Farmet FALCON 3 User manual

web: www.farmet.cz

e-mail: farmet@farmet.cz

IČ: 46504931

DIČ: CZ46504931

Farmet a. s.

Jiřinková 276

552 03 Česká Skalice, CZ

telefon: +420 491 450 111

fax: +420 491 450 136

GSM: +420 774 715 738

OPERATING MANUAL

FALCON

3| 4| 6| 8

Edition: 7 | effective from: 1.7.2020

Manual

FALCON 3 | 4 | 6 | 8

2 │99

Dear customer,

The FALCON disc sowing machines are high-quality products by Farmet a.s. Česká Skalice.

You can start to fully use the qualities of your machine after you have thoroughly studied the operating

manual. The serial number of the machine is imprinted on the production label and recorded in the operating

manual. Please use this serial number whenever you order spare parts in case of a repair. The production label

is located on the central frame near the pole.

Use only spare parts for these machines according to the Spare Part Catalogue officially published by the

producer, the company Farmet a.s. Česká Skalice.

Possibilities of Use of Your Machine

The disc sowing machines are intended for areal sowing with the option to sow broad-line cultures into

strips. The sowing machine is intended for sowing a wide range of farming products, such as cereal, pulses, oil

bearing crops, clover crops, grass etc. The actual conditions for sowing individual farming products are stated

below. The machine is intended for aggregation with tractors with the output from 90kW, 117 kW, 161 kW and

from 205 kW according to the soil conditions and depth of sowing. The optimal working speed is 10 - 20 km/hour.

The machine allows additional fertilising by granulated fertilisers while sowing.

Production label of the machine FALCON 3

Production label of the machine FALCON 4

Production label of the machine FALCON 6

Production label of the machine FALCON 8

FALCON 3

FALCON 4

FALCON 6

FALCON 8

Manual

FALCON 3 | 4 | 6 | 8

3 │99

CONTENT

1QUICK START .................................................................................................................................................. 5

2CRITICAL PARAMETERS OF THE MACHINE ..................................................................................................... 7

3TECHNICAL PARAMETERS............................................................................................................................... 7

Safety warning................................................................................................................................................... 9

A. GENERAL INSTRUCTIONS FOR USE ................................................................................................................. 9

Protective equipment...................................................................................................................................... 10

B. TRANSPORTING THE MACHINE .................................................................................................................... 10

C. MANIPULATING THE MACHINE BY LIFTING EQUIPMENT............................................................................. 10

D. TRANSPORTING THE MACHINE ON GROUND COMMUNICATIONS.............................................................. 10

E. WORK SAFETY LABELS .................................................................................................................................. 11

4DESCRIPTION OF THE MACHINE................................................................................................................... 14

4.1 Working parts of the machine ............................................................................................................. 14

5ASSEMBLY OF THE MACHINE AT THE CUSTOMER’S SITE ............................................................................. 17

6PUTTING INTO OPERATION .......................................................................................................................... 17

6.1. Aggregation to the tractor ................................................................................................................... 18

6.2. Connecting the hydraulics.................................................................................................................... 19

6.3. Hydraulic diagram of the machine....................................................................................................... 20

6.4. Connecting the elektronic unit............................................................................................................. 21

6.5. Connecting the hydraulic motor of the fan.......................................................................................... 23

6.6. Proper connection to the tractor......................................................................................................... 24

7. ELECTRONIC SYSTEM OF THE MACHINE....................................................................................................... 26

7.1. Turning the sowing on and off ............................................................................................................. 27

7.2. Description of machine control by Müller electronics......................................................................... 28

7.3. Description of the basic display ........................................................................................................... 28

7.4. Controlling hydraulics .......................................................................................................................... 29

7.5. Rail lines setting system ....................................................................................................................... 32

7.6. Reference data..................................................................................................................................... 40

7.6.1 Creating an order......................................................................................................................... 40

7.6.2 Levels of seeds in the hopper ...................................................................................................... 41

7.7. Setting passage sensors ....................................................................................................................... 41

7.7.1 Seeding sensors diagnostics ........................................................................................................ 44

7.7.2 Switching off the seed flow system sensor.................................................................................. 44

7.7.3 Designation of motors and dosers............................................................................................... 45

8. UNFOLDING AND FOLDING MACHINE.......................................................................................................... 45

8.1. Unfolding the machine......................................................................................................................... 46

8.2. Folding the machine............................................................................................................................. 48

9. LOWERING AND LIFTING .............................................................................................................................. 50

10. FILLING UP THE SEED/FERTILIZER CONTAINER............................................................................................. 50

11. SETTING THE FILLED SEEDS/FERTILIZER........................................................................................................ 51

12. SETTING OF THE SOWING BATCH................................................................................................................. 52

12.1. Screw dispecer for side dressing.......................................................................................................... 61

12.2. Setting the fine seeds sowing............................................................................................................... 62

13. SETTING VENTILATOR SPEED ACCORDING TO SEEDS................................................................................... 63

14. ADJUSTMENT OF THE WORKING PARTS OF THE MACHINE ......................................................................... 64

15. ADJUSTING THE MACHINE WORK DEPTH..................................................................................................... 64

15.1 Adjusting the machine by tps arms of the tractor ............................................................................... 65

15.2 Setting the sowing depth ..................................................................................................................... 66

15.3 Setting the down pressure of the sowing bodies................................................................................. 67

15.4 Setting the leveller behind the seed boots .......................................................................................... 69

15.5 Adjusting the working depth of the front section................................................................................ 70

15.6 Adjusting of the levelling...................................................................................................................... 73

15.7 Setting of the markers.......................................................................................................................... 74

15.8 Setting of the deep fertilizing disc........................................................................................................ 75

16. ERRORS ......................................................................................................................................................... 76

17. COMPLETION OF SOWING............................................................................................................................ 88

18. MAINTENANCE AND REPAIRS OF THE MACHINE.......................................................................................... 90

18.1. Replacement of worn discs ................................................................................................................. 90

18.2. Maintenance plan ................................................................................................................................ 91

Manual

FALCON 3 | 4 | 6 | 8

4 │99

18.3. Machine lubrication schedule.............................................................................................................. 95

18.4. Manipulation with lubricans ................................................................................................................ 95

18.5. The pressure in the tyres ..................................................................................................................... 96

18.6. Recommended tightening torques of bolting ...................................................................................... 97

19. STORING THE MACHINE ............................................................................................................................... 97

20. PROTECTION OF ENVIRONMEN.................................................................................................................... 97

21. DISPOSAL OF THE MACHINE AFTER THE END OF ITS USABLE LIFE ............................................................... 97

22. MAINTENANCE AND TERMS OF GUARANTEE............................................................................................... 98

22.1. Maintenance ........................................................................................................................................ 98

22.2. Guarantee ............................................................................................................................................ 98

Manual

FALCON 3 | 4 | 6 | 8

5 │99

1QUICK START

0

Safety warning

9

1

Pull the Falcon with the pulling device

18

2

Connect the return hydraulic hose

24

3

Connect the other hydraulic hoses

19

4

Connect the 7-pin cable for the road lights of the machine

5

Connect the machine electronics with the pulling vehicle.

