Excellent HLPA07D543B User manual

Excellent

“The Name Defines The Quality”

Excellent Inverters

Operation Manual

We are your excellent choice

C -17, PAWANA INDUSTRIAL ESTATE, T 204, MIDC - BHOSARI, PUNE 411026

Tel: 7119505 / Fax: 020 - 7119405,

Automation & Control Systems

E-mail : acsindia@ vsnl.com

Visit us at : www.acs-india.com

CONTENTS

1.Introduction----------------------------------------------------------------------------------

1.1 Conformation upon delivery---------------------------------------------------------------------

1.2 Nameplate information----------------------------------------------------------------------------

2. Safety And Precautions ----------------------------------------------------------------

2.1 Before delivery the current----------------------------------------------------------------------

2.2 In delivery of current------------------------------------------------------------------------------

2.3 In running condition-------------------------------------------------------------------------------

3. Standard Specifications----------------------------------------------------------------

3.1 Individual specification----------------------------------------------------------------------------

3.2 Common specification----------------------------------------------------------------------------

4. Storage And Installation----------------------------------------------------------------

4.1 Storage-----------------------------------------------------------------------------------------------

4.2 In working condition-------------------------------------------------------------------------------

4.3 Positioning-------------------------------------------------------------------------------------------

5. Wiring----------------------------------------------------------------------------------------

5.1 Main circuit schematic diagram----------------------------------------------------------------

5.2 Terminals--------------------------------------------------------------------------------------------

5.3 Standard connection diagram------------------------------------------------------------------

5.4 Caution on wiring----------------------------------------------------------------------------------

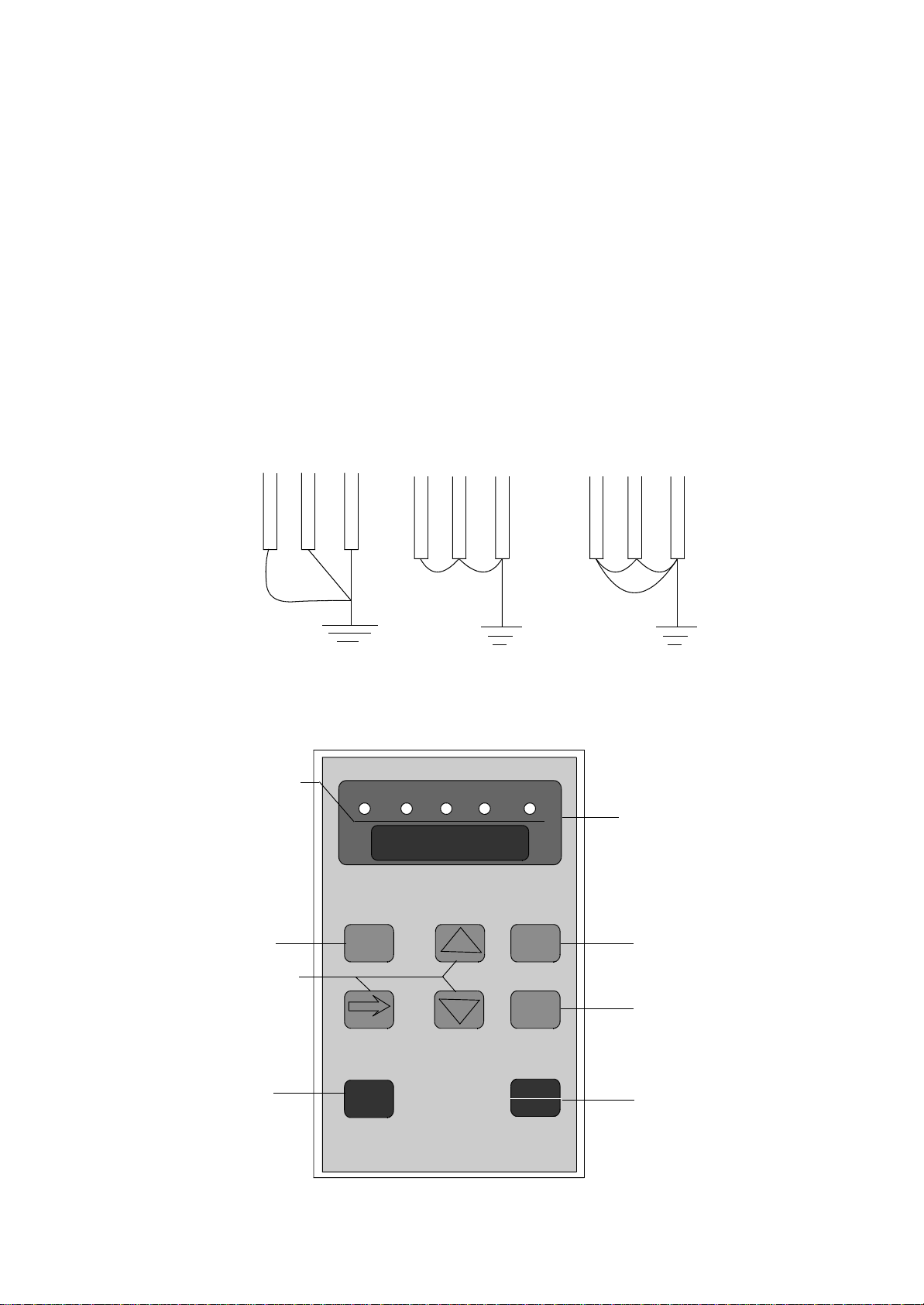

6. Description Of Digital Operator------------------------------------------------------

6.1 Display status--------------------------------------------------------------------------------------

6.2 Explanation of programming the parameter------------------------------------------------

7. Trial Operator Procedure---------------------------------------------------------------

8. Function List-------------------------------------------------------------------------------

9. Detail Explanation Of Function------------------------------------------------------

10 .Maintenance, Inspection And Troubleshooting-------------------------------

10.1 Precaution about main an d inspection-----------------------------------------------------

10.2 Period main and inspection item-------------------------------------------------------------

10.3 Error inspection and its troubleshooting----------------------------------------------------

10.4 Troubleshooting-----------------------------------------------------------------------------------

11. Peripherals Devices And Specifications Of Option--------------------------

11.1 Peripheral devices-------------------------------------------------------------------------------

11.2 Proper specification of option-----------------------------------------------------------------

12. Appendices--------------------------------------------------------------------------------

12.1 Appendices demonstrations-------------------------------------------------------------------

12.2 Record and feedback from the user---------------------------------------------------------

1

1

2

2

2

3

3

3

3

4

5

5

5

5

6

6

7

9

10

11

12

13

14

15

20

53

53

53

54

56

57

57

58

59

59

70

Page no.

1. Introduction

