3

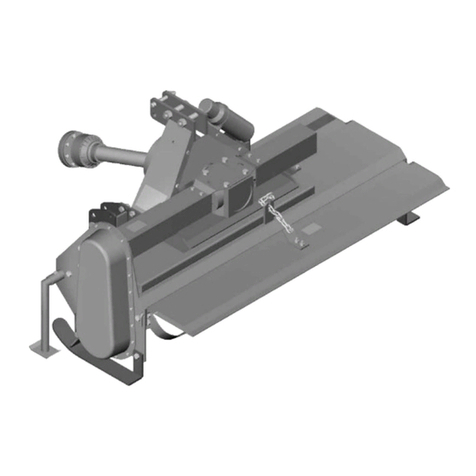

Table of Contents - Conventional Auger Mover

Table of Contents

Introduction .................................................................................................................................4

Safety............................................................................................................................................5

• Safety ................................................................................................................................5

• General Safety..................................................................................................................5

• Start-up Safety .................................................................................................................6

• Operation Safety ..............................................................................................................6

• Transport Safety...............................................................................................................7

• Service and Maintenance Safety ....................................................................................7

• Storage Safety..................................................................................................................7

Assembly......................................................................................................................................8

• Wheel Drive Installation ..................................................................................................8

• Mover Axle Assembly......................................................................................................8

• Mover Frame Assembly ..................................................................................................9

• HydraulicTank and Winch Assembly ..............................................................................9

• Hydraulic Pump, Valve and Hose Assembly ................................................................10

• Belt Guard Assembly.....................................................................................................10

Operation ...................................................................................................................................12

Bolt Torque .................................................................................................................................13

• Checking BoltTorque .....................................................................................................13

Parts Drawings...........................................................................................................................14

• Conventional Auger Mover ...........................................................................................14

• Exploded Views of Drive Motors ..................................................................................15

• Exploded Views of Winch and OilTank .........................................................................16

• Exploded View of Hydraulic Pump Mount ...................................................................17

• Parts List .........................................................................................................................18

• Right Drive Wheel Assembly and Parts List.................................................................22

• Motor Stop Assembly and Parts List............................................................................24

• Hydraulic Pump Assembly and Parts List ....................................................................26

• Hydraulic Fittings and Parts List ...................................................................................28

• Hydraulic Hoses - Small Mover and Parts List ............................................................30

• Hydraulic Hoses - Large Mover Parts List ....................................................................32

• Conventional Auger Mover Belt Guards and Parts List ..............................................34

Shipping Kit and Bundle Numbers ..........................................................................................36

Warranty.....................................................................................................................................38

Manufacturer’s statement: for technical reasons Buhler Industries Inc. reserves the right to modify

machinery design and specifications provided herein without any preliminary notice.

Information provided herein is of descriptive nature. Performance quality may depend on soil fertility,

applied agricultural techniques, weather conditions and other factors.