21

6

Lift the front supporting leg of the machine and secure it

7

Release the pins for unfolding the front section

46

8

Open the valve for unfolding (blue marking)

46

9

Open the valve for lifting the front preparatory section (yellow marking)

50

10

Use the main switch to switch on the seed drill terminal

11

Unfold the machine using the hydraulic circuit and the control terminal

46

12

Set the pressure using the pressure reducing valve

68

13

Check the seed cleanliness

88

14

Check for leakage of the planer in the seedbed

88

15

Check the flow of the fertilizer hoses

16

Check the seed hose for continuity

17

Pour the seed

50

18

Pour the fertilizer

50

19

Check and adjust the seeder plane

65

20

Set the lower end of the tractor's TPS

65

21

Set the sowing depth

66

22

Adjust the depth of the front section

70

23

Set the dose in the electronics

58

24

Set the value on the doser

52

25

Perform a test shot

59

26

Enter the value of the weighed sample into the terminal

59

27

Check that the seeding speed range displayed on the terminal is optimal: 1.5-20 km/h

59

28

Set sensor sensitivity according to the table in the manual

41

29

Set the priority on the fan's hydraulic circuit

30

Adjust the oil flow for the fertilizer hydromotor

19

31

Set the fan speed, by seed and batch

63

32

Set the required hydraulic functions - indicators, track markers, etc.

30

33

Set the required pressure on the seedbed, depending on the soil conditions (20-60bar).

68

Manual

FALCON 3 | 4 | 6 | 8

6 │99

Manual

FALCON 3 | 4 | 6 | 8

7 │99

2CRITICAL PARAMETERS OF THE MACHINE

The machine is designated for sowing common cereals and broad-line cultures in aggregation with an

agricultural wheel or caterpillar tractor. Another type of use exceeding the determined purpose is forbidden.

(x) The machine is only operated by one person –the tractor driver.

(x) The operator must not use the machine for other purposes, particularly:

(x) For transporting people and animals on the construction of the machine,

(x) For transporting load on the construction of the machine,

(x) Aggregation of the machine with other tractive equipment than stated in Chapter „6.1./P.18“.

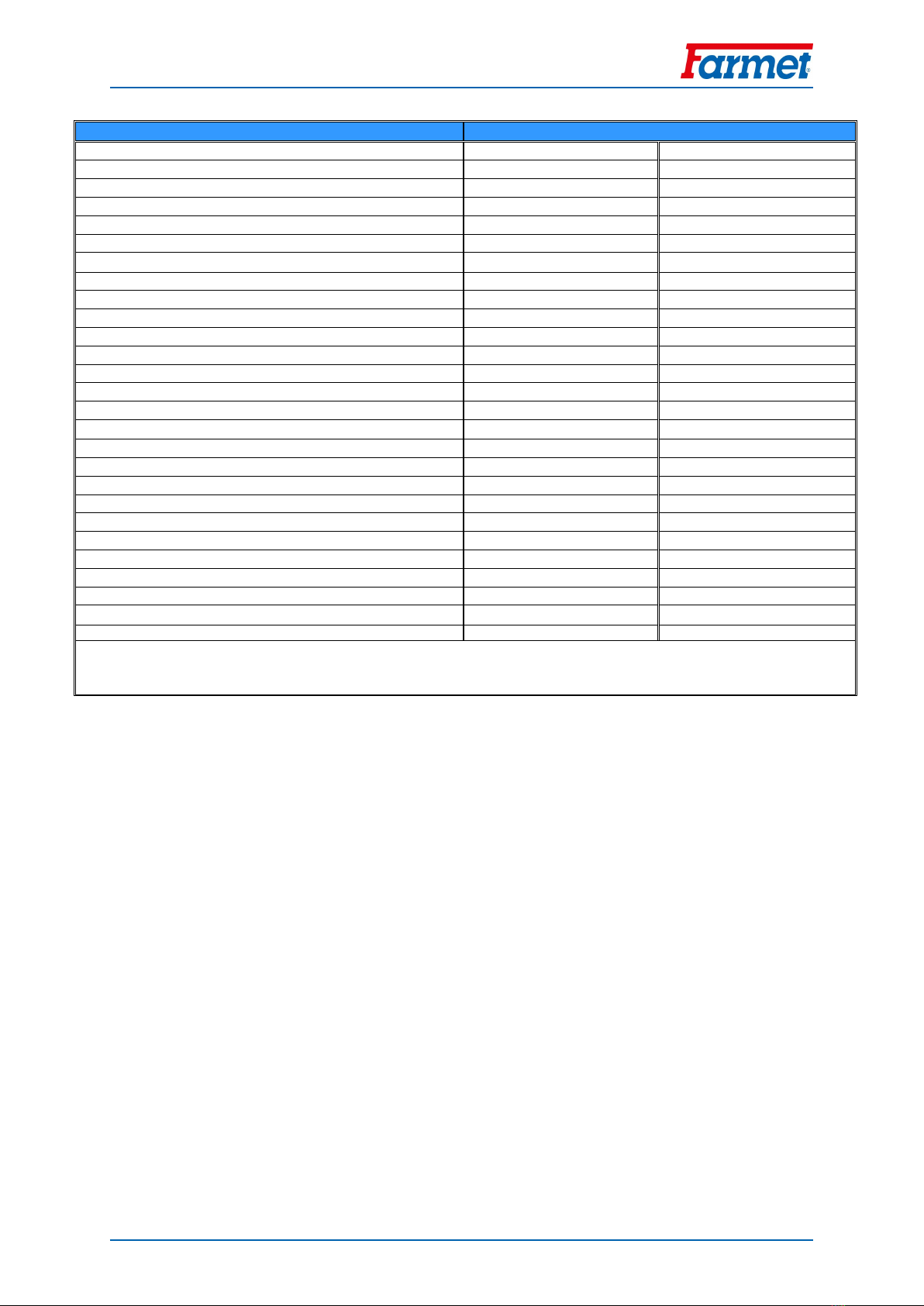

3TECHNICAL PARAMETERS

Tab. 1 –Technical parameters of the machine

PARAMETERS

FALCON 3

FALCON 4

FALCON 6

FALCON 8

Working width (mm)

3000

4 000

6 000

8 000

Transport width (mm)

3 000

3 000

3 000

3 000

Transport height (mm)

3 300

3 300

3 300

4 000

Total length of the machine (mm)

7 500

7 500

7 500

7 500

Working depth (mm)

0 –100

0 –100

0 –100

0 –100

Container capacity without fertilization ( l )

4000

4000

4000

4000

Container capacity with fertilization ( l ) (ratio 40 : 60)

6000

6000

6000

8500

Filling height of the container (mm)

2650

2 650

2 650

3 400

Dimensions of the filling opening w/out fertilization (m)

2x0,52 / 1,2x0,52

2x0,52 / 1,2x0,52

2x0,52 / 1,2x0,52

2x0,52 / 1,2x0,52

Number of drill coulters (spacing 125 / 150 mm)

24/20

32 / 26

48 / 40

64 / 52

Number of fertilizer boots (spacing 250 / 300 mm)

12/10

16 / 13

24 / 20

32 / 26

Pressure of drill coulters / fertilizer boots (kg)

