Preparation

Page 9

Advanced Preparations:

Be familiar with the controls of the range hood by reading

through Range Hood Operations,Page 12.

Place the range hood on a at, stable surface. Connect the

range hood to a designated standard outlet, 110~120V/60Hz

(220~240V/50Hz for Europe & other countries), AC only

and turn on the range hood. Verify all operations of the

range hood by referring to Range Hood Operations, Page

12.

Place all supplied parts and required hardware on a at, stable surface and verify the existence of all sup-

plied parts listed on Page 4.

Carefully remove the white plastic protective coat from the chimney covers and range hood.

Preparations:

Determine and mark the center line on the ceiling where the range hood will be installed. Make sure there is

proper clearance within the ceiling or wall for exhaust vent.

Due to the weight and size of this unit, please make sure that the support system or framework being used is

stable and secure in the wall.

Put a thick, protective covering over counter top, cook top or range to protect from damage or dirt. Remove

any hazardous objects around the area when installing.

Mark the locations of the support mounting bracket holes, vent cutout (if used) and power supply cable cut-

out on the ceiling. Use drill and saber saw or keyhole saw to cut openings for power supply cable and vent

(see Venting requirements and Electrical requirements, Pages 5-8).

If venting to the outside install vent system (see Venting Requirements, Page 5). Use caulking to seal exte-

rior wall or roof openings.

Disconnect main electrical supply, prepare and run electrical wiring through ceiling or wall. Leave approxi-

mately 12” of electrical cord hanging from the ceiling. Do not restore power until wiring is completed.

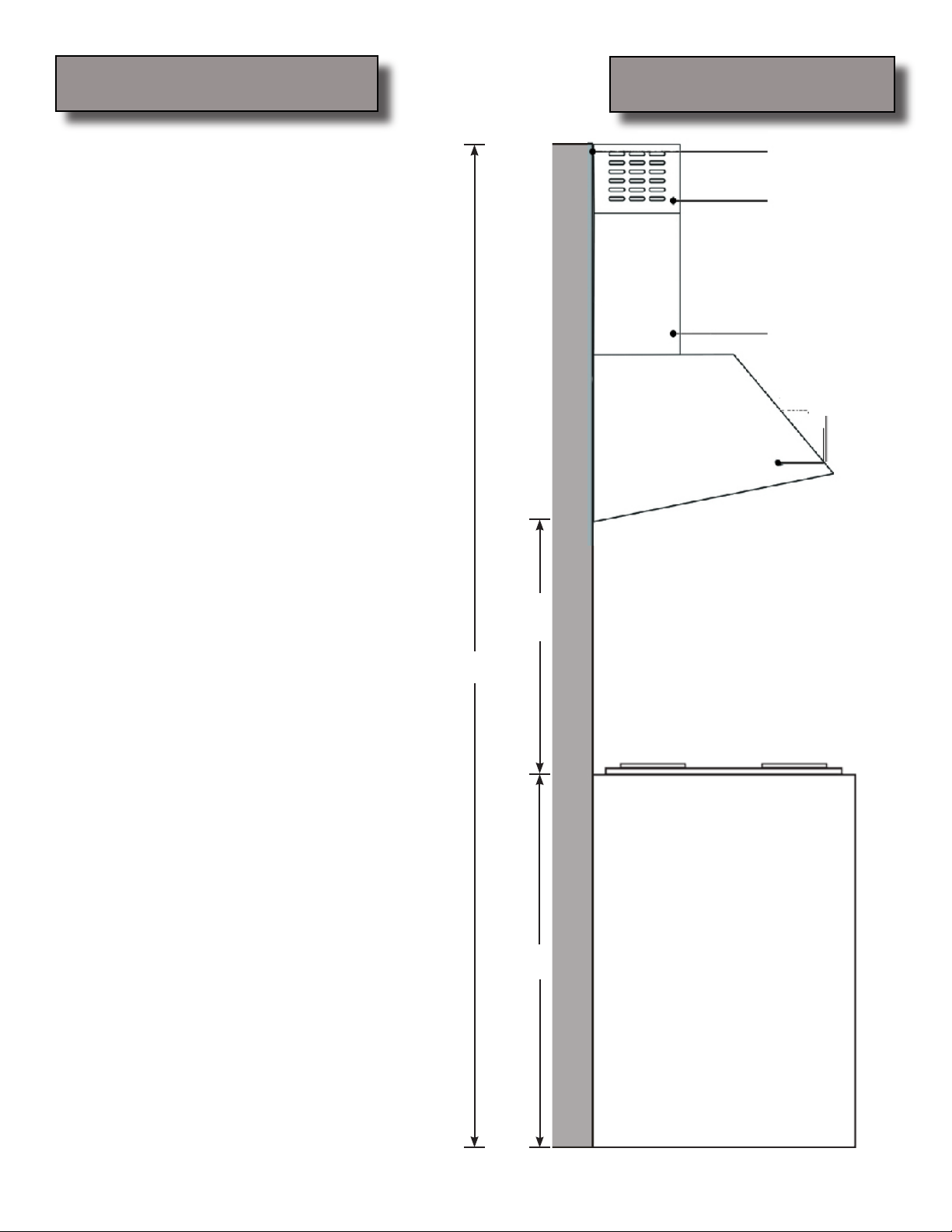

Disconnect power cord, remove the stainless steel lters by pulling down toward the direction of solid ar-

row while holding both of the metal handles, gently pull the stainless steel lters toward the direction of

dashed arrow as shown in Figure 1.

Remove the grease cup by sliding it sideway, see Figure 2 for location of the grease cup.

Set aside the stainless steel lters and grease cup until the range hood is properly installed.

If the range hood comes with a glass canopy and has not already been mounted to the hood, loosen the four

canopy screws and washers from the hood top, carefully place the canopy on the hood top, and loosely tighten

the four canopy screws along with washers. DO NOT put excessive pressure against the glass.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Excessive Weight

Require three or more person to move and

install this range hood. Spinal or other bodi-

ly injuries could occur if it is not followed.

WARNING

WARNING

Severe Injury

Rotating fan can cause severe

injury. Stay clear of fan when

motor is running.

Figure 2

Figure 1