SD - 1000

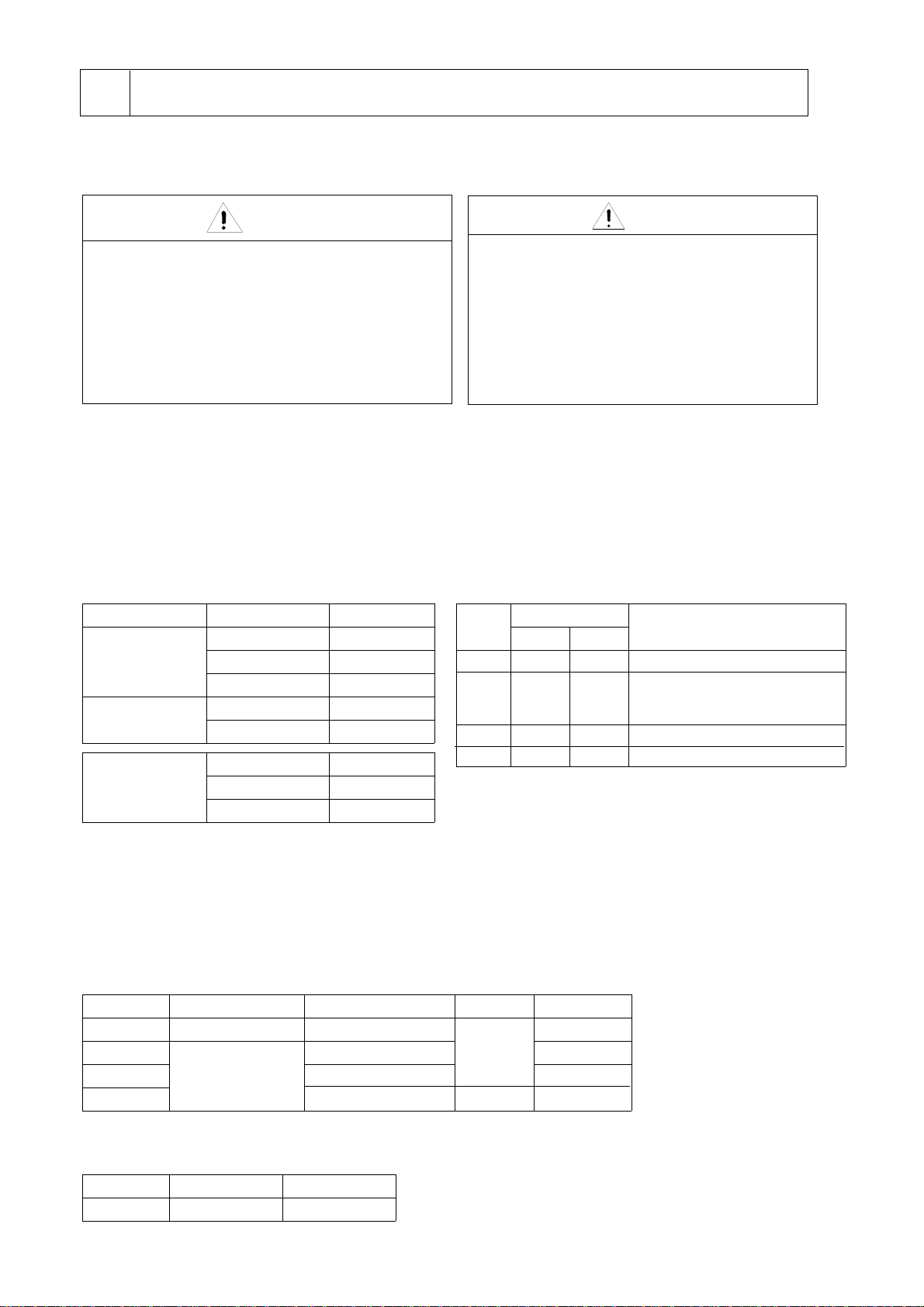

Max 1500ml/h

40 ~ 200°C

±1°C

Digital display 1 ~ 250°C

Digital display 1 ~ 250°C

Digital display 0.2 ~ 0.95m3/min

Digital display 10 ~ 300 kPa

PID control, zero cross output

Pt 100Ω

Pt 100Ω

3 kW, SUS 316

0 ~ 10 mV (at 50 ~ 250 °C)

0 ~ 10 mV (at 50 ~ 250 °C)

0 ~ 10 mV (at 0 ~ 1 m3/min)

