FAST CLEAN SS WSC21 User manual

OWNER’S MANUAL

FAST

CLEAN

SS WSC21

Battery Powered Automatic

Walk-behind Scrubber

FAST CLEAN, INC.

210 Southwest Ave. Tallmadge OH 44278

(833) 801-2358

SS WSC21

2

Before operation or use of this machine, please carefully

read this manual.

When ordering the replacement parts, please refer to the

spare and accessory parts manual attached to the

machine. Before matching parts or accessories, please

first determine your machine model and serial number.

You can order parts and accessories from any authorized

service center or dealer. This machine can provide

excellent service. Please follow the instructions in the

manual.

Follow manufacturer’s instructions for operating the

machine.

Perform maintenance according to the maintenance

instructions provided in the operation manual.

Use the OE or same-grade parts for maintenance.

Please dispose of old machine components

such as packaging material, battery, etc. and

toxic liquid such as antifreeze and oil

according to your local regulations on waste

disposal and environmental safety.

Machine Information (Please fill in for future reference.)

Model number-

Machine number-

Machine option-

Sales representative-

Tel. of sales representative-

Customer ID-

Installation date-

Table of Contents

Precautions ......................................................................3

Basic Safety Instructions...................................................3

Maintenance Instructions .................................................3

Transporting the Machine ................................................3

Machine Diagram .............................................................4

Control Panel ...................................................................4

Machine Unpackaging ......................................................4

Battery Installation ............................................................4

Battery Power Gauge .......................................................5

Battery Charging ..............................................................5

Squeegee Installation .......................................................5

Scrub Brush/Scrub Pad Installation .................................6

Scrub Brush & Scrub Pad Recommendations .................6

Replacement of Squeegee ..............................................6

Before Running the Scrubber ..........................................6

Filling the Solution Tank ...................................................6

Starting the Machine ...................................................... 7

Running the Machine ..................................................... 7

Daily Maintenance .......................................................... 7

Drainage of Recovery Tank ........................................... 8

Monthly & Quarterly Maintenance .................................. 8

Machine Storage ............................................................ 8

Troubleshooting ............................................................. 9

Specifications.................................................................. 10

Warranty Card ............................................................... 10

SS WSC21

3

Precautions

This machine is intended for indoor hard floors only.

Please use the suggested scrubbing pads and brushes as

well as the manufacturer recommended cleaning chem-

icals suitable for this machine.

All operators should read, understand, and observe the fol-

lowing safety precautions and guidelines in this manual.

Warning! Fire or explosion hazard:

The battery releases hydrogen. Please keep away from

spark or open fire. The battery compartment should be

kept open when charging.

Do not use flammable liquid in the machine. Do not

operate the machine where there are flammable liquids,

vapors or dust.

This machine is not equipped with an explosion-proof

motor. If it is used where there is flammable vapor, liquid

or dust, the electric motor may generate a spark while

starting the machine. This may cause flash fire or

explosion.

This machine is not recommended for vacuuming up

flammable materials, reactive metals, or corrosive liquids.

Warning! To avoid injury, turn off the power before

performing routine maintenance on the machine. We also

recommend disconnecting the battery wiring before

performing any electrical maintenance.

Basic Safety Instructions

1. Before starting the machine please ensure that all safety

guards are in place and operating correctly.

2. Proceed slowly when operating on a slope or slippery

surface, or when turning the machine.

3. Please discontinue use and have machine serviced if

it is damaged or not operating properly.

4. Follow the chemical manufacturer’s mixing ratio and

instructions.

5. Do not leave machine unattended without first turning

off the power.

6. Do not allow children on or around the machine.

7. Please wear anti-skid shoes.

Maintenance Instructions

All maintenance should be carried out by trained, qualified

personnel.

Do not change the original design of the machine without

consulting the manufacturer.

Use replacement parts provided or recognized by the

manufacturer or local dealer.

Turn off machine and disconnect battery wiring before

performing maintenance. Avoid moving parts. Do not wear

loose clothing that may catch in the machine.

If performing maintenance on batteries, wear appropriate

safety gear such as gloves, apron and safety glasses.

Avoid contact with battery acid as it is extremely corrosive.

