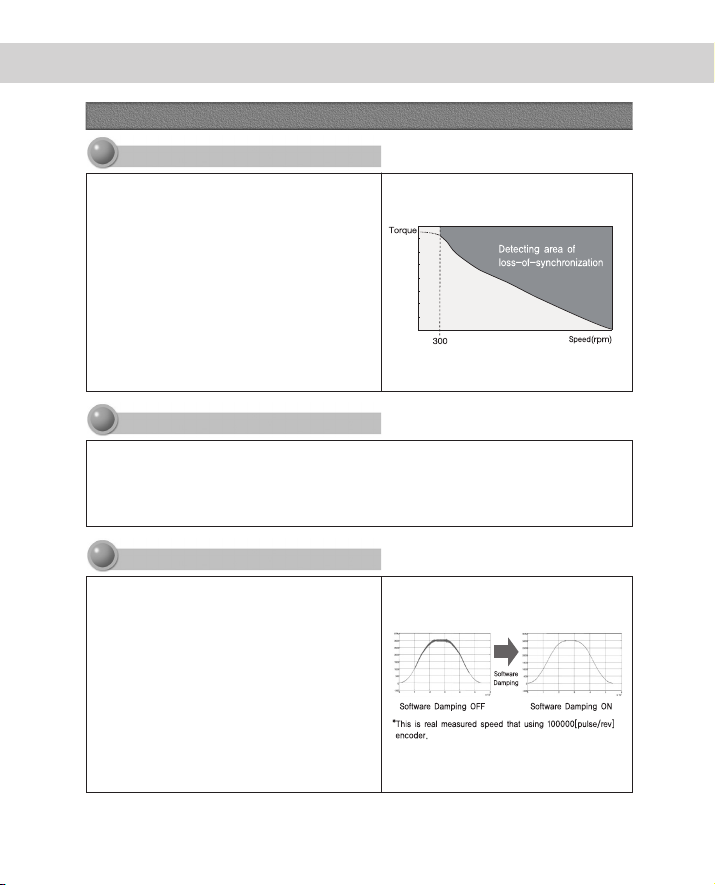

Fastech Ezi-Step BT-42 Series User manual

This manual suits for next models

12

Table of contents

Other Fastech Engine manuals

Popular Engine manuals by other brands

Pride Mobility

Pride Mobility DRVMOTR1269 Technical instructions

helvenco

helvenco AERO 1000 owner's manual

Briggs & Stratton

Briggs & Stratton Vanguard 610000 Operating & maintenance instructions

Texas Instruments

Texas Instruments AMIC110 ICE user guide

Nice

Nice Era Star A Series Instructions and warnings for installation and use

DR

DR R100 Safety and operating instructions

Mazda

Mazda SKYACTIV-G 2.5 Workshop manual

SOMFY

SOMFY ILT 2 installation guide

Turbines

Turbines ATJ SV Series user manual

Universal Motors

Universal Motors Universal diesel 5416 Service manual

Mitsubishi Electric

Mitsubishi Electric VS-HE120U user manual

Predator

Predator 69731 Owner's manual & safety instructions