Thank you for purchasing our high quality Excellent HLP series inverter.Before installation

and operation, please read the instruction in this manual throughly. For your safety, the

product should only be installed, tested and programmed by professional personnel. If

you have any questions or problem, please contact our local agency. The information

contained in this manual is subject to change without notice.

WARNING indicates precautions that, if not avoided, could result in death or serious

injury to personnel.

CAUTION indicates precautions that, if not avoided, could result in minor or

moderate injury to personnel and damage to equipment.

WARNING

1.Always turn off the input power supply before wiring.

2.Do not touch any inner part of the inverter when the Charging lamp is still on, shortly

after the AC power is cut off.

3.Do not check signals while the inverter is running.

4.Do not attempt to modify or alter the inverter by yourself, doing so can result in electrical

shock or injury or even explosion.

5. Be sure to ground the E terminals.

1.Do not perform voltage withstand tests on the inverter.

2.Never connect the AC main circuit power supply to output terminals U.V and W.

3.This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies Static

control precautions are required when installing, testing, or servicing this assembly.

Component damage may result if ESD control procedures are not followed.

4.Installation, testing and maintenance must be performed by professional person.

5.The inverter should be discarded as industrial waste. Avoid burning.

CAUTION

1.1 Receiving

Before unpacking please check the following:

1. Inspect the entire exterior of the inverter to see if , there are any scratches or other

damage resulting from shipping.

2. Check if there is an inverter and an operation manual in the packages as soon as you

open the package.

3. Check the model on the nameplate on the side of the inverter to see if this is the right

model you want.

4. Check if there is something is wrong on the inner parts, wiring and circuit board.

5. Use a screwdriver to other tools to check for tightness.

6. Check if there is any other things in the machine.

7. Check if the operator buttons are all right.

8. Check if the optional device you ordered is contained in it.

9. Check if there is a certificate of qualification and warranty card.

1

MODEL : HLPA07D543B

INPUT : 3PH415V50Hz

OUTPUT : 3PH415V17.5A7.5KW

FREQ-RANGE : 0.5-400Hz

EXCELLENT DRIVES

1.2 Nameplate information:

2. Safety precautions

2.1Before delivery of Current

CAUTION

1. This symbol is of ground terminal, make sure to ground it properly

2. Do not connect electromagnetic switches or contactors to the output circuit.

Marked edges RED

E(Circuit terminal)

WARNING

1. R.S.T terminals are power input terminals, never mix them with the U.V.W terminals

Be sure that the wiring of the main circuit is correct.

CAUTION

===

KM

X

X

1.Always hold the case when carrying the inverter. If the inverter is held by its cover, the

main body of the inverter may fall, possibly resulting in injury.

2.Mount the inverter to a metal or other noncombustible material.

3.Install the inverter in a safe site, avoid high temperature, direct sunlight, humidity air or water.

4.Keep the inverter from the reach of children.

5.Install a cooling fan or other cooling device when installing more than one inverter in the

same enclosure so that the temperature of the air entering the inverter is below 40 C

6. Check whether the front cover is attached before turning on the power supply. Do not

install the inverter in a space with explosive gas.

7. If the inverter is used at or above seal

level, the cooling efficiency will be worse,

so please run it downgraded.

8. Do not connect contactors and related

capacitor or

voltage dependent resistor

etc, to the output circuits

9. If it is must to connect such devices, be

sure to guarantee no voltage or current

supplied to output when operating these

devices. Otherwise, it will result in

damage to the inverter. The installation

diagram for this is forbidden.