Wash immediately with soap and water if you come in

contact with battery acid.

We do not recommend using pressure washer or steam

cleaner to clean the machine.

Instructions for Transporting the Machine

1. Please turn off the power before moving the machine.

2. Lift the brush head to the transport position.

3. Use a ramp when loading or unloading the machine.

4. Lean the front of the machine closely against the front

part of the truck or trailer in order to brace for tie down.

5. When the machine is in place, lower the brush head,

and make sure the key is in the off position.

6. Place blocks behind the wheels to keep the machine

from sliding.

7. Use a rope or strap to tie the top of the machine in order

to keep it from shifting during transportation.

8. For safety: when transporting the machine, we recom-

mend using a ramp when loading or unloading the

machine from truck or trailer.

SS WSC21

4

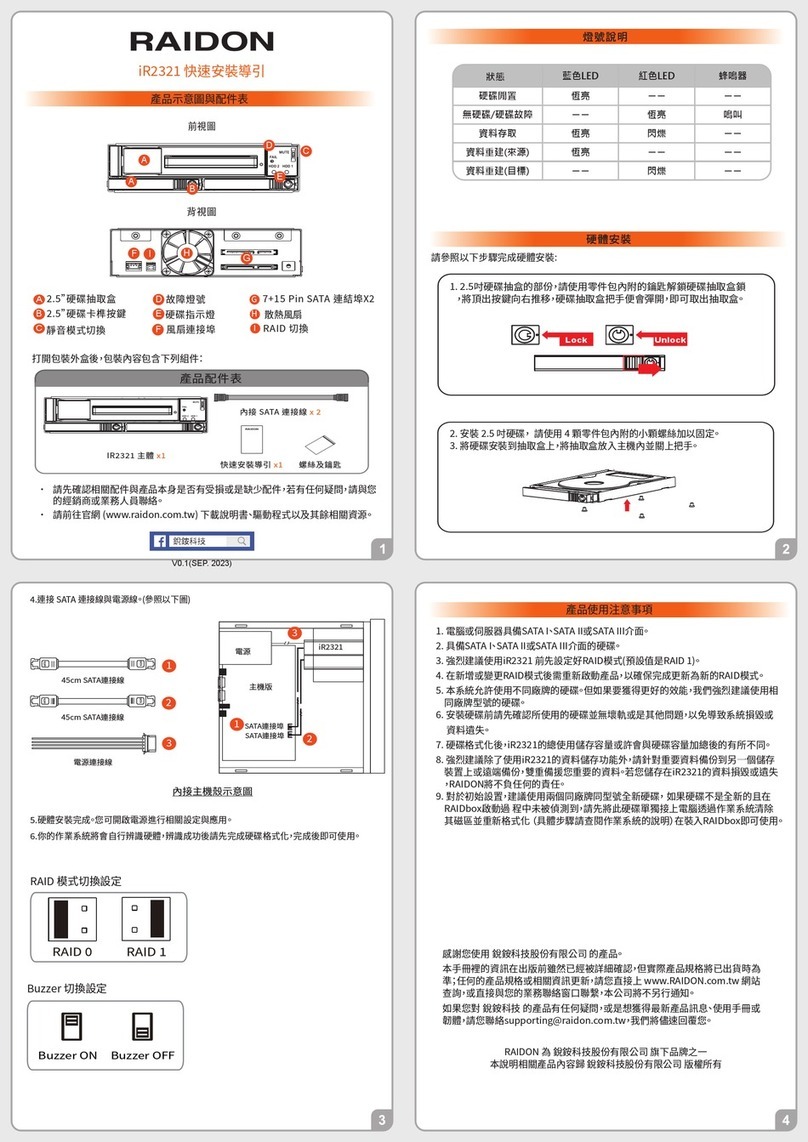

Machine Diagram

1. Steering (Brush Propelled)

2. Control Panel

3. Recovery Tank Drain Hose (on back)

4. Squeegee Raise/Lower Lever

5. Vac Hose (on back)

6. Brush Head Lift/Lower Pedal

7. Battery Charge Port (on back)

8. Squeegee Assembly

9. Wheels

10. Adjustable Solution Flow Lever (on back)

11. Recovery Tank Lid

12. Solution Tank Fill Port (inside)

13. Battery Compartment & Lock Nuts (lift\

recovery tank)

14. Brush Head

Control Panel Operations

1. Forward/Reverse (Manual)

2. Brush On/Off

3. Power On/Off (Key switch)

4. Vac On/Off

5. Battery Power Indicator

Machine Unpackaging

1. After receiving, please inspect whether there is damage

to the packing crate of the machine. If there is, please

immediately notify carrier.

