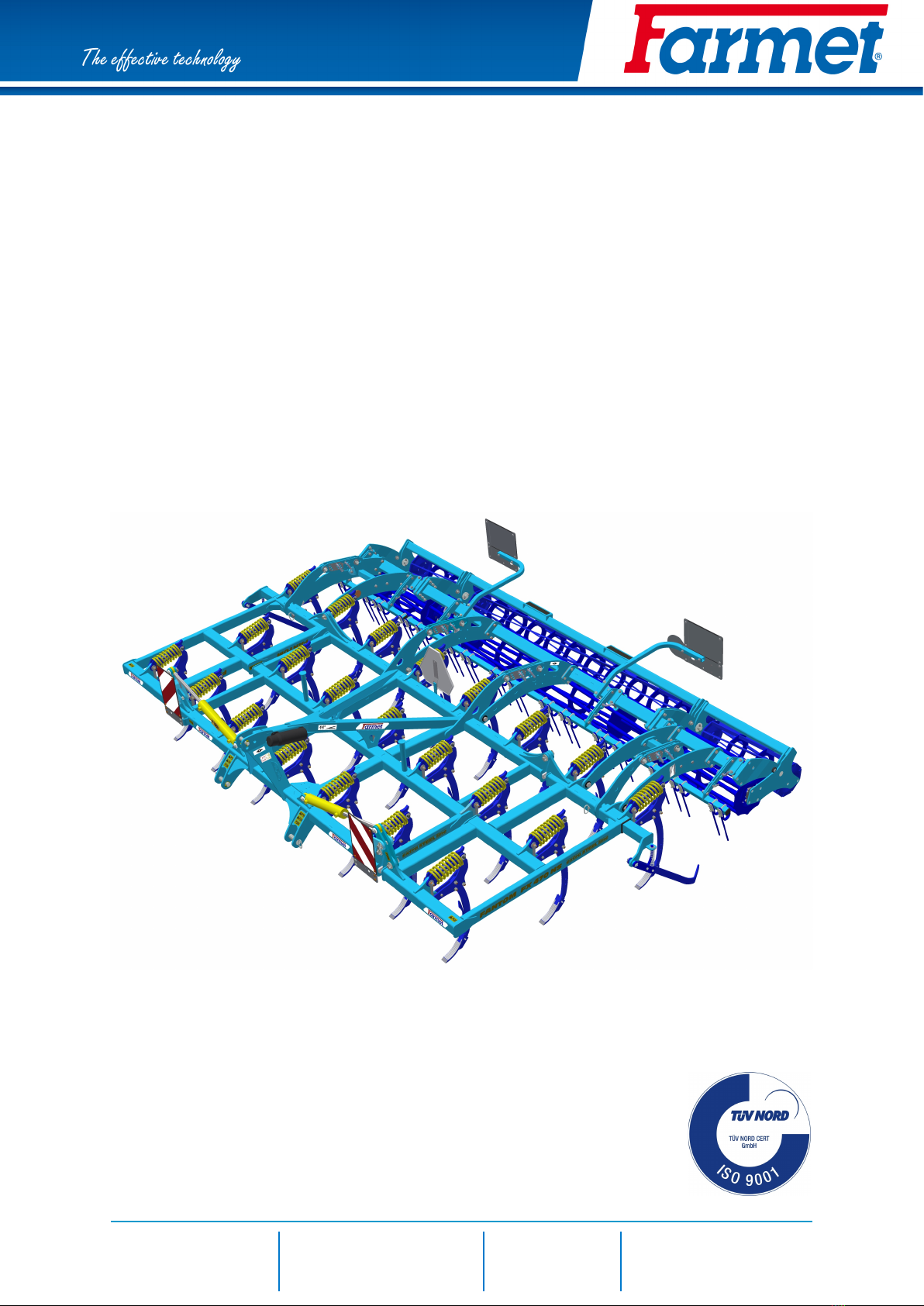

Farmet FANTOM FX 470 NS User manual

FANTOM

FFXX 447700 NNSS

Edition: 3Effective from: 1.1.2018

FARMET a.s.

