Outline of the product

2

2-1 Use application

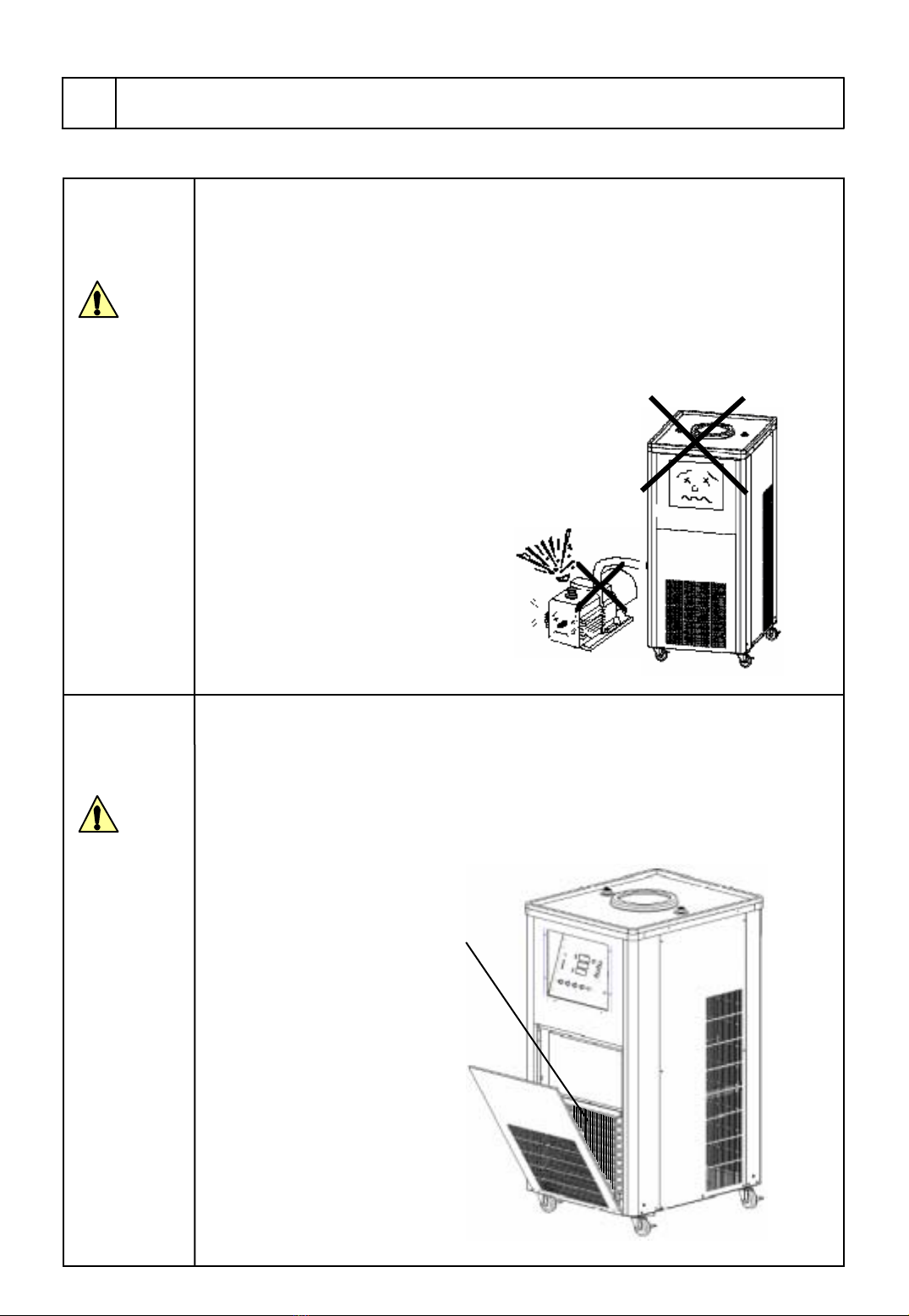

Do not remodel the product.

Do not use it out of intended application.

Remodeling or using the product out of intended

Application may cause electric shock or

malfunction.

WARNING This product can be used for drying dilutional solution

such as protein, enzyme or extraction solution of biological

sample, or biogenic sample such as urine, blood serum and

etc.