2

Model:

0

400

WARNING

Never add or remove motor while it is running. Surge current, if created, will cause damage to

the inverter, even may cause burning of the main circuit.

2.3 In running condition

1.Never remove the front cover of the inverter while it is running.

2.Do not come close to the machine when the fault restart function is used. If the alarm is

cleared, the machine may start moving suddenly.

3.The function of the STOP button can only br available after setting. It is different from the

emergency stop button. Please note.

CAUTION

CAUTION

1.Do not touch the heat sink, braking resistor, or braking resistor unit. These can become very

hot.

2.Be sure that the motor and machine is within the applicable ranges before starting the

operation.

3.Do not check the power signals while the inverter is running.

4.Be careful when changing inverter settings. The inverter has been preset to factory setting.

5.Do consider the noise, vibration, and the speed limit of the motor and mechanical devices

when the inverter is running at or above the frequency of 50Hz.

3. Standard Specifications.

3.1 Individual Specifications.

MODEL Input voltage Power Driver

Capacity Output

Current Suitable

Motor

(KW) (KWA) (A) (KW)

HLPA00D423B

HLPA0D7523B

HLPA01D523B

HLPA02D223B

HLPA0D7543B

HLPA07D543B

HLPA005543B

220V 50Hz 0.4 1.0 2.5 0.4

220V 50Hz 0.75 2.0 5.0 0.75

220V 50Hz 1.5 2.8 7.0 1.5

220V 50Hz 2.2 4.0 10 2.2

3F400V 50Hz 0.75 2.2 2.7 0.75

HLPA01D543B 3F400V 50Hz 1.5 3.2 4.0 1.5

HLPA02D243B 3F400V 50Hz 2.2 4.0 5.0 2.2

HLPA03D743B 3F400V 50Hz 3.7 6.8 8.5 3.7

HLPA05D543B 3F400V 50Hz 5.5 10 12.5 5.5

3F400V 50Hz 7.5 14 17.5 7.5

HLPA001143B 3F400V 50Hz 11 19 24 11

HLPA001542B 3F400V 50Hz 15 26 33 15

HLPA18B543B 3F400V 50Hz 18.5 32 40 18.5

HLPA002243B 3F400V 50Hz 22 37 47 22

HLPA003043B 3F400V 50Hz 30 52 65 30

HLPA003743B 3F400V 50Hz 37 64 80 37

HLPA004543B 3F400V 50Hz 45 72 91 45

3F400V 50Hz 55 84 110 55

HLPA007543B 3F400V 50Hz 75 116 152 75

HLPA009043B 3F380V 50Hz 90 134 176 90

HLPA011043B 3F400V 50Hz 110 160 210 110

HLPA013243B 3F400V 50Hz 132 84 110 132

HLPA016043B 3F400V 50Hz 160 230 304 160

3

2.2 Common Specifications.

Control Method

Input Power Supply

Output frequency Range

Frequency Precision

Frequency Analog input

control

resolution Digital input

Output Resolution

Operating setting

Method

Analog setting

Method

Other function

Acceleration/Decel

time

Voltage/frequency

characteristics

Torque Control

Multi-function input

terminals

Multi-funciton output

terminals

Other functions

Digital Operator

monitor

Communication

Control

Ambient Temp

Ambient Humidity

Vibration

Instantaneous over

current

Over Load

Motor Overload

protection

PWM

415V Power Supply: 415+15%

220V Power Supply: 220+15%

0.10~400.00Hz

Within 0.1% of max. output frequency(25 C (53 F)+

10 C(+21.2 F)) during analog input & within 0.01% of the

set output frequency( )

during digital input

1% of Max operating frequency

0.01Hz

0.01 Hz

Press or 10 set

0-5V/0-10V, 4-20mA/0-20mA

frequency upper/lower limit, starting frequency stopping

frequency, three skip frequencies can be individually set.

Counter setting etc.

Four selectable combinations of independent acceleration

and deceleration setting Range: 0.1sec to 6500sec.

Set V/F curve at will.

Max Torque upto 10.0% max output voltage .The starting

torque can reach 150% of max output voltage at 1.0Hz.

6 multi-function input terminals for 8 multi-speed, counter

4 Accel/Decel time select, UP/DOWN command, external

emergency stop.

5 multifunction output terminals for the displaying and

warning of no- running, zero speed, counting and external

fault information.

Decelerating stop or self-stop, DC brake, auto restart

tracking, easy PLC auto energy-saving adjustable carrier

Frequency(Max 20KHz) etc.

Frequency command, output frequency, speed output

current, output voltage. DC bus voltage and of rotation.

Rs485

-10 C(-21.2 F) to 40 C(+84.8 F)

0-95% RH(relative humidity).

0.5G (0.5 x 9.8 = 4.9 m/s) or lower.

Approx. 200% rate current.

Inverter: 150% 1 minute

electronic thermal overload relay..

