Excell P-120S User manual

1

IP68 Waterproof Indicator

P-120S

User Manual

© Excell Precision Limited. All rights reserved worldwide.

The information contained herein is the property of Excell Precision Limited and is supplied

without liability for errors or omissions. No part may be reproduced or used except as

authorised by contract or other written permission. The copyright and the foregoing restriction

on reproduction and use extend to all media in which the information may be embodied.

V23. 1003

EXCELL PRECISION CO., LTD

1

ZSME400000014

04011XXX

Table of Contents

Special Notice..............................................................................................................................3

Safety...........................................................................................................................................3

Features.......................................................................................................................................4

CHAPTER 1 FRONTAND REAR PANEL SPECIFICATIONS .....................................................5

1-1 Front panel......................................................................................................................5

1-2 Keyboard description......................................................................................................5

1-3 Assembly diagram ..........................................................................................................6

1-4 A/D Conversion...............................................................................................................7

1-5 Power supply..................................................................................................................7

1-6 Indicator appearance......................................................................................................7

1-7 Circuit board description.................................................................................................8

CHAPTER 2 GENERAL FUNCTION GUIDE...............................................................................9

2-1 Function setup and operation procedures ......................................................................9

2-2 Function setting ..................................................................................12

CHAPTER 3 CALIBRATION ......................................................................................................15

3-1 Load cell connection.....................................................................................................15

3-2 Parameter setting and calibration flow chart.................................................................16

3-3 MODBUS calibration ..........................................................................18

3-4 Specification calibration ......................................................................19

3-5 General Calibration ............................................................................21

3-6 Linearity calibration ............................................................................22

3-7 Digital calibration

...........................................................................24

3-8 Calibration Error Messages..........................................................................................25

CHAPTER 4 WEIGHT COMPARISON PROCEDURES ............................................................26

4-1 Function configuration menu ........................................................................................26

4-2 Check weighing configuration.......................................................................................29

4-3 Batching signal outputs.................................................................................................32

4-4 Normal batching flow chart (SQ-01=1)..........................................................................33

4-5 Loss-in Weight flow chart ( SQ-01 = 2 )........................................................................34

4-6 Hi, OK, Lo output flow chart..........................................................................................35

4-7 Normal batching (built-in program) flow chart (SQ-01=4) .............................................36

4-8 Loss-in Weight (built in program) (SQ-01=5)................................................................37

4-9 Hold mode (SQ-01 = 6).................................................................................................38

4-9-1 Hold mode flow chart..........................................................................................39

4-9-2 Hi, OK, Lo comparison .......................................................................................40

4-10 Totalizing (ACCU.) Auto / Transmit .............................................................................40

CHAPTER 5 INTERFACE..........................................................................................................41

5-1 Serial input/output interface (OP-01) ............................................................................41

5-2 Analogue Current / Voltage Output Interface (OP-03)...................................................50

5-3 External parallel input / output interface (OP-04, OP-05)..............................................53

CHAPTER 6 MAINTENANCE....................................................................................................58

6-1 Restore all parameters to their default factory values...................................................58

6-2 Maintenance function parameters.................................................................................58

6-2-1 Restore the function parameter back to its default value....................................59

6-2-2 Clear zero compensation and TARE values.......................................................59

6-2-3 Clear batch setting .............................................................................................59

6-2-4 Display zero voltage (mV/V)...............................................................................59

EXCELL PRECISION CO., LTD

2

ZSME400000014

04011XXX

6-2-5 Clear batch setting .............................................................................................60

6-3 Test mode.....................................................................................................................61

6-3-1 7 segment display testing...................................................................................62

6-3-2 Keypad and calibration SW testing.....................................................................62

6-3-3 Display A/D internal value display ......................................................................62

6-3-4 RS-232 serial loop back testing..........................................................................62

6-3-5 EEPROM memory testing ..................................................................................62

6-3-6 Option interface card testing...............................................................................62

Appendix 1: Description of 7 segment characters......................................................................64

Appendix 2: Function Table........................................................................................................65

Appendix 3: MODBUS DataAddress Table I .............................................................................75

Appendix 4: MODBUS Data Address Table II ............................................................................76

Appendix 5: Examples for Input and Output of Modbus.............................................................77

Check Firmware Version

During power-on countdown, press

F1

key to display firmware

version 04011XXX, where XXX is maintenance number.