50 -115 / až 200

50 -115 / až 200

50 -115 / až 200

50 -115 / až 200

Diameter of the sowing disk, two-disk coulter / press-wheel

(mm)

355 / 340

355 / 340

355 / 340

355 / 340

Diameter of the sowing disk, single-disk coulter / press-

wheel (mm)

410 / 690

410 / 690

410 / 690

410 / 690

Number of discs

490

Front

12

16

25

34

Rear

11

15

24

33

Number of chisels of 2-row section, depth 200mm

(spacing 250 / 300 mm)

12/10

16 / 13

24 / 20

32 / 26

Number of chisels of 3-row section, depth 200mm

(spacing 250 / 300 mm)

12/10

16 / 13

24 / 20

32 / 26

Number of chisels of 2-row section, depth 300mm

(spacing 375 mm)

8

16

24

32

Working capacity (ha/h)

3 - 4,5

4 –6

6 - 9

8 - 12

Pulling vehicle (kW)

92 / 125

117 / 160 *

161 / 220 *

205 / 280 *

Working speed (km/h)

10 –20

10 –20

10 –20

10 –20

Maximum transport speed (km/h)

25

25

25

25

Maximum slope accessibility (°)

6

6

6

6

Tyre dimensions

405/70-20

405/70-20

405/70-20

405/70-20

Type of brakes / distribution 1)

air / two-line***

air / two-line***

air / two-line***

air / two-line***

Required pressure (kPa)

8,5

8,5***

8,5***

8,5***

Number of hydraulic circuits / pressure (bar)

9 / 200

3 / 200

3 / 200

3 / 200

Number of quick-coupling devices / type

5 / ISO 12,5

5 / ISO 12,5

5 / ISO 12,5

5 / ISO 12,5

Non-pressure return line (max. 5 bar)

1 / ISO 20

1 / ISO 20

1 / ISO 20

1 / ISO 20

Hydraulic fan oil flow ( l/min)

30 - 40

30 - 40

30 - 40

30 - 40

Oil flow for machine control (l/min)

50 - 60

50 - 60

50 - 60

50 - 60

Electric system requirement

12 V DC / 40 A

12 V DC / 40 A

12 V DC / 40 A

12 V DC / 40 A

Tractor suspension requirement

TPS kat. 3

TPS kat. 3

TPS kat. 3

TPS kat. 3

Machine weight without fertilization (kg)

4 830 –5840**

5 340 –6 580**

6 800 –8 000**

8 440 –9 950**

Machine weight with fertilization (kg)

5 630 –6140**

6 630 –8 420**

8 000 –9 860**

9 600 –12 100**

* recommended pulling vehicle, the actual pulling force may significantly change according to the selected version of the machine, processing depth, soil

conditions, inclination of land, wear and tear of the working parts and their adjustment

** weight of the machine according to accessories

*** hydraulic brake alternative / operating pressure 130±5 bar

Technical Advice!

1) Transport/Brake System: Follow the national regulations valid for transportation of machines on public roads. Check

the legal provisions valid in the country and regulations on maximum permissible total axle weights and loads and also

on the necessary potential use of a brake system. If you have any further questions, please contact our sales

representative.

Manual

FALCON 3 | 4 | 6 | 8

8 │99

PARAMETERS

FALCON 3 Compact

FALCON 4 Compact

Working width (mm)

3000

4 000

Transport width (mm)

3 000

3 000

Transport height (mm)

2 800

2 800

Total length of the machine (mm)

7 000

7 000

Working depth (mm)

0 –100

0 –100

Container capacity ( l )

3000

3000

Filling height of the container (mm)

2600

2600

Dimensions of the filling opening (m)

0,52x1,92

0,52x1,92

Number of drill coulters (150 mm)

20

26

Pressure of drill coulters / fertilizer boots (kg)

50 -115

50 -115

Diameter of the sowing disk (mm)

355

355

Number of discs

23

31

Working capacity (ha/h)

3 - 4,5

4 –6

Pulling vehicle (kW)

92 / 125

117 / 160 *

Working speed (km/h)

10 –20

10 –20

Maximum transport speed (km/h)

25

25

Maximum slope accessibility (°)

6

6

Tyre dimensions

7,5-16

7,5-16

Type of brakes / distribution 1)

air / two-line***

air / two-line***

Number of hydraulic circuits / pressure (bar)

2 / 210

2 / 200

Number of quick-coupling devices / type

4 / ISO 12,5

4 / ISO 12,5

Non-pressure return line (max. 5 bar)

1 / ISO 20

1 / ISO 20

Hydraulic fan oil flow ( l/min)

30 - 40

30 - 40

Oil flow for machine control (l/min)

30

30

Electric system requirement

12 V DC / 25 A

12 V DC / 25 A

Tractor suspension requirement

TPS kat. 2 a 3

TPS kat. 2 a 3

Machine weight without (kg)

3 800

4 400

* recommended pulling vehicle, the actual pulling force may significantly change according to the selected version of the machine, processing depth, soil

conditions, inclination of land, wear and tear of the working parts and their adjustment

Manual

FALCON 3 | 4 | 6 | 8

9 │99

SAFETY WARNING

A. GENERAL INSTRUCTIONS FOR USE

A.1 (x) The machine is produced in compliance with the latest technological conditions and approved safety

regulations. However, the use of the machine may still cause injuries to the user or third persons or

damage to the machine or occurrence of other material damages.

A.2 (xx) Use the machine only in a technically unexceptionable condition, in compliance with its purpose, with

awareness of potential risks and observance of safety instructions stated in this manual!

The Manufacturer is not liable for damages caused by the use of the machine that is in contradiction with

the limit parameters of the machine (p. 7) and with the instructions for the use of the machine (Chapter

A and 3). The User bears the risk.

Immediately eliminate all defects that could have a negative impact on safety!

A.3 (7) The machine may only be operated by a person authorized by the owner under the following

conditions:

(8) He or she must have a valid driving licence in the relevant category,

(9) He or she must be verifiably informed on the safety rules of working with the machine and must

have command of the operation of the machine in practice,

(10) The machine must not be operated by a minor (minors),

(11) He or she must understand the meaning of warning symbols placed on the machine. Respecting

the symbols is important for a safe and reliable operation of the machine.

A.4 (12) Maintenance and service repairs may only be performed by a person:

(13) Authorized by the owner,

(14) Trained in an engineering field with the knowledge of repairs of similar machinery,

(15) Verifiably informed on the safety rules of working with the machine,

(16) With a driving licence in the relevant category for repairs of the machine attached to a tractor.

A.5 (17) The operator of the machine must ensure safety of other people during the work with the machine and

its transportation.

A.6 (18) During machine work in the field or during transport, the operator must control the machine from the

tractor's cabin.

A.7 (19) The operator may only enter the construction of the machine when the machine is off and secured

against movement only in order to:

(20) adjust the working parts of the machine,

(21) repair and maintain the machine,

(29) release or secure the ball valves of the axle,

(27) secure the ball valves of the axle before tilting the side frame,

(28) adjust the working parts of the machine after opening the side frame.

A.8 (xxx) When climbing onto the machine, do not step on the tyres of the rolls or other revolving parts as they

may roll over and you can seriously hurt yourself if you fall down.