4

Storage & Installation

Storage

This product must be stored in its package box before installation. Pay special

attention to the followings when in shortages

1. It must be stored in a dry place without rubbish or dust

2. The suitable temperature for storage is between-20 C and + 65 C

3. The relative humidity required is 0-95%, no condensation.

4. There is no corrosive gas or liquid.

5. It’s better to lay the inverter in its original package on a shelf.

5

Location

Note: The working conditions of the inverter will affect its services life, please

install the inverter under the following conditions.

1. Ambient operating temperature -10 C to 40 C.

2. IP rating: IP 20 for all models

3. Protected from rain & moisture.

4. Shielded from direct sunshine.

5. Free from metallic particles and corrosive gas.

6. Free from excessive vibration.

4.3 Positioning

1. There must be enough space left around the inverter for easy maintenance and

effective ventilation .See diagram 1

2. The inverter must be installed with heat sink ribs oriented vertically for effective

ventilation.

3. If there is any instability when installing the inverter, please put a flat board under

the inverter bottom base and install again .If the inverter is installed on a loose

surface, stress may cause damage in main circuit.

4. The inverter should be installed on non-combustible materials, such as iron plates

5. If several inverter are installed together in one cabinet, please add heat

dissipation plates and provide enough space between the inverters.

Caution

War ni ng

********

*********

50

50

5 Wiring

5.1 Main circuit schematic diagram

6

Excellent

Caution

Warning

************

********

1. Power supply: Verify that the inverter rated

voltage coincides with AC power supply voltage.

2. Fuse breaker or ground fault interrupter.

3.Magnetic contactor

Note: Don’t use the magnetic contactor as the

power supply on/off to the inverter.

4.AC reactor for power factor improvement

5.Excellent - inverter

6. 3 phase squirrel cage induction motor.

E R S T U V W P Pr

E R S T U V W P1P Pr

R S T E P N U V W

HLPA00D423B-HLPA02D223B

HLPA0D7543B-HLPA03D743B

HLPA05D543B-HLPA07D543B

HLPA001143B-HLPA030043B

7

FA FB FC EV SPL SMP SPH RST DCM REV FOR

KA KB UPF DRV +10 VI AI ACM AM RS- RS+

Control circuit terminals arrangement

FA FB FC KA KB IPV UPF DRV DCM SPL SPM SPH RST REV FOR +10 VI AI ACM AM RS- RS+

HLPA00D423B HLPA01D523B HLPA0D7543B HLPA02D243B

HLPA02D22B HLPA03D743B HLPA07543B

UPF DRV FOR REV DCM RST SPH SPM SPL P24 AM ACM AI VI +10 EKB EKA EFC EFB EFA

HLPA02D22B HLPA03D743B HLPA07543B

5.2 Terminals

5.2.1 Main circuit Terminals Arrangement

Functional description of main circuit terminals

SYMBOL FUNCTION DESCRIPTION

R.S.T input terminal of AC line power

P.Pr External braking resistor terminals

P .P1 External DC reactor terminals

P.N External Braking unit terminals

U.V.W. Output terminals to motor

E Ground terminal.

Functional description of control circuit terminals

Symbol Functions Factory setting

FOR Multi -Function input 1 Forward run

REV Multi -Function input 2 Reverse run

RST Multi -Function input 3 Reset

SPH Multi-Function input 4 High Speed

SPM Multi-Function input 5 Medium Speed

SPL Multi -Function input 6 Low Speed

DCM Ground common for input

terminals

EV(IPV) + 12V power supply Max output current 200mA

P24 +24V power supply Max output current 200mA

+10 Power supply for analog frequency +10V

VI Analog frequency reference 0 ~+10Vcorresponding to

input(voltage) highest operating frequency

AI Analog frequency reference input 4~20m

(current)

ACM Common for analog input signal

DRV Multi -function output terminal 1 Optical couple output DC

24V/100mA

UPF Multi-funcation output terminal 2

FA(EFA), Fault relay output(N/O or

FB(EFB), Multi-funcation output terminal 3 N/C) 3 A/250VAC,3A/30VDC

FC(EFC)

KA(EKA) Multi-funcation output terminal 4 Fault relay output(N/O)

KB(KEB) 3A/250AC,3A/30VDC

AM Digital frequency output terminal 0-10V

RS+RS- RS-485 communications

8

9

5.3 Standard Connection Diagram

The whole circuit is divided into two parts. Main power circuit terminal connections and control

circuit terminal connections. Users can see the main circuit terminal, and the control

circuit terminals after removing the outer cover .The terminals must be connected as

shown in the following diagrams .

The following diagram shows the standard connection of Excellent drive.