150 ~ 1700 ml/h (Usable tubing : ID3.15mm x OD5.2mm

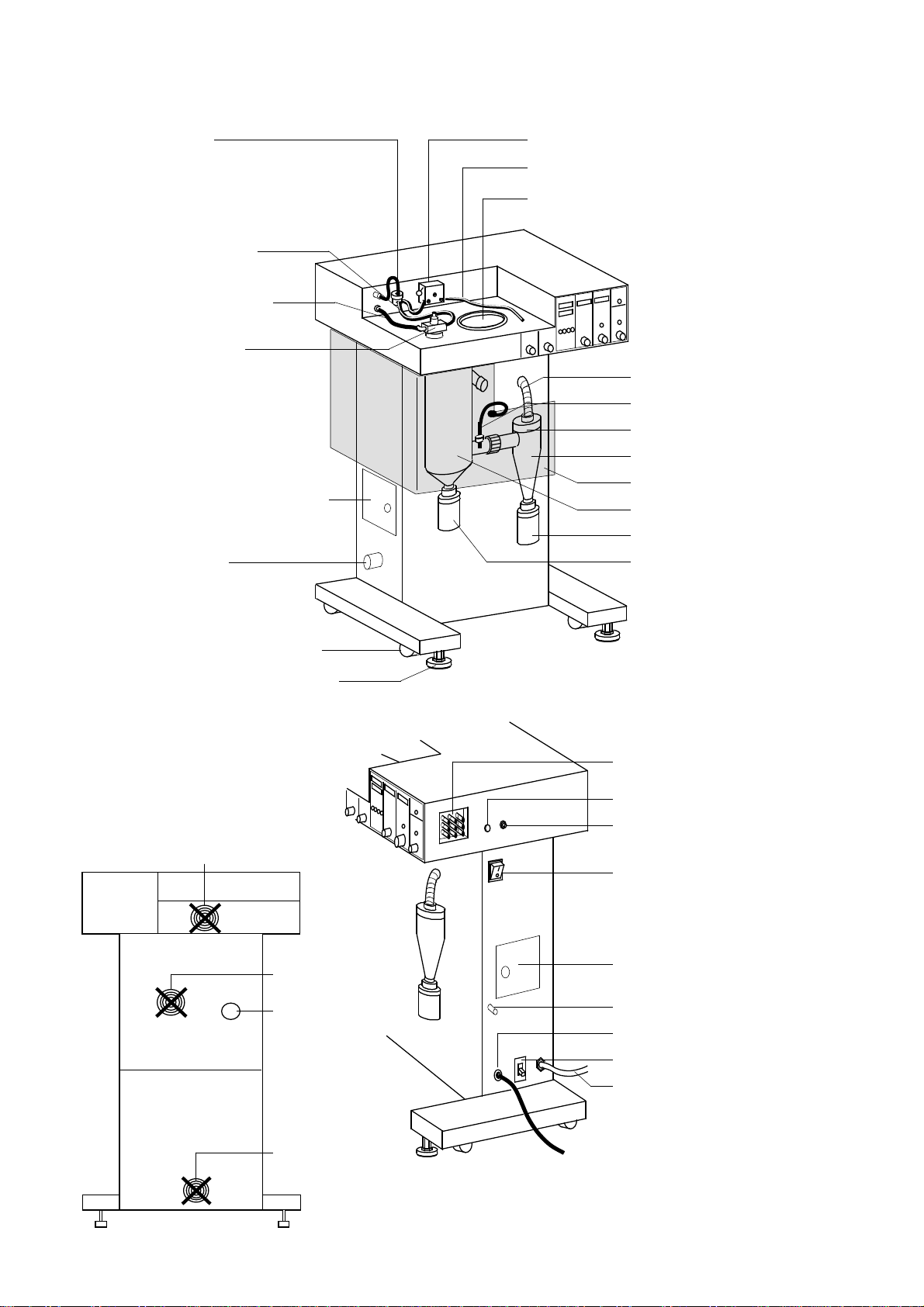

700W x 620D x 1500H mm

Pressure : 294 kPa (3 kg/cm2), Flow rate : 25L/min or more

OD 50 mm

Double fluid nozzle (outlet size for sample : ø0.71mm)