This warning symbol warns against an imminent dangerous situation that

could lead to death or serious injury.

This warning symbol warns against a dangerous situation that could lead

to death or serious injury.

This warning symbol warns against a situation that could lead to a small or

minor injury. It also points out dangerous tasks related to the activity that

could lead to an injury.

Manual

FALCON 3 | 4 | 6 | 8

10 │99

A.9 (22) Any changes or adjustments of the machine may only be performed with a written consent of the

producer. The producer is not responsible for any potential damages occurred as a result of non-

compliance with this instruction. The machine must always be equipped with the prescribed accessories,

equipment and gear including the safety labels. All warning and safety signs must be always legible and

at their positions. They must be replaced if damaged or lost without delay.

A.10 (23) The operating manual and the requirements of the safety at work must be always available to the

operator.

A.11 (24) When operating the machine, the operator must not consume alcohol, medicine, narcotic and

hallucinogenic substances that reduce attention and coordination abilities. If the operator has to take

medicine prescribed by the physician or if he or she uses over the counter medicine, he or she must be

informed by the physician whether he or she is able to reliably and safely operate the machine under these

circumstances.

PROTECTIVE EQUIPMENT

For the operation and maintenance use:

Close-fitting clothing

Protective gloves and goggles for protection from dust and sharp parts

of the machine

B. TRANSPORTING THE MACHINE

B.1 (1) The vehicle intended for the transportation of the machine must have at least the same bearing capacity

as the weight of the transported machine is. The total weight of the machine is stated on the production

label.

B.2 (2) The dimensions of the transported machine including the vehicle must comply with valid regulations

for traffic on ground communications (decrees, acts).

B.3 (3) The transported machine must be always attached to the vehicle so that it cannot be released during

transportation.

B.4 (4) The carrier is responsible for damages caused by the release of incorrectly or insufficiently attached

machine to the vehicle.

C. MANIPULATING THE MACHINE BY LIFTING EQUIPMENT

C.1 (1) The lifting equipment and binding instruments intended for manipulation with the machine must have

at least the same bearing capacity as the weight of the manipulated machine is.

C.2 (2) The machine may only be attached for manipulation in designated places marked by stick-on labels

showing a “chain“.

C.3 (3) When attached (suspended) in designated places, it is not allowed to move in the area of potential reach

of the manipulated machine.

D. TRANSPORTING THE MACHINE ON GROUND COMMUNICATIONS

Transport Position of FALCON

Attach the machine to the tractor by hanging with the use of the two-point suspension equipment

(TPS 3).

The side frames must be folded in the vertical position.

The machine must be equipped with removable shields displaying the boundaries, functional lighting

and a board of rear label for slow vehicles (pursuant to ECE No.69).

The lighting must be turned on when in operation on ground communications.

The tractors must be equipped with a special light appliance with orange colour that must be turned

on when in operation on ground communications.

The operator must drive with increased caution and consideration for other participants of the traffic.

Manual

FALCON 3 | 4 | 6 | 8

11 │99

The operator must secure the arms of the rear TPS of the tractor in the transport position when

operating on ground communications. At the same time, the arms of the rear TPS of the tractor must

be secured against swinging sideways.

It is strictly forbidden to transport people or load on the machine or connect another machine, semi-

trailer or additional equipment to it.

The maximum transport speed during travelling on roads is 25 km/hour.

Ban of transport with decreased visibility!

The machine may only be driven on roads when equipped with air brakes (the customer receives a

certificate of roadworthiness). Otherwise, it is prohibited to drive the machine on roads!

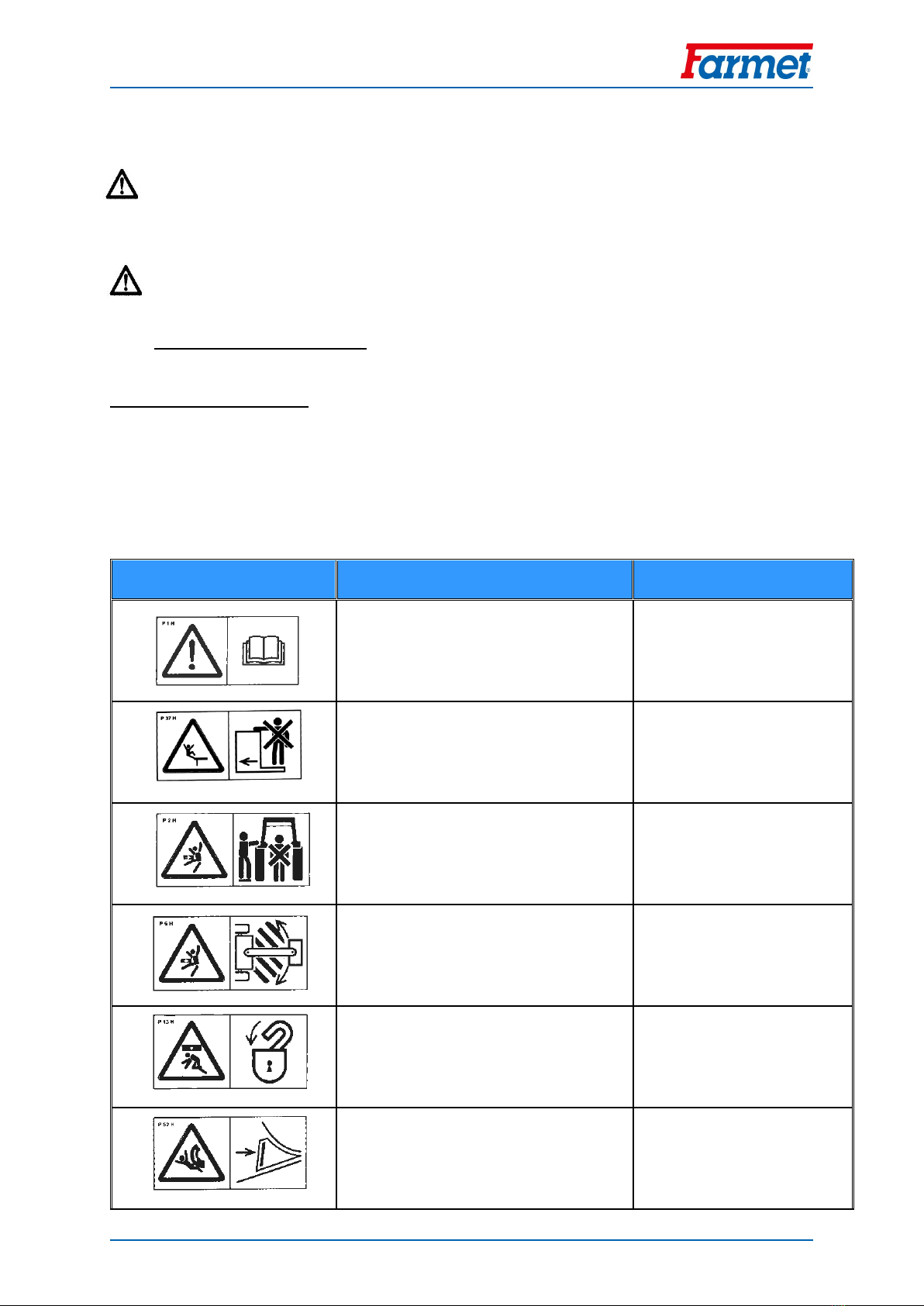

E. WORK SAFETY LABELS

Warning safety labels are used for the protection of the operator.