2. Check the freight list. If there is any omission, please

contact the distributor. Your crate should contain:

- Two 12V wet, maintenance–free batteries - standard

- One 24V/15A battery charger - standard

- One set of battery cables - standard

- One squeegee - standard

- One scrub brush - standard

- One pad driver - standard

- (Optional) Other accessories - additionally purchased

3. Before unpackaging the machine, please remove

cardboard box and loosen or cut the straps that fasten the

machine to the pallet. With at least one other person,

carefully unload the machine from the pallet.

Note: Please install the batteries after unloading the

machine from the pallet. (See following).

Do not drive the machine directly off the pallet without

using a ramp.

Battery Installation & Instructions

Warning: Fire or explosion hazard. The batteries release

hydrogen. Please keep away from spark or open flame.

The battery compartment should be kept open when

charging.

For safety: Please wear appropriate protective gear:

safety glasses, apron and gloves when performing battery

maintenance or wiring. Avoid contact with battery acid.

Place the machine on the level ground and take out the

start key.

Lift up the recovery tank to access the battery compart-

ment. (Make sure the recovery tank is clean and dry first).

Place batteries into the battery compartment and connect

the battery wiring according to the diagram on next page:

1

2

1

3

4

5

Black

Red

Be careful that

the poles are

connected

properly!

1

2

3

5

6

7

8

9

12

13

14

10

4

11

SS WSC21

5

Note: Place batteries carefully into compartment in order to

avoid damage to the battery and the machine.

Before connecting the batteries, please inspect whether

the electrodes and terminals are clean. Use terminal

cleaning fluid and wire brush as required.

Paint a thin layer of metal-free lubricating oil or protective

spray on the connected wiring to avoid battery corrosion.

After the batteries are installed, please check the power

gauge. If all lights are lit, batteries are ready for use. If

not, batteries need to be recharged.

Battery Power Gauge

The battery power gauge will display the power level of the

battery. When the batteries are fully charged, all indicator

lights will be on. As the machine runs and power is drawn

from the batteries, the indicator lights will go out. In order

to prolong the life of the batteries, do not let the batteries

run completely down.

Battery Charging

Note: To prolong the life of the batteries and ensure the

optimum efficiencyof the machine, the batteries should be

charged after the machine has been used 30 minutes or

more. Please do not let batteries run too low before

recharging. Do not leave batteries unused for long periods of

time, without recharging routinely, as they will slowlylose

their charge even when not in use. The following charging

instructions are specifically for the charger attached to this

machine. Please besure to use the charger of the following

specification to avoid damaging batteries.

Charger specifications:

Battery type –maintenance free wet batteries

Output voltage - 24V

Output current - 15A

Intended for deep cycle battery charging

Charger lights indicate the following:

- Red: Battery or charger failure. Try replacing batteries

or contact local service center for assistance.

- Yellow: Charging is completed.

- Green: Battery charging is in progress.

Proper ventilation is recommended in the area where

batteries are being charged.

Warning! Fire or explosion hazard. The batteries release

hydrogen. Please keep away from spark or open flame. Do

not place tools, metal shavings or other metal instruments

on batteries as this could cause an electrical arc.

1. Stop and park the machine on level ground and

turn off power with the key.

2. Before charging, check the electrolyte level in each

battery (if batteries are not the standard maintenance-

free type).

3. For safety: Please wear appropriate protective gear:

safety glasses, apron and gloves when performing

battery maintenance or wiring. Avoid contact with

battery acid.

4. When charging, please open recovery/solution

tank to facilitate ventilation.

5. Plug the AC (alternating current) power cord of the

charger to the outlet/power source.