Jiřinková 276

552 03 Česká Skalice, CZ

phone: +420 491 450 111

fax: +420 491 450 136

GSM: +420 774 715 738

IČ: 46504931

DIĆ: CZ46504931

www.farmet.cz

e-mail: [email protected]

OPERATING MANUAL

FFAANNTTOOMM

FFXX 447700 NNSS

2 | 37

Prepared by: Technical Department, Farmet a.s.

on 24.4.2019, changes reserved

PREFACE

3 | 37

PREFACE

Dear customer,

The agricultural machine you have purchased is a high-quality product of Farmet a.s. Česká Skalice.

You can fully utilise the advantages of your machine after thoroughly studying the operating manual.

The serial number of the machine is punched on the production label and written in the operating

manual (Your Machine Characteristics). This machine serial number must be stated whenever ordering spare

parts for possible repairs. The production label is located on the frame .

Use only spare parts for these machines according to the Spare parts catalogue officially issued by

the manufacturer, Farmet a.s. Česka Skalice.

Possibilities of Use of the Cultivator

The FANTOM cultivator is designed for cultivation of all types of soils up to a processing depth of 15 cm.

Your Machine Characteristics :

MACHINE TYPE :

MACHINE SERIAL NUMBER :

SPECIAL DESIGN OR ACCESSORIES :

PREFACE

5 | 37

Contents

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 MACHINE LIMIT PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Technical parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Safety statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 GENERAL INSTRUCTIONS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 MACHINE TRANSPORT USING TRANSPORT MEANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 MACHINE HANDLING USING LIFTING EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 WORK SAFETY LABELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Working parts of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 MACHINE ASSEMBLY AT THE CUSTOMER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 COMMISSIONING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1 Agregation to a tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.2 Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 Folding and unfolding of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.4 Description of the share/chisel replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9 REAR ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.1 Setting levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.1.1 Setting the angle of rear levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10 MACHINE TRANSPORT ON ROADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11 MACHINE ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.1 Adjusting the working depth of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.2 Setting side deflectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11.3 Share securing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

12 MACHINE MAINTENANCE AND REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13 MACHINE STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

14 MACHINE LUBRICATION SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

15 ENVIROMENTAL PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

16 MACHINE DISPOSAL AFTER SERVICE LIFE EXPIRY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

17 SERVICING AND WARRANTY CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

17.1 Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

17.2 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7 | 37

MACHINE LIMIT PARAMETERS

1 MACHINE LIMIT PARAMETERS

• The machine is designed for soil ploughing up to a depth of 15 cm when agricultural soil cultivation.

Another type of use exceeding the determined purpose is forbidden.

• The machine is only operated by one person – the tractor operator.

• Machine operator must not use the machine in a different way, especially:

Transport of persons and animals on the machine structure,

Transport of burdens on the machine structure,

Aggregation of the machine with another towing equipment than stated in Chapter „8.1“.

