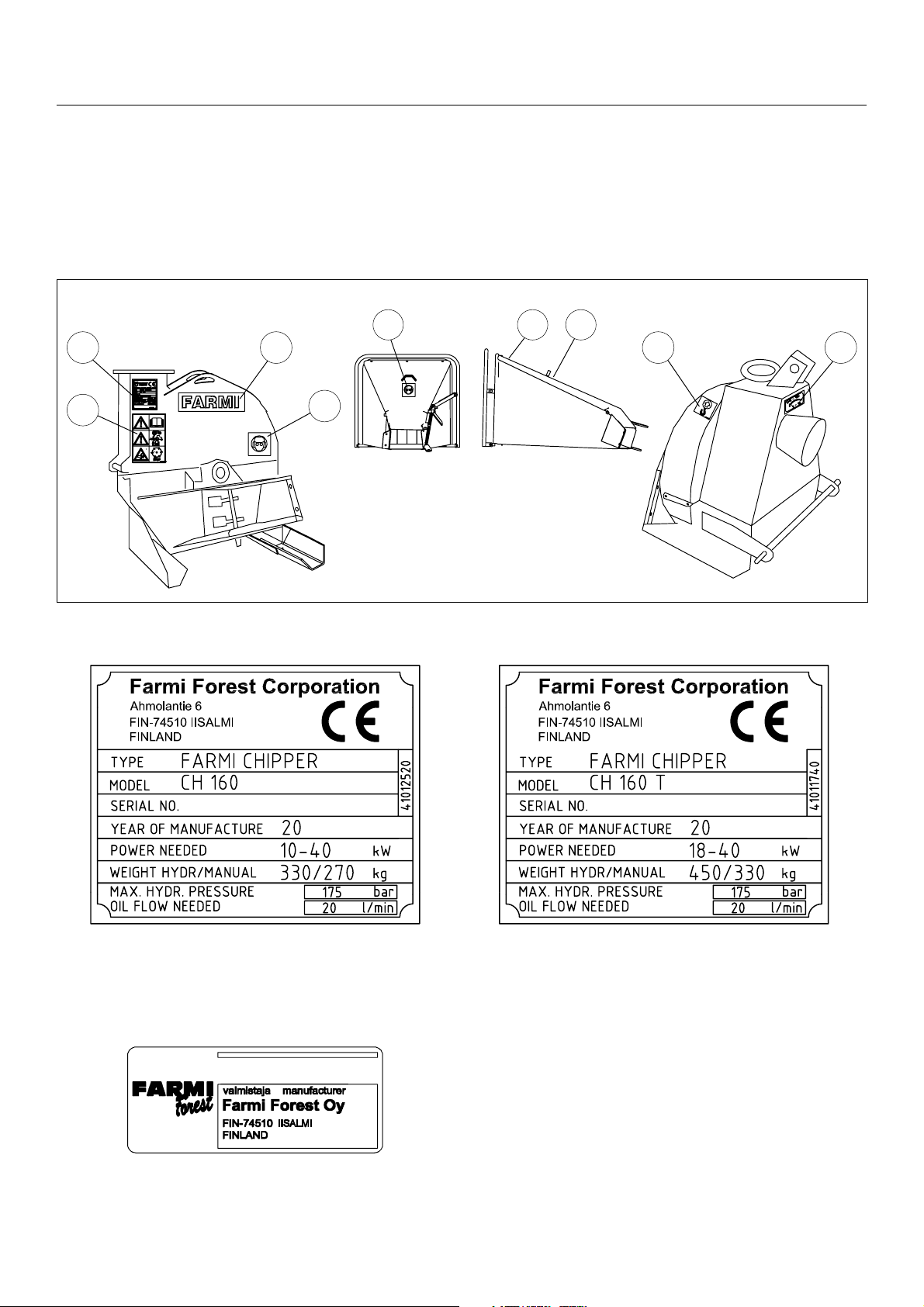

CH160

6

OPERATION

Many occupational accidents

take place in abnormal

circumstances. Therefore it is

important to take into account

all the possible circumstances

that may arise during operation

of the machine.

Depending on the machine’s type, it will have

diverse safety devices and protectors. These are

meant to protect the machine and its operator,

and they must never be removed or altered.

Never start up or use the machine without all

the safety devices and protectors in place. Also

check the universal joint’s safety equipment and

joins.

Never insert any body part into the machine with

the engine running.

If any faults arise that may jeopardize occupational

safety, turn off the machine.

During operation, the machine’s operator is

responsible for safety in the whole work area.

Work may not be carried out in the presence of

any factors that jeopardize occupational safety.

Exercise extreme caution when hitching /

unhitching the machine from a tractor/trailer.

The machine’s operator must

have constant, unobstructed

visibility of the work area. If

this is not possible, the ope-

rator must work with an assis-

tant.

Look out for moving parts when the machine is

in operation.

Secure the machine against unauthorized and

accidental operation (e.g. moving when parked)

whenever it is left unattended.

Never leave the machine running unattended.

Avoid causing fast, stroke-like loading.

Never exceed the given operating values.

All safety and warning signs on and in the

machine must be legible and intact.

The machine may not be operated by persons

ZKRDUHXQZHOORUXQGHUWKHLQÀXHQFHRIGUXJV

or alcohol.

•

•

•

•

•

•

•

•

•

•

•

•

MAINTENANCE

The machine may only be serviced and repaired

by professionals.

Electrical and hydraulic faults may only be

repaired by authorized professionals.

In cases requiring welding, contact

the manufacturer.

Turn off the tractor engine and disconnect the

universal joint before beginning service or

maintenance actions.

Ensure that there is no pressure in the hydraulic

system.

Take out the key from the tractor’s ignition for

the duration of the servicing or maintenance.

Check that the power is off from the machine

you are working on.

When servicing the machine, place it on a level

surface and ensure that it cannot be moved.

Observe the service intervals and annual safety

inspections.

$OOVSDUHSDUWVDQGHTXLSPHQWPXVWIXO¿OOWKH

manufacturer’s requirements. This can be

guaranteed by using original parts.

Put all safety devices back into place immediately

once servicing or maintenance is complete.

When lifting the machine,

check that the lifting/hoisting

equipment is in perfect

working order. Check the

weight of the machine before

lifting it. Choose lifting

trajectories so that they do not

cause any danger.

0DQ\FRXQWULHVKDYHVSHFL¿FOHJLVODWLRQRQOLIWLQJ

hoisting cables and hoists. Always comply with local

safety regulations.

OILS AND LUBRICATION

Always use the oil types recommended by the

manufacturer. Other types of oil may cause

faults or improper operation of the equipment,

which could lead to serious damage to people or

property.

Never mix different liquids or oils.

Always follow the manufacturer’s lubrication

instructions.

Use control equipment carefully until the hydraulic

oil has had time to reach its operating temperature.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

DANGER!

!

CAUTION!

!

CAUTION!

!