6. Plug the DC (direct current) power cord of the charger to

the battery charging port at the rear of the machine.

7. The charger will automatically begin charging, and will

automatically switch off when the batteries are fully

charged.

Note: The machine will not operate while it is charging.

While charging, please do not pull the DC cord out of the

port at the back of the machine. If charging must be halted

before it is complete, please unplug the AC power cord

from power source first.

8. After the charging is completed, recheck the electrolyte

level in the batteries (only if equipped with non-

maintenance-free batteries).

Contact your local service center or authorized dealer if

you have questions regarding battery maintenance or type

of batteries to use with this machine. Note: maintenance-

free gel batteries may be available with this model as a

non-standard option. Contact your dealer for details.

Installation of Squeegee Assembly

1

2

Be careful that

the poles are

connected

properly!

SS WSC21

6

1. Connect vac hose into port.

2. Adjust squeegee pitch by turning knob.

Scrub Brush and Pad Driver Installation

1. Turn off machine with key switch. Remove key.

2. Lift brush plate 45° and rotate counterclockwise

direction.

3. Remove scrub brush or pad driver.

4. Install new scrub brush or pad driver and rotate

clockwise until it fits into place.

5. Rotate brush plate back into place.

Note:Turning thestar knob on the brush head clockwise

accelerates brush/pad speed. Turning the knob counter-

clockwise decelerates

brush/pad speed. We

recommend lowering the

brush speed before the

installation process and

returning brush speed to

normal afterward. Adjust

knob until brush/pad

operates at the desired

speed/pitch.

Scrub Brush and Scrub Pad Recommendations

In order to ensure the optimum efficiency, please use the

suggested type of brush or pad for the surface you are

cleaning. Please read the following:

Soft nylon brush (white) –Recommended for use on

coated floors to avoid abrading the surface.

Polishing pad (white) –Recommended for maintaining

highly smooth or polished floors.

Scrubbing pad (red) –Recommended for lightly scrubbing

dirt without damaging the floor.

Grit scrub pad (black) - Recommended for aggressively

removing heavy buildup or base or super-powerful

scrubbing.

Please consult your local dealer if you have any questions.

Replacement of Squeegee

1. Park the machine on level ground, turn off power switch

and take out the start key.

2. Lower squeegee assembly to operating position by

pulling down the lever on the back side.

3. Disconnect the vac hose (1).

4. Unscrew the star handles (2).

5. Take out wing nuts (3).

6. Remove squeegee from bracket and flip over or replace

with new squeegee if all edges are worn (4).

7. Replace wing nuts (3).

8. Screw in the vac hose assembly and tighten star

handles (2).

9. Connect the vac hose to the port on squeegee

assembly (1).

10. Examine thesqueegee and adjust so that it fits the

assembly and meets the floor properly

11. Squeegee assembly may rotate up to 5° in order to

clean more efficiently. Turn the adjustment knob (5) in

order to adjust pitch.

Checklist Before Running the Scrubber

□Check the battery power. Charge batteries if less than a

full charge is indicated by the power gauge. New

batteries take about 6 hours to charge.

□Check the condition of the scrub brush or pad. Replace if

they are worn. (Pads may be flipped over and reused.

Replace if they are worn on both sides.)

□Check the condition of the squeegee and reposition or

replace if needed. (Squeegee edge should be square

and meet the floor properly). Clean squeegee if needed.

□Check that the recovery tank is empty and that floating

filter screen is clean. Replace if needed.

□Check the condition of the skirt around the scrub deck.

Replace if worn.

Operating Instructions

Filling the Solution Tank

1. Open the recovery tank lid.

Note the port on the right

hand side of the front of the

machine. This is where to pour cleaning detergent

1

2

2

3

3

3

3

5

4

SS WSC21

7

and water for use in scrubbing.

2. Use only low foam detergents recommended by

the manufacturer. Do not use harsh solvents or corro-

sive cleaning agents in the machine.

3. Do not use a higher concentration of cleaning chemical

than what is recommended by the chemical

manufacturer.

4. Do not use water or solution hotter than 140°F.

If you have any questions regarding chemicals or mixing

ratio, consult chemical manufacturer instructions or your

local dealer.

