FAAST 8251BPI and 8100

INSTALLATION AND MAINTENANCE INSTRUCTIONS

1

TABLE OF CONTENTS

Document Colour Code Key: (refer to Page 24)

Black: applies to both 8251BPI and 8100 Devices

Orange: applies to 8251BPI FAAST XM Only

Green: applies to 8100 FAAST XM Only

SPECIFICATIONS:

Electrical Characteristics

External Supply Voltage 18 –30VDC

Remote Reset Time External monitor must be pulled low for a minimum of 100msec.

Power Reset 10 secs (FAAST 8251BPI); 1 sec (FAAST 8100)

Average Operating Current 500mA @ 24VDC

Alarm Current 650mA –All relays active, all alarm levels displayed. Voltage @

24VDC

Average Loop Driver Operating Current: 700uA

Loop Driver Voltage Range: 15 –32VDC

Relay Contact Ratings 3.0A @ 30VDC, 0.5A @ 125VAC

Environmental Ratings

Operating Temperature 0°C to 38°C (32°F to 100°F)

Sampled Air Temperature -20°C to 60°C (-4°F to 140°F)

Humidity 10 to 95% (non-condensing)

IP Rating IP30

Coverage Area 1000m2(8,000ft2)

Air Movement 0 - 1,219.2 m/min. (0 –4,000 ft./min.)

Mechanical Characteristics

Exterior Dimensions 337 x 330 x 127 H x W x Dmm

Cable Access 4 x 25.4mm cable entry holes on top and bottom of unit.

Wire Gauge 2.0mm (12 AWG) max to 0.5mm (24 AWG) min.

