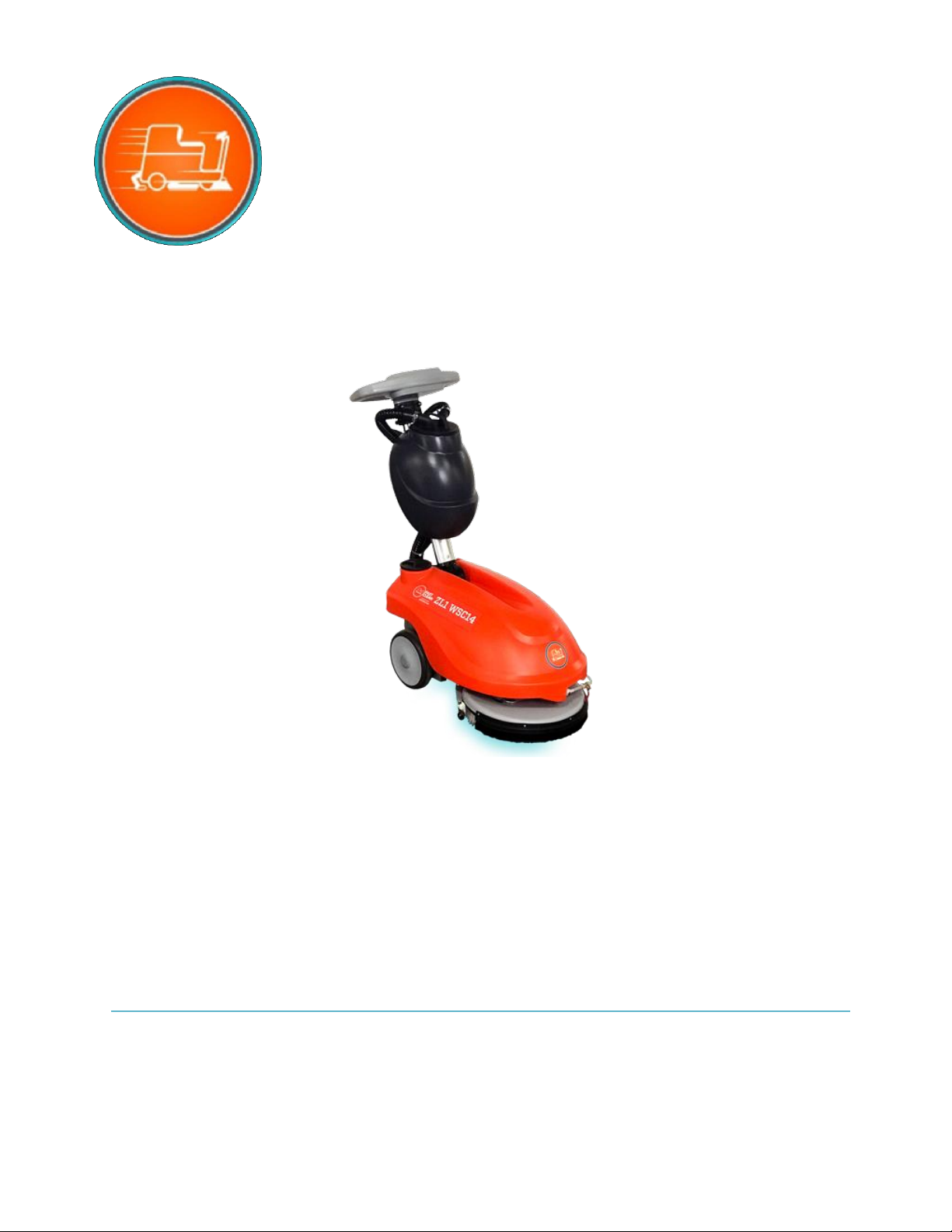

FAST CLEAN ZL1 WSC14 User manual

OWNER’S MANUAL

FAST

CLEAN

ZL1 WSC14

Battery Powered Automatic

Walk-behind Scrubber

FAST CLEAN, INC.