EXCELL PRECISION CO., LTD

3

ZSME400000014

04011XXX

!

Special Notice

The indicator is IP68 waterproof design. Only the cables with ψ4~ψ7mm calibre could

be used or will affect the waterproof design. In some certain conditions, the stainless case of

indicator would be opened to set up the load cell, to connect the power cable, or to change the

new rechargeable battery. Before open the stainless case, please make sure the indicator is dry,

if necessary the liquid should be wiped off. The assembling notice should be accurately followed

to assure the waterproof performance. We also strongly suggest that these procedures should

be operated by the technical staff of your supplier.

ASSEMBLING NOTICE:

After the desired steps are done, screw the case with 12 kgf-cm in the following orders.

Do not screw tightly before all screws are in the positions.

Screwing orders:

Safety

When the instrument is installed, connect an earth bonding conductor from FG to the earth

connection marked “ ”.

Disconnect the mains power supply before opening the instrument housing. NOTE: There

are no user serviceable parts inside.

To install the optional interface cards, it is necessary to disconnect the mains power supply

and fit a yellow/green earth bonding cable to the rear panel.

Before turning the power on ensure the supply voltage is within the acceptable range,

AC100V ~ AC240V.

The operating ambient temperature range is -10oC ~ +40oC.

(+14°F ~ +104°F)

The indicator is IP68 waterproof design. Only the cables with ψ4~ψ7mm calibre could

be used or will affect the waterproof design.

1st

2nd

3rd

4th

5th

6th

EXCELL PRECISION CO., LTD

4

ZSME400000014

04011XXX

Features

P-120S is an IP68 waterproof weighing indicator and has a wide range of applications from

batching to simple weighing.

Features:

Sturdy and durable stainless steel waterproof and dustproof IP68 design

Stainless steel IP 68 Waterproof design

The stainless steel body can be easily mounted on the control panel.

High performance A/D interface

016 VD sensitivity

Maximum sampling speed of 120 times/second

Measurement range -0.1~ 4.0 mV/V

Flexible Calibration Method

Regular 2-points weight calibration

5-points linear calibration

Key in the signal voltage value (mV/V) directly via the keyboard, no need to apply any

weight to the bottomwork to calibrate the weigher.

Display load cell output voltage (mV/V) for future maintenance

Adjustable digital filter

Can effectively suppress vibrations generated by the on-site environment

Six weight comparison modes cover most application situations

Stand alone batching mode or connect to PLC for external system control

Built in batching / dosing functions

Manual / automatic discharge operation

Set cycle times in a batch

Totalise weight and number of cycles

RS232C bi-directional and current loop one way serial interface

Built in MODBUS

The body is made of stainless steel and can be easily mounted on the control panel.

Interface options:

OP-01 RS422/485/232 serial interface

OP-03 16 Bit Analogue current/voltage output interface (4 ~ 20 mA/ 0 ~ 10V)

OP-04 Control I/O (4In / 4Out) + Setpoint In (BCD code)

OP-05 Control I/O (8In / 8Out)

EXCELL PRECISION CO., LTD

5

ZSME400000014

04011XXX

F2FF1

Tare

Zero G/N

P-120S

CHAPTER 1 FRONT AND REAR PANEL

SPECIFICATIONS

1-1 Front panel

Display

6 digits, bright red, 7 segment LED display, character height 16mm (0.63”).

Display can be switched between Gross Weight / Net Weight / Totalised Weight /

Number of transactions in the total.

Indication icons “◄”

ZERO

◄

:

Zero Indication

MD

◄

:

Unstable weight Indication

GROSS

◄

:

Gross weight Indication

NET

◄

:

Net weight Indication

The indicator is supplied with suitable labels to customise the icon displays. Refer to

FNC. 07 ~ FNC.10 to set up S1 ~ S4 indication depending the need.

Weighing Units

Weighing Units kg / g / t / lb.

1-2 Keyboard description

:

When entering data or reference setting, it means “ESC”.

In the normal operation, it puts the indicator in standby mode or escape. Entering

standby mode: All of the display (except ZERO “” symbol) and serial data output

are disabled.

Escape from standby mode: Re-power on mains for normal operation.

:

In the normal mode, it performs as Zero operation.