Shipping Weight 5.26 kg, includes packing material

Nett Weight

Pipe Network Size Up to 1000m2

Maximum single pipe length 80m

External pipe diameter 25mm

Internal pipe diameter 15 - 21mm

Specifications:…………………………………………1

Introduction:……………………………………………2

Scope of this Manual……………………………….2

Description:………………………………………….…2

Features……………..………………………………2

Items Included with Unit.........…………………….2

Installation:.…………………………………………....2

Pipe Installation..…..……………………………….2

Physical Unit Installation........………………….....2

Securing the Mounting Bracket……………….2

Mounting the Detector to the Bracket………..3

Connecting the Air Sampling Pipe..…………. 3

Exhaust Pipe……………..……………………. 3

Wiring........……………………………………...…..3

Power Cables…………………………….……. 3

Conduit Usage………………………………….3

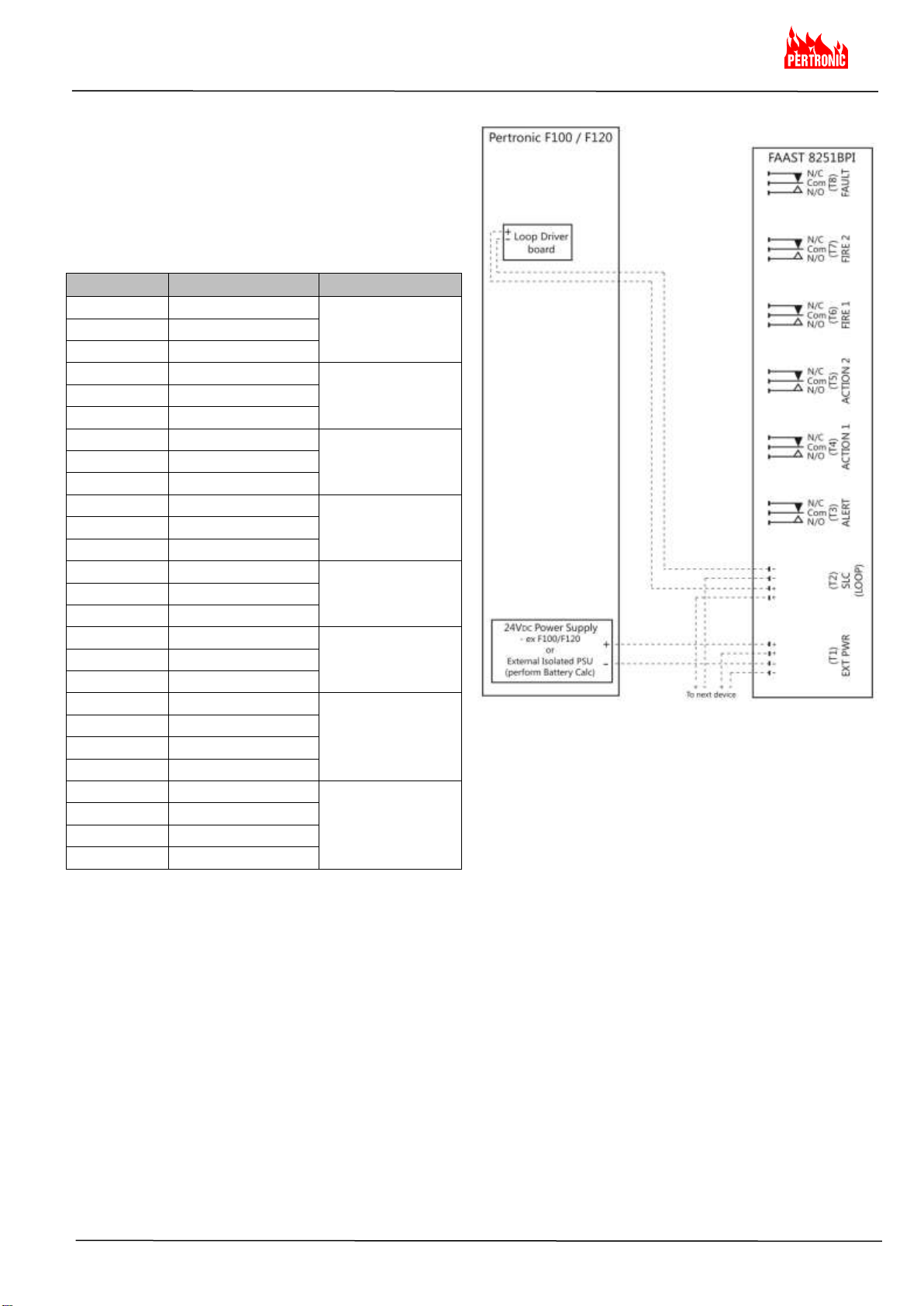

FAAST 8251BPI Cabling Requirements…….......4

FAAST 8251BPI System Powering…….……..….4