210 Southwest Ave. Tallmadge OH 44278

(833) 801-2358

ZL1 WSC14

2

NOTICE: Descriptions, features and specifications of the

machine in this publication are not binding, and are subject

to change without notice. The manufacturer reserves the

right to make necessary changes and modifications as

conditions warrant. Reproduction of the text and diagrams

contained in the present manual, without manufacturer

consent, is illegal.

IMPORTANT: Before operation or use of this machine,

please carefully read this manual.

When ordering the replacement parts, please refer to the

spare and accessory parts manual attached to the

machine. Before matching parts or accessories, please

first determine your machine model and serial number.

You may order parts and accessories from any authorized

service center or dealer. Please follow the instructions in

the manual.

Follow manufacturer’s instructions for operating the

machine.

Perform maintenance according to the maintenance

instructions provided in the operation manual.

Use the OE or same-grade parts for maintenance.

Please dispose of old machine components

such as packaging material, battery, etc.

and toxic liquid such as antifreeze and oil

according to your local regulations on waste

disposal and on environmental safety.

Machine Information (Please fill in for future reference.)

Model number-

Machine number-

Machine option-

Sales representative-

Tel. of sales representative-

Customer ID-

Installation date-

Table of Contents

General Operating Instructions.........................................2

User Responsibility ...........................................................3

Unpacking the Machine ....................................................3

Battery Instructions ..........................................................3

Recharging the Batteries...................................................3

Battery Power Gauge .......................................................3

Machine Diagram .............................................................4

Control Panel ...................................................................4

Machine Unpackaging ......................................................4

Battery Installation ............................................................4

Preparing the Machine for Use .........................................4

Filling the Solution Tank....................................................5

Operating the Machine ....................................................5

Routine Maintenance and Cleaning of Machine ..............5

Brush/Pad Recommendations .........................................5

Specifications

Troubleshooting ...............................................................5

Warranty Card ..................................................................6

General Operating Instructions

Scrubber should only be operated in designated areas by

trained personnel.

Scrubber should not be left unattended while running. Turn

off the machine before walking away.

Always be aware of your surroundings before and during

operation of the scrubber. Be careful operating around

obstacles, stairs, drop-offs, and steep inclines. Also

ZL1 WSC14

3

operate carefully around other workers in the area. Keep

children away from the machine.

Use only manufacturer-recommended low foam cleaning

detergents in the machine. Follow chemical manufacturer

directions for mixing and dilution ratios.

Warning: Do not use in an area where explosive or

corrosive vapors, such as gasoline fumes or paint thinner,

are present.

Warning: Do not use acetone or other harsh solvents in or

around the scrubber, as this may cause corrosion to

sensitive machine parts.

Warning: Do not operate scrubber on floor surface where

the slope exceeds 5%.

Maintenance and repairs should be done only by factory-

trained personnel. Contact manufacturer or local dealer for

more information.

When cleaning, servicing, transporting, or performing

maintenance on the machine, be sure to turn off

machine, and disconnect the power.

Warning: Do not use steam or pressure washer to clean

the scrubber as this may allow water into electrical

components, and damage the machine.

Be sure that brush, squeegee, hoses, solution and

recovery tanks are properly fitted before using.

Do not attempt to operate or perform maintenance on the

machine in a manner other than recommended by manu-

facturer.

User Responsibility

ZL1 WSC14 is designed for scrubbing and vacuuming

indoor hard floor surfaces. (It is not intended for parking

lots, sidewalks, or other outdoor areas). Please follow the

manufacturer’s instructions for operation, maintenance,

and transportation of machine as given in this manual. If

the machine is operated outside manufacturer’s guidelines

and recommendations, the manufacturer will not be held

liable for the consequences.

Machine should be operated, maintained, and repaired by

trained personnel. Operators must comply with accident

prevention, safety, and health regulations.

