10 11

MACHINE INSTALLATION

Explanation: As for the brush and scouring pad suggested for use, please refer to the section of [Informa-

tion on Brush and Scouring Pad] in this Guide or consult your local authorized dealer.

1. Stop and place the machine on the level ground and take out the key.

2. Step on the brush head lifting pedal to lift up the brush head from the ground.

3. Place the scouring pad on the holder and then install the drive disc. Fasten the central lock to x the

scouring pad.

4. Align the holder/brush installation stud at the motor drive disc buckle and press the motor switch of the

brush.

5. If the holder and brush are to be dismantled, step on the brush head lifting pedal to lift up the brush head

from the ground, press the motor switch of the brush.

Installation of Brush/Scouring Pad

MACHINE OPERATION

FOR SAFETY: Please do not operate this machine before reading and undertanding the operation manual.

WARNING: Fire or Explosion Hazard: Do not operate the machine close to or in the place

where there is ammable liquid, air or dust.

Pre-operational Examination

[ ] Clean the dust on the ground.

[ ] Check the scale of the battery coulombmeter. (refer to the battery coulombmeter)

[ ] Check the abrasion conditions of the scouring pad/brush.

[ ] Check the abrasion conditions of the squeegee adhesive tape and reasonably adjust the angle.

[ ] Conrm that the waste water tank is empty and has been equipped with clean oating lter screen.

[ ] Check the abrasion conditions of the skirt section of the brush head.

1. Switch the key of the main power supply to the position of (I).

2. Pull down the squeegee lifting rod to lower the squeegee component to the ground.

3. Step on the brush head lifting pedal to lower the brush head to the ground.

4. Switch on the clean water control knob.

5. Press the motor switch of the brush and press the switch of water suction motor.

6. Motor drive model: adjust the speed control knob to the cleaning speed required by you.

Explanation: It is suggested to use the cleaning speed of 45-60 meters/min.

1. Each cleaning path overlaps by 5cm.

2. Let the machine advance constantly to avoid ground damage.

3. If there is drag mark on the ground after the squeegee absorbs water, remove the waste with duster

cloth wiping adhesive tape. Clean in advance to prevent drag mark.

Machine Operation

Machine Operation Duration

WARNING: Fire or Explosion Hazard: Please do not pick up ammable materials or reactive

metals.

4. Do not operate the machine on the slope with a slope over 5% (3°).

For safety, please move slowly on slope or skid surface.

5. If there is too much foam, it is suggested to pour the used defoamer solution into the waste water tank.

6. Use double cleaning method to clean the extremely dirty area. Lift up the squeegee firstly for cleaning,

sink with solution for 3-5 min, lower the squeegee for re-cleaning.

7. Replace or rotate the scouring pad as required.

8. Observe the power consumption of the battery coulombmeter (refer to the battery coulombmeter).

9. Observe the residual liquid amount through the liquidometer of the clean water tank. In traditional

scrubbing method, the consumption for each 10 min is about 10l.

10. When the solution in the clean water tank is used up, empty the waste water tank firstly, then re-pour

the solution.

11. When the staff leaves the machine, stop and place the machine on the level ground and take out the key.

12. After cleaning, carry out daily maintenance procedure.

MACHINE INSTALLATION

Note: Do not let the foam enter the lter screen so as to avoid damage to vacuum motor. The foam

will make the switch of the lter screen invalid.