M

U

V

W

PrP1

R

S

T

E

VR(+10V)

VI

ACM

AI

FOR

REV

RST

SPH

SPM

SPL

DCM ACM

AM Analog frequency output

0~10V

DRV

UPF

DCM

Multi-function Output <Relay O/P>

24V/100mA

RS+ RS-

KA

KB

EV(IPV)

AC Power Supply

10K

Analog Current

input

Multi-function output <relay N/O>

3A/250VAC 3A/30 VDC

+ 12V

FC

FA

FB

Multi-function output <relay N/O N/C>

3A/250VAC

3A/30VAC

P

DC Reactor Braking Resistor

M

U

V

W

PrP

R

S

T

E

VR(+10V)

VI

ACM

AI

FOR

REV

RST

SPH

SPM

SPL

DCM ACM

AM Analog frequency

0~10V

DRV

UPF

DCM

Multi-function Output

24V/100mA

RS+ RS-

KA

KB

EV(IPV)

AC Power Supply

10K

Analog Current

input

Multi-function output <relay N/0>

3A/250VAC 3A/30 VDC

+ 12V

FC

FA

FB

Multi-function output <relay N/0 N/C>

3A/250VAC

3A/30VAC

Braking Resistor

5.4 Cautions on Wiring

5.4.1 For main circuit wiring

1) No Fuse Breaker required for the power supply and the input terminals (R.S.T).

(If using ground fault interrupter, please choose the one corresponding to high frequency)

2) Never connect AC power to the output terminals of U.V.W. On the inverter.

3) Output wire must not be in touch the metal part of the outer cover ,or it will cause earth short-circuit.

4) Phase -shifting capacitor, LC, RC noise filters, etc. can never be connected between motor and

output terminals(U.V.W)

5) The main circuit wire must be enough far away from other control equipments.

6) If there is a relatively long distance between the inverter and the motor, please lower the carrier

frequency. Because the high leakage current will cause damage to the inverter and other

equipments.

7) If the wire is more than 15m for 220V class products (or 30m for380Vclass products)between

the inverter and the motor, please choose an AC motor ,special for inverter or add a reactor

on the side of the inverter, because a very high dv/dt produced in the motor coil will cause

damage to the insulation layer of the motor .

Model

CB

Wire size

Screw

Model

CB

Wire size

Screw

HLPA00 HLPA0 HLPA01 HLPA0 HLPA0 HLPA01 HLPA02 HLPA03 HLPA05

D423B D7523B D523B2 D223B D7543B D543B D243B D743B D543B

16A 16A 32A 32A 16A 16A 16A 16A 32A

2.5mm 2.5mm 2.5mm 4mm 2.5mm 2.5mm 2.5mm 2.5mm 4mm

M4 M4 M4 M4 M4 M4 M4 M4 M5

HLPA07 HLPA00 HLPA00 HLPA18 HLPA00 HLPA00 HLPA00 HLPA00 HLPA0055

D543B 1143B 1543B D543B 2243B 3043B 3743B 4543B 43B

40A 63A 63A 100A 100A 160A 160A 200A 200A

6mm 6mm 10mm 10mm 16mm 25mm 25mm 25mm 35mm

M5 M6 M6 M6 M8 M8 M8 M10 M10

2 2 2 2 2 2 2 2 2

2 2 2 2 2 2 2 2 2

10

M

U

V

W

NP

R

S

T

E

+10V

VI

ACM

AI

FOR

REV

RST

SPH

SPM

SPL

DCM ACM

AM Analog frequency

0~10V

DRV

UPF

DCM

Multi-function Output <O/P>

24V/100mA

EKA

FKB

P24

AC Power Supply

10K

Analog Current

input

Multi-function output <relay N/O>

3A/250VAC 3A/30 VDC

(+ 12V)

EFC

EFA

EFB

Multi-function output <relay N/O, N/C>

3A/250VAC 3A/30VAC

RS485

DC Braking resistor unit

Note:- The parameter above are only for reference, not a standard.

Specification of wire

5.4.2 For control circuit wiring ( signal line)

1. Separate control circuit wire from main circuit wire and other high -power lines .

2. Use twisted -pair or shielded twisted -pair cables for control circuits to prevent

operating faults .The size should be 0.5-2mm.

3. Use the control terminals correctly according to your needs.

5.4.3 Grounding

1. Choose grounding wires according to the requirement of the electrical equipments .

2. Avoid sharing grounding wires with other large power equipment .The grounding wire

should be kept away from the power supply wires .

3. The grounding method for several inverter together should be done as the first and second

diagrams. Avoid the third diagram .