The following applies generally:

A) Strictly observe the warning safety labels.

B) All safety instructions also apply to other users.

C) If the aforementioned “SAFETY LABEL” located on the machine is damaged or destroyed, THE OPERATOR

MUST REPLACE IT WITH A NEW ONE!!!

The position, appearance and exact meaning of work safety labels on the machine are given in the

following tables (Tab.2/p.11-12) and the picture (Picture 1,2/p.13).

Tb.2 - Self-adhesive warning safety labels located on the machine

WARNING SAFETY LABEL

TEXT TO THE LABEL

POSITION ON THE

MACHINE

Read carefully the operating manual before

manipulation with the machine.

Observe the instructions and safety rules

when operating the machine.

P 1 H

Driving the machine and transportation on

its construction is strictly forbidden.

P 37 H

When connecting and disconnecting, do not

enter the area between the tractor and the

machine. Do not enter that area unless the

tractor and the machine are not moving and

the engine is off.

P 2 H

Stay beyond reach of the set Tractor –

Agricultural Machine when the tractor

engine is running.

P 6 H

Secure the axle of the machine against an

unexpected drop before its transportation.

P 13 H

Secure the machine against unwanted

movement.

P 52 H

Manual

FALCON 3 | 4 | 6 | 8

12 │99

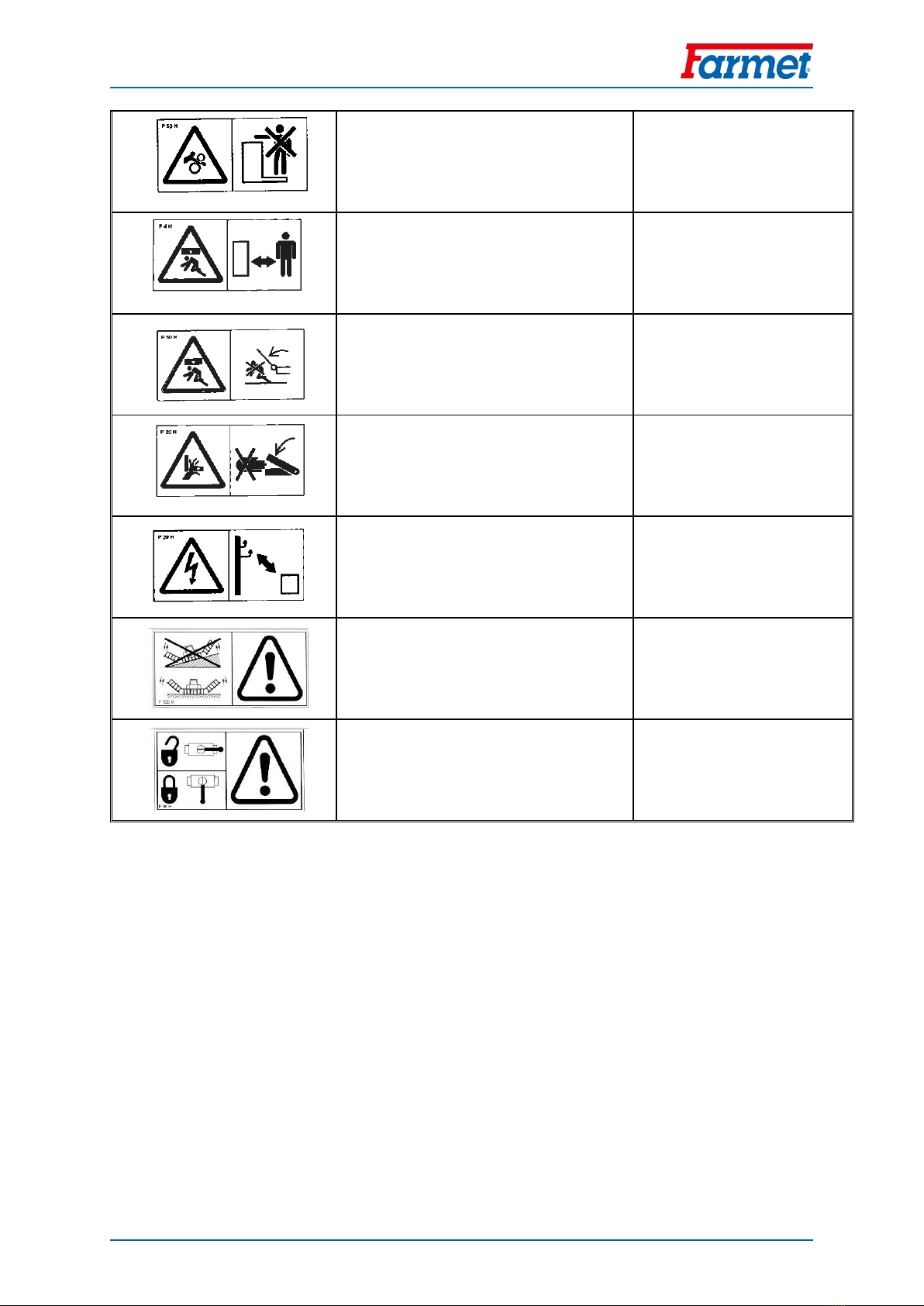

Do not approach the rotary parts of the

machine unless they are standing still, i.e.

they are not rotating.

P 53 H

Stay beyond reach of the lifted machine.

P 4 H

When folding and unfolding the side frames

and service bridge, stay beyond their reach.

P 50 H

When tipping the service bridge, stay beyond

its reach.

P 20 H

When working with the machine as well as

during its transportation, keep a safe

distance from electric appliances.

P 39 H

It is forbidden to fold and unfold the side

frames of the machine on a slope or an

inclined plane.

P 100 H

Pictured positions of the lever and the

hydraulic ball valve function located on the

piston-rod.

