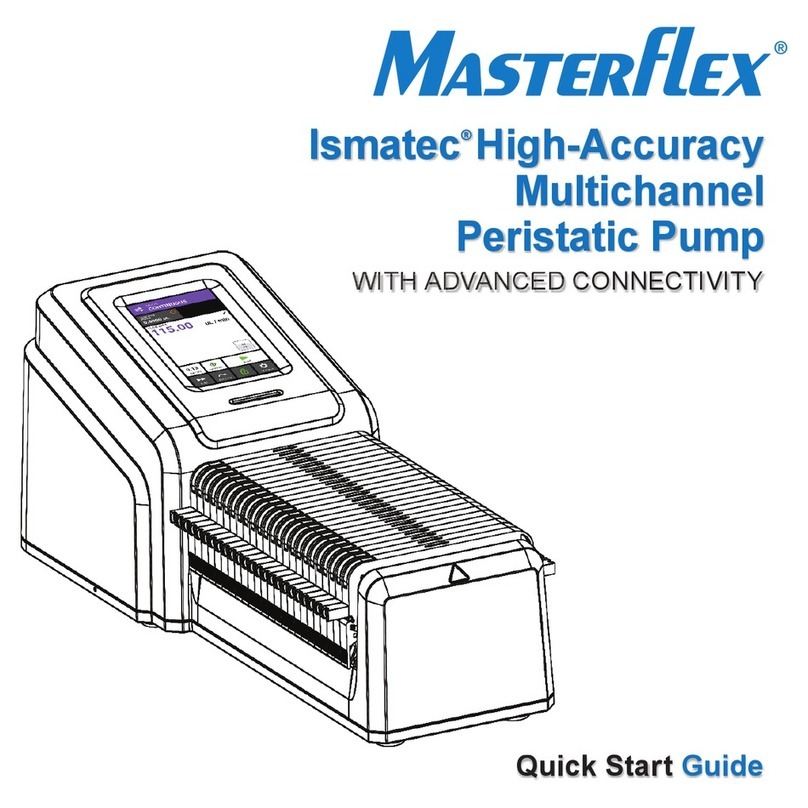

Variable Speed Pump Installation and User’s Guide

iii

IMPORTANT PUMP

WARNING AND SAFETY INSTRUCTIONS

For Installation of Electrical Controls at Equipment Pa

Switches, Timers and Automation Load Center)

Install all electrical controls at equipm

on/off switches, timers, and control sys

allow the operation (startup, shut-down,

any pump or filter so the user does not pl

portion of his/her body over or near the p

filter lid or valve closures. This installati

allow the user enough space to stand cl

and pump during system start-up, shut

servicing of the system filter.

The Virginia Graeme Baker (VGB) Pool and Spa Safety

requirements for owners and operators of commercial swim

spas.

Commercial pools or spas constructed on or after December

utilize:

(A) A multiple main drain system without isolation capability wit

outlet covers that meet ASME/ANSI A112.19.8a Suction Fittings

Swimming Pools, Wading Pools, Spas, and Hot Tubs and ei

(i) A safety vacuum release system (SVRS) meeting ASME

A112.19.17 Manufactured Safety Vacuum Release syste

for Residential and Commercial Swimming Pool, Spa, Hot

Wading Pool Suction Systems and/or ASTM F2387 Standa

Specification for Manufactured Safety Vacuum Release Sy

for Swimming pools, Spas and Hot Tubs or

(ii) A properly designed and tested suction-limiting vent sys

(iii) An automatic pump shut-off system.

Commercial pools and spas constructed prior to December

single submerged suction outlet shall use a suction outlet c

that meets ASME/ANSI A112.19.8a and either:

(A) A SVRS meeting ASME/ANSI A112.19.17 and/or AS

(B) A properly designed and tested suction-limiting vent

(C) An automatic pump shut-off system, or

(D) Disabled submerged outlets, or

(E) Suction outlets shall be reconfigured into return inlets.