:

When parameter setting, it increments the flashing digit or steps up the select item.

In the normal mode, it performs a Gross/Net switch operation.

:

In the normal mode, it performs as Tare operation.

:

When parameter setting, it move flashing to right.

In the normal mode, it accesses the FNC-06 setting.

Tare

F2

Zero

G/N

EXCELL PRECISION CO., LTD

6

ZSME400000014

04011XXX

:

When parameter setting, it decrements the flashing digit or steps down the select

item.

In the normal mode, it accesses the FNC-05 setting.

:

When parameter setting, it move flashing to left.

In the normal mode, it accesses the FNC-04 setting.

:

Confirm / enter key

Function FNC-03 can be used to selectively disable individual keys.

Zero operation, will be limited by functions CSP-05 and CSP-10.

Zero operation, will be limited by functions CSP-10 and CSP-11.

1-3 Assembly diagram

正面

背面

OP-01

OP-03

OP-05

OP-04

Back

Front

F1

F

EXCELL PRECISION CO., LTD

7

ZSME400000014

04011XXX

1-4 A/D Conversion

* Input Sensitivity

* Internal Resolution

* Max. Sampling Speed

* Application Range

* Load Cell Excitation Voltage

: Minimum of 0.16 uV/D

: 1 / 1,000,000

: 120 times/sec.

: - 0.1 mV/V ~ 4.0 mV/V

: 5 VDC ±5%, 120mA

(Up to eight (8) 350 Ω load cells can be connected)

1-5 Power supply

AC 100V ~ 240V 50/60Hz

Power consumption is about 10VA

1-6 Indicator appearance

Front view

Back view

Side view

Top view

EXCELL PRECISION CO., LTD

8

ZSME400000014

04011XXX

1-7 Circuit board description

N

L

Frame Ground

CN2

J4

J2 J5 J1 J3

CN1

SW1

CN2

CN3

CN8

3

2

1

3

2

1

SHLD

EXC-

EXC+

SEN+

SEN-

SIG+

SIG-

CN1 Connect to one of

OP-03-CN2, OP-04-CN3,

OP-05-CN3

J4 4Wire/2Wire

short pin 1, 2 → 4 Wire

short pin 2, 3 → 2 Wire

J2, J5, J1, J3 RS422/RS232

short pin 1, 2 → RS422

short pin 2, 3 → RS232

SW1 Calibration Switch

ON: Calibration Mode

OFF: Weighing Mode

SDA

SDB/TxD

RDA/RxD

RDB

GND

TRM

C-LOOP1

C-LOOP2

EXCELL PRECISION CO., LTD

9

ZSME400000014

04011XXX

CHAPTER 2 GENERAL FUNCTION GUIDE

2-1 Function setup and operation procedures

Function

Operation

Display

Description

Enter calibration mode

Turn the calibration switch to “ON”

See 3-2 for details

Enter function setting

Press not release,

then press key

after the power is turned on

See 2-2 for details

Reset all parameters

back to default

Turn the power on then turn the

calibration switch to “ON” then

press and hold the

and keys

during the self-testing sequence

.

See 6-1 for details

Reset general function

parameters back to

default

Turn the power on and

Press and keys

during self-testing sequence

See 6-2-1 for details

Clear zero point

compensation and tare

value

Turn the power on and

press and keys

during self-testing sequence, and

then press

See 6-2-2 for details

Clear setpoint parameter

setting

Turn the power on and

press and keys

during self-testing sequence, and

then press two times

See 6-2-3 for details

Value of zero point

voltage(mV/V)

Turn the power on and

Press and , then

press three times.

See 6-2-4 for details

Value of Span voltage

(mV/V)

Turn the power on and

Press and , then

Press

See 6-2-5 for details

Entering to test mode

Turn the power on and

press and keys

during self-testing sequence

.

See 6-3 for details

F

F

F

F

G/N

F

G/N

G/N

F

F

F1

EXCELL PRECISION CO., LTD

10

ZSME400000014

04011XXX

Function

Operation

Display

Description

Check weighing setpoint

parameter setting

Press the key to set

the parameter of FUNC.4 to 1 in

the normal mode

.

or

.