P 101 H

Manual

FALCON 3 | 4 | 6 | 8

13 │99

Picture 1

Picture 2

P 100 H

P 101 H

P 1 H

P 2 H

P 6 H

P 20 H

P 50 H

P 39 H

P 37 H

P 4 H

P 39 H

P 37 H

P 4 H

P 50 H

P 37 H

P 52 H

P 53 H

P 20 H

P 50 H

P 13 H

P 20 H

P 20 H

P 52 H

P 53 H

P 50 H

P 37 H

P 39 H

P 37 H

P 4 H

Manual

FALCON 3 | 4 | 6 | 8

14 │99

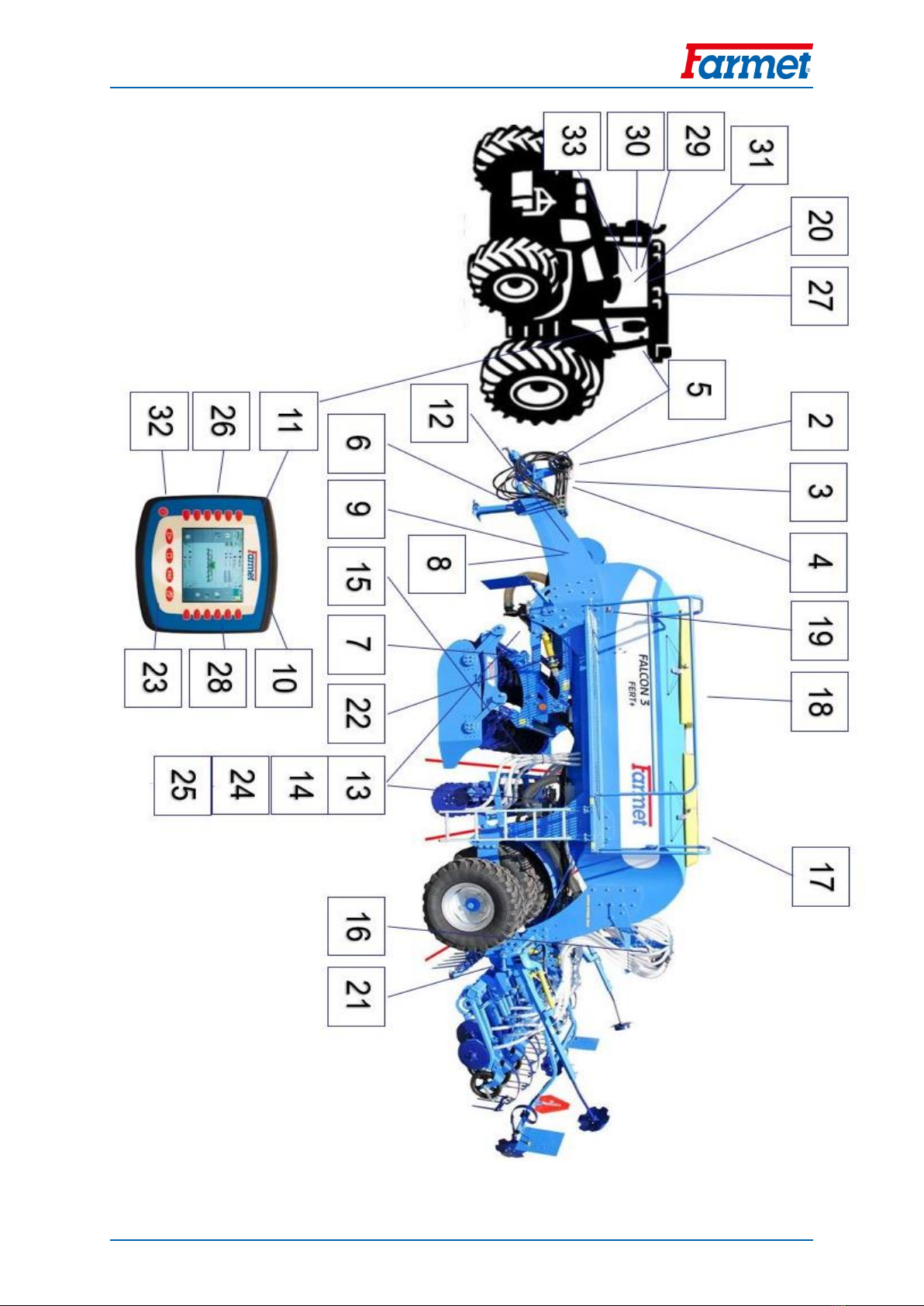

4DESCRIPTION OF THE MACHINE

The FALCON disc sowing machine is designed as semi-carried and folding. It is connected to the tractor using

a drawbar with pins of Cat III in the bottom arms of the tractor three-point suspension (TPS). In the front, there

is a preparatory section for soil processing and levelling larger unevenness followed by a pneumatic-tyred

ramming roller that levels and compacts soil in front of the sowing bodies. Then there is a leveller installed in the

axis of each sowing body. At the end there are sowing bodies with compacting wheels and a leveller. Some of

the tyres of the roller are also used for transport in the transport position. The seed container is equipped by a

sowing mechanism commonly used in the standard ACCORD pneumatic sowing machines. There is also possibility

to have Farmet Dispenser (Roller replacement system). The seeds are carried by air flow through seed tubes to

the sowing body where it is placed in the soil in rows. The soil is then compacted by the wheel and levelled out

with the leveller. The seeding mechanism is driven by electric motors. The fan for the transport of seeds is driven

by hydraulic motor from the hydraulic circuit of the tractor. The machine is equipped with central markers and

markers of rail lines. The electronic system of the machine allows checking the functions of the machine,

regulation of the sowing batch and formation of rail lines. The transport wheels may be equipped with pneumatic

brakes or hydraulic brakes.