Do not make changes or modifications to the machine

without manufacturer’s consent. Manufacturer will not be held

responsible for damages resulting from such changes.

Unpacking the Machine

Please carefully inspect whether there is damage to the

packing crate of the machine. If there is, please imme-

diately notify your carrier.

The machine should arrive in a cardboard box of the

approximate dimensions as shown in the following

diagram. If you are transporting or shipping multiple

machines, we recommend stacking no higher than four

packages.

A: 20” B : 18 ¼” C: 37 ½”

1. Open the top of the cardboard box.

2. Carefully remove the machine from the packaging, and

cut straps, cords, and fastenings.

3. Remove machine from pallet.

4. Take out the recovery tank, charger, and scrub pads.

Battery Instructions

ZL1 WSC14 comes standard with two 12 volt lead acid

(wet) rechargeable batteries, and 24V/15A battery charger.

Optional no-maintenance gel

batteries are available. Consult

your local dealer for details.

Battery dimensions should not

exceed (L/W/H): 10 ¾”, x 3 ½”, x 7

¾”. The battery weight should not

exceed 26.5 lb. per battery.

ZL1 WSC14

4

In order to achieve a capacity of 24V, the batteries must

be connected in series, and the connection process should

carried out by trained personnel. Consult your local dealer

or service center if you have questions.

ATTENTION: If you are using optional gel

batteries, the PCB board must be reset by a

trained professional. Consult your local dealer or

service station before installing gel batteries!

Battery Installation

The batteries are housed in the battery compartment

under the solution tank. To install the batteries you must:

1. Remove the solution tank

2. Open the two rear latches that

fasten the battery compartment.

3. Rotate the handlebar by lifting the

handlebar control lever.

4. Place the batteries in the

compartment (as shown on left).

5. Connect the battery cables.

ATTENTION: We recommend using factory

sealed batteries to avoid acid leakage.

Please wear appropriate protective gear: safety

glasses, apron and gloves when performing

battery maintenance. Avoid contact with battery

acid as it is highly corrosive.

Recharging the Batteries

Check the battery power level. If anything less than 4 (full

charge) is indicated, please charge batteries before using

the machine.

Note: Make sure that the battery charger matches the

installed batteries, both in capacity and in type. Never use

a charger that is not intended for your batteries.

To charge the batteries, follow these instructions:

1. Be sure machine is turned off.

2. Take machine to recharging area.

3. Plug DC cable into charging port

as shown in the photo.

4. Plug AC cord into outlet/power

source.

Warning! Never charge a GEL battery with an

unsuitable battery charger. Strictly follow the

instructions provided by the battery and battery

charger manufacturer.

IMPORTANT! In order to avoid permanent damage to the

batteries, they should not be allowed to run completely

down. Batteries should be recharged within a few minutes

after the low battery warning light starts to flash. Do not

leave batteries for long periods of time without recharging

routinely, as they will slowly lose their charge even when

not in use.

We recommend proper ventilation in the area where

batteries are being charged.

Warning! Fire or explosion hazard. The batteries may release

hydrogen. Please keep away from spark or open flame. The

battery compartment must be kept open when charging.

The machine will not operate while it is charging. While

charging, please do not pull the DC cord out of the port at

the back of the machine. If charging must be halted before

it is complete, please unplug the AC power cord from

power source first.

Battery Power Gauge

The batteries’ power gauge is digital with 5 power level

indicators as follows:

4 = Maximum charge (near 100%)

3 = 75% charge

2 = 50% charge

1 = 25% charge

0 = near 0% charge (blinking)

Warning! 8 seconds after the “0” blinks, the brush motor

automatically switches off. Recharge the batteries before

reusing or storing the machine. It may shorten the life of the

batteries if they are allowed to run completely out of charge.

Operation Controls for ZL1 WSC14

*Note: the control panel arrangement on your

machine may not be exactly like the above

photo, but it will use the same icons.