1.1 Technical parameters

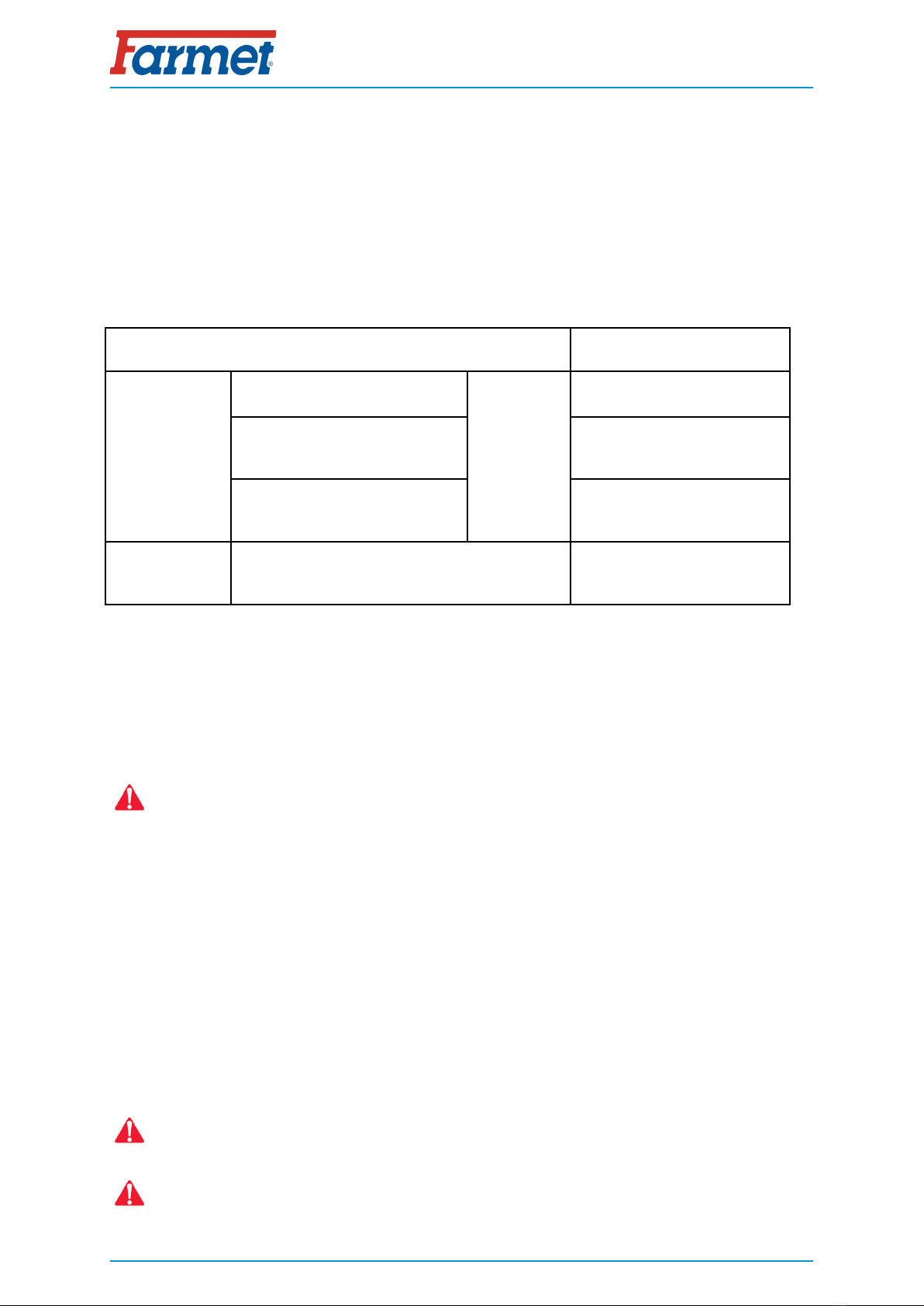

PARAMETERS FANTOM FX 470 NS

Working width 4,68 m

Transport width 3 m

Transport height 1,9 m

Machine total length 3,5 m

Working depth max. 15 cm

Number of shares 22

Working performance 3,7 –5,6 ha/h

Towing means 160 – 220 kW*

Working speed 8 - 12 km/h

Maximum transport speed 20 km/h

Maximum slope grade (°) 6

Machine weight 2030 kg

* Recommended towing means, the real towing force may significantly vary according to the processing

depth, soil conditions, land slope, working body wear and adjustment.

1.2 Safety statement

This warning sign warns about an immediate dangerous situation ending with death or

severe injury.

This warning sign warns about a dangerous situation ending with death or severe injury.

This warning sign warns about a situation that may end with a smaller or slight injury. It

also warns about dangerous actions related to the activity that could lead to an injury.

8 | 37

GENERAL INSTRUCTIONS FOR USE

2 GENERAL INSTRUCTIONS FOR USE

• The machine is made in accordance with the latest equipment state and approved safety

regulations. However, dangers of user or third person injury or machine damage or

creation of other material damage may arise during use.

• Use the machine only in a technically sound condition, in accordance with its purpose,

aware of possible dangers, and while adhering to the safety instructions of this operating

manual! The manufacturer is not liable for damages caused by the use of the machine

that is in contradiction with the limit parameters of the machine and with the

instructions for the use of the machine . The user bears the risk.

Immediately remove especially the failures that may negatively affect safety!

