BA_D8600_EN

4 / 13

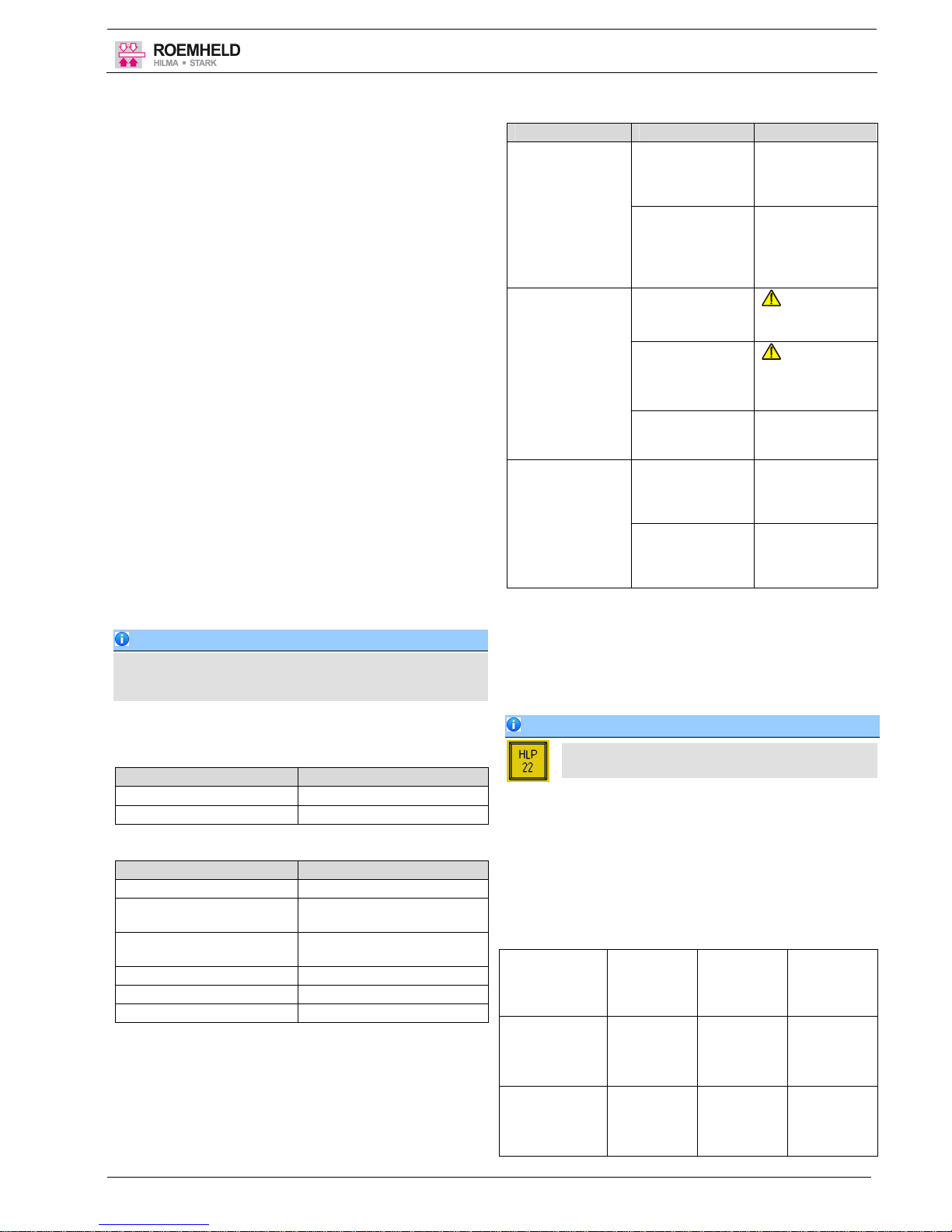

6.2 Misapplication

Pos: 12.5 /Warnung/AAA_ WARNUNG @ 12\mod_13 58317877485_12 319.doc@ 1 30104 @ @ 1

WARNING

Pos: 12.6 /Warnung/ AA Verletzung - Keine Modi fikationen am Produkt vornehmen. @ 1\m od_12112641871 11_12319.doc @ 1815 5 @ @ 1

Injuries, material damages or malfunctions!