Jet cleaner

Automatic (Interval timer setting : OFF or 1 ~ 20min. / Manual

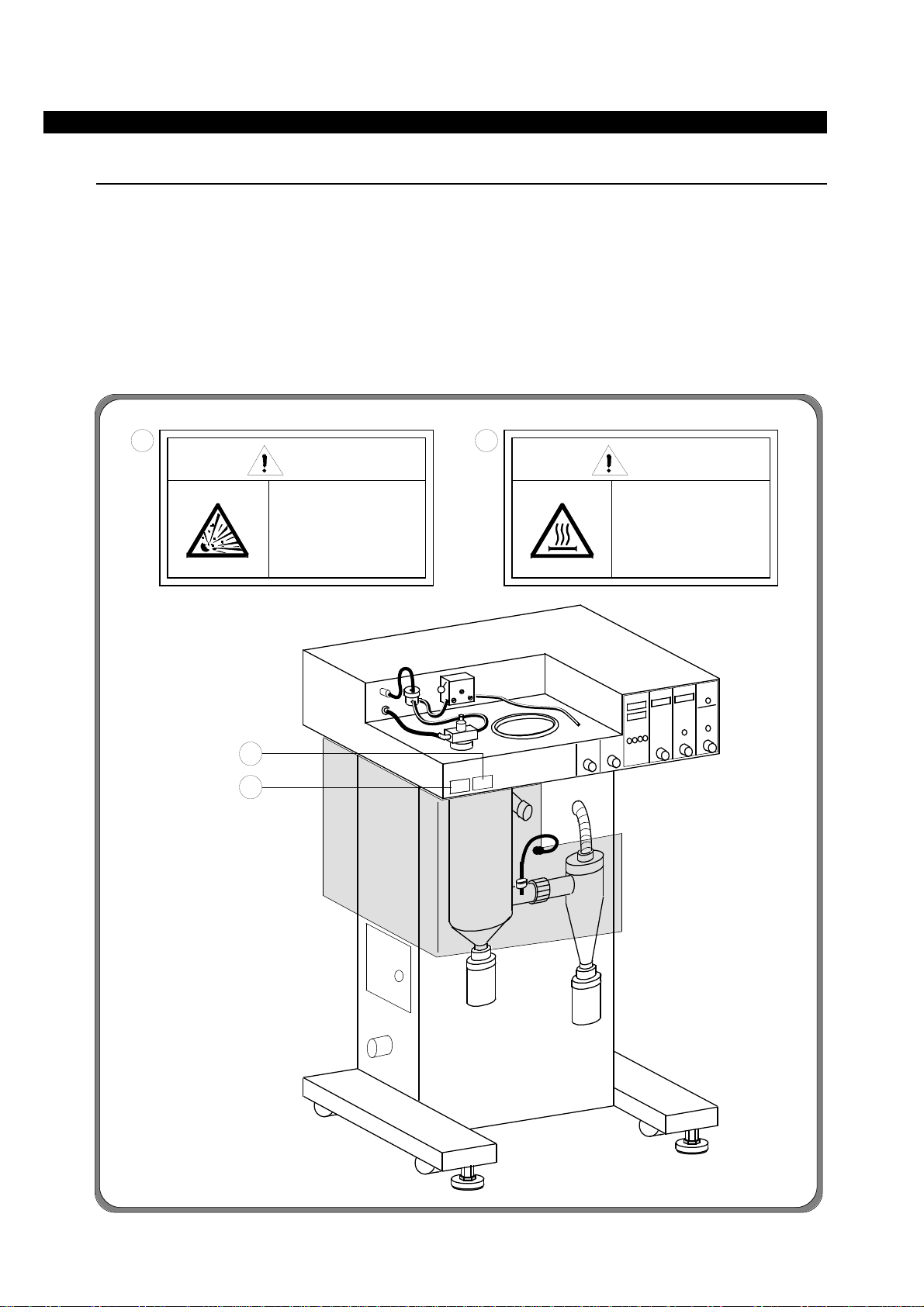

Temperature alarm, Sensor alarm, Upper limit alarm for outlet temperature,

Air flow alarm, Heater alarm, SSR alarm, Pump line pressure alarm,

Spraying pressure alarm)

49 ~ 245 kPa (0.5 ~ 2.5 kg/cm2)

5 ~ 35°C

Excess current, power breaker, over temperature protector, manual recovering

after power failure

100 ~ 1000 rpm ( Rotation speed is changeable by volume knob)

0.2 ~ 0.75 m3/min ( Flow rate is changeable by control knob)

21 A, 4.2 kVA

AC 200 V Single phase, 50/60 Hz

110 kg

ID4 mm x OD6 mm (Soft urethane tube union)