See 4-2 for details

Key actions in function set up mode

Increases the number of the flashing digit

Decreases the number of the flashing digit

Moves the flashing digit one space to the left

Moves the flashing digit one space to the right

Saves the configuration

Quits set up mode / Escape

F

F2

F

G/N

F1

EXCELL PRECISION CO., LTD

11

ZSME400000014

04011XXX

Function Setting

First Serial Port Interface

Second Serial Port

Interface

BCD Parallel Port output

interface

Analogue current / voltage

output interface

External parallel control

input interface

External parallel trip output

interface

Function Setting Procedures

With weight displayed press and hold the key. Then, press

See 5-1 for details

See 5-2 for details

See 5-3 for details

See 5-1 for details

See Function Setting 2-2

for details

See Chapter 4 for details

See 5-4 for details

See 5-4 for details

Set Point Procedure

F1

F1

F1

F1

F1

F1

F1

F1

G/N

G/N

G/N

G/N

G/N

G/N

G/N

G/N

F

EXCELL PRECISION CO., LTD

12

ZSME400000014

04011XXX

2-2 Function setting

Press

Input desired

Parameter code

Press

Display shows the

previous parameter

code. Input the new

code as required

press

To continue the next function setting

or press to escape

Increment flashing

digit

Decrement flashing

digit

Move flashing point

left.

Move flashing point

right

Store data in

memory

Exit / Escape

*Function Parameter code

Digital Filter I

Digital Filter II

Lock keypad function

“F” function setting

“F1” function setting

“F2”function setting

Front panel indication “S1” setting status

Front panel indication “S2” setting status

Front panel indication “S3” setting status

Front panel indication “S4” setting status

Terms of back to zero

Hold

Display the rate of refreshment

G/N

F1

F

F2

EXCELL PRECISION CO., LTD

13

ZSME400000014

04011XXX

FNC Group function setting

Item

Function

Setting value

Default

Parameter

Description

FNC-01

Digital Filter I

0

5 Hz

4

1

4.17 Hz

2

2.5 Hz

3

2.08 Hz

4

1.25 Hz

5

1.04 Hz

6

0.63 Hz

7

0.52 Hz

8

0.31 Hz

9

0.26 Hz

FNC-02

Digital Filter II

0

Disabled

2

1

Less filter

Greater

2

3

4

5

FNC-03

Key –Locked

000000

111111

0

Normal

(lock disable)

0 0 0 0 0 0

Tare G/N Zero F2 F1 F

000000

1

Close

(lock enable)

FNC-04

“F” function setting

Parameter Description

0 Setpoint parameter setting

1 Tare reset

2Manually output of serial, parallel print

3Start load

4Stop load

5Start comparison

6Unload command

7Totalise weight and counts command

8Clear totalised weight and counts

9Hold mode

10 Escape Hold mode(I/O DSP)

11 Convert to Gross / Net / totalised weight /

totalised Count

0

FNC-05

“F1” function setting

1

FNC-06

“F2” function setting

2

EXCELL PRECISION CO., LTD

14

ZSME400000014

04011XXX

Item

Function

Setting value

Default

Parameter

Description

FNC-07

Front panel indication

“S1” setting

Parameter Description

0Accu. V

1Accu. C

2SP1

3SP2

4SP3

5Hi

6OK

7Lo

8Under

9Over

10 Unloading

11 Running

12 Hold

0

FNC-08

Front panel indication

“S2” setting

0

FNC-09

Front panel indication

“S3” setting

0

FNC-10

Front panel indication

“S4” setting

0

FNC-11

Return to zero band

0

5 d

0

1

10 d

2

20 d

3

40 d

4

60 d

5

80 d

6

100 d

7

150 d

8

200 d

9

250 d

FNC-12

Hold

0

Hold

0

1

Peak hold (positive)(1)

2

Peak hold (negative)

3

Peak hold (absolute value)

4

Peak hold (positive)(2)

FNC-13

Rate for display rewrite

0

No limitation

0

1

20 times/sec

2

10 times/sec

3

5 times/sec

4

1 time/sec

The indications of FNC-07~FNC-10 are necessarily operated with OPTION CARD.