• Do not modify the product!

Pos: 12.7 /Warnung/AAA_ ENDE @ 12\mod_13583180 66188_0.doc @ 130112 @ @ 1

Pos: 12.8 /Ver wendung/Allge mein/Besti mmungswi drige Ver wendung @ 3 \mod_12 58611534209 _12319.doc @ 40640 @ @ 1

The use of these products is not admitted:

• For domestic use.

• On pallets or machine tool tables in primary shaping and

metal forming machine tools.

• If due to vibrations or other physical / chemical effects dam-

ages of the products or seals can be caused.

• In machines, on pallets or machine tool tables that are used

to change the characteristics of the material (magnetise, ra-

diation, photochemical procedures, etc.).

• In areas for which special guidelines apply, especially in-

stallations and machines:

- For the use on fun fairs and in leisure parks.

- In food processing or in areas with special hygiene regu-

lations.

- For military purposes.

- In mines.

- In explosive and aggressive environments (e.g. ATEX).

- In medical engineering.

- In the aerospace industry.

- For passenger transport.

• For other operating and environmental conditions e.g.:

- Higher operating pressures than indicated on the data

sheet or installation drawing.

- With hydraulic fluids that do not correspond to the speci-

fications.

Pos: 12.9 /Verwendung /Allgemein/Besti mmungswidrig e Verwendung andere Dr uckflüssigkeiten @ 5\mod_12843712 89905_12319.do c@ 5 4218 @ @ 1

• With other specifications of the hydraulic fluids than the

ones approved below technical specifications.

Pos: 13 /------ ------ Spaltenumbruch ---- ------- - @0\ mod_1175587512 406_12319.doc @ 12332 @ @ 1

Pos: 14.1 /Überschriften/Tra nsport @ 2\mod_121732 2966174_12319.doc @ 208 84@ 1 @ 1

7 Transport

Pos: 14.2 /Gefahr/U mweltgefährlich, ausla ufendes Öl bei unsachg emäßen Transport @ 4\mod_1269349 511993_12319.d oc @4 7697 @ @ 1

Hazardous to the environment

During improper transit, escaping oil residuals can

lead to environmental pollutions.

Transport the product only in an upright position!

Pay attention to the sign on the packaging: "Top, do

not overturn".

Pos: 14.3 /Warnung/AAA_ WARNUNG @ 12\mod_13 58317877485_12 319.doc@ 1 30104 @ @ 1

WARNING

Pos: 14.4 /Warnung/ AA Verletzu ng- u mstürzendes Pro dukt - Transport @ 1\mod_12075 76318690_12 319.doc @ 15711 @ @ 1

Injury due to overturning product!

• Overturning product due to inappropriate means of trans-

portation.

• Do not stand below the load during lifting and lowering, stay

outside the danger zone.

• Use suitable means of transportation.

• Pay attention to the weight of the equipment.

• Pay attention that the product is safely located (centre of

gravity see instruction sign).

Pos: 14.5 /Warnung/AAA_ ENDE @ 12\mod_13583180 66188_0.doc @ 130112 @ @ 1

Pos: 14.6 /Gebotszeich en/Schutzausrüs tung tragen @ 4\mo d_1271410780776_ 12319.doc @ 483 11@ @ 1

For works at and with the product, wear suitable

protection equipment!

Pos: 14.7 /Transport/0 60H ydraulik-Druc kerzeuger/Allge mein/Beschreibu ngTr ansport Druckerz euger in Karton @ 4\mod _1269345306570 _12319.doc @ 47691 @ @ 1

The product is delivered in a solid carton box (on a throw-away

pallet) and may only be transported to the installation site by

means of a corresponding conveyor (pay attention to the min.

lifting force).

The product must only be lifted down from the transport pallet

by means of a conveyor, the product must centrally rest on the

two fork rakes e.g. of the fork-lift truck.