• Machine operation may be performed by a person authorised by the operator under

these conditions :

• It must own a valid driver's licence of the corresponding category,

• It must be demonstrably familiarised with the safety regulations for work with the

machine and must practically master the machine operation,

• The machine may not be operated by juveniles,

• It must know the meaning of the safety signs located on the machine. Their

respecting is important for safe and reliable machine operation.

• Maintenance and servicing repairs on the machine may only be performed by a person :

• Authorised by the operator,

• Educated in the machinery field with knowledge of repairs of similar machines,

• Demonstrably familiarised with safety regulations for work with the machine,

• During a repair of a machine connected to a tractor, it must own a driver's licence of

the corresponding category.

• Machine operator must secure the safety of other persons when working with the

machine or transporting the machine.

• During machine work in the field or during transport, the operator must control the

machine from the tractor's cabin.

• The operator may enter the machine structure only with the machine at rest and blocked

against movement, namely only for these reasons :

• Adjustment of the machine working parts,

• Repair and maintenance of the machine,

• When stepping on the machine, do not step on roller, tyres or other rotary parts. Those

may turn and you can cause very serious injuries by the subsequent fall.

• Any changes or modifications of machine may be performed only with written consent of

the manufacturer.

For possible damage arisen due to ignoring this instruction, the producer bears no

responsibility.

The machine must be maintained equipped with prescribed accessories and equipment

including safety marking.

All warning and safety signs must be legible and in their places. In case of damage or loss,

these signs must be immediately renewed.

• The operator must have the Operating Manual with the work safety requirements

available at any time when working with the machine.

GENERAL INSTRUCTIONS FOR USE

• The operator must not consume alcohol, medicines, narcotic and hallucinogenic

substances that decrease his attention and coordination capabilities while using the

machine.

If the operator must use medicines prescribed by a physician or uses freely sold

medicines, he must be informed by a physician, whether he is capable of responsible and

safe operation of the machine under these circumstances.

Protective equipment

For operation and maintenance use:

• tight clothes

• protective gloves and goggles against dust and

sharp parts of the machine.

9 | 37

10 | 37

MACHINE TRANSPORT USING TRANSPORT MEANS

3 MACHINE TRANSPORT USING TRANSPORT MEANS

• The transport means designed for machine transport must have the load capacity minimally

identical with the weight of the transported machine. The total weight of the machine is stated

on the production label.

• The dimensions of the transported machine including the transport means must comply with

the valid regulations for road traffic (decrees, laws).

• The transported machine must be always fastened to the transport means so that its

spontaneous loosening could not happen.

• The carrier is responsible for damage caused by the loosening of incorrectly or insufficiently

fastened machine to the transport means.

11 | 37

MACHINE HANDLING USING LIFTING EQUIPMENT

4 MACHINE HANDLING USING LIFTING EQUIPMENT

• The lifting equipment and tying means designed for handling of the machine must have their

load capacity at least identical with the weight of the handled machine.

• Machine fastening for handling may only be performed in places designed for that and

marked with self-adhesive labels showing the "chain" symbol.

• After fastening (suspending) at designated points, it is forbidden to move in the space of

possible reach of the handled machine.