ZL1 WSC14

5

Turn Power On/Off

Turn Solution Flow On/Off

Turn Brushes On/Off

Turn Vac On/Off

Battery Power Level (0 –4)

Machine Diagram

1.

Steering, Control Panel, Main Power, Battery Power Gauge

2. (On front) Vac Hose to Recovery Tank and Waste Water

Intake Hose (On back) Squeegee Raise/Lower & Center

Pole Height Levers

3. Recovery Tank

(Detachable)

4. Solution Tank

Fill Port

5. Solution Tank

(Detachable)

6. Battery Compartment

7. Wheel

8. Scrub Deck &

Squeegee Assembly

9. Recovery Tank Lid

& Hose Fittings

10. Handlebar

11. Solution Tank Flow

Adjustment Valve, Drainage

Plug & Quick Disconnect

Preparing the Machine for Use

In order make it more compact for shipping and trans-

porting, the scrubber is packaged with the handlebar

folded, and recovery tank detached. Follow these

instructions in order to prepare the machine for use:

1. Adjust the handlebar by

pulling up on the lever on the

back right. (See top photo and

#2 in machine diagram). Adjust

to comfortable working height.

2. Mount the recovery tank on

handlebar using the two

hooks.

3. Put the lid onto the recovery

tank. Insert the connecting

hoses into the fittings on the lid

of the recovery tank as shown

in photo at right and in the

machine diagram at left (note

hoses at #2)..

4. Be sure connecting hose from solution tank is properly

fitted into the port in recovery tank as shown in machine

diagram (behind #4 Solution Tank Fill Port).

5. Check that the solution tank flow adjustment plug is

properly inserted and the quick disconnect is closed. (See

#11 in machine diagram at left.)

6. Check to see that brushes and squeegee are properly

installed and tightened. (See “Cleaning the Squeegee” and

“Removing the Scrub Brush” later on for details about

installing/changing squeegee and brushes/scrub pads.)

7. Turn on machine and check power gauge. If it is less

than “4”, we advise charging the batteries (see instructions

on previous page regarding batteries).

Filling the Solution Tank

1. Open the solution fill port by twisting off the plug (see #4

in machine diagram at left). Make sure solution tank is

securely fitted into place. (It is detachable).

2. Check that the drainage plug is securely in place and

connection is tight. See that the solution flow valve is

open. Check for kinks, blockages or loose connection in

the tube. (See #11 in machine diagram).

3. Pour in clean water through the fill port at a temperature

that does not exceed 140°F (50°C). Add low foam cleaning

chemical, and use mixtures recommended by the chemical

manufacturer. Do not overfill.

1

3

9

10

5

6

7

4

2

8

11

ZL1 WSC14

6

Warning: Do not use a high foaming agent, or too high a

concentration of cleaning chemical as this could cause

excessive foam buildup in the machine, which could

damage the vac motor.

Warning: Do not use harsh solvents or other strongly

corrosive chemical agents, as this may damage the

machine. Consult your local dealer or service center if you

have questions.

Warning! Do not exceed maximum temperature

recommendation (50°C or 140°F) forcontent of

solution & recoverytanks.

Operating the Machine

1. Turn the flow adjustment valve on. (See above left

photo and #11 in Machine Diagram.)

2. Pull the lever to lower the squeegee and brush head.

(See above right photo and #2 in Machine Diagram).

3. Press the power button and make sure that gauge

reads “4” (fully charged). If it is less than 4, we

recommend turning off the machine and charging the

batteries before proceeding.

4. Turn brushes on.

5. Turn solution flow on.

6. Turn vac motor on.

7. Allow machine to move forward. (Motion of the scrub

brush or pad will naturally pull the machine forward).

Warning! Do not attempt to back machine up without first

raising the squeegee. (Lift lever on back).

Warning: Fire or explosion hazard. Do not attempt to vac

up flammable or corrosive liquids, dust, vapor, or reactive

metals.

