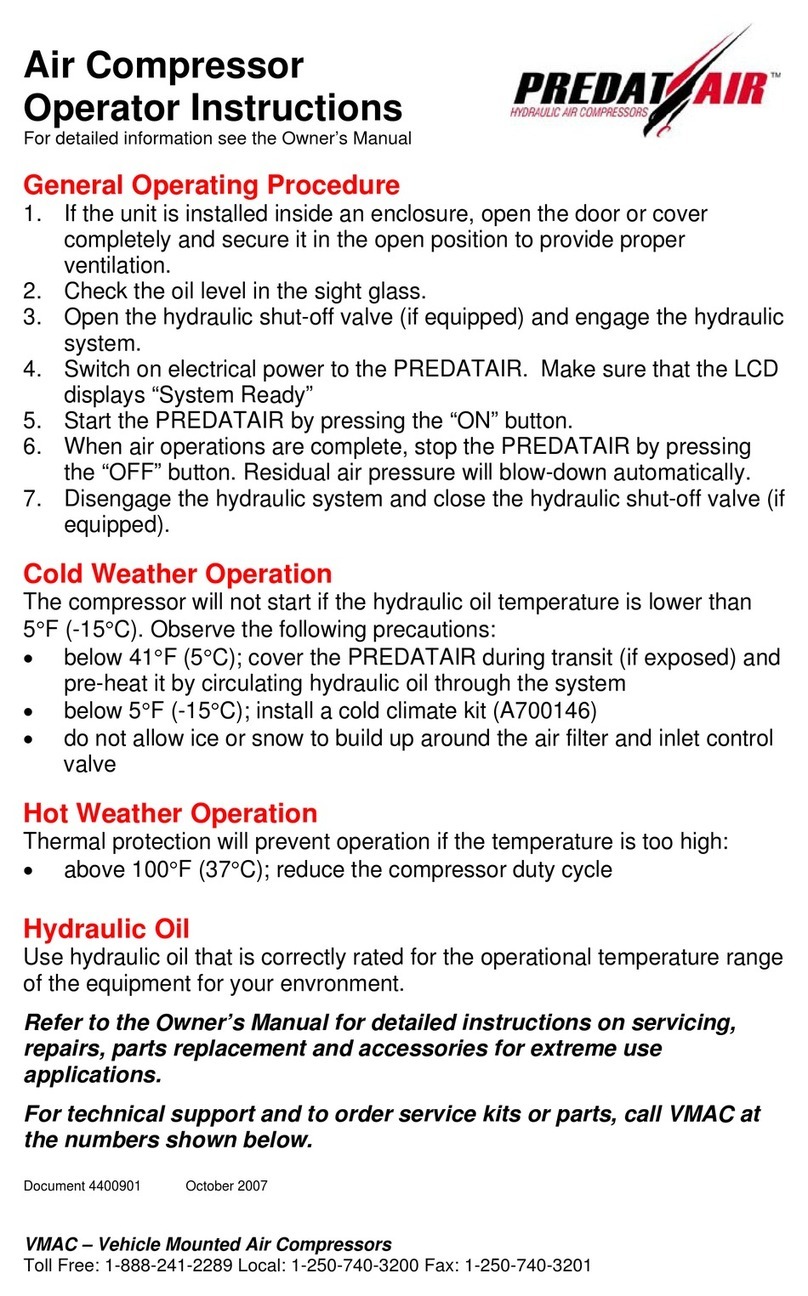

Vmac PREDATAIR60 User manual

Table of contents

Other Vmac Air Compressor manuals

Vmac

Vmac AIR INNOVATED H600009 Installation instructions

Vmac

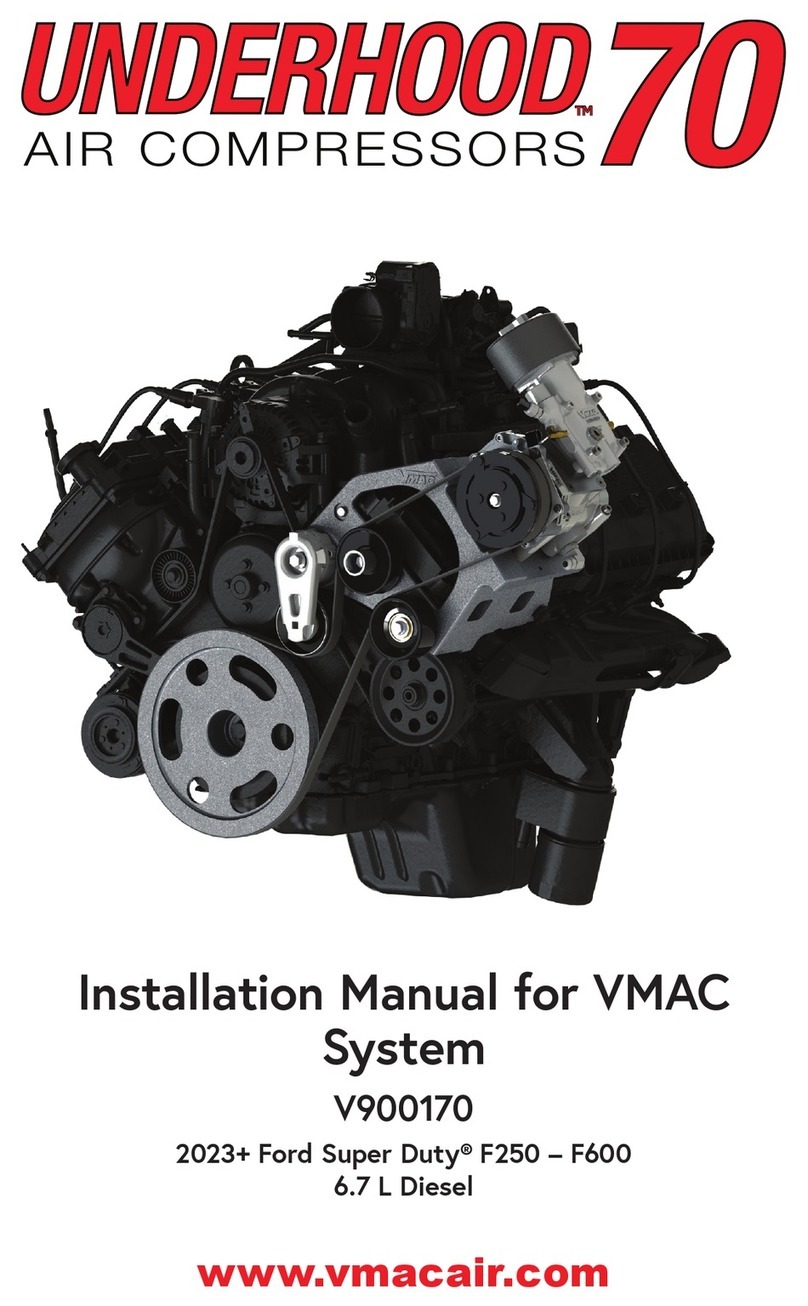

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac G300003 User manual

Vmac

Vmac DM00021 User manual

Vmac

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac V400011 User manual

