Rev. 2.0, 2-15-2012

Fancy Foam Models, LLC

635 Laramie Cir. Maize, Ks. 67101

.fancyfoam.com

3Decathlon – Assembly Instructions.

Recommended Electronics and motors:

Motor: Hacker A10-15s outrunner or any equivalent motor

Speed control: Castle Creations PHX10, Thunderbird 9 or

equal.

Battery: 250 to 350, 2s , 20C rated or equivalent.

Receiver: 4 channel eighing less than 8 grams.

Servos: S75 or HS55 for ailerons, and S60 servos for the

tail. To get full thro , you must use a long dual servo arm

on ailerons.

Disclaimer: Fancy Foam Models has done everything

we can to caution and inform the end user regarding

the use of Lithium polymer battery technology. We

are in no way responsible for any damage that may

be caused by these batteries. lease read,

understand and follow all instructions for the

charger and batteries. Failure to use this battery

technology properly can result in the risk of fire. If

you are not comfortable with this technology, return

the batteries packs and kit to us for a refund. By

building the kit and using the batteries, you accept

full responsibility for the safety of these batteries.

Recommended building methods and glues:

Much of the construction of this model is done by laying

the parts on a flat table. It is strongly recommended that

you put ax paper do n on the surface first so any excess

glue doesn’t soak through the foam and glue the parts to

the table. For all assembly, use thin “foam safe” CA glue.

Gap filling or “medium” glue just adds eight. Al ays use

accelerant or “kicker” to get the glue to set. If possible,

apply the glue to one part and the kicker to the other part

and then press them together and hold until cured. Wipe

off any excess glue ith tissues before it cures.

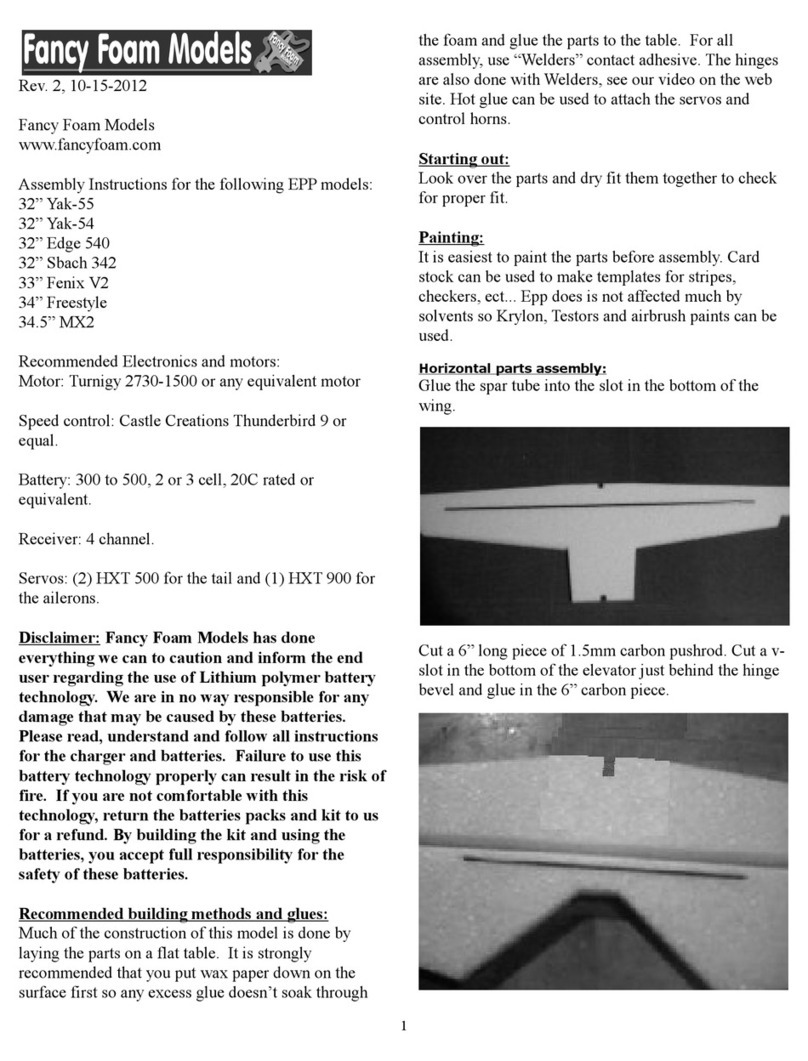

Wing reparation:

Apply hinge tape to the top of the aileron hinge lines.

Carefully fold the aileron back onto the ing. Using

medium sandpaper and very light pressure sand the

inside of the vee so that the aileron ill move freely.

On the “vee” side of the hinge, apply a 1” long piece of

hinge tape in the area of the bottom ing here the

control horn slots are (near the center of the ing).

Cut one flat carbon piece 32 1/2” long. Lightly sand the

“glue side” of the carbon strip to improve glue adhesion.

Lay the ing on a flat table ( ith ax paper underneath).

Carefully glue the flat carbon to the leading edge of the

ing. The easiest ay is to apply glue to the flat carbon,

spray kicker on the ing leading edge and then bring the

t o together (on a flat surface). Do one ing panel first,

then once it is cured, rap the carbon past the ing

centerline and do the other half of the ing.

1