For Best Scrubbing Performance:

If floors are especially dirty, we recommend a two-pass

system. On the first pass, turn off vac and dispense clean-

ing solution. Allow the detergent to work on floor for 3-5

minutes (follow recommendations of the chemical manu-

facturer). On the second pass, turn on the vac and allow

the machine to vacuum up the solution from the floor.

Routine Maintenance Instructions

Cleaning the Machine After Use:

1. Turn off the brushes, solution flow and vac.

2. Turn off power.

3. Raise squeegee by lifting the lever in back.

4. Move the machine to cleaning/draining area.

5. Drain the solution tank by pulling the drainage plug at

the front of the machine (To the left of the valve in the

photo on the left).

6. Remove the hoses from the recovery tank and allow it

to drain. Take recovery tank off handlebar and flush

with water until it is clean, then allow it to drain and air

dry.

7. Dismantle the scrub brush or scrub pad and rinse with

water. Inspect condition of brush or pad and flip over

or replace with new one if necessary.

8. Clean the squeegee. Inspect condition of squeegee

and reposition or replace squeegee if necessary.

Important: We do not recommend using steam

cleaning or pressure washer to clean the scrubber.

ATTENTION! Always wear gloves during maintenance

procedures to avoid any contact with potentially

harmful substances. Follow maintenance procedures

and allow machine to air dry thoroughly before storing

in order to avoid buildup of unpleasant odors,

residues, or harmful bacteria inside machine or on

brushes.

Recovery Tank Cleaning:

1. Remove the hoses from the ports on top of tank. Clean

hoses according to directions under “Weekly Mainten-

ance Instructions”.

2. Open the recovery tank cover by turning it

counterclockwise.

3. Drain recovery tank.

4. Take out the filter and rinse with water. Inspect for

corrosion or damage, and replace if necessary

5. Rinse the recovery tank with water and clean with mild

detergent if necessary. Do not use steam or pressure

washer to clean the machine.

6. Leave recovery tank open and allow to air dry.

Cleaning the Squeegee

The squeegee must be in perfect working condition in

order to dry the floor properly. If the scrubber is leaving

dirty streaks behind, you will need to clean, reposition, or

replace the squeegee:

1. Raise the squeegee assembly bypushing the left lever

on back.

ZL1 WSC14

7

2. Lift the machine (see photo 1)

3. Remove the hose from the squeegee assembly (see

photo 2).

4. Loosen the 2 screws as shown in the picture to

remove the squeegee (see photo 3).

5. Carefully clean the squeegee and squeegee holders.

6. Reassemble everything.

Note: Each squeegee has four working edges. If you flip

over the squeegee and put it back into the assembly, you

can reuse it until all the edges are worn down. (Working

edge of squeegee should be square and meet the ground

properly).

Showing all parts of squeegee assembly:

Removing the Scrub Brush

1. Raise the squeegee assembly. (See photo 5).

2. Lift the machine by pushing down on the handlebar.

3. When the base is lifted, turn the brush control

clockwise. The brush releases automatically.

Weekly Maintenance Instructions

Clean the Vac Hose

Weekly or whenever the vacuum

loses suction, it is necessary to

flush out the vac hose as follows:

1. 1. Remove the hose from the

squeegee assembly.

2. 2. Unplug the other end from the

recovery tank.

3. 3. Wash the inside of the pipe with

a jet of water, from the side that

plugs into the tank as shown.

4. Reassemble the hose.

ATTENTION! DO NOT WASH THE PIPE THAT

CONNECTS THE VACUUM MOTOR AND RECOVERY

TANK! DOING SO MAY DAMAGE VAC MOTOR!

Clean the Solution Tank

1. Unscrew the plug on the solution tank.

2. Flush the inside of the solution tank with clean water.

3. Remove tank and dump.

ZL1 WSC14

8

4. Allow tank to drain and air dry.

5. Reinstall the plug.

Brush Recommendations:

Polypropylene Brush(PPL)

This general purpose scrub brush is recommended for all

floor types and offers good resistance to wear and to hot

water (not over 60°C / 140°F). PPL is not hygroscopic (it

does not absorb moisture), and is ideal for working on wet

floors.

