5

3. Safety and Control Instructions

The recommended maintenance procedures will

depend on the hardness of your water supply

and it is good practice to establish these routine

instructions on a weekly basis and then adjust the

frequency as your conditions indicate.

• Only qualified staff, who understand all

operating and safety procedures may operate the

Shower Panel.

• Always physically check water temperature

before and during showering and that the

thermoscopic mixer functions properly.

• Read the separate product manual for

calibrating the thermostat.

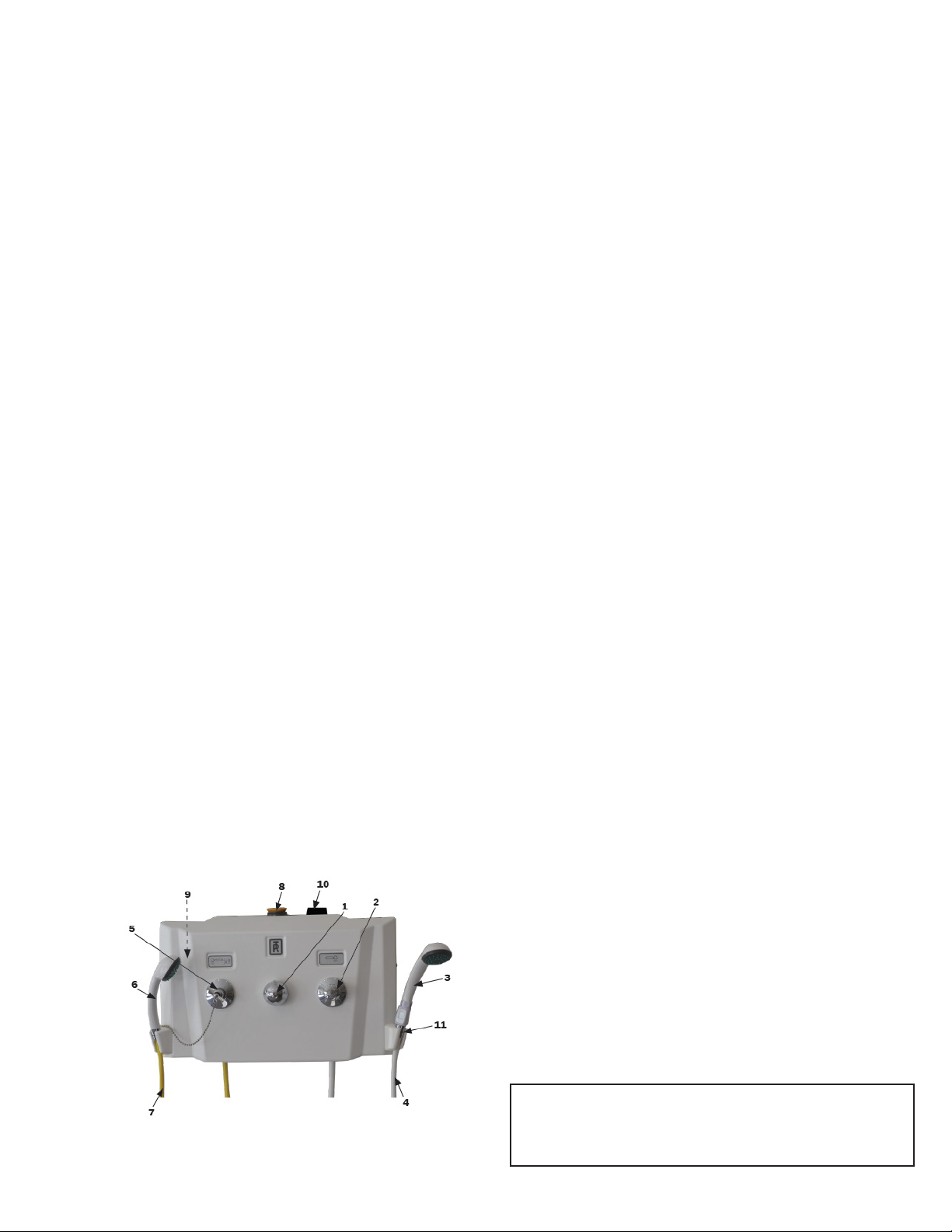

• Make sure that both valves (2 and 5) on the

front of the Panel are closed after each use.

• Make sure that the bottle (8) is filled with

concentrated cleaning detergent before

cleaning.

• Do not use solvent based cleaning liquids,

iodine based detergent, bromine or methylene

blue or a nonabrasive type cleaner.

• Do not use any cleaning detergent containing

more than 40 % of alcohol.

• After cleaning, rinse with fresh water.

• Clean the strainers on the patient and cleaning

shower heads in hot water and rub it with your

thumb.

• Make sure that hoses, controls, connections and

mixer are free from damages.

• Shower Panel should not be used if defects are

noticed. Prompt service is required.