Vmac

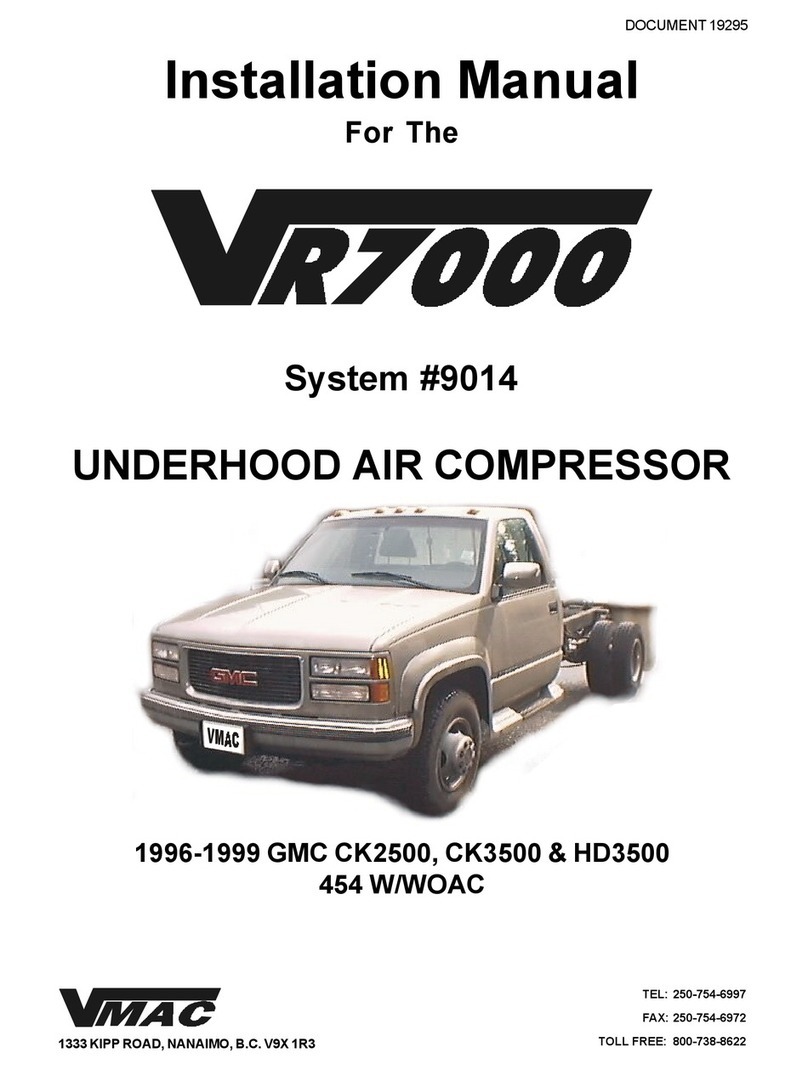

Vmac VR7000 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac G300004 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac PredatAir Series Specifications

Vmac

Vmac DM00030 User manual

Vmac

Vmac PREDATAIR Installation instructions

Vmac

Vmac RAPTAIR60 Manual

Vmac

Vmac H400016 Installation instructions

