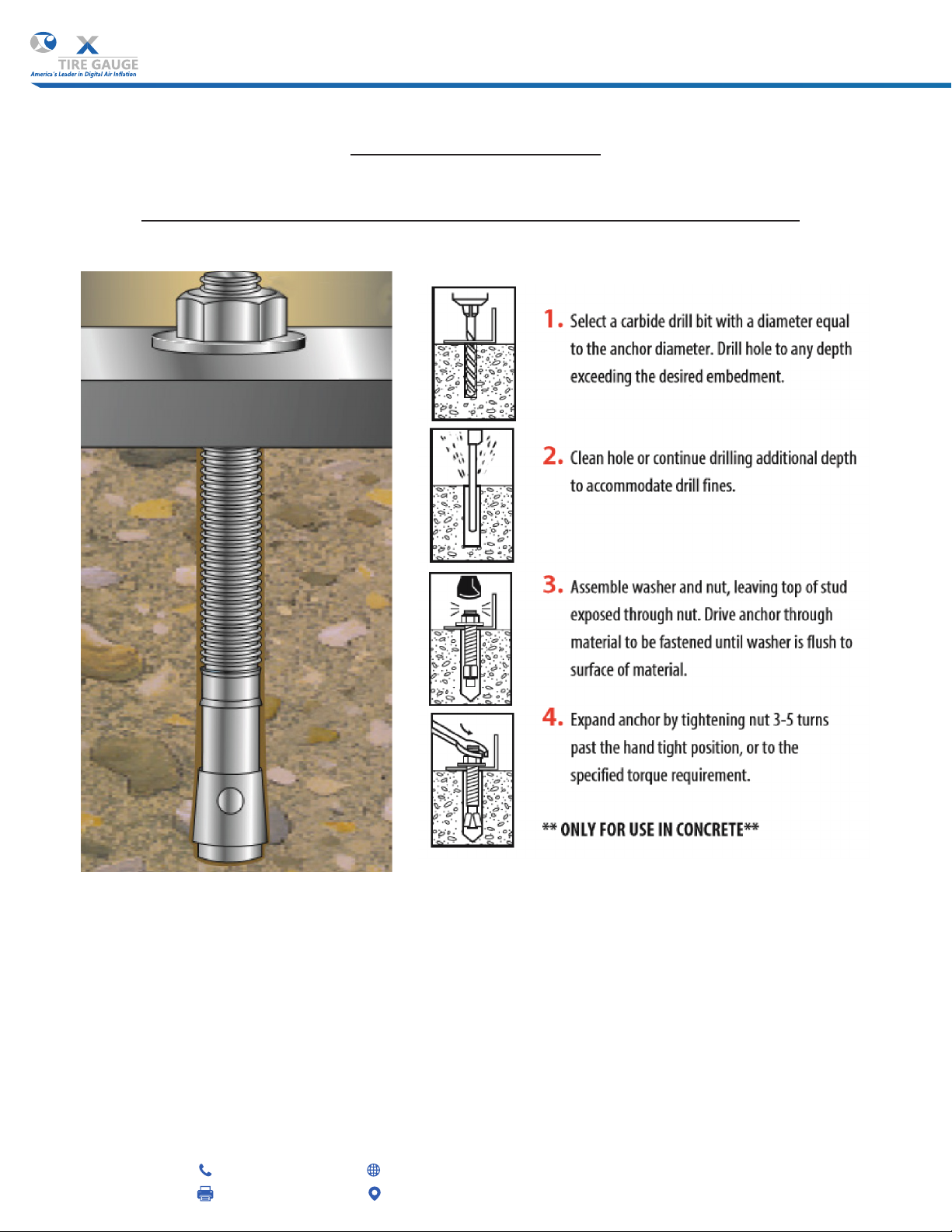

INSTALLATION

WEDGE ANCHOR INSTALLATION INSTRUCTIONS

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 1313

TYPICAL INSTALLATION

Remove lower side access panel with a T27 Tamperproof security bit. If unit is

equipped with a vault, remove coin box and vault base plate to expose the two front

3/4” mounting holes.