4. Short grounding wire are better.

2

(1) Correct (2) Correct (3) Wrong

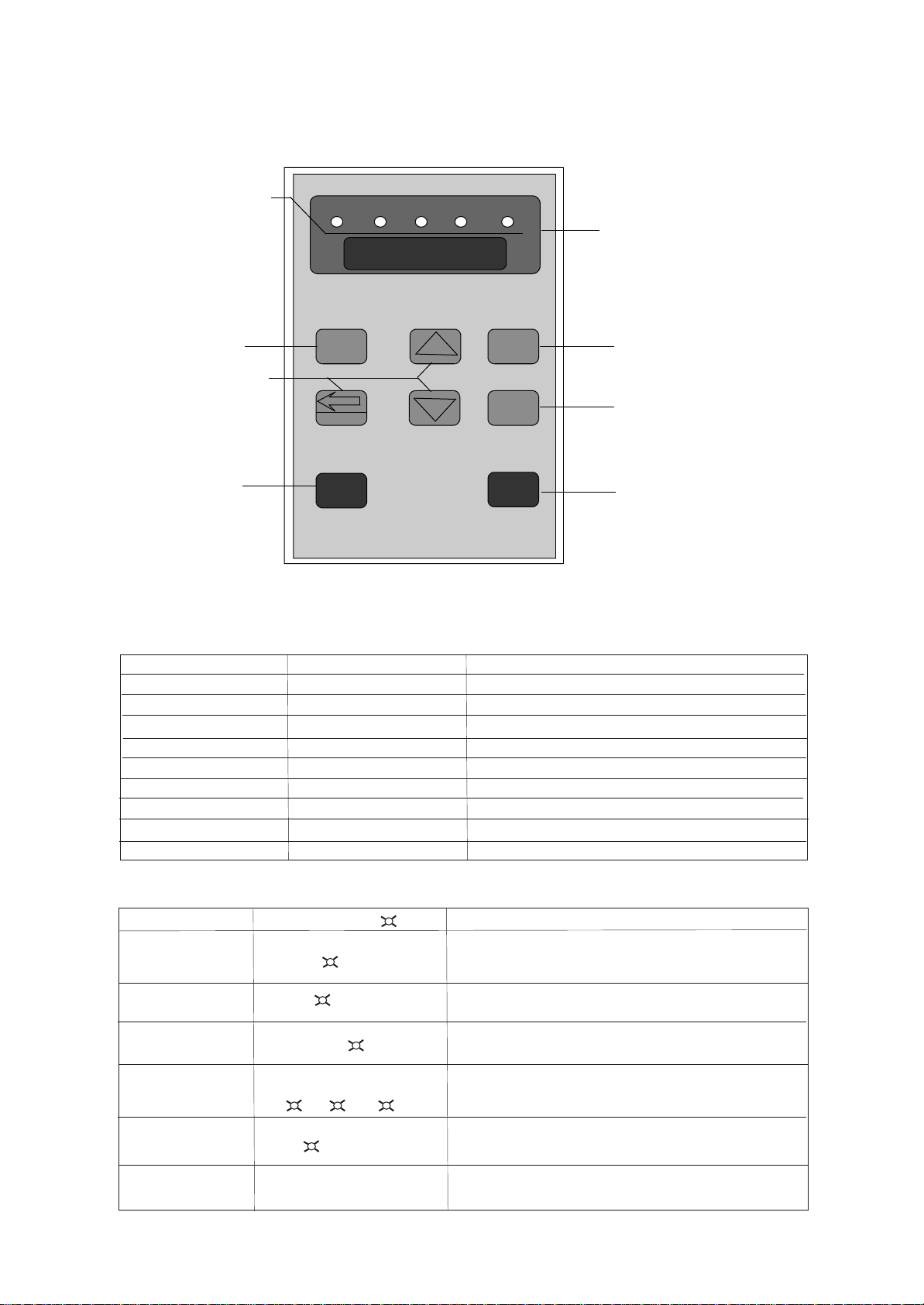

6.Description of Digital Operator

11

2

8.8.8.8.8.

FOR REV HZ AR/min

F/R PROG

ENTER

STOP

RESET

RUN

Run Key Stop/RESET Key

Read/Write Key

Function Selection

key

Main Display Area of

Voltage, frequency, current AC

DC voltage, rotation speed

counter, temperature.

Operation ModeIndicators forword

run,reverserun frequency current

speed

Forward or reverse

run key

Numerical key

(use for incrementing &

decrementing thesettings)

Output

6.2 Display Status

6.2.1Display status description

Indicators Status Explanation

FOR On Forward run

REV On Reverse run

HZ On Display set frequency or output frequency

A On Display output current

ROTT On Display motor speed

HZ A On Display DC Voltage

A ROTT On Display output voltage

HZ ROTT On Display counting data

HZ A ROTT On Display inverter temperature

6.2.2 Explanation of data display

Display item Indicator On Explanation

050.00 HZ Present set frequency or output frequency.

5.5 A Current (in amperes)

1440 ROTT Motor speed (in rpm)

30.0 HZ A ROTT Present inverter heat sink temperature

CD 100 HZ Function item

EOC.A Error information

12

8.8.8.8.8.

FOR REV HZ AR/min

F/R PROG

DISP SET

STOP

RUN

Run Key Stop/RESET Key

Read/Write Key

Function Selection

key

Main Display Area of

Voltage, frequency, AC current

DC voltage, rotation speed

counter, temperature

Operation Mode Indicators

forword run, reverse run

frequency current speed

Forward or reverse

run key

Numerical change key

Output

6.3Explanation of programming the parameters.

Example

Procedures Data Display Explanation

power on dsp.1flashing FOR Hz Self inspection after power on, showing

uEr1.3 its version number ( flashing ), then

000.00 its set frequency

Prog CD 000 FOR Hz Function number CD000.

Enter 000.0 FOR Hz Display the value of FUNCTION CD000

Enter 50.00 FOR Hz Modify the value of Function CD 000.

