Safety

Operation

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

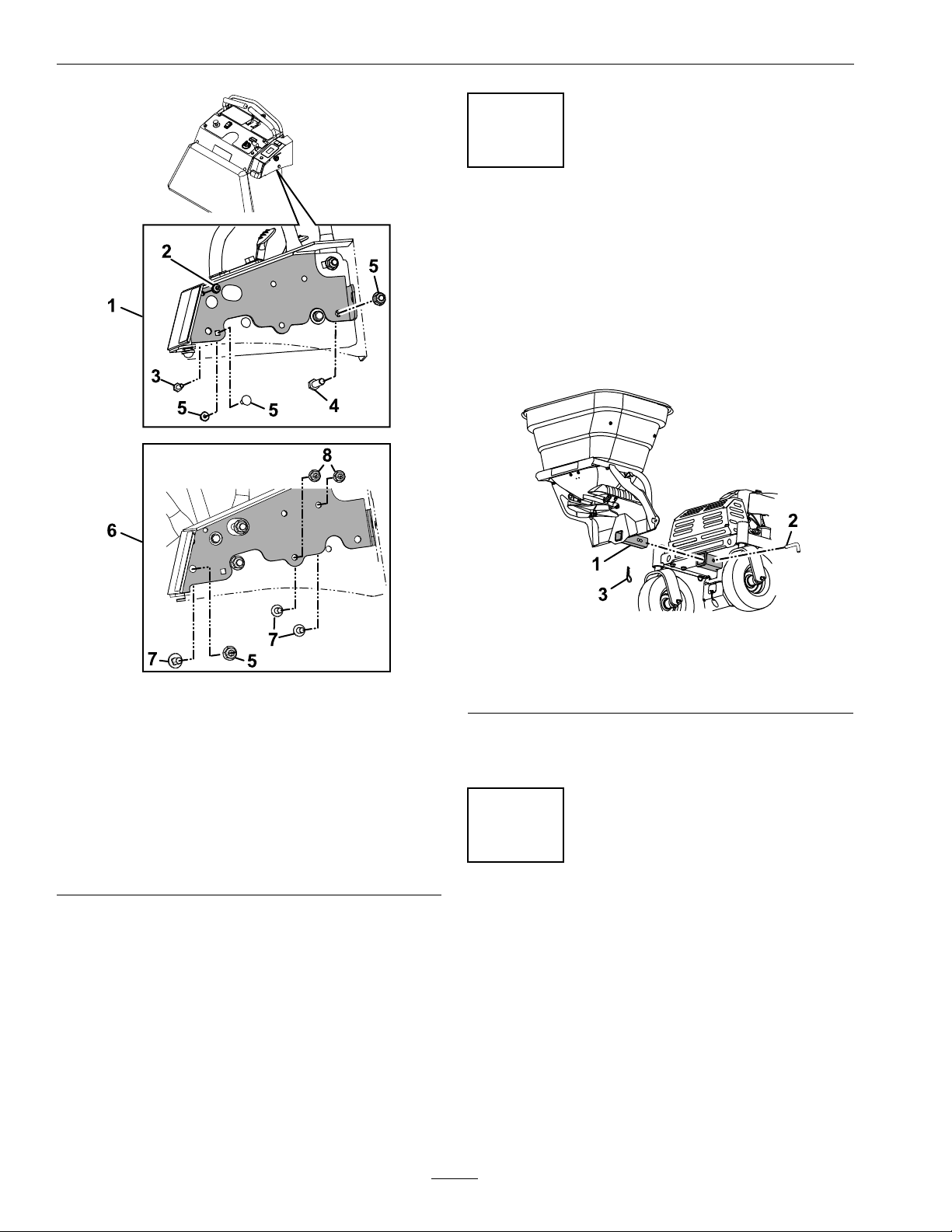

•DoNotoperatethemachinewithoutguards,

shields,andsafetydevicesinplaceand

workingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Operateonlyindaylightorgoodarticiallight,

keepingawayfromholesandhiddenhazards.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

DoNotoperatethemachine;seekshelter.

•Beawareofweatherconditionsandcheckthat

spreaderpatternsandvolumearesuitable.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Parkmachineonlevelground.Stopengine,wait

forallmovingpartstostop,removekeyand

engageparkingbrakewheneveryouleavethe

machine.

•Stopspreadingwhenmakingtightturnsto

minimizeunevendistributionpatternand

applicationrate.

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningoftheunit.

•Materialloadscanshift.Thisshiftinghappens

mostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingover

roughsurfaces.Shiftingloadscancausetheunit

totipover.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientstoppingdistance.

Useextracautiononslopes.

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthemachinetobecomeunstable.

•Heavyloadsaffectstability.Reducetheweightof

theloadandyourspeedwhenoperatingonhills.

MaintenanceandStorage

•Closethespreadergate,settheparkingbrake,

stopengineandremovekeyordisconnectspark

plugwire.Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Emptythehopperbeforetiltingunitfor

maintenanceandbeforestoring.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththe

engineand/ortheimpellerrunning.

•Keepallguards,shieldsandallsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,traction,

andsafetyofthemachine.Failuretouseoriginal

Exmarkpartscouldcauseseriousinjuryor

death.Makingunauthorizedchangestothe

engine,fuelorventingsystem,mayviolateEPA

andCARBregulations.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,tines,andfuelsystemcomponents

withoriginalExmarkparts.

6