12 | 37

WORK SAFETY LABELS

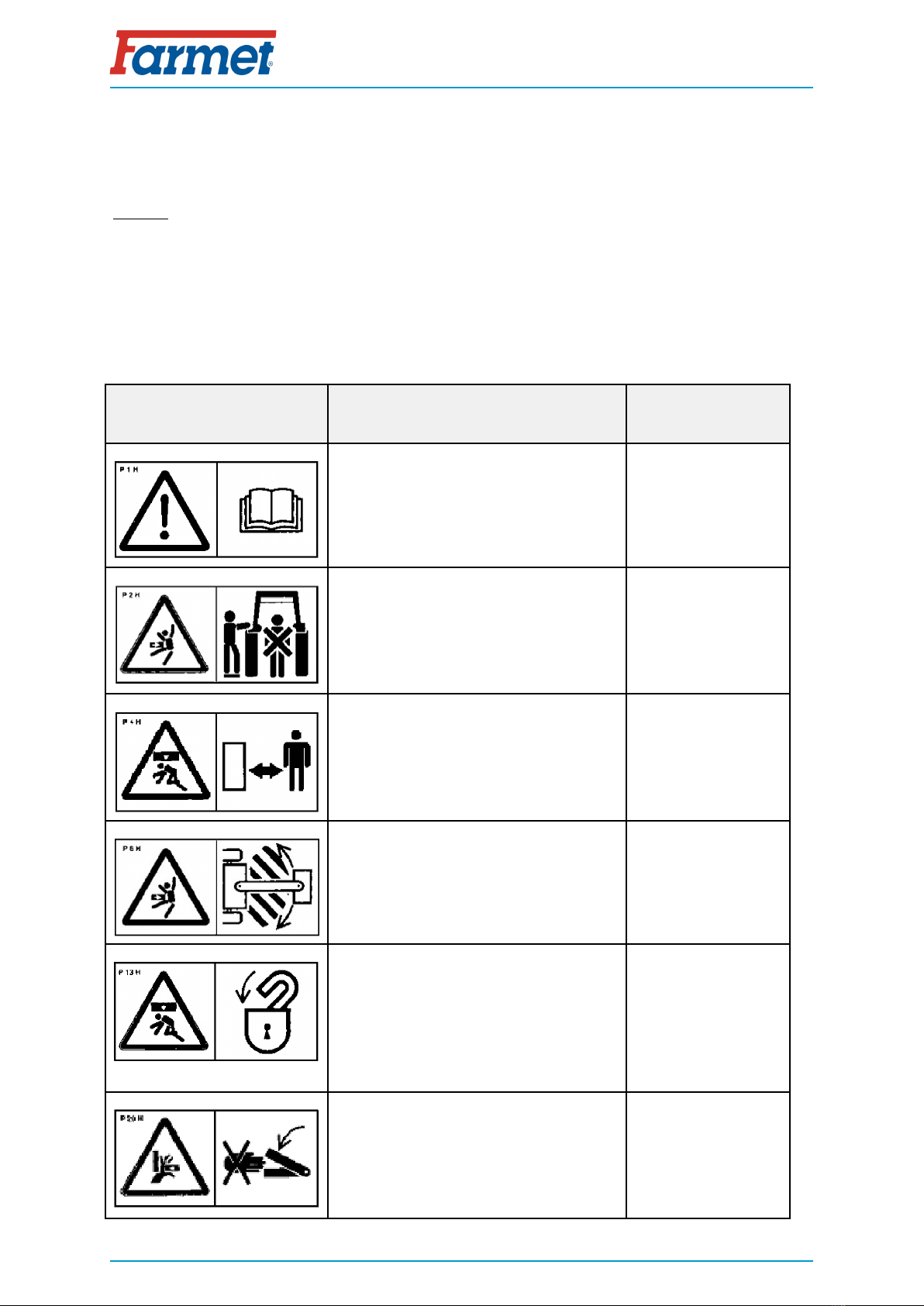

5 WORK SAFETY LABELS

Warning safety labels serve for operator protection.

General:

• Strictly observe the warning safety labels.

• All safety instructions also apply to other users.

• Upon damage or destruction of the aforementioned "SAFETY LABEL" located on the machine, THE

OPERATOR IS OBLIGED TO REPLACE IT WITH A NEW ONE!!!

• The position, appearance and the precise meaning of the work safety labels on the machine are

defined in the following tables and the figure .

WARNING SAFETY LABEL LABEL TEXT MACHINE

POSITION

Before handling the machine, carefully read

the operating manual.

Observe the instructions and safety

regulations for machine operation during

use.

P 1 H

When connecting or disconnecting, do not

step between the tractor and the machine,

also do not enter this space, if the tractor

and the machine are not at rest and the

engine is not turned off.

P 2 H

Stay out of reach of the drawn-up machine. P 4 H

Stay outside the reach of the tractor -

agricultural machine set, if the tractor

engine is in operation. P 6 H

The side extensible disc must be secured

with the stopper for transport and during

work.

The rear twin roller must be secured with

the stopper for transport.

Before commencing the machine transport,

secure the axle with spherical valves against

unexpected drop.

P 13 H

When folding the side frames, do not reach

into the space of the machine folding joints.