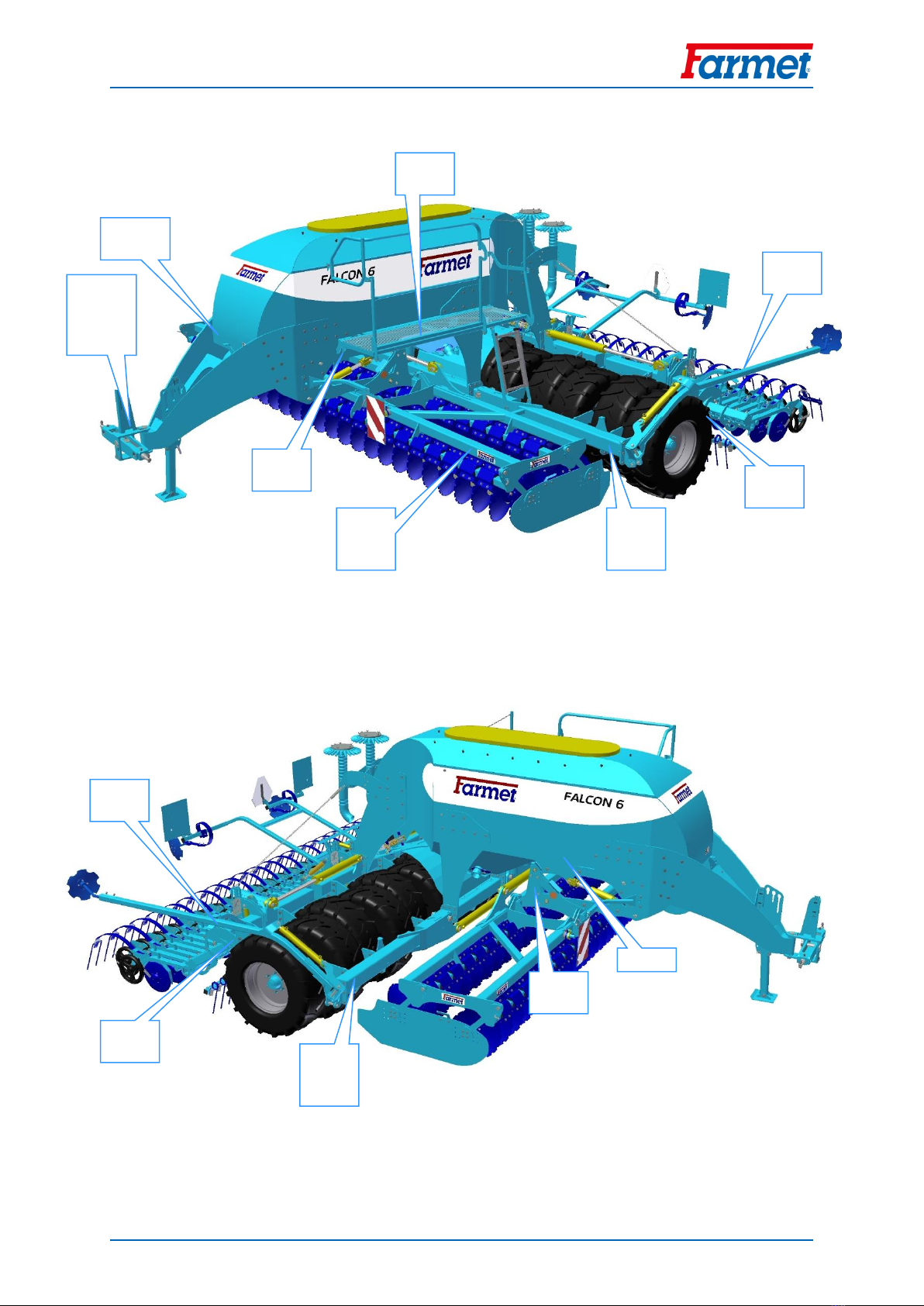

4.1 WORKING PARTS OF THE MACHINE

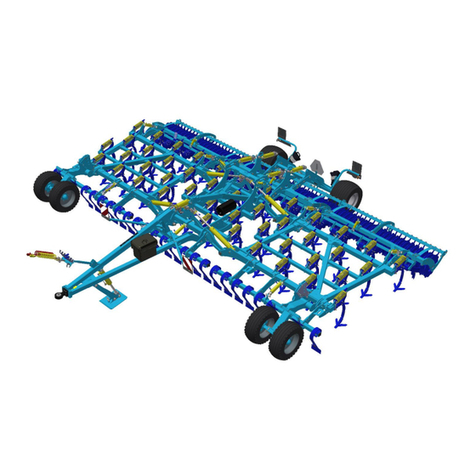

Picture 3.1 –Working parts of the machine FALCON PRO

4.1.1 Drawbar with a collapsible resting leg 4.1.5 Leveller section

4.1.2 Front preparatory section 4.1.6 Sowing bodies with press-wheels

4.1.3 Disk fertilizing section 4.1.7 Leveller after the sowing bodies

4.1.4 Pneumatic-tyred flotation roller 4.1.8 Markers

Seed hopper with moveable orifice plate Easy release of fertilizer distribution

Seed / fertilizer

Seed hopper with

moveable orifice plate

4.1.1

4.1.3

4.1.4

4.1.5

4.1.2

4.1.6

4.1.8

4.1.7

Manual

FALCON 3 | 4 | 6 | 8

15 │99

Seed / fertilizer

Seed hopper with

moveable orifice plate

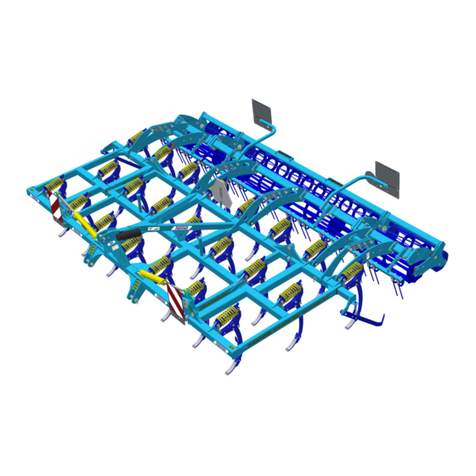

Picture 3.2 –Working parts of the machine FALCON PRO with CHISEL SECTION

4.1.1 Drawbar with a collapsible resting leg 4.1.5 Sowing bodies with press-wheels

4.1.2 Chisel section 4.1.6 Leveller after the sowing bodies

4.1.3 Pneumatic-tyred flotation roller 4.1.7 Markers

4.1.4 Leveller section

Seed hopper with moveable orifice plate Easy release of fertilizer distribution

4.1.2 new replaceable chisel shape

4.1.1

4.1.3

4.1.4

4.1.5

4.1.2

4.1.6

4.1.7

Manual

FALCON 3 | 4 | 6 | 8

16 │99

Seed

Picture 3.3 –Working parts of the machine FALCON COMPACT

4.1.1 Drawbar with a collapsible resting leg 4.1.4 Sowing bodies with press-wheels

4.1.2 Disk section 4.1.5 Leveller after the sowing bodies

4.1.3 Pneumatic-tyred flotation roller 4.1.6 Markers

4.1.1

4.1.3

4.1.4

4.1.5

4.1.2

4.1.6

Manual

FALCON 3 | 4 | 6 | 8

17 │99

5ASSEMBLY OF THE MACHINE AT THE CUSTOMER’S SITE

The owner must execute the assembly according to the producer’s instructions, if possible in cooperation

with a professional service technician determined by the producer.

The owner must execute a functional test of all assembled parts after the completion of the assembly

of the machine.

The owner must ensure that the manipulation with the machine by lifting equipment corresponds with

Chapter „C“.

6PUTTING INTO OPERATION

Before you take over the machine, test and check it for any damages incurred during transportation and

check that all parts included in the delivery note have been delivered.

Before you put the machine into operation, read the operating manual carefully, particularly chapters A-

E p.9-13. Learn about the control elements of the machine and its overall function before the first use.

When working with the machine, observe the instructions in the manual as well as generally valid rules

for the safety at work, protection of health, fire and traffic safety and protection of environment.

The operator must check the machine before every use (putting into operation) for aspects in the field

of completeness, safety at work, work hygiene, fire safety, traffic safety and protection of environment.

If the machine shows signs of damage, it must not be put into operation.

Execute aggregation of the machine with the tractor on an even and compact surface.

When working on slopes, observe the lowest allowable slope accessibility of the whole set TRACTOR –

MACHINE.

Before turning on the engine of the tractor, check that there are no people or animals in the working area

of the set and press the warning sound signal.

The operator is responsible for safety and for all damages caused by the operation of the tractor and the

attached machine.

The operator must observe technical and safety regulations of the machine determined by the producer

when working with the machine.

The operator must lift the machine when turning at the plough turning end, i.e. the working parts must

not be in the ground.

The operator must observe the prescribed working depths and speeds set in the instructions for use in

Tab. 9/p.64 when working with the machine.

The operator must lower the machine to the ground and secure the set against movement before leaving

the cabin of the tractor.

Manual

FALCON 3 | 4 | 6 | 8

18 │99

6.1. AGGREGATION TO THE TRACTOR

The machine may only be connected to a tractor whose standby weight equals or is higher than the total

weight of the attached machine.

The operator must observe all generally valid regulations for the safety at work, protection of health, fire

safety and protection of environment.

The operator may only attach the machine to a tractor which is equipped with a rear three-point

suspension (TPS) and a functional undamaged hydraulic system.