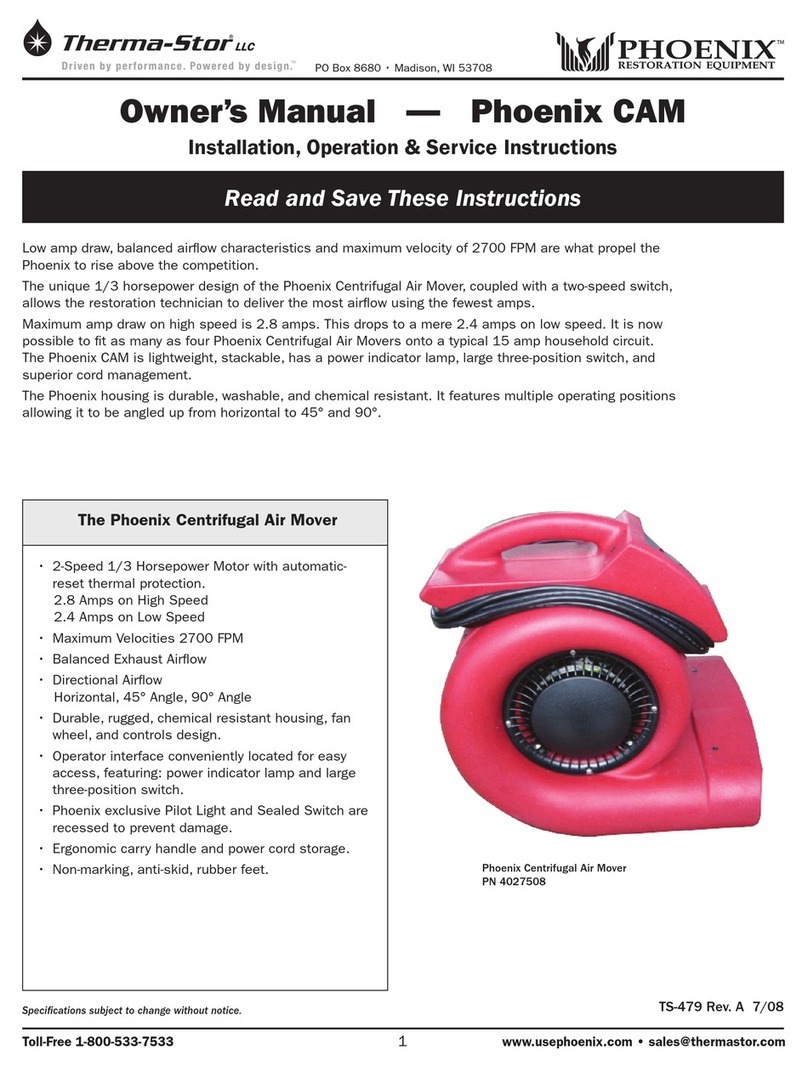

Popular Air Compressor manuals by other brands

Gardner Denver

Gardner Denver ELECTRA-SCREW 60 HP Service manual

Invacare

Invacare Envoy Jr. IRC1001 owner's manual

Danfoss

Danfoss VLZ065 Application guidelines

California Air Tools

California Air Tools 20040DCAD owner's manual

Clarke

Clarke RAIDER 15/550 Operation & maintenance instructions

MSW

MSW MSW-HCSC-01 user manual