END 50.00 Display :End 50.00 CD0001

CD001 withdraw form the programming status

prog FOR Hz

050.00

Run 50.00 FOR H z Display : Forward run status and set

frequency

50.00 FOR Hz Switching to display running frequency.

0.00 50.00

Disp

0005.0 FOR Hz Switching to display output current.

Disp

01440 FOR Hz Switching to display rotating speed.

Disp

050.00 FOR Hz Return to main display ,showing set

Prog frequency.

050.00 REV Hz Forward RUN/REVERSE RUN shift

F/R display '' reverse run '' status.

050.00 REV Hz Switching to frequency adjustable status.

030.00 REV Hz Adjust the set frequency, that is the value

of CD000.

030.00 REV Hz Enter the new value which will be

ENTER remembered as CD000.

Stop 030.00 REV Hz Stop .

13

Function List Parameter and Function List (Part 1)

Item Function Function Set range & function Factory

code explanation Setting

Cd000 Main Frequency 0.00~400.00 Hz 0.00

CD001 Max output voltage 0-1V---* 220/380

CD002 Base Frequency 0.01~400.00Hz 50.00

CD003 Voltage at medium

Frequency 0.1V---* 15/27.5

CD004 Medium Frequency 0.01~400.00Hz 2.50

CD005 Voltage at lowest

Frequency 0.1~50.0V 8.0/13.5

CD006 Lowest frequency 0.01~20.0Hz 0.50

CD007 Max operating system 50.00~400.00Hz 50.00

CD008 Frequency upper limit 0.01~400.00Hz 50.00

CD009 Frequency lower limit 0.00~400.0Hz 0.00

CD010 Parameter lock select 0: invalid 1: valid 0

CD011 Factory setting 00~10 only No.08 meansto 00

to reset to factory setting

CD012 Accel.Time 1 0.1~6500.0S 10.0/25.0

CD013 Decel.Time 1 0.1~6500.0S 10.0/25.0

CD014 Accel.Time 2 0.1~6500.0S 50.0

CD015 Decel.Time 2 0.1~6500.0S 50.0

CD016 Accel.Time 3 0.1~6500.0S 100

CD017 Decel.Time 3 0.1~6500.0S 100

CD018 Accel.Time 4 0.1~6500.0S 200

CD019 Decel.Time 4 0.1~6500.0S 200

CD020

Reserved

CD030

CD031 Start mode 0: start from starting frequency 0

1: start by former frequency

track

CD032 Stop mode 0: decelerate to stop 1:free 0

run to stop

CD033 Control mode select 0: digital operator

1: external terminals 0

2: communications

CD034 Frequency command 0: digital operator

1: external terminals 0

2: communications

CD035 Carrier frequency 0~15 5

CD036 Jog frequency 0.00~4.00.0Hz 5.00

CD037 FOR/REV select 0: Reverse run forbidden 1

1: Reverse run available

CD038 “STOP” key select 0: Stop key ineffective in

remote control mode

1: Stop key effective in

remote control mode

CD039

Reserved

CD040

CD041 Starting frequency 0.1~10.0 Hz 0.5

14

Applied parameter

Basic parameter

Function List Parameter and Function List (Part 1)