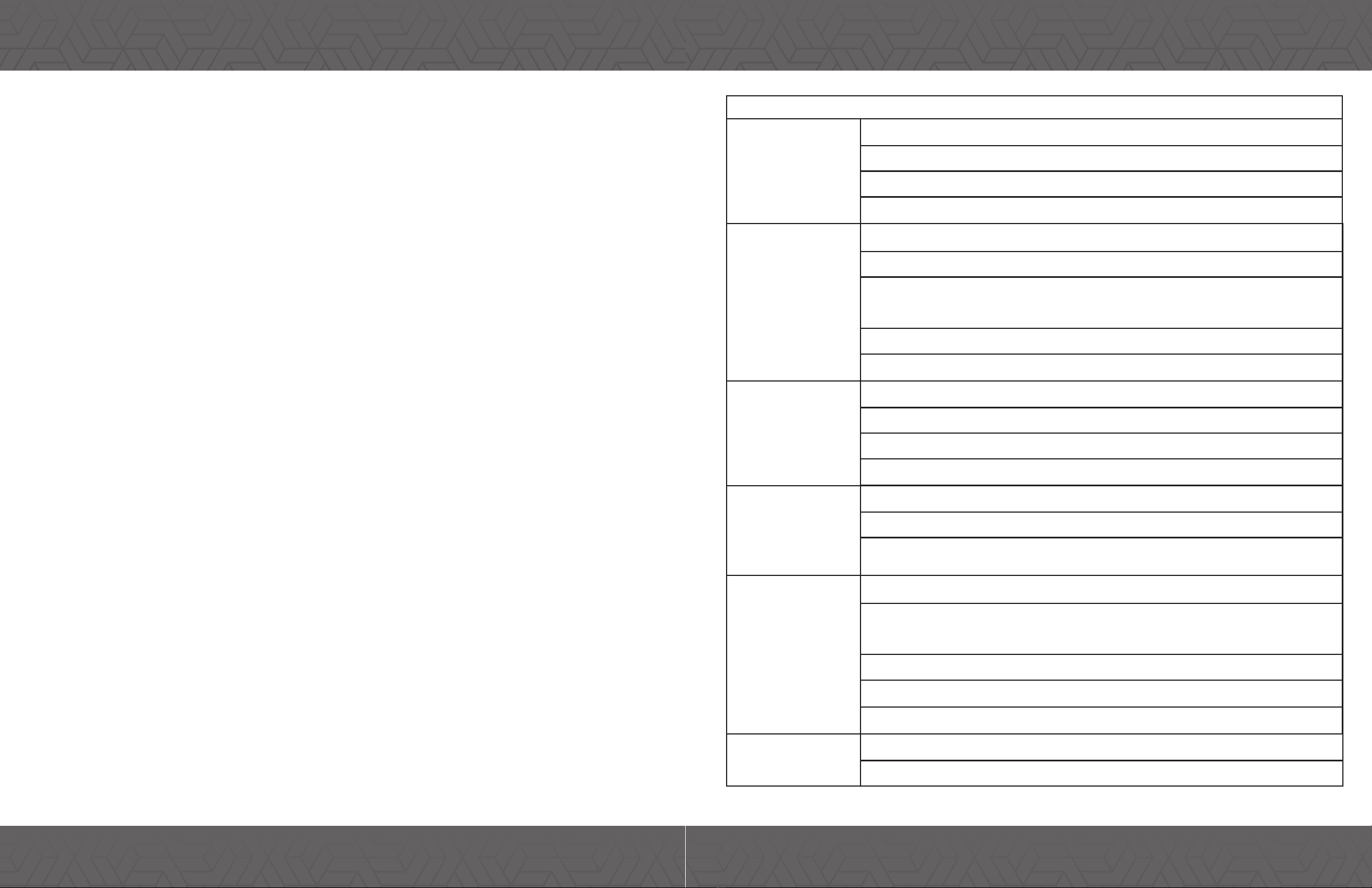

The battery coulombmeter will display the power quantity of the battery. When the battery is full of pow-

er, all indicator lights will be on. Along with the consumption of the power quantity, the indicator lights will

go out from the right to the left. To prolong the life of the battery, do not let the indicator lights go out to

below the following power consumption.

Explanation: To prolong the life of the battery, please ensure to charge the battery after the total use time

of the machine exceeds 30min.

After each use, the waste water tank shall be drained and cleaned. The clean water tank shall be periodical-

ly cleaned to remove any corroded parts. Carry the machine to the drainage place, switch o the key of the

power supply, and drain the water according to the following drainage instructions: for safety: please stop

and place the machine on the level ground and shut down the machine and take out the key before leaving

or maintaining the machine.

1. Unscrew the drain pipe cover of the waste water tank counterclockwise and take it down.

2. Open the cover of the waste water tank and ush the water tank.

3. Dismantle and ush the oating lter screen in the waste water tank.

Battery Coulombmeter

Drainage of Water Tank

Drainage of Waste Water Tank