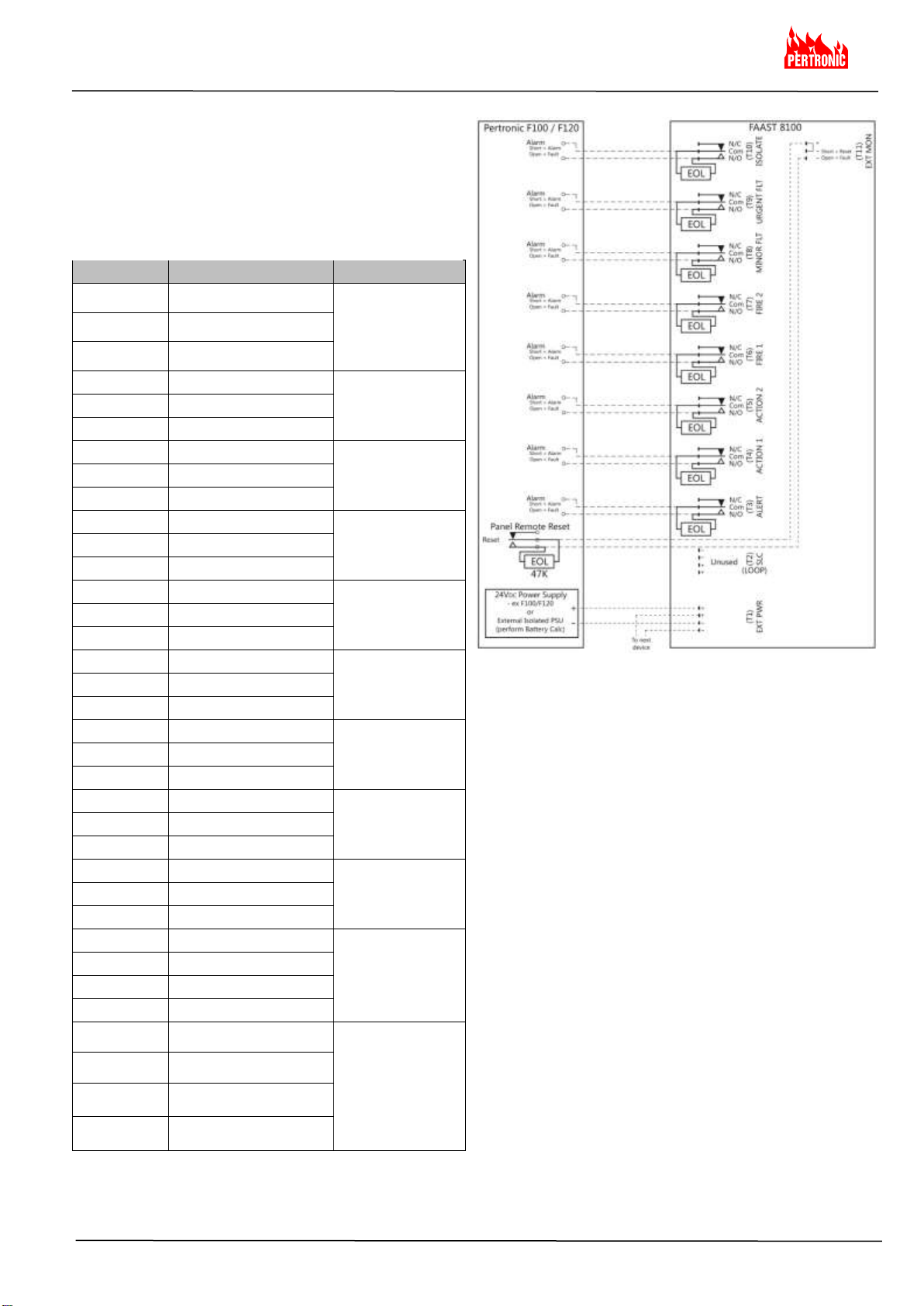

FAAST 8100 Cabling Requirements…….……….5

FAAST 8100 System Powering …………….…. 5

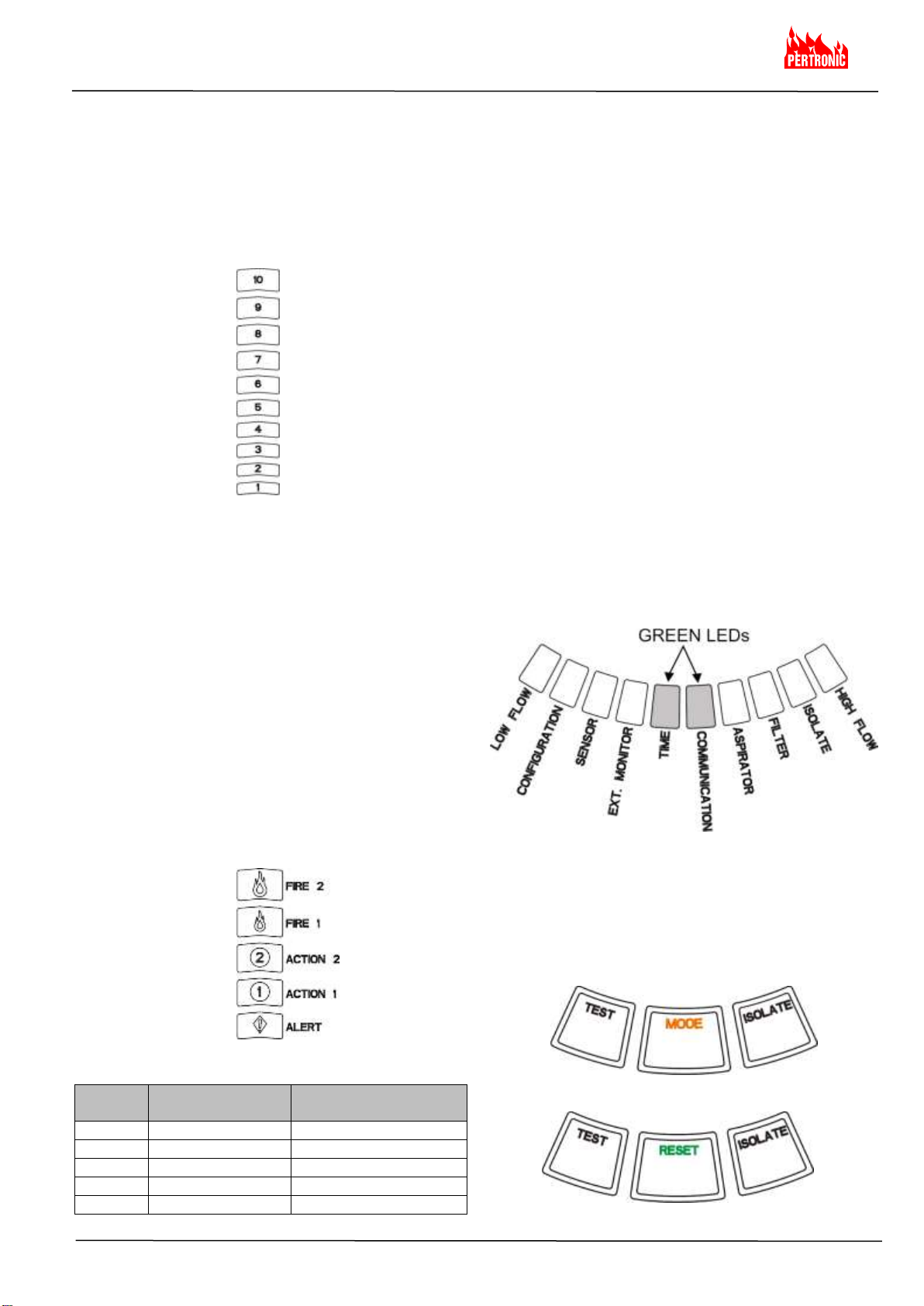

User Interface:.…..………………………………….... 6

FAAST 8251BPI User Interface……….………….6

FAAST 8100 User Interface……………………….6

User Interface Card Installation……………....…..6

Particulate Level Display…………………..….......6

Alarm Level Display ……………………..……..….7

Alarm Level Programmable Ranges……..…. 7

Air Flow / Fault Display……..…………..……..…. 7

Labels………………………………..…………. 7

User Interface Buttons….………………………….7

Modes of Operation:……..………….…………….... 8

Initialisation…………………………...….………….8

Startup……………………………………………….8

Configuration…………………………………....…. 8

Normal Mode………………………………..….......8

Test Mode………………….……………..……..….8

Reset Mode…………..……………...….…………. 8

Acclimate…………………………………………….9

Setting Acclimate Mode………………………. 9

Day, Night and Weekend Mode……………....…..9

Isolate………………………………………..….......9

Disable………….………….……………..……..…. 9

User Button Alternate Functions…..…………….10

Passcode Access……………….…………….10

Address Blink Mode….……………………….10

IP Address Blink Mode……………………….11

Real-Time Clock..…..………………………..……11

Logs........………………………………………......11

Event Log…………………………………..….11

Data Trend Log…………….………………....11

Message Log………………………………….11

External Monitor / Reset…………………...….. 11

Ethernet Connection………………………....... 11

Faults…….…………………………………...…. 12

Pipe Network.…………………………………..… 13

Web Server………………………………….….…13

Email Notification…….………………………..….13

Canned Smoke Tests…………………………….13

Maintenance……………...............................…..13

FAAST XM Detector Base……..…………....…..13

Glossary:…………………..………….……………....14

Key Terms………………………...….……..……. 14

Document Colour Code Key………………….. 14

FAAST System Validation Form….…………….... 15