A clearly labeled emergency shut-off s

must be in an easily accessible, obviou

TO MINIMIZE THE RISK OF INJURY

SUCTION ENTRAPMENT HAZARD:

•A properly installed and secured ANSI/ASME A112.19.

anti-entrapment suction cover must be used for each d

•Each suction cover must be installed at least three (3’)

measured from the nearest point to nearest point.

•Regularly inspect all covers for cracks, damage and ad

weathering.

•If a cover becomes loose, cracked, damaged, broken o

replace with an appropriate certified cover.

•Replace drain covers as necessary. Drain covers deteri

time due to exposure to sunlight and weather

•Avoid getting hair, limbs or body in close proximity

cover, pool drain or outlet.

•Disable suction outlets or reconfigure into return inlets.

Mechanical Entrapment: When jewelry, swimsuit, hair decor

or knuckle is caught in an opening of an outlet or drain cover.

present when the drain cover is missing, broken, loose, crack

secured.

NOTE: ALL SUCTION PLUMBING MUST BE INSTALLED I

ACCORDANCE WITH THE LATEST NATIONAL AND LOC

STANDARDS AND GUIDELINES.

Make sure users know where it is and how to use it in cas

ARNING AND SAFETY INSTR

For Installation of Electrical Controls at Equipment Pa

d (ON/OFF

Install all electrical controls at equipment

pad, such as

on/off switches, timers, and control syste

ms, etc. to

r servicing) of

any pump or filter so the user does not pla

ce any

mp strainer lid,

filter lid or valve closures. This installation

should

allow the user enough space to stand clea

r of the filter

or SAVE THESE I

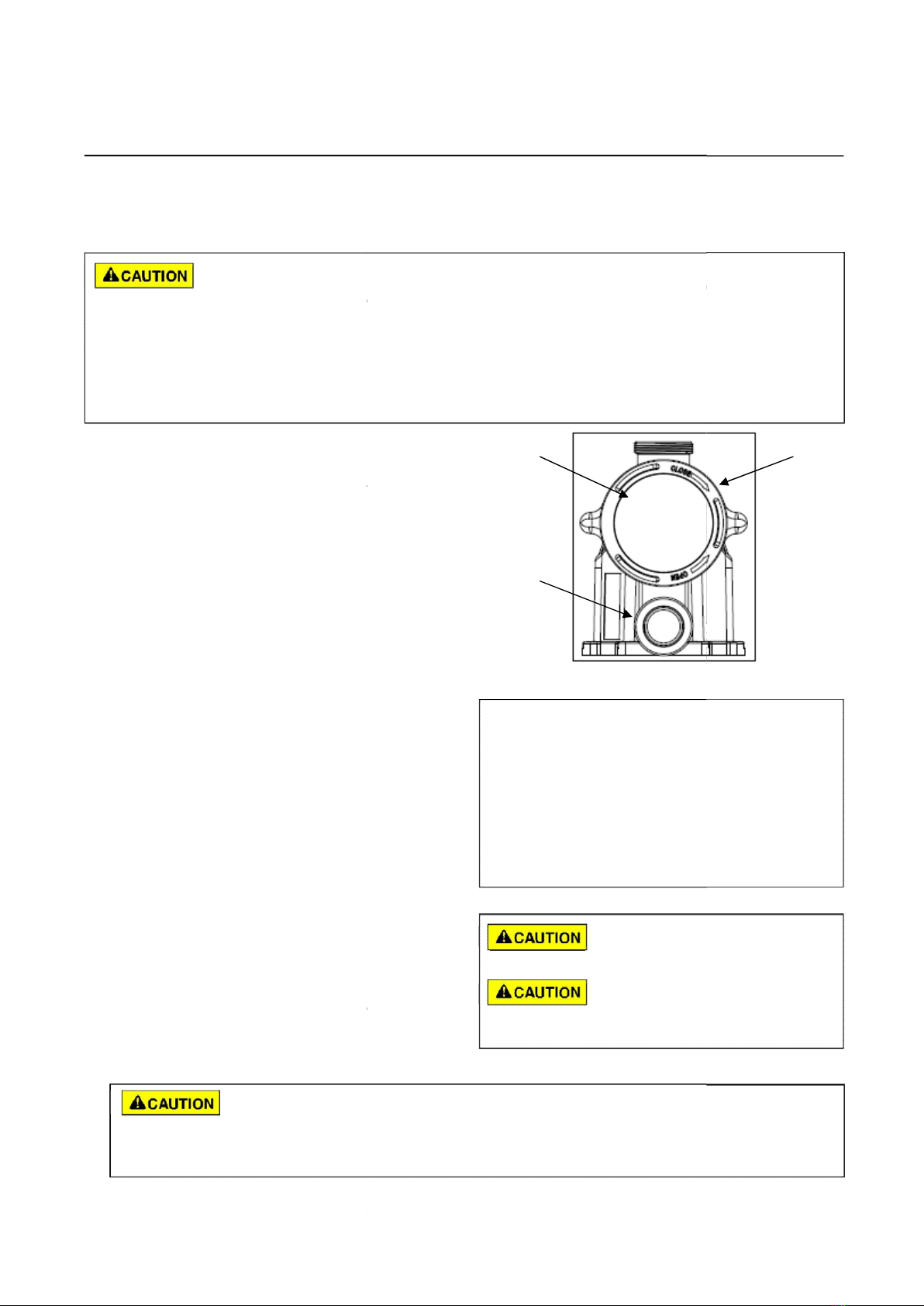

HAZARDOUS PRESS

AND FILTER DURING

Circulation systems

operate under high pressure.

When any part of the

locking ring, pump, filt

er, valves, etc.) is serviced,

air can enter the sys

tem and become pressurized.

Before servicing equipment, make note of t

controls are set to ensure the system cannot i

during service. Turn off all power to the pump.

manual air relief valve in the open position

and wait for all pressure in the

system to be relieved.

Before starting the system, fully open the m

anual air relief valve and place all

system valves in the “open”position to allow

water to flow freely from the

and back to the tank. Stand clear of all equipmen

