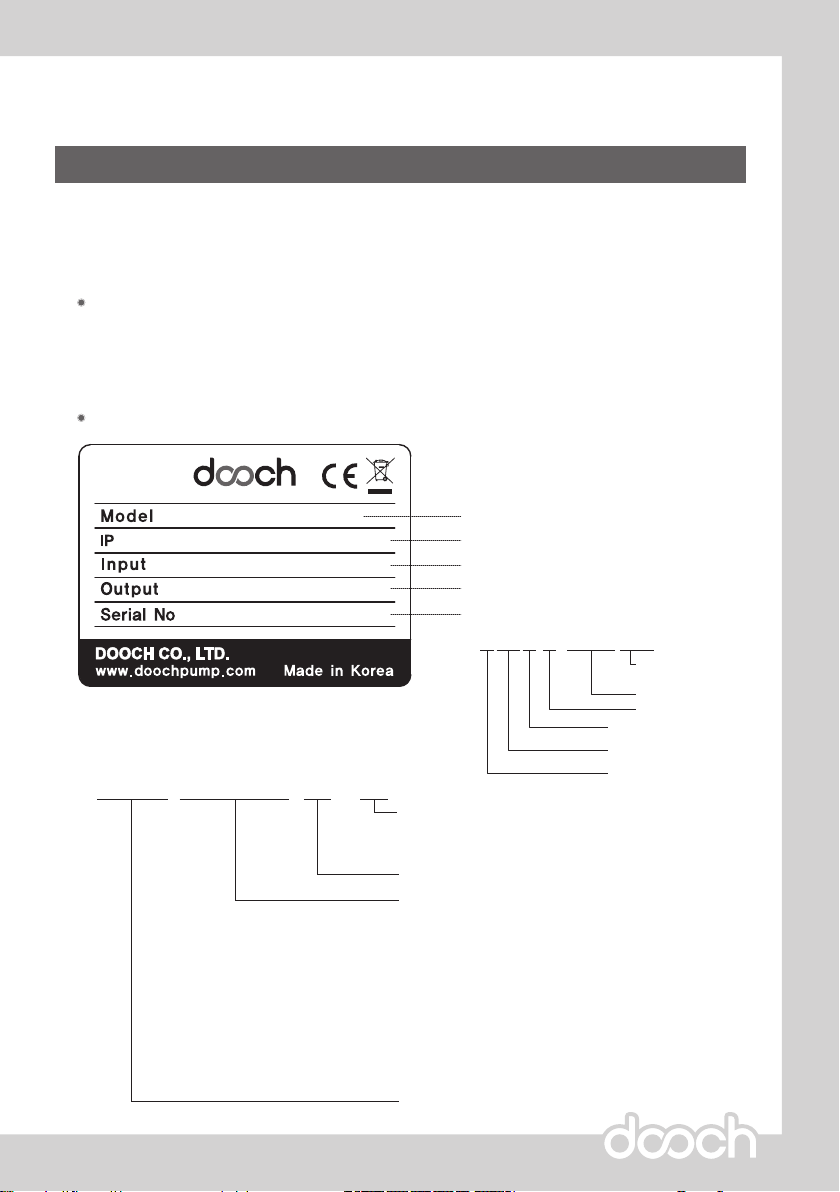

Safety Instructions

Cautions for Use

A. Transportation and Installation

Be sure to carry VFD in a proper way suitable for its weight, or it may result in damage to the VFD.

Be sure to use heat-treated wooden crate when you adopt wooden packaging for the product.

Do not pile up VFD's above allowable limit.

Be sure to install the VFD as directed in this instruction manual.

Do not turn off the power supply to the damaged VFD.

Do not open the front cover while carrying the VFD.

Do not place the heavy material on the VFD.

The direction of installation should be observed properly as criterions specified in this manual show.

Make sure that you should not put screw, metal material, water, oil and the inflammable something else.

Keep in mind that the VFD is very vulnerable to drop from the mid air and strong shock.

Don't let the inverter exposed to rain, snow, fog, dust, etc.

Do not cover, nor block, the ventilating system having cooling fan. It may cause the VFD overheated.

Be sure to check the power is off when installing the VFD.

To prevent the risk of fire or electric shock, keep the connected wire in a sound condition.

Use the wire that meets the standard in a recommended length.

Grounding class3 (for 200V class) / Grounding class special 3 (for 400V class) are required for drives.

B. Wiring

A professional installer should have done the wiring and checking.

Do wiring after installing the VFD body.

Do not connect phase-leading capacitors, surge filter, radio noise filter to the output of the VFD.

Output terminals (terminals named U, V, W respectively) should be connected in a proper phase sequence.

Make sure that there is not any short circuit terminal, wrong wiring. It may cause spurious operation

or failure.

Refrain from using a cable other than the cable shielded when you connect control circuit wiring.

Adopt the shielded wire only when wiring the control circuit. It may cause the failure of the VFD in its

operation.

Use the twisted pair shield wire for the ground terminal of the VFD.

Do not install the earth leakage breaker to the input of the VFD.

In case you have any problem or question, please contact us or our agents.

Installation Location Free of corrosive gas, inflammable gas, oil sludge and dust, etc

Temperature/Humidity -10 ~ 40℃/ Below 90% RH (Dewdrop should not be formed)

Storage Temperature -20~65℃

Elevation/Vibration Altitude 1,000m or lower / below 5.9m/sec²(=0.6g)

Ambient Atmospheric Pressure 70~106 kpa

5