Starting the Machine

1. Switch the key of the main power supply to the ON

position. (Note the power level gauge. If it does not

indicate full charge, please charge the batteries before

running the machine).

2. Pull down the squeegee lifting lever (in the middle on

the back side) to lower the squeegee assembly to the

ground.

3. Step on the brush head raise/lower pedal (on the back

side, bottom right) to lower the brush head to the ground.

4. Turn on the solution control valve (on back side, top left)

to dispense cleaning solution.

5. Turn on the brushes.

6. Turn on the vac motor.

7. Push the handlebars forward to drive forward and

backward to drive backward. Amount of pressure

determines drive speed.

Running the Machine

Warning: Fire or explosion hazard. Do not attempt to vac

up flammable or corrosive liquids or dust, or reactive

metals.

1. Overlap each cleaning pass by 3 inches.

2. Keep machine moving while scrubbing in order to avoid

abrading floors.

3. If there are drag marks on the floor behind the squee-

gee, you mayneed to clean or replace the squeegee (if

it is worn down) or turn off solution flow and run scrubber

over the area again with vac turned on.

4. Do not operate the machine on any slope steeper than 2%.

5. We strongly recommend using onlylow foam detergents

in the scrubber. Consult your local dealer for details. If

you are getting too much foam while cleaning, we

recommend pouring a defoaming agent into the recov-

ery tank. Also try using a lower concentration of cleaner.

Note: Do not let the foam enter the filter screen so as to

avoid damage to vacuum motor. The foam mayalso

damage the switch of the filter screen.

6. Use a double pass method for cleaning extremely dirty

floors. Lift squeegee assembly for first pass. Deposit

detergent and let sit for 3-5 min. Then lower the

squeegee, turn on the vac, and run the second pass.

7. Keep an eye on the power consumption of the batteries.

Normal run time for brand new batteries is about 4 hours.

8. Observe the liquid level through the liquid meter of the

solution tank (if equipped). Normal consumption for

10 minutes of operation is about 1.3 gallons.

9. When the solution tank is empty, before refilling it,

be sure to empty the recovery tank completely.

10. If the machine is to be left unattended, stop and place

the machine on level ground. Switch off power and

take out the key.

11. After running the machine, carry out daily maintenance

procedures.

Daily Maintenance

1. Turn off solution flow with lever on top left of back side.

2. Turn off brushes and vac withswitches on control panel.

3. Raise squeegee assembly with lifting lever on back side.

4. If solution tank is not completely

empty, push machine to drain-

age area and open valve to

allow solution tank to drain out

(see picture).

5. Drain, flush, and clean recovery tank (see following sec-

tion). Leave tank open and allow to air dry.

6. Clean squeegee and inspect for wear. If working edge

is not square, reposition or replace as needed. (See

“Installation and Replacement of Squeegee”).

7. Wipe down with machine with cloth and multipurpose

cleaner.

8. Check vac filter. Clean or replace if necessary.

SS WSC21

8

9. Rinse brushes or scrub pads. Replace if they are worn

out.

10. Charge the batteries. To prolong the life of the

batteries and ensure the optimum efficiency of the

machine, the batteries should be charged if the

machine has been run for more than 30 minutes.

Drainage of Recovery Tank

After each use, the recovery tank should be drained and

cleaned. Filters and hoses should also be inspected for

corrosion or blockage, and cleaned and replaced as

needed.

Follow these steps for draining & cleaning the recovery

tank:

1. Switch off machine with power key and take the

machine to the drainage/maintenance area.

2. Unscrew (counterclockwise) the

lid of the recovery tank drainage

hose and take the hose down.

Be sure hose will direct waste

flow into drain or other designated

waste disposal area.

3. Once the recovery tank has completely drained, open the

lid of the recovery tank and rinse with clean water. Allow

waste to continue to drain out of tank through the hose.

If tank is especially dirty, scrub lightly with scrub brush

and appropriate multipurpose cleaning agent. (Do not use

harsh solvents, pressure washer, or steam to clean the

interior of the recovery tank.) Consult manufacturer or local

dealer if you have any questions.

