Table of Contents 1

C300 series of non-sensor current vector-control inverter manual

Table of Contents

1 INTRODUCTION …………………………………………………………………1

1.1 Model explanation …………………………………………………………..

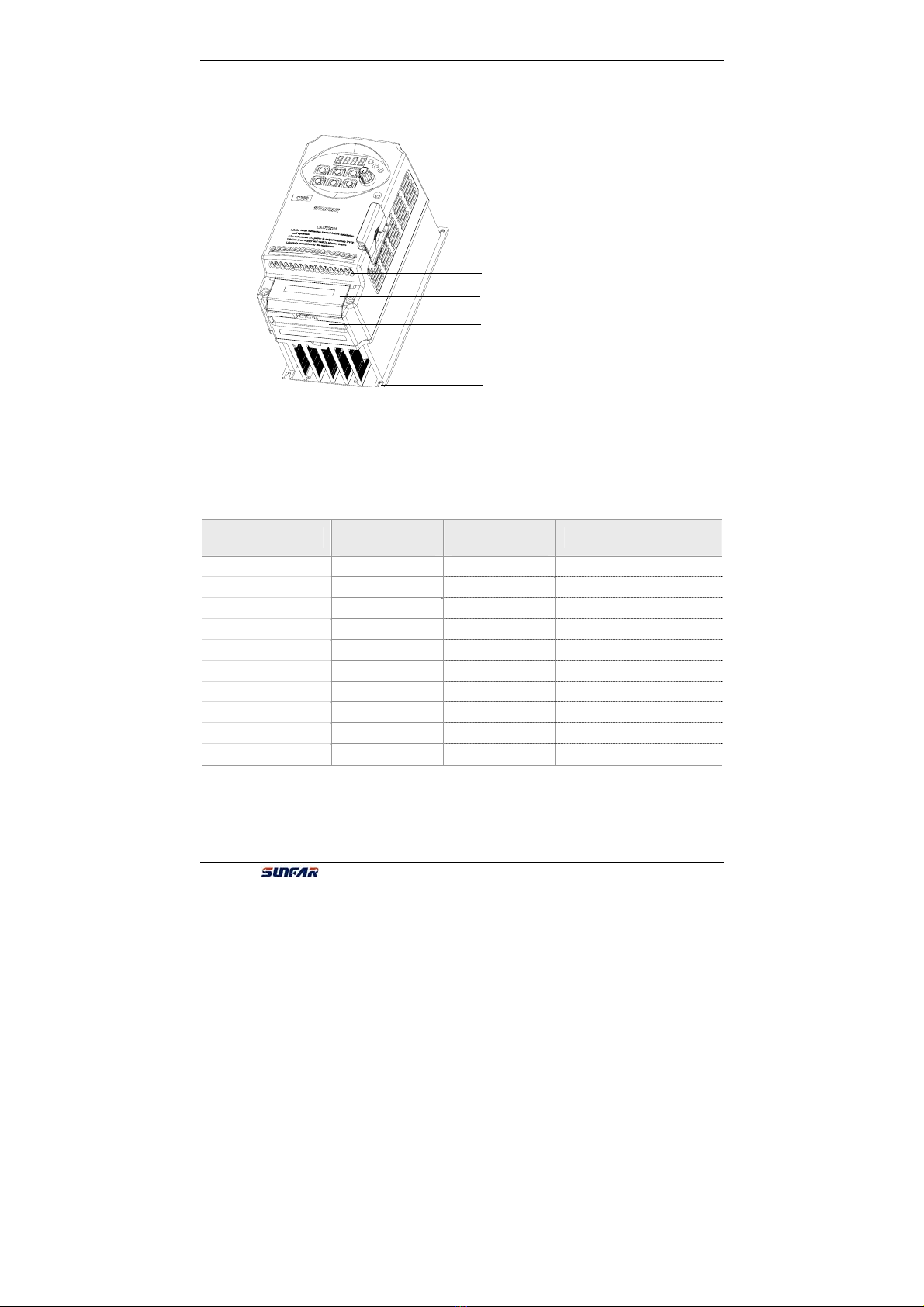

1.2 Appearance description ……………………………………………………

1.3 Model of inverter………………………………………………………………

1.4 Specifications………………………………………………………………..

2 INSTALLATION GUIDELINES……………………………………………….

2.1 Environmental requirements ……………………………………………… 5

2.2 Installation dimension of inverter ………………………………………………

3 WIRING PROCEDURE……………………………………………………7

3.1 Precautions …………………………………………………………………7

3.2 Wiring of external components ………………………………………………

3.3 Basic wiring ……………………………………………………………………

3.4 Terminal of main circuit ……………………………………………………

3.5 Terminal of Control circuit …………………………………………………

3.6 Wiring of RS485 interface and

remote panel interface………………………………………………………….

4 PANEL OPERATIONS……………………………………………………………

4.1Panel functions………………………………………………………………

4.2 Panel operation ………………………………………………………………

4.3 State monitor parameter ……………………………………………………….

4.4 Operations …………………………………………………………………….

5 PARAMETERS LIST………………………………………………………………

6 DESCRIPTION OF SPECIFIC FUNCTIONS …………………………………

6.1 Basic operation parameter unit ………………………………………………

6.2 Primary application of parameter unit……………………………………….

6.3 Analog I/O parameter unit …………………………………………………

6.4 Digital O/I parameter unit ……………………………………………….…

6.5 Auxiliary running parameter unit …………………………………………..

6.6 Multi-speed running parameter unit ……………………………………….

6.7 Advanced running parameter unit ………………………………………

1

1

2

3

3

6

6

7

8

8

9

10

11

12

13

14

14

15

16

17

19

39

39

45

51

54

58

64

67