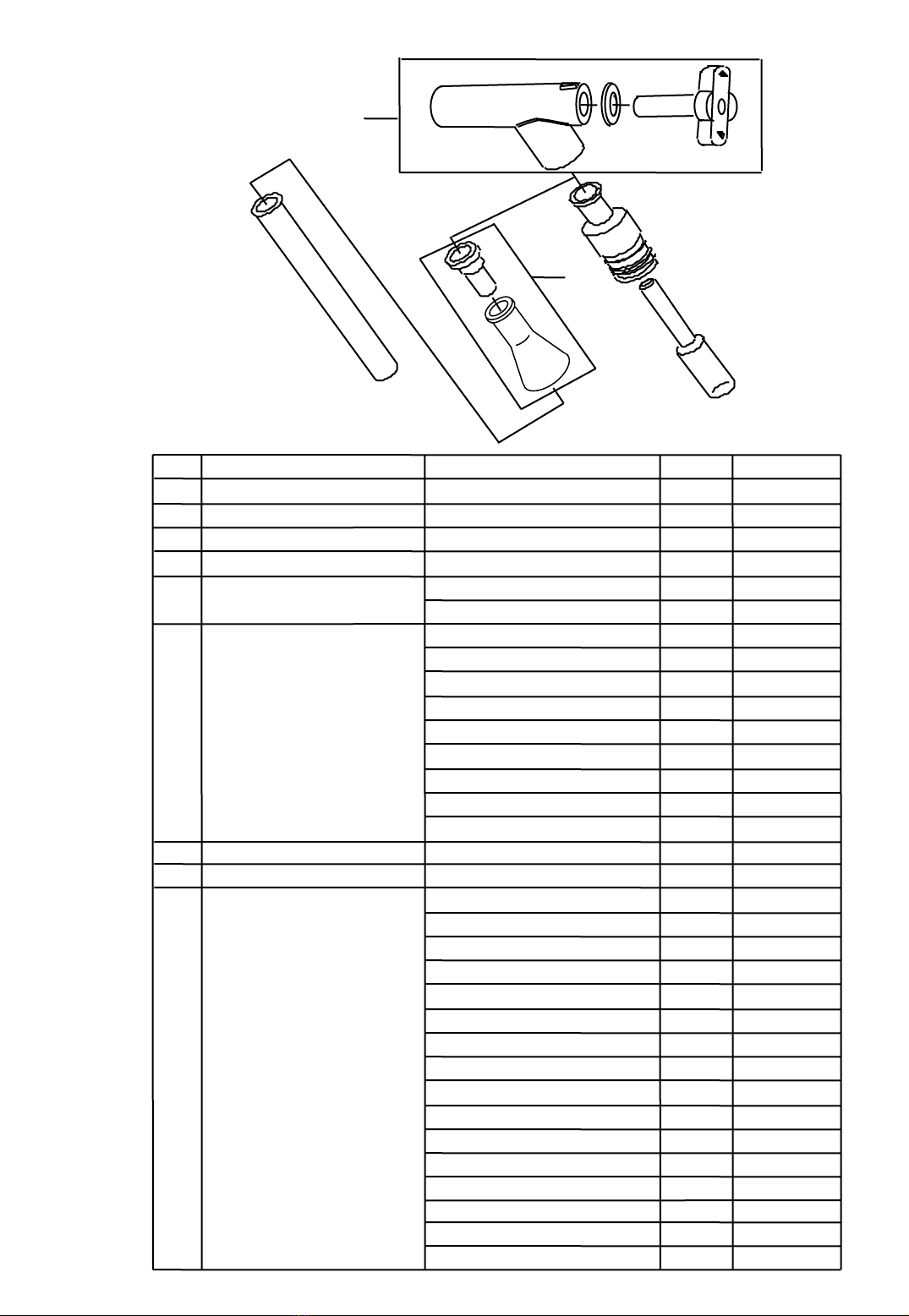

2-2 Specification

Pirani gauge

Digital display 0.0〜533.3Pa

Recorder output Trap temperature 1℃/1mV Vacuum degree 1Pa/1mV

Voltage

Rated supply AC100V±10%、50/60Hz

Features

C

O

N

F

I

G

.

Model

Refrigerator(Output)

Service outlet

S

P

E

C

.

Mass

Product name

F

U

N

C

I

T

I

O

N

S

Refrigerant

Range of available ambient temperature

Freeze dryer

FDU‑2200

Trap cooling temp.

Dehumidifying amount

Trap defrosting function

Trap measurement (mm) material

Vacuum gauge

Defrosting by hot gas

153(Bore diameter)×225(Height)、SUS304

External measurement(mm)

−80℃

1 ℓ/Time

400W × 2

5〜35℃

450(W)×550(D)×935(H)

Approx.67kg

Cooling system Cooled into drum-shaped container

※1

Required displacement of vacuum

pump More 50/60L/min(50/60Hz)(option)

Other functions Vacuum pump control, display of the availability of freeze drying,

display of vacuum pump operation time,

Stop watch function, selecting power recover function,

Detecting abnormal vacuum degree(fixed value), Protection timer for

refrigerator

Displaying accuracy at 0.4〜4.0Pa ±2.0Pa

at 4.1〜10.0Pa ±3.0Pa

at 10.1〜15.0Pa ±4.0Pa

at 15.1〜40.0Pa ±7.0Pa

HFC(R404A)(Primary refrigerator)+R23(Secondary refrigerator)

For vacuum pump(Max.6A )For dry chamber(Max.2A )

AC100V 12A

※2

※3

※1.Measured in the following condition; ambient temperature:20℃, NO load

※2.Protruding portion is not included.

※3.Capacty of service outlet is not included.

‑2‐