IMPORTANT: Do not close filter manual air re

has been discharged from the valve and a

appears. Observe filter pressure gauge and

be sure it is not higher than the

pre-service condition

.

Pressurized air can cause the pump housing

cover, filter lid, and valves to

violently separate which can result in sever

e personal injury or death.

Filter tank lid and strainer cover must be prop

erly secured to prevent violent

separation. Stand clear of all circulation syste

turning on or starting up pump.

General Installation Information

•All work must be performed by a qualified

service professional, and

conform to all national, state, and local code

•Install to provide drainage of compartment fo

•These instructions contain information for a

variety of pump models and

therefore some instructions may not apply to

a specific model. All models

are intended for use in swimming pool applic

therefore some instructions may not apply to

a specific model. All models

are intended for use in swimming pool applic

ations. The pump will function

correctly only if it is properly sized to the spe

cific application and properly

installed.

Pumps improperly siz

ed or installed or used in

applications other t

han for which the pump was

intended can result in severe personal injury

or death. These risks may

include but not be limited to electric shock, fir

entrapment or severe injury or property dam

age caused by a structural

failure of the pump or other system compon

The pump can produc

e high levels of suction within

the suction side of

the plumbing system. These high

levels of suction can pose a risk if a person

of the suction openings. A person can be s

this high level of vacuum or may become t

absolutely critical that the suction plumbin

g be installed in accordance

with the latest national and local codes for

The Virginia Graeme Baker (VGB) Pool and Spa Safety Act

creates new

requirements for owners and operators of commercial swimm

ing pools and

Commercial pools or spas constructed on or after December

19, 2008, shall

(A) Amultiple main drain system withoutisolation capability wit

h suction

outlet covers that meet ASME/ANSI A112.19.8a Suction Fittings

for Use in

Swimming Pools, Wading Pools, Spas, and Hot Tubs and ei

ther:

ANSI

A112.19.17 Manufactured Safety Vacuum Release system

s (SVRS)

for Residential and Commercial Swimming Pool, Spa, Hot T

ub, and

Wading Pool Suction Systems and/or ASTM F2387 Standar

d

Specification for Manufactured Safety Vacuum Release Sys

tems (SVRS)

m or

Commercial pools and spas constructed prior to December

19, 2008, with a

single submerged suction outlet shall use a suction outlet co

ver

(A) A SVRS meeting ASME/ANSI A112.19.17 and/or AST

M F2387, or

tem, or

itch for the pump

ust be in an easily accessible, obvious

place.

TO MINIMIZE THE RISK OF INJURY D

UE TO

A properly installed and secured ANSI/ASME A112.19.8 ap

proved

entrapment suction cover must be used for each dr

ain.

cover must be installed at least three (3’) fee

t apart, as

Regularly inspect all covers for cracks, damage and adv

anced

If a cover becomes loose, cracked, damaged, broken or

is missing,

Replace drain covers as necessary. Drain covers deteri

orate over

Avoid getting hair, limbs or body in close proximity to an

y suction

When jewelry, swimsuit, hair decorat

ions, finger, toe

or knuckle is caught in an opening of an outlet or drain cover. T

his hazard is

sing, broken, loose, cracked

, or not properly

NOTE: ALL SUCTION PLUMBING MUST BE INSTALLED IN

ACCORDANCE WITH THE LATEST NATIONAL AND LOCA

L CODES,

Make sure users know where it is and how to use it in case o

f emergency.

IMPORTANT PUMP WARNING AND SAFETY INSTRUC

TIONS

TRUCTIO

E: STAND CLEAR OF PUM

START UP

erate under high pressure.

rculating system (i.e.

locking ring, pump, filte

r, valves, etc.) is serviced,

m and become pressurized.

Before servicing equipment, make note of the

filter pressure. Be sure that all

controls are set to ensure the system cannot ina

dvertently start

during service. Turn off all power to the pump.

IMPORTANT: Place filter

manual air relief valve in the open position

and wait for all pressure in the

Before starting the system, fully open the manua

l air relief valve and place all

system valves in the “open”position to allow wa

ter to flow freely from the tank

and back to the tank. Stand clear of all equipment

and start the pump.

o not close filter manual air rel

ief valve until all pressure

has been discharged from the valve and a s

teady stream of water

Observe filter pressure gauge and be

sure it is not higher than the

over, filter lid, and valves to

violently separate which can result in severe p

ersonal injury or death.

Filter tank lid and strainer cover must be prope

rly secured to prevent violent

separation. Stand clear of all circulation system

equipment when

•All work must be performed by a qualified

service professional, and must

conform to all national, state, and local codes

.

•Install to provide drainage of compartment for

electrical components.

•These instructions contain information for a v

ariety of pump models and

therefore some instructions may not apply to a

specific model. All models

ions. The pump and

therefore some instructions may not apply to a

specific model. All models

are intended for use in swimming pool applicat

ions. The pump will function

correctly only if it is properly sized to the spec

ific application and properly

r installed or used in

for which the pump was

intended can result in severe personal injury o

r death. These risks may

include but not be limited to electric shock, fire,

flooding, suction

caused by a structural

failure of the pump or other system componen

t.

high levels of suction within

the suction side of the p

lumbing system. These high

levels of suction can pose a risk if a person

comes within the close proximi

of the suction openings. A person can be s

eriously injured by

this high level of vacuum or may become tr

apped and drown. It is

absolutely critical that the suction plumbing

be installed in accordance

wimming pools.