Item Function Function Set range & function Factory

code explanation Setting

CD042 Stopping Frequency 0.1~10.0 Hz 0.5

CD043 Torque Boost 0-10% 2.0%

CD044 Skip Frequency 1 0.00~400.00Hz 0.00

CD045 Skip Frequency 2 0.00~400.00 Hz 0.00

CD046 Skip Frequency 3 0.00~400.00Hz 0.00

CD047 Skip Frequency 0.00~2.00 Hz 0.5

CD048 Reserved

CD049

CD050 Multi -input 1 ( FOR) 00: invalid 01:run 02: forward 02

CD051 Multi- input 2 ( RST) run03:reverse run 04:stop 03

CD052 Multi-input 3 (RST) 05:for/rev run 06: jog 10

CD053 Multi-input 4 ( SPL) 07:forward jog 08:reverse jog 17

CD054 Multi-input 5 (SPL) 09:external emergency stop 18

Cd055 Multi-input 6 (SPL) 10:reset 11: reserved 19

12: overheat of motor 17: high

speed 18: medium speed

19:low sped 20:multi -speed1

21:multi -speed2

22:multi-speed3

23:accel/decel select 1

24:accel/decel select 2

CD056 Multi-output1( DRV) 00: Invalid 01:run mode 01

CD057 Multi-output2 ( UPF) 02: Fault signal 03: zero speed 05

CD058 Multi-output3 FA FB 04: Brake indication 05:Up to 02

FC) setting frequency 06: Up to

desired frequency 1 07:Up to

CD059 Multi -output 4 desired frequency 2 08 :in 00

( KA KB) accelerating 09:In

decelerating 10: Inverter

overload 11:Motor overload

13: Under voltage 14: Finish

indication for single stage

15: Finish indication for

process 16: counting arrival

27: Drafting arrival 28: PID

lower limit alarm 29; PID

upper limit alarm 30: Fan

running 31:Reserver

32:Braking resistor action

CD060 Multi -output 5( AM) 1

CD061 UP -to desired 0.00~400.00 Hz

frequency 1 setting

CD062 UP-to desired 0.00~400.00 Hz 0.00

frequency 2 setting

Cd063 UP -to frequency 10.10~10.00 Hz 0.50

setting detection width

CD064 Counter set 00~65500 00

15

Function List Parameter and Function List

Item Function Function Set range & function Factory

code explanation Setting

CD065 Analog input select 0:~10V 1:0~5V

2:0~20mA 3:4~20mA 0

4:0~10V plus 4~ 20mA

CD066 Lower analog frequency 0.00~400.00Hz 0

set point

CD067 lower analog frequency 0:Positive

bias direction 1: negative

CD068 Higher analog frequency 0.00~400.00Hz 50.00

set point

CD069 Higher analog frequency 0: positive

bias direction 1: negative 0

CD070 Negative bias reverse 0:invalid 1:vaild 1

select

CD071 Analog output gain 0.0~100.0% 100

CD072 Up/down function select 0:recoreded 1

1: non-recoreded

CD073 Reserved

Cd075

0: normal running 0

1: external control four speed

Cd076 PLC mode select 2: external control multi

speed3:ddistrubance 4:inner

control multi speed

0: stop after one circle 0

1:cirulating running 2: stop after

auto running one circle (with

CD077 Auto PLC select STOP interval ) 3: auto

circulating running

(with STOP interval)

CD078 PLC running direction 0~255(0:Positive 1: Negative )

CD079 PLC accel/decel .time 0~65535

CD080 Multi-speed 2 0.00~400.00 Hz 15.00

CD081 Multi-speed 3 0.00~400.00 Hz 20.00

CD082 Multi-speed 4 0.00~400.00 Hz 25.00

CD083 Multi-speed 5 0.00~400.00 HZ 30.00

CD084 Multi-speed 6 0.00~400.00 Hz 35.00

CD085 Multi-speed 7 0.00~400.00 Hz 40.00

CD086 Multi-speed 8 0.00~400.00 Hz 0.50

CD087 Timer 1 0.0~6500.0s 10.0

CD088 Timer 2 0.0~6500.0s 10.0

CD089 Timer 3 0.0~6500.0s 0.0

CD090 Timer 4 0.0~6500.0s 0.0

CD091 Timer 5 0.0~6500.0s 0.0

CD092 Timer 6 0.0~6500.0s 0.0

CD093 Timer 7 0.0~6500.0s 0.0

CD094 Timer 8 0.0~6500.0s 0.0

CD095 Reserved

CD0119

16

I/P & O/P terminals

Function List Parameter and Function List (Part 1)

Item Function Function Set range & function Factory

code explanation Setting

CD120 Stall prevention select 0:invalid 1: valid 1

CD121 Stall prevention level 0~200% 150

during accel

CD122 Stall prevention level 0~200% 0

during running

CD123 Stall prevention level

during decel 0~200% 150

CD124 Reserved

CD125 Overtorque detection 0~200% 1.0

level

CD126 Overtorque detection 0~200%

time

CD127 Reserved

CD129

CD130 Rated voltage according to the motor nameplate *

CD131 Rated current according to the motor *

nameplate 40

CD132 Motor poles 02-10 1440

CD133 Rated rotatory speed 00---9999

CD134 Reserved

CD139

CD140 DC braking level 0.0~20.0% 2.0

CD141 DC braking time at 0.0~25.0S 0.0

starting

CD142 DC braking time at 0.0~25.0S 0.0

stopping

CD143 Speed search time 0~20.0S 5.0

CD144 Speed search current 0~200% 150

level

CD145 Power loss allowable 0: invalid 1:restart by speed 0

search

CD146 Number of auto restart 0.1~ 5.0s 0.5

CD147 Attempt 0---10 00

CD148 Auto voltage regulation 0: invalid 1:valid 1

CD149 Auto energy saving 0~10% 0

CD150 P 0.0---1000.00% 100%

CD151 I 0.1~3600.00s 5.0

CD152 D 0.01~10.00s

CD153 Target value 0.0~100.0%

CD154 Target value source 0: digital operator 1: external *

terminals(0-10V) *

CD155 PID upper limit 0~100% 100%

CD156 PID lower limit 0~100% 0%

CD157

Reserved

CD159

17

Applied parameter

Basic parameter

Function List Parameter and Function List (Part 1)

Item Function code Function Set range & function Factory Setting

explanation

CD168 Display mode select Rated 0-15 00

CD169 Voltage of the inverter According to the actual *

model set *

CD170 Rated current of the inverter according to the actual *

CD171 Software version model ---

CD172 Fault Record 1 Note :- means no fault ---

CD173 Fault Record 2 record ---

CD174 Fault Record 3

CD175 Fault Record 4

CD176 Fault cleared 00--10 (01 is fault record ---

cleared

CD177 Reserved

CD178 Frequency standard of the 0:50Hz 1:60Hz 0

inverter

CD179 Manufacture Date Factory set *

CD180 Sequence Number *

CD181 Reserved

CD250

18

Table of contents