Place unit of template in its intended location. Mark the locations of the four 3/4”

mounting holes onto the concrete base. Drill four 1/2” Diameter holes with a hammer

drill and masonary bit in the marked locations to accept the wedge anchors bolts.

Shimming in between the concrete base and the base plate with 1/2” fender washers

may by necessary to plumb and level the air machine if the concrete base is not level.

Install wedge anchors bolts, place the air machine onto the bolts, and secure the air

machine to the concrete base.

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

1414

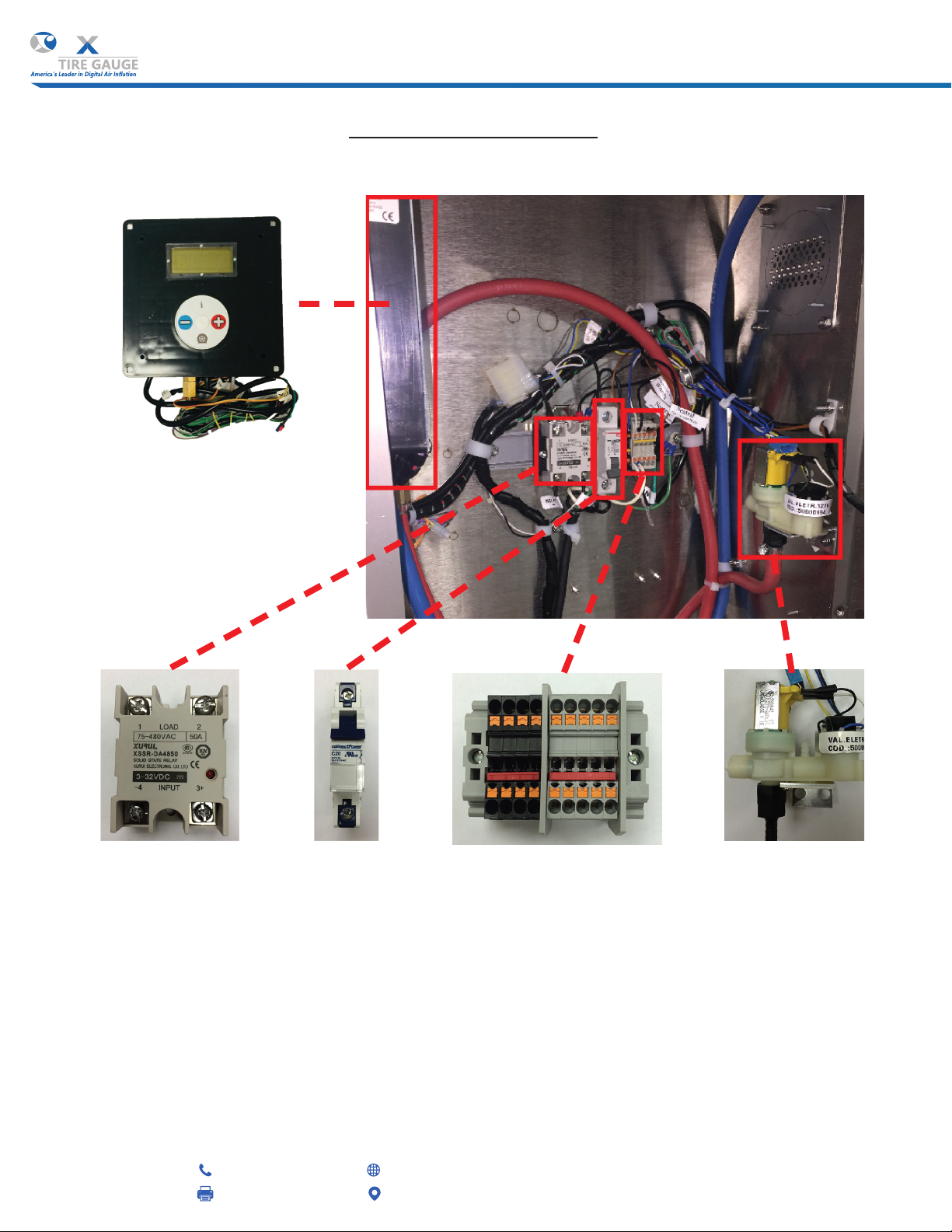

COMPONENTS

50000372

Digital Control Gauge

SR50

Solid State Relay

I20A

20amp

BREAKER

1 HP unit

I32A

32amp

BREAKER

HO unit

(Truck)