There is a danger of cutting when setting

the depth of the machine. P 20 H

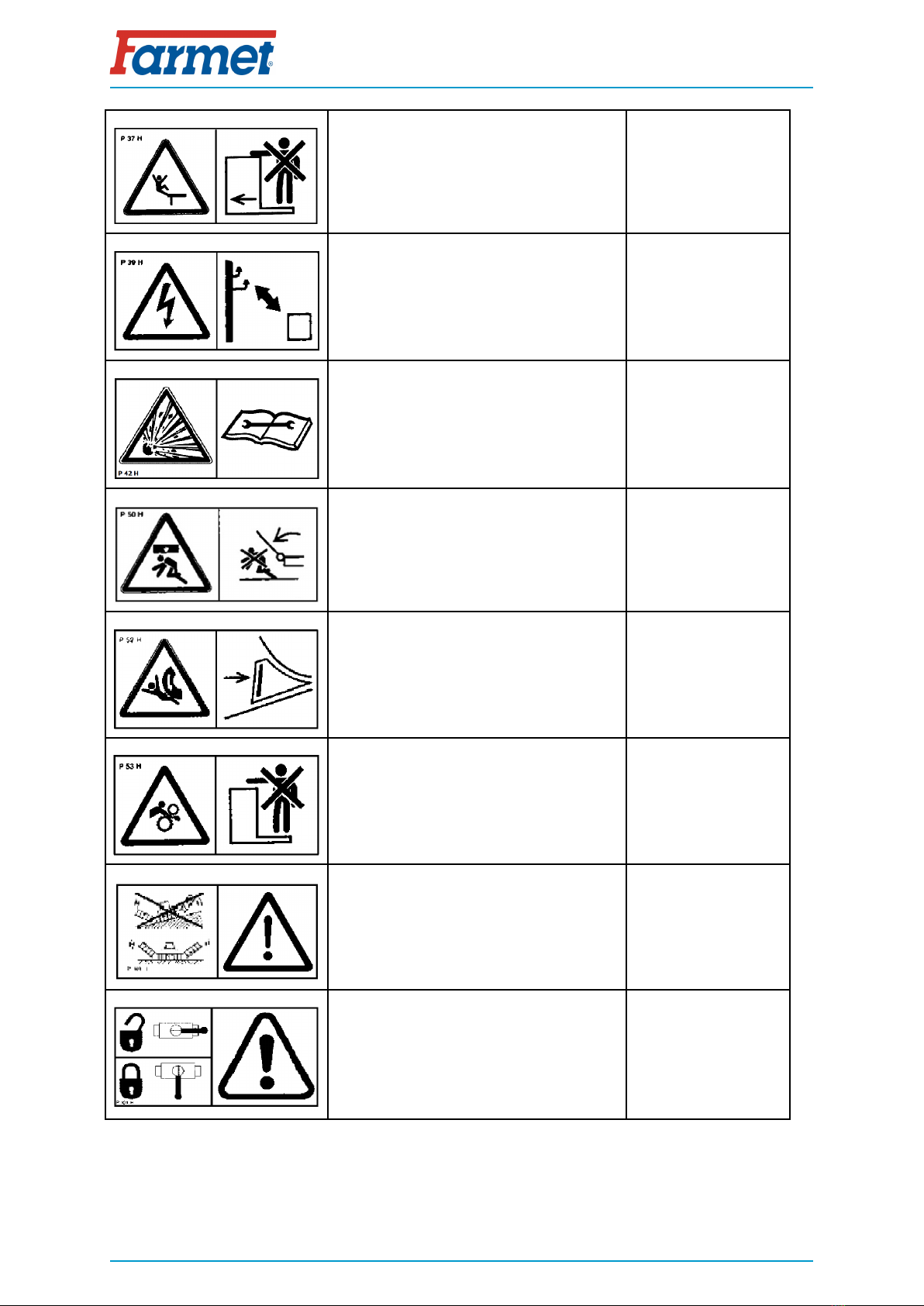

WORK SAFETY LABELS

Travelling and transport on the machine

structure is strictly forbidden. P 37 H

When working and transporting the

machine, maintain safe distance from the

electric appliances P 39 H

The pressure vessel is under gas and oil

pressure. Execute disassembly and repairs

only according to the instructions in the

manual. P 42 H

When folding and unfolding the side frames,

stay outside their reach. P 50 H

Secure the machine against unwanted

movement by positioning on its working

bodies (shares). P 52 H

Stay outside the reach of the tractor -

agricultural machine set, if the tractor

engine is in operation. P 53 H

It is strictly folding and unfolding the side

frames on slopes or inclined surfaces. P 100 H

The shown positions of the lever and the

function of the hydraulic spherical valve

located on the piston rod. P 101 H

13 | 37

15 | 37

DESCRIPTION

6 DESCRIPTION

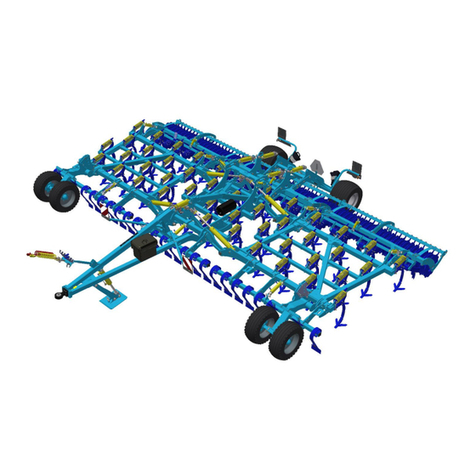

The machine FANTOM FX 470 NS is structurally solved as carried. It is equipped with a three-point hitch,

TBZ 3. It consists of a central frame and two folding side frames where the tines with chisels in three rows.

The tines are protected against overload with compression springs. The rear frames, equipped with rollers,

are also hung on the frames. A row of spring levellers or flexi-boards can be attached to the rear frames.

The side frames are folded using linear hydraulic motors connected to the external hydraulic circuit.

6.1 Working parts of the machine

1. TPS tractive suspension

2. Machine framework

3. Setting the depth of the rollers

4. Share section in three rows, chisel shares on tines

5. Spring leveller section

6. Rear roller (see chapter 9)

16 | 37

MACHINE ASSEMBLY AT THE CUSTOMER

7 MACHINE ASSEMBLY AT THE CUSTOMER

• The operator must perform the assembly according to the instructions of the producer,

best in cooperation with the expert servicing technician determined by the producer.

• The operator must secure a functional test of all assembled parts after the completion

of the machine assembly.

• The operator must secure that the handling of the machine using lifting equipment during

its assembly is in accordance with chapter „4“.

17 | 37

COMMISSIONING