4. Installation Instructions

Plumbing rough - In

All pipes, fittings, backflow preventors, vacuum

valves, shut-off valves and connections to panel

to be supplied and installed by others to comply

with local building and plumbing codes. The

manufacturer refers to the European standard EN

1717. To prevent backflow, any bathtub, toilet chair

or similar product may not be installed within reach

of the patient shower hose.

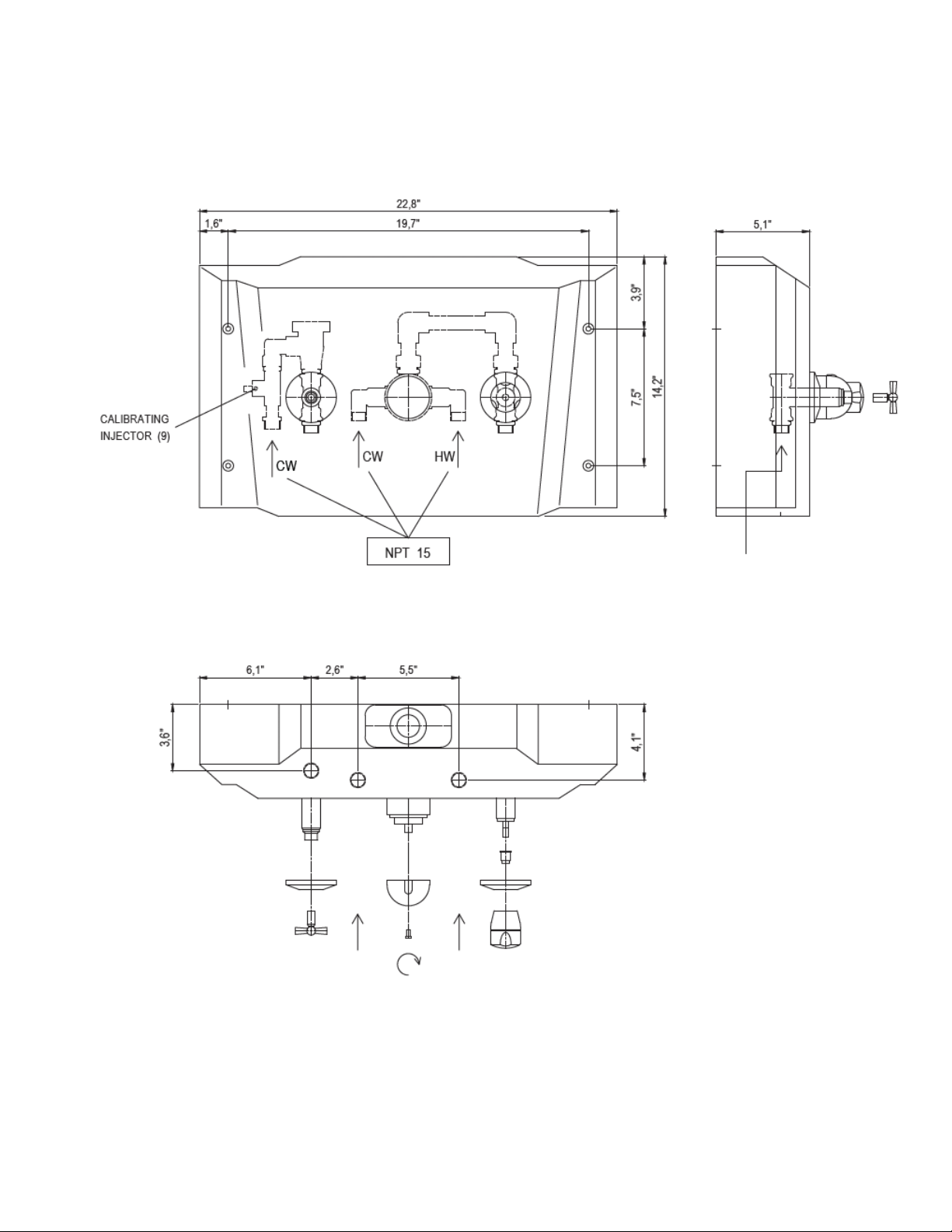

The patient shower system has a Rada 215-t3 oem

thermostat, a main valve on the panel front and a

shower handle without on/off trigger.

The Rada 215-t3 oem thermostat has built in filters

and check valves and is factory set to give maximum

38 degrees Celsius. The thermostat shall be installed

to R15 (½”) cold and hot water supply.

We refer to the enclosed Rada 215-t3 oem

thermostat product manual.

The yellow cleaning shower (for cleaning

equipment only) has a main safety valve on the

panel front and a cleaning handle without on/off

trigger.

The cleaning shower shall be installed to a R15

(1/2") cold water supply and if demanded, to a

separate “class A tank”.

The concentrated cleaning liquid is preset to give

about 2 % mixture in the cleaning shower and

the cleaning bottle shall be filled by the cap. See

operating manual.

To eliminate pipe debris it is essential that the hot

and cold supply pipes are thoroughly flushed before

connection to the shower panel.

Recommended mounting height from floor 47".

Important: this product manual is the property of

the customer and must be retained with the product

for maintenance and operational purposes.