Rev. 2, 10-2-2011

Fancy Foam Models, LLC

635 Laramie Cir. Maize, Ks. 67101

.fancyfoam.com

Assembly Instructions for the follo ing models:

32” Yak-55 Airfoil

32” Edge 540 Airfoil

33” Fenix V2 Airfoil

34” Freestyle Airfoil

34” MX2 Airfoil

Recommended Electronics and motors:

Motor: Turnigy 2730-1500 or any equivalent motor

Speed control: Castle Creations Thunderbird 9 or

equal.

Battery: 300 to 500, 2 or 3 cell, 20C rated or

equivalent.

Receiver: 4 channel.

Servos: (2) HXT 500 for the tail and (1) HXT 900 for

the ailerons.

Disclaimer: Fancy Foam Models has done

everything we can to caution and inform the end

user regarding the use of Lithium polymer battery

technology. We are in no way responsible for any

damage that may be caused by these batteries.

lease read, understand and follow all instructions

for the charger and batteries. Failure to use this

battery technology properly can result in the risk of

fire. If you are not comfortable with this

technology, return the batteries packs and kit to us

for a refund. By building the kit and using the

batteries, you accept full responsibility for the

safety of these batteries.

Recommended building methods and glues:

Much of the construction of this model is done by

laying the parts on a flat table. It is strongly

recommended that you put ax paper do n on the

surface first so any excess glue doesn’t soak through

the foam and glue the parts to the table. For all

assembly, use “Welders” contact adhesive. The hinges

are also done ith Welders, see our video on the eb

site. Hot glue can be used to attach the servos and

control horns.

ainting:

It is easiest to paint the parts before assembly. Card

stock can be used to make templates for stripes,

checkers, ect... Epp does is not affected much by

solvents so Krylon, Testors and airbrush paints can be

used.

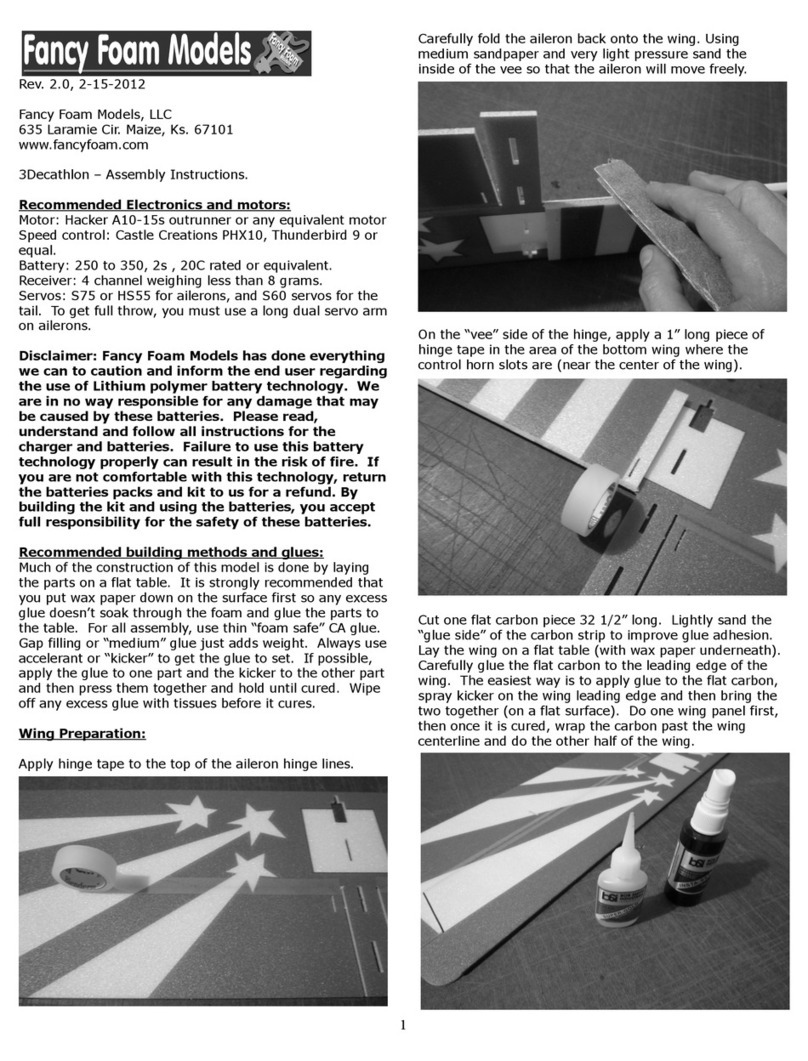

Horizontal parts assembly:

Start by gluing the ing halves together. Next, note the

marks on the ing tips and using a strait edge cut a slot

1/8” deep and 30” long centered, top and bottom of the

ing. Cut t o 30” long pieces of 1.5mm carbon rod

and press it into the slots. Sight along the leading edge

of the ing and adjust the ing so it is strait. Wick

thin CA along the top spar slot. When dry flip it over

and glue the bottom spar.

1