8 COMMISSIONING

• Before taking over the machine, test and check, whether damage occurred during transport

and whether all parts contained in the bill of delivery were supplied.

• Before commissioning the machine, carefully read this operating manual, especially Chapters

1–5. Before the first use of the machine, familiarise yourselves with its controls and overall

function.

• During work with the machine, observe not only the instructions of this operating manual but

also generally valid regulations of work safety, health protection, fire and transport safety,

and environmental protection.

• The operator must check the machine before every use (commissioning) from the standpoint

of completeness, work safety, work hygiene, fire safety, transport safety, and environmental

protection. A machine showing signs of damage must not be commissioned.

• Aggregation of the machine with the tractor is to be performed on a flat and hardened

surface.

• When working on slopes, observe the lowest allowable slope grade of the set TRACTOR -

MACHINE.

• Before starting the tractor motor, check whether no person or animal is in the working space

of the set and push the warning sound signal.

• The operator is responsible for the safety and all damage caused by the operation of the

tractor and the connected machine.

• The operator is obliged to adhere to the technical and safety regulations of the machine

determined by the producer when working.

• The operator is obliged to retract the working bodies of the machine from the ground when

turning at the headland.

• The operator is obliged to observe the prescribed working depths and speeds stated in the

manual in. chap.1.

• The operator is obliged to lower the machine to the ground and secure the set against

movement before leaving the tractor cabin.

• Lower the machine with caution so that the chisels and shares are not damaged by sharp

lowering to the ground. Position the machine on a flat ground so that the weight of the

machine is evenly transferred to all shares.

COMMISSIONING

8.1 Agregation to a tractor

• The machine can be connected only to a tractor, whose curb weight is identical or higher than

the overall weight of the connected machine.

• The machine operator must observe all generally valid regulations of work safety, health

protection, fire safety, and environmental protection.