Pos: 15 /------ ------ Spaltenumbruch ---- ------- - @0\ mod_1175587512 406_12319.doc @ 12332 @ @ 1

Pos: 16.1 /Überschrift en/Montage @ 0\mod _11755880918 12_12319.doc @ 12337 @ 1 @1

8 Installation

Pos: 16.2 /Gefahr/AAA_GEF AHR@ 1 2\mod_135850 7477815_12319.doc @ 130 327 @ @ 1

DANGER

Pos: 16.3 /Gefahr/AA Gefahr durch uner wartetenA nlauf @ 5\mod_1 28436854944 9_12319.doc @ 54181 @ @ 1

Unexpected start of the connected cylinders when switch-

ing on the power units!

• When switching on, the operating pressure will be gener-

ated and in the process the cylinders can move!

• Secure the working area adequately!

Pos: 16.4 /Gefahr/AAA_EN DE @ 12\mod_135850714 2413_0.doc @ 130300 @ @ 1

Pos: 16.5 /Warnung/AAA_ WARNUNG @ 12\mod_13 58317877485_12 319.doc@ 1 30104 @ @ 1

WARNING

Pos: 16.6 /Warnung/ AA Verletzung - Kundenseitig Schutzvorric htung vorsehen @ 4\mo d_127720935 9408_12319.doc @ 500 70@ @ 1

Injuries caused by missing safety devices!

• To avoid injuries appropriate safety devices must be pro-

vided by the customer.

Pos: 16.7 /Warnung/AA Verletz ung- Hoc hdruckinjektion - Unsachg emäßer Anschluss mit Hydrauli kanschluss @ 0\mod_1181641 972765_12319. doc@ 1257 6@ @ 1

Injury by high-pressure injection (squirting out of hydraulic

oil under high pressure)!

• Improper connection can lead to escapes of oil under high

pressure at the connections.

• Mounting or dismounting of the element must only be made

in depressurised mode of the hydraulic system.

• Connection of the hydraulic line as per

DIN 3852/ISO 1179.

• Unused connections have to be locked professionally.

• Use all mounting holes.

Pos: 16.8 /Warnung/ AA Vergiftung - durch Kont akt mitH ydrauli köl!@ 1\m od_120763403 2554_12319.doc @ 157 40 @ @ 1

Poisoning due to contact with hydraulic oil!

Wear, damage of the seals, ageing and incorrect mounting of

the seal kit by the operator can lead to escapes of oil.

Incorrect connection can lead to escapes of oil at the ports.

• For handling with hydraulic oil consider the material safety

data sheet.

• Wear protection equipment.

Pos: 16.9 /Warnung/AAA_ ENDE @ 12\mod_13583180 66188_0.doc @ 130112 @ @ 1

Pos: 16.10/ Gebotszeichen/ Schutzausrüstung trage n@ 4\ mod_1271410780 776_12319.doc @ 48311 @ @ 1

For works at and with the product, wear suitable

protection equipment!

Pos: 16.11/Hi nweis/AAA_H INWEIS @ 12\mod_1358 508459726_12319.d oc@ 1 30355 @ @ 1

Note

Pos: 16.12/Hi nweis/AA Pneu matik Versorgung @ 5\mod_128 8867333438_12319. doc @ 56922 @ @ 1

Pneumatic supply

When connecting the product to the pneumatic supply line, the

hydro-pneumatic pump unit starts to deliver.

Pos: 16.13 /Hinweis/ AA Lufthydraulische n Spannpumpe ein Ha nd-Absperrventil zu i nstallieren @ 5\mod_12 88696562839_1 2319.doc @ 56725 @ @ 1

Note

We recommend to install a hand-operated shut-off valve just in

front of the hydro-pneumatic pump unit. By this valve the hydro-

pneumatic pump unit can be quickly switched off in case of

emergency or for maintenance works.

Pos: 16.14/Hi nweis/AAA_ ENDE @ 12\mod_13585071 78129_0.doc @ 130318 @ @ 1

Pos: 16.15/Ü berschriften/Ü bersicht der Komponenten @ 4\m od_12677129805 91_12319.doc @ 46724 @ 2 @ 1