IASSET

Quick Connect

Terminal Block Set

P100

Electronic

Relief Valve

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 1515

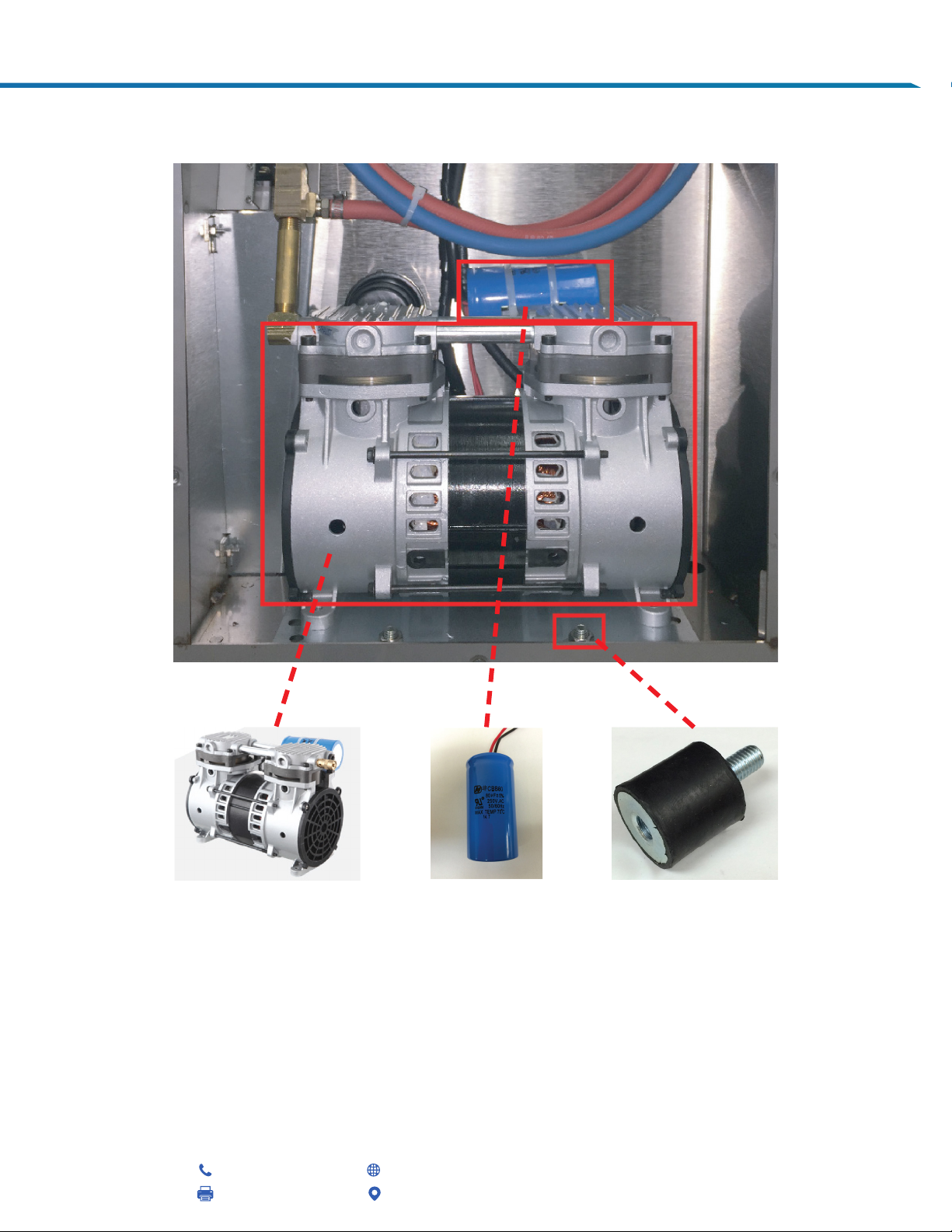

02-90515

GSE Compressor

29050900

Excel Compressor

Start Capacitor

3CC12

Compressor

Isolation Mount

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

1616

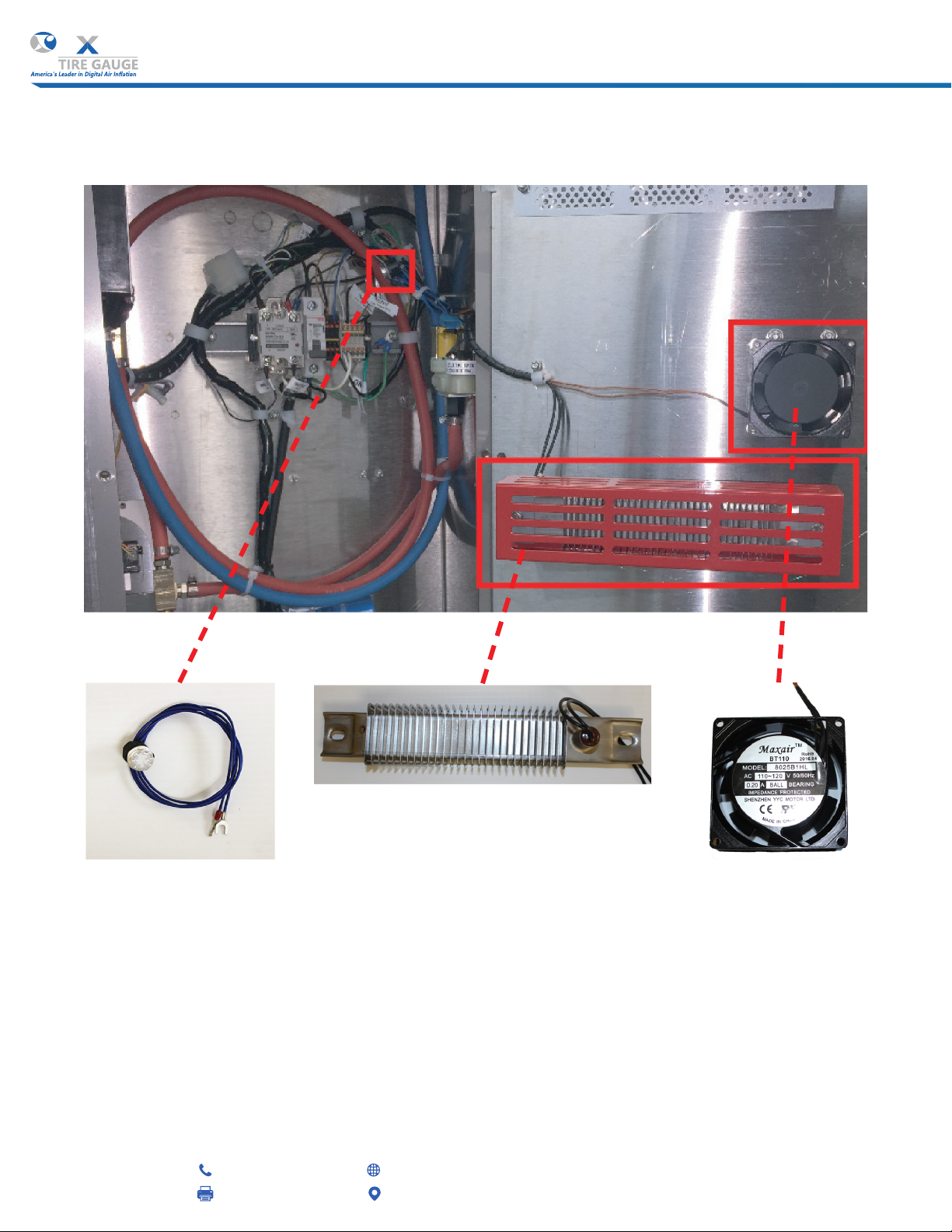

400152

Heater

Thermostat

SCXFAN

Heater

Fan

OSF 1310

Heater

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 1717

EXHAUST FAN OPTION

UF80A12-BWHR

Exhaust Fan

6UED4

Fan Switch

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

1818

VAL6336

Excel Vac Motor

VAC10HOSE156

15 FT Vacuum Hose

VAC10CLAW

Vac Claw

with Adapter

VAC FILTER KIT

Cloth Filter, Sping

and Mold Housing

E cel

SC05SS/Vac Manual

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157 1919

ZW500D2 SPECIFICATIONS

High Flow Compressor

Open Flow 4.4 CFM (125 LPM)

Max. Pressure 100 PSI (7 bar)

Input Power/Current <600 W / <5.4A

Voltage/Frequency 115V / 60 HZ

Sound Level 68< dbA (@ 1met)

Termal Protection 257<5% °F / (125<5% °C)