EXCELL PRECISION CO., LTD

15

ZSME400000014

04011XXX

CHAPTER 3 CALIBRATION

3-1 Load cell connection

When using a 6 wire cable to connect the load cell, the SEN+ and SEN- can

be left unconnected (see below diagram)

EXC-

SIG-

SIG+

SEN+

SEN-

EXC+

SHLD

EXC+

SEN+

EXC-

SEN-

SIG+

SIG-

EXCELL PRECISION CO., LTD

16

ZSME400000014

04011XXX

3-2 Parameter setting and calibration flow chart

Calibration

Switch ON

Select 1 Point for

Weight Calibration

(1P~5P)

Zero point

Calibration

Weight Calibration

Calibration Switch

OFF

Calibration

Completed

Zero Point Voltage

Calibration

Span Voltage

Calibration

MODBUS

Calibration

Specification

Calibration

General

Calibration

Linearity

Calibration

Digital

Calibration

EXCELL PRECISION CO., LTD

17

ZSME400000014

04011XXX

Calibration process

Before the Linearity Calibration, the General Calibration should be completed.

General Calibration

Linearity Calibration

Digital calibration

Entering the Digital

calibration, see 3.7 for

details

Entering the linearity

calibration, see 3.6 for

details

Entering the General

calibration, see 3.5 for

details

Calibration Switch set to ON

G/N

G/N

F1

F1

F1

G/N

Entering the specification

calibration, see 3.4 for

details

G/N

F1

Spec. Calibration

Entering the MODBUS

calibration, see 3.3 for

details

G/N

F1

MODBUS. Calibration

EXCELL PRECISION CO., LTD

18

ZSME400000014

04011XXX

3-3 MODBUS calibration

Set RS1-02 to 4 (MODBUS RTU mode) and set RS1-07 to 01 (address)

Calibration switch adjusted to “on” position

For example:

Zero point calibration

Enter 01050423FF007CC0 ← perform zero point calibration

Read the status of zero point calibration

1. Command: Enter 010100410005AC1D

The first “01” means the address of the scale.

The second “01” means “use function code 01 to read the status of the scale”

“00 41” is 65 in decimal, which is the address of the MODBUS.

“00 05” means “ask five addresses in a row which is 65, 66, 67, 68, 69”

2. Scale responses: 01010105919B

The first “01” means the address of the scale.

The second “01” means “use function code 01 to read the status of the scale”

The third “01” means “response with 1 byte”

“05” is “0000 0101” in binary.

The 1st bit of 1 means “address 65 = 1”, which means “in process of zero point

calibration”.

The 2nd bit of 0 means “address 66 = 0”, which means “not in process of span

calibration”.

Please refer to Appendix III Modbus Data Address Table for details.

Zero point calibration is complete when the process is finished without any Error status.

Span calibration

Enter 0110044C0001020BB8EADE ← enter 3000 for calibration weight

Put 3kg weight on the weighing pan

Enter 01050424FF00CD01 ← perform span calibration

Read the status of span calibration

1. Command: Enter 0101004200015DDE.

2. Scale responses: 010101019048.

The first “01” means the address of the scale.

The second “01” means “use function code 01 to read the status of the scale”

The third “01” means “response with 1 byte”

The fourth “01” is “0000 0001” in binary.

The 1st bit of 1 means “address 66 = 1”, which means “in process of span calibration”.

Please refer to Appendix III Modbus Data Address Table for details.

“9048” is the CRC check code.

Press key

CCP flashes

EXCELL PRECISION CO., LTD

19

ZSME400000014

04011XXX

3-4 Specification calibration

Press

Key in calibration

code

Press

Display shows the

previous parameter

code. Input the new

code as required

Press

To continue the next function setting

or press to escape

Increment flashing

digit

Decrement flashing

digit

Move flashing point

left.

Move flashing point

right

Store data in

memory

Exit / Escape

*Calibration parameter code

Unit

Decimal Point

Min. Division

Max. Capacity

Zero Range

Time of Zero tracking

Range of Zero tracking

Investigate period of unstable

Investigate range of unstable

Function Zero and Tare when

the weight is unstable.

Tare function availability when

gross weight is negative.