• The operator may connect the machine exclusively to a tractor that is equipped with a rear

three-point suspension and a functional undamaged hydraulic system.

• The table of requirements for the towing means for work with the machine:

Requirement for the tractor engine power for the machine

FANTOM FX 470 NS > 160 kW *

Requirement for

the tractor's TPS

Spacing of the lower suspension

joints (measured at the joint axes)

TPS 3

895 ± 1,5 mm

1100 ± 1,5 mm

ø of the hole of the lower

suspension joints for the machine

suspension pivots

37,4 – 37,75 mm

ø of the hole of the upper

suspension joint for the machine

suspension pivot

32 – 32,25 mm

Requirement for

the tractor's

hydraulic system

Side frame folding circuit

Circuit pressure 200 bar, 2 pcs

of quick-coupler sockets ISO

12,5

* Recommended towing means, the real towing force may significantly vary according to the processing

depth, soil conditions, land slope, working body wear and adjustment

• Connect the machine using the TPS suspension bar to the lower arms of the rear TPS of the tractor,

secure the TPS arms using pins against disconnecting

• The machine aggregated with the tractor changes the distribution of the weight to the individual axles of

the tractor. The weight of the front axle is reduced and therefore the controllability gets worse. It also

affects braking properties

When connecting, no persons may stay in the space between the tractor and the machine.

8.2 Hydraulics

• Connect the hydraulics only when the hydraulic circuits of the machine and the tractor

(aggregate) are in a pressure-less condition.

• The hydraulic system is under high pressure. Regularly check for leaks and immediately

remove obvious damage of all lines, hoses, and pipe unions.

• When seeking and removing leaks, use only the suitable tools.

• For connecting the hydraulic system of the machine to the tractor, use the plug (on the

machine) and the socket (on the tractor) of the quick-couplers of the same type. Perform the

connection of the quick-couplers of the machine to the hydraulic circuits of the tractor so that

the folding of the side frames (BLUE and WHITE DUST CAP) is on one control circuit.

In order to prevent accidental or foreign person (children, passengers) caused movement of the

hydraulics, the control switchboards on the tractor must be secured or blocked in the transport

position.

Parts of the hydraulic system of the machine, which are under pressure, are forbidden to

disassemble. Hydraulic oil that penetrates the skin under high pressure causes severe injuries.

In case of injury, seek a physician immediately.

18 | 37

COMMISSIONING

8.3 Folding and unfolding of the machine

• With all hydraulic movements, lower the speed of the moving parts of the machine

before stopping by throttling the corresponding valve at the control unit!

• The hydraulics for the folding and unfolding must be connected to the double-action

control unit.

• The operator must ensure that during folding and unfolding of the side frames, no

person or animal is within their reach (i.e. at the place of their impact) or vicinity and

that no one puts his fingers into the joint space.

• Perform folding and unfolding on flat and solid surfaces or laterally to the slope with the

fully open control unit.

• Only perform folding or unfolding with a machine that is lifted on the suspender of the

tractor.

• Remove stuck soil from folding points, soil may impair function and cause damage to the

mechanics.

• During folding or unfolding, check the side frames and have them continuously fold into

the end position to the stoppers.

Procedure for lowering the machine:

• Remove the securing stoppers located under the lowering joints.

• Lift the machine on the suspender of the tractor.

• Lower the side frameworks smoothly.

• Block or close the controlling unit.

Procedure for unfolding the machine:

• Lift the machine on the suspender of the tractor.

• Unfold the side frameworks smoothly.

• Secure the side frameworks from lifting during work with securing stoppers.

• Block or close the controlling unit.

19 | 37

COMMISSIONING

8.4 Description of the share/chisel replacement

• If the ploughshare / chisel wear is high, this working tool must be replaced

• Tools required for replacement:

• HAMMER

• DRIVER - 12 mm

• The installation is the same for all types of working parts

The machine is sufficiently

lifted so that the working part

can be removed from the

shoe.

Using the prepared tools,

drive the spring pin out and

remove the ploughshare from

the shoe.

Drive a new working part in

the shoe and secure it with

the spring pin 12x50mm.

20 | 37

Table of contents

Other Farmet Tiller manuals