Restart Pressure 100 PSI (7 bar)

Insulation Class B

Net Weight 16.5 Ib (7.5 kg)

~

~

~~

~

E cel

215 Jefferson Blvd, Warwick, RI 02888

(401) 732-8420 www.exceltiregauge.com

(401) 384-6157

2020

HI FLOW TRUCK COMPRESSOR

SPECIFICATION

6.40 CFM @ 40 PSI

5.30 CFM @ 90 PSI

- Ultra Quiet & Oil-Free Air Compressor Pump/Motor is designed to be one of the quietest

in the industry having only 70 decibels of sound.

- The Ultra Quiet Air Compressor Motors have been designed to increase duty cycle and

allow for longer continuous run times.

- These motors are engineered to dissipate the heat better which allows for a cooler

operation reducing wear and increasing life before service.

- The motor has a new valve plate design made with Swedish reed valves which improves

air flow, reduces wear and decrease the sound level.

- The powerful 2.0 HP motor operates at only 1680 RPM creating less noise and less wear.

- The Oil-Free Dual Piston Pump System is engineered for high performance and

durability.

Features:

* Ultra Quiet - Only 70 decibels

* Oil-Free Pump – Cleaner air for better tool operation

Less maintenance and Costs

* Thermal Overload Protector

* 150 PSI Maximum Pressure

* 110v / 60 hz

* Low Amp Draw - 15 Amps

* 40 pounds

* L (12.4”) x W (6.1”) x H (11.7”)

* Comes complete with - Capacitor, Air Filter and (4) Shock Struts

* ETL

* 1 Year Limited Warranty

The pump/motor has a Oil-Free Dual Piston pump designed to have a life cycle of 3000

plus hours before repair

Table of contents

Popular Air Compressor manuals by other brands

Schulz

Schulz MSI 8,5/25 AIR PRO Cleaning & maintenance tips

Sears

Sears 919.72512 owner's manual

hecht

hecht 2360 TRANSLATION OF ORIGINAL INSTRUCTIONS FOR USE

Craftsman

Craftsman 919.727121 owner's manual

DV Systems

DV Systems HDI Installation maintenance and service manual

BOCK

BOCK HA44e Assembly instructions

Stanley

Stanley HY 227/8/6E Instruction manual for owner's use

mycom

mycom 4032**C Series instruction manual

Atlas Copco

Atlas Copco XAHS 70 KD8 WUX instruction manual

Clarke

Clarke SHHH 2 Operating & maintenance instructions

Stealth

Stealth SAQ-1234 Operator's manual

Ingersoll-Rand

Ingersoll-Rand EP 20 SE Operators/Instruction Manual Options