Nylon Brush

This brush is used on all floor types and offers excellent

resistance to wear and to hot water (not over 60°C /

140°F). Nylon is hygroscopic (it absorbs moisture) and

tends, over a period of time, to lose its character when

working on wet floors.

Pad Driver

Scrubbing pads are recommended for cleaning polished

surfaces, there are two types of pad holders:

1. Traditional pad holders with set of anchor stubs that

hold and turn the scrub pad during operation.

2. Center lock pad holders that have anchor stubs and a

plastic snap-in center lock system. This allows perfect

centering of the scrub pad and ensures it is kept

anchored without slipping during the operation of the

machine.

Consult your local dealer or service center for more details

about scrub brush and scrub pad/driver types & uses.

Machine Specifications

Specifications

Unit

ZL1 WSC14

Voltage

V

24V (2 x 12V)

Amps

AH

35

Run Time

hrs

2 (approx.)

Cleaning Efficiency

ft2/hr

9,000 (approx.)

Drive Speed

mph

2.2

Max Surface Gradient

%

2

Scrubbing Path

in

14

Vacuuming Path

in

17

Vac Lifting Power

bar

.1

Brush Speed

rpm

180

Brush Motor

hp

54

Vac Motor

hp

50

Solution Tank Capacity

hp

50

RecoveryTank Capacity

gal

3

Solution Tank Capacity

gal

3.5

Weight (w/Batteries)

lb

154

Machine Dimensions

in

28 x 36x 17

Troubleshooting

Problem

Cause

Solution

Insufficient water and detergent

on the scrub brush/pad.

Solution tank is empty.

Refill solution tank.

Solenoid valve switch is off.

Turn on solenoid valve switch.

Flow control valve is off.

Open flow control valve.

Quick-fit connection is loose or

disconnected on solution hose.

Fix quick fit connection.

Machine is not cleaning well.

Brush or scrub pad is worn down.

Check condition of brush or pad and

replace with new one if necessary.

ZL1 WSC14

9

Detergent in machine is not aggressive

enough to remove soil from floor.

Try using a different detergent, or use a

two-pass cleaning system and allow

detergent to sit on floor surface for 3-5

minutes before second pass. (Consult

cleaning chemical manufacturer or local

dealer if you have questions).

Brush or pad is not aggressive enough

for your application.

Consult your local dealer for advice for

appropriate brush/pad for your

particular application.

Squeegee is not drying the

floor, or is leaving drag marks.

Squeegee is dirty or worn down.

Clean squeegee. Reposition or replace

worn squeegee with new one.

Vac motor is not turned on.

Turn on vac motor.

There is a blockage in the hose

between vac pipe and recovery tank.

Drain recovery tank, check the hose

and clean it.

Vac unit is dirty or malfunctioning.

Try cleaning vac unit. If it is still not

working, contact local service center.

Too much foam is forming in

recovery tank.

Too high a concentration of detergent

is in solution tank, or wrong detergent

has been used.

Try adding an anti-foam liquid to the

solution in machine. Use lower

concentration of detergent in the

solution tank or try a different

detergent. (Consult chemical

manufacturer or local dealer).

The machine cannot be

operated.

Batteries have no power.

Charge batteries.

Batteries will not charge.

Replace batteries

Battery wiring is not connected.

Check battery wiring. Connection may

be loose.

Fuse has blown.

Replace the fuse.

Run time has shortened.

Batteries have worn out.

Replace batteries.

Battery charger has failed.

Replace charger or contact service

center.

Warranty Card

(please fill out and return to dealer)

Name Phone #

Address

City State Zip

Purchase Date Invoice #

Model # Serial #

Local Dealer Local Dealer City/State

Warranty provided with purchase invoice.

Table of contents

Other FAST CLEAN Scrubber manuals