−3−

2-3 Specifications

Spray dryer

Model

Evaporating rate

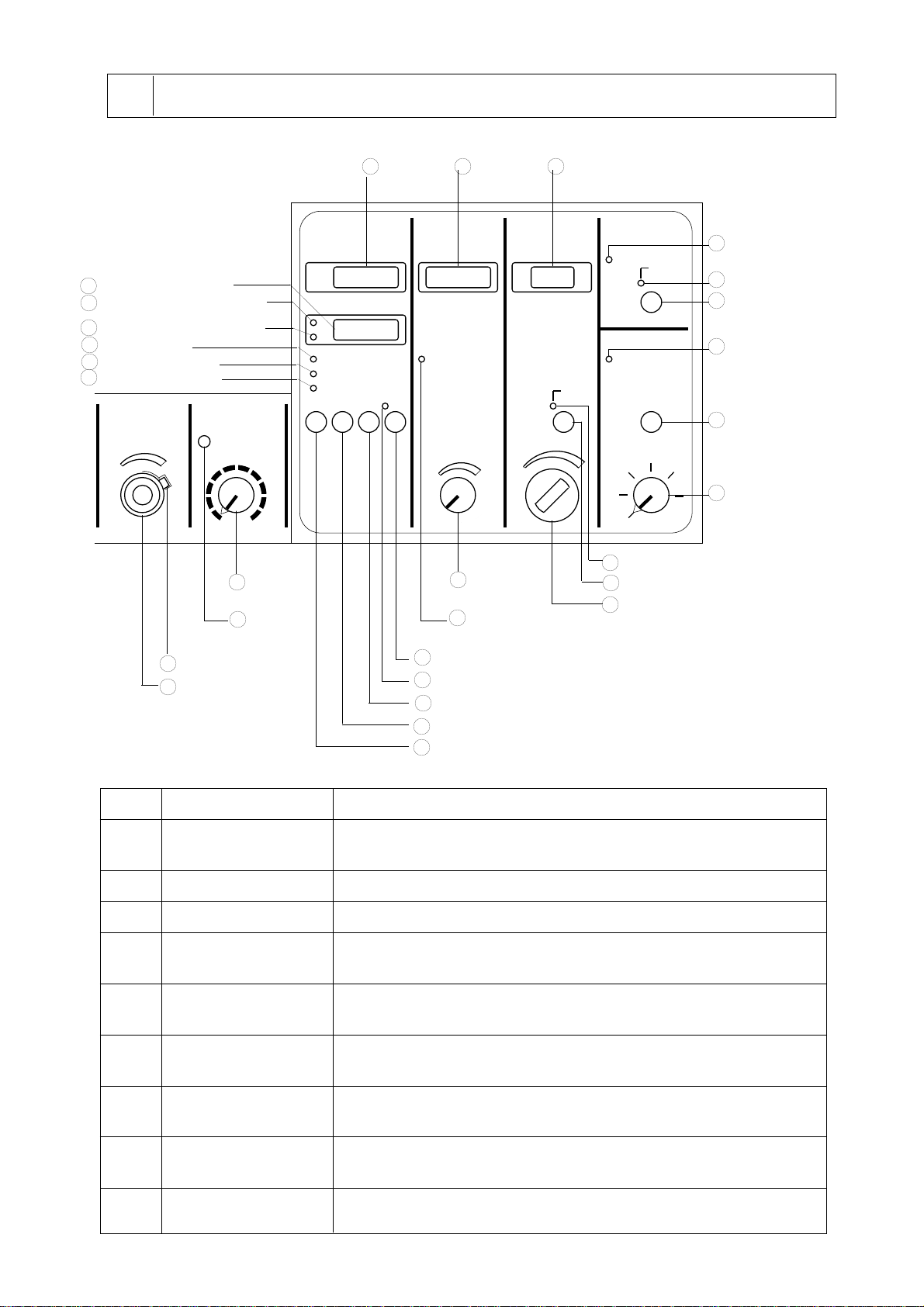

Inlet temp. control range

Inlet temp. control accuracy

Drying air flow rate control range

Spraying air press. control range

Flow rate control range

Stirring speed control range of

source liquid

Inlet temperature display

Outlet temperature display

Drying air volume display

Spraying pressure display

Temperature controller

Inlet temperature sensor

Outlet temperature sensor

Heater wattage and material

Inlet temp. recorder output

Outlet temp. recorder output

Drying air volume output

Spray nozzle

Spraying air line

Automatic cleaning system

Safety feature

Alarm function

Spraying air connection port size

Spraying air pressure

Exhaust port size

Ambient temperature range

Overall dimensions

Net weight

Power consumption

Power source