The table with the requirements for the tractive instrument for work with the machine:

Tab.3

(5) Requirement for the engine power of the tractor for FALCON 3

90 kW*

(5) Requirement for the engine power of the tractor for FALCON 4

117 kW*

(5) Requirement for the engine power of the tractor for FALCON 6

161 kW*

(5) Requirement for the engine power of the tractor for FALCON 8

205 kW*

(6)Requirement for TPS of the tractor

(7)distance of the bottom suspension

hinges (at the axes of the hinges)

1010±1,5 mm,

(can be also set to 910±1,5 mm)

(8)holes of the bottom suspension

joints for the suspension hinge pins of

the machine

37,5 mm

(9)Requirement for the hydraulic system

of the tractor

(x)circuit of the electric distributor

(14)Pressure in the circuit

min.190 bar –max.230

60 l/min., 2 sockets for snap

coupling ISO 12.5

(19)circuit of the hydraulic engine

(20)Pressure in the filling branch

min.130 bar–max.230 bar, 1

socket for snap coupling ISO

12.5

(21)Pressure in the waste branch

max.3 bar, 1 socket for snap

coupling ISO 20

(x)down-pressure of the sowing bodies

(14)Pressure in the circuit

min.190 bar –max.230

10 l/min., 1 sockets for snap

coupling ISO 12.5

(x)circuit of lifting and lowering the

preparatory section

(14)Pressure in the circuit

min.190 bar –max.230

40 l/min., 2 sockets for snap

coupling ISO 12.5

(12)Requirement for the air system of the

tractor (if the machine is equipped with

brakes)

(13) circuit of braking of the machine

axle

(16)Pressure in the circuit min.6

bar –max. 15 bar, 1 clutch head

for single circuit brakes

(x)Requirement for the electric system of

the tractor *

(x) connection of the electronic system

of the machine

12V / 40 A

+ red

-black

Connect the machine with the carrier bar TPS to the lower arm of the tractor TPS and secure the TPS arms

with pegs against disconnection.

When connecting the machine, there must not be any people in the area between the machine

and the tractor.

Manual

FALCON 3 | 4 | 6 | 8

19 │99

6.2. CONNECTING THE HYDRAULICS

Connect the hydraulics only if the hydraulic circuits of the machine and the tractor (aggregate) are without

any pressure.

The hydraulic system is under great pressure. Check regularly for leakages and immediately eliminate any

visible damage to all distribution, tubes and screw joints.

When checking for and eliminating leakages, use appropriate equipment.

Use the plug (on the machine) and the socket (on the tractor) of the same type of snap coupling when

connecting the hydraulic system of the machine to the tractor. Execute the connection of the snap

coupling of the machine to the hydraulic circuits of the tractor according to Tab. 4.

Tab. 4 - Connection of the hydraulic circuits and setting up the flow of oil

Circuit

Plug

Cover colour

Oil flow direction

Flow of oil

Hydraulic motor of the fan

ISO 12,5

red

pressure tube

20 –40 l/min

ISO 20

black

open waste

Controls of the machine

hydraulics

ISO 12,5

blue

pressure tube

50 –60 l/min

ISO 12,5

blue

reverse tube

Hydraulic drift drive

ISO 12,5

green

pressure tube

10 –15 l/min

Micro drill

ISO 12,5

black

pressure tube

15 –20 l/min

Flexi boards

ISO 12,5

white

pressure tube

15 –20 l/min

ISO 12,5

white

reverse tube

15 –20 l/min

Lifting the front section

ISO 12,5

yellow

pressure tube

20 –40 l/min

ISO 12,5

yellow

reverse tube

In order to rule out unintentional movement of the hydraulics or movement caused by third persons

(children, passengers), the controlling distributors in the tractor must be secured or blocked and the

controlling unit switched off if the machine is not used or if it is in the transport position.

The parts of the hydraulic system of the machine that are under pressure must not be disassembled.

The hydraulic oil causes serious injuries when it penetrates the skin under the high pressure. In case of injury,

immediately seek a doctor.

Manual

FALCON 3 | 4 | 6 | 8

20 │99

6.3. HYDRAULIC DIAGRAM OF THE MACHINE

This manual suits for next models

5

Table of contents

Other Farmet Tiller manuals

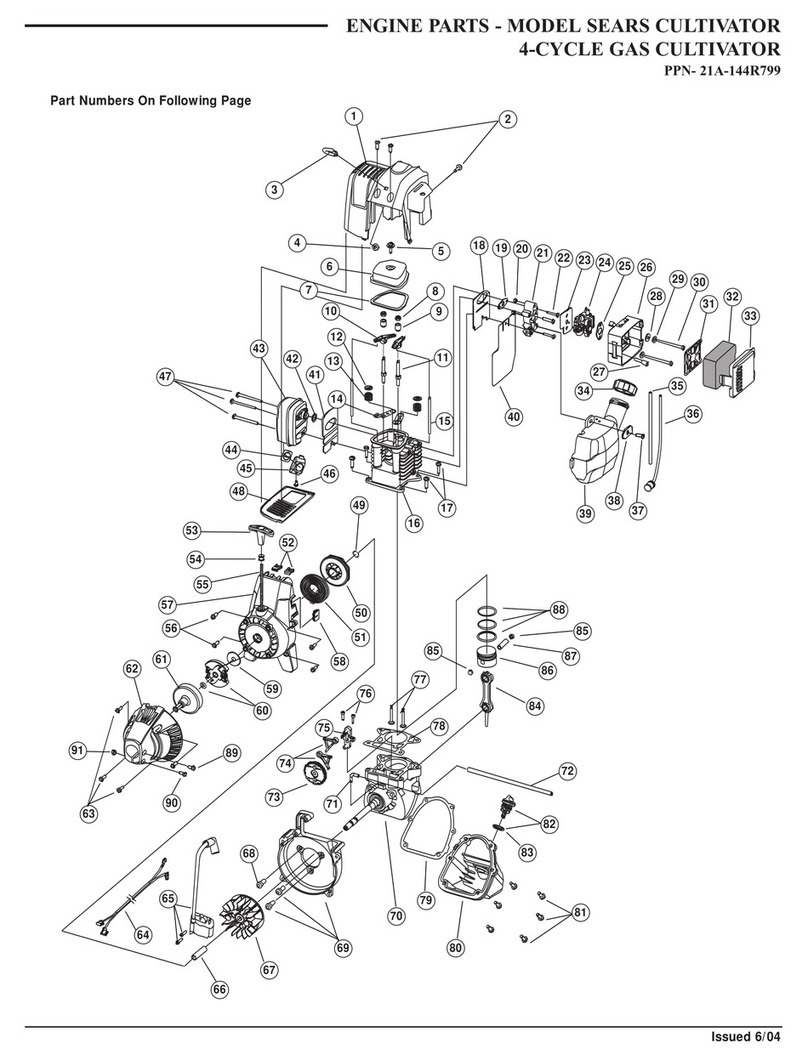

Popular Tiller manuals by other brands

SNOWJOE

SNOWJOE Sunjoe 24V-TLR-CT Operator's manual

Poulan Pro

Poulan Pro 96092001501 Illustrated parts list

Homelite

Homelite 24666 Instructions-parts list

Craftsman

Craftsman 293410 Repair parts manual

Gardol

Gardol GLV 1200-31 Original operating instructions

Craftsman

Craftsman INCREDI.PULL 316.299371 Operator's manual