4. Dismantle and flush the floating filter screen in the

recovery tank. Dry and replace when finished. Inspect

for corrosion and wear. Replace filter if necessary.

5. Allow all waste and rinse water to drain from recovery

tank then leave open to air dry.

Monthly Maintenance (or after 80 hours of use)

In addition to daily maintenance, we recommend the

following maintenance procedures to keep your machine in

prime working condition.

Warning: Electric shock hazard. Disconnect the battery

wiring before performing electrical maintenance on the

machine.

1. Remove the filter of the solution tank clean the filter

screen. Ensure the solution tank is emptied before

dismantling the filter.

2. Clean the top of the battery to prevent terminal

corrosion. Check battery acidity level and perform

battery maintenance if needed.

3. Inspect battery wiring and make sure it is in proper

position and in good condition.

4. Check and clean the cover of the recovery tank and

seals and replace if there is any damage.

5. Spray silica gel dry lubricant on all pivots and wheels,

and coat with a layer of water-proof lubricating oil to

ensure smooth operation.

6. Check the nuts and bolts on the machine and tighten if

they are loose.

7. Check for leaks.

Quarterly Maintenance (or every 250 hours)

Examine the condition of the carbon brush of drive motor

(if equipped), vac motor, and brush motor. When the

abrasion length of the carbon brush is within 10mm (3/8

in), the carbon brush needs to be replaced. Please contact

your local dealer or authorized service center.

Machine Storage

1. Please charge the batteries before storing the machine.

2. Drain, thoroughly clean, and air dry the recovery tank.

(Storing the machine without cleaning the recovery tank

may cause a buildup of harmful bacteria or odors.)

3. We recommend storing the machine indoors in a dry

place.

.

4. Store with the brush head in raised position.

5. Leave the cover of the recovery tank open.

6. If the scrubber will be stored in a cold environment,

please be sure to drain all liquids from the machine or

use antifreeze.

SS WSC21

9

Troubleshooting

The machine will not operate.

Batteries have no power.

Charge batteries.

Batteries will not charge.

Replace batteries

Battery wiring is not

connected.

Check battery wiring for loose

connection. Tighten if needed.

Fuse has blown.

Replace the fuse.

Brush motor will not work, or brushes will not

turn.

Brush head is raised.

Lower brush head.

Something has entangled

the brush head and

prevented it from turning.

Check brushes and remove

obstructions.

Batteries have run down.

Charge batteries.

Brush switch is faulty.

Please contact service center.

Carbon brush on motor is

worn out.

Please contact service center.

Vac motor will not work.

Squeegee is in raised

position.

Lower the squeegee assembly.

Batteries have run down.

Charge batteries.

Vac motor fuse has blown.

Replace vac fuse.

Vac motor or vac motor

wiring has failed.

Please contact service center.

Carbon brush on vac motor

is worn out.

Please contact service center.

Machine is not vacuuming properly

Vac motor cover seal leaks.

Replace vac motor cover seal.

Vac filter is clogged.

Clean or replace vac filter.

Vac hose is clogged or hose

leaks.

Clean or replace vac hose.

Squeegee is worn or

damaged.

Reposition or replace the

squeegee.

Solution flow valve is closed.

Open solution flow valve.

The recovery tank is full.

Drain the recovery tank.

Vac motor has failed.

Contact service center.

Little or no cleaning solution flows out of

machine.

The solution tank filter or

hose is blocked.

Inspect filter and hoses and

clean them.

Flow control is set too low.

Adjust flow control.

Bolt on flow control knob is

loose.

Tighten bolt on flow control

knob.

Run time has shortened.

Batteries have worn out.

Replace batteries.

Battery charger has failed.

Replace charger or contact

service center.

SS WSC21

10

Specifications

Specification

Unit

SS WSC21

Specification

Unit

SS WSC21

Voltage

V

24 (2 x 12)

Brush speed

rpm

185

Amperage

AH

100

Brush pressure

lb/in2

3.2

Run Time

hours

4 (approx.)