G/N

F1

F

F2

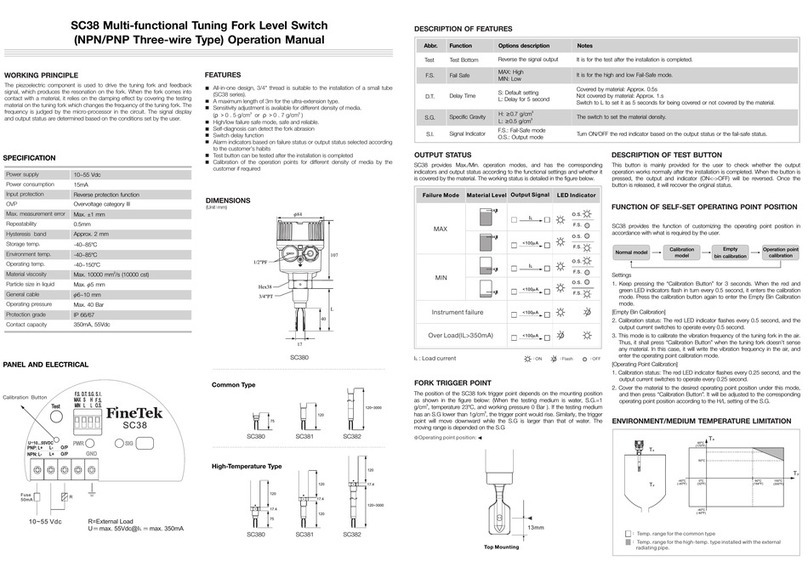

Table of contents

Other Excell Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bender

Bender PEM533 manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS CYBERSCAN PHION 510 PHION METER instruction manual

RADEX

RADEX QUARTA quick start guide

Keysight

Keysight N9030A Installation note

Emos

Emos P5801 user manual

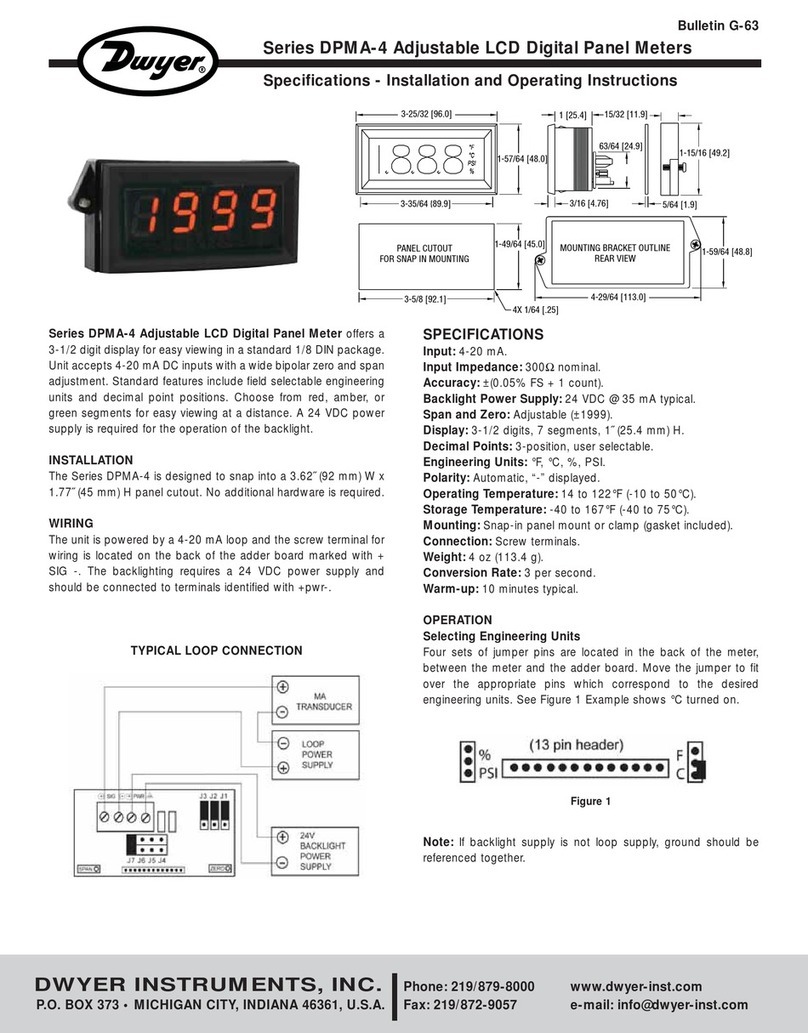

Dwyer Instruments

Dwyer Instruments DPMA-4 Series Installation and operating instructions