Vac motor power

hp

.67

Cleaning width

in

21

Drive motor power

hp

-

Vacuuming width

in

30

Solution Tank Capacity

gal

13

Drive Speed

mph

2.5

Recovery Tank Capacity

gal

14.5

Cleaning efficiency

ft2/h

22,600

Weight (w/batteries)

lb

428

Brush motor power

hp

.87

Machine Dimensions

in

46 x 21 x 42

Warranty Card

(please fill out and return to dealer)

Name Phone #

Address

City State Zip

Purchase Date Invoice #

Model # Serial #

Local Dealer Local Dealer City/State

Warranty provided with purchase invoice.

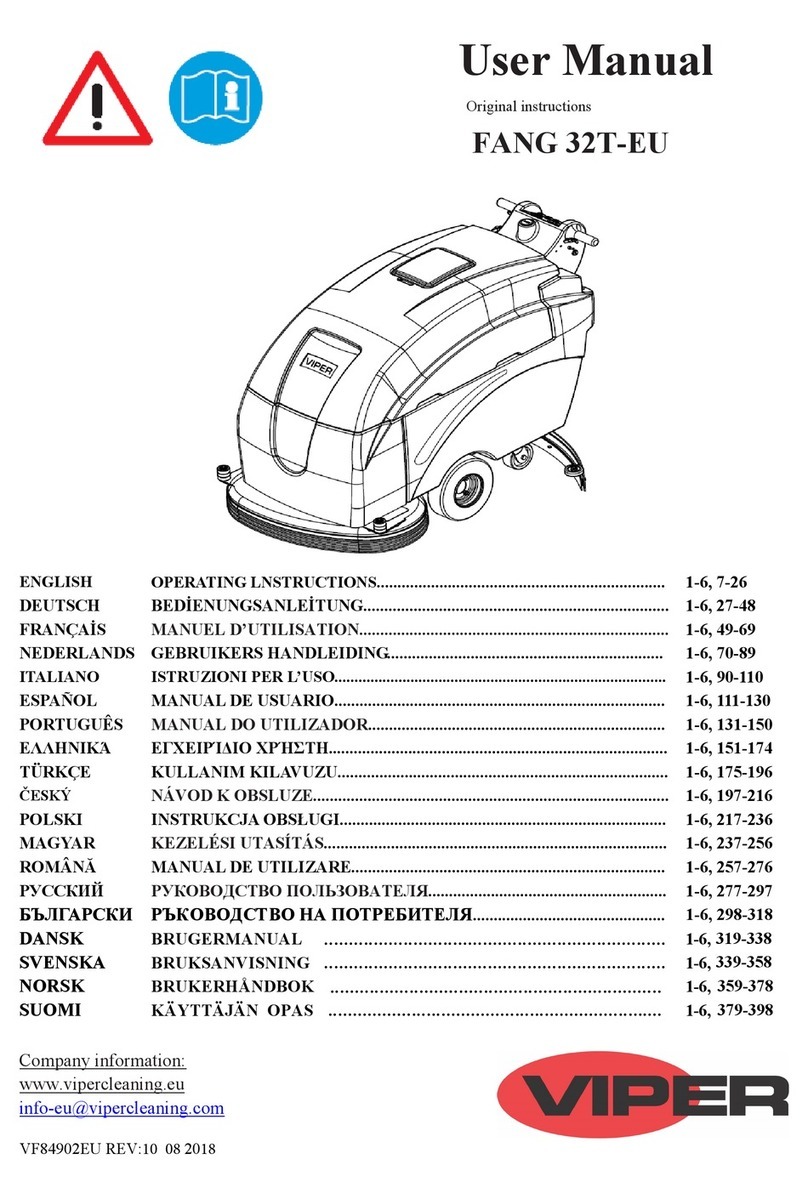

Table of contents

Other FAST CLEAN Scrubber manuals

Popular Scrubber manuals by other brands

Advance acoustic

Advance acoustic ecoflex SC3000 26 Disc Charger Instructions for use

Johnny Vac

Johnny Vac JVC85BCT user guide

Ghibli & Wirbel

Ghibli & Wirbel RAPID 40 SM 55 Touch Faq

Tennant

Tennant T581 Technical & service manual

Homyeko

Homyeko AES023 user manual

Black & Decker

Black & Decker SB450 ScumBuster instruction manual