helvenco AERO 1000 User manual

2

Index

Page

3Important terms

4System installation

5System dimensions

6-9 Engine preparation

10 Wiring diagram

11 Fuel pump installation

12-14 Exchange of PTO pulley

15 Clutch drum position

16-18 Exchange of propeller pulley

19 Belt tension

20-21 EFI installation guide

22-23 Start-up

24-25 Maintenance & Oil change

26 Speed Conversion table & Reset ECU DTC codes

27 Goodwill and warranty regulations

28 Voucher

3

Important terms

helvenco AG assumes that the user has read, understood and accept the terms below

before operating the engine. They are helpful for a better understanding of the product

and useful to prevent and to minimize the risks.

helvenco AG only supplies OEM’s and specialized aviation engine distributors that have

sufficient technical knowledge to ensure the AERO products of helvenco AG are installed and

serviced/repaired correctly.

helvenco AG emphasizes that the AERO product line is not certified and is made for

experimental aircraft only. It is important the user understands that the engine can stall/or break

with an emergency landing as a result; this can occur to injuries or death! The AERO1000/1500

should be used in open spaces only and during daylight. This product is neither covered by

product nor public liability.

Who flies with a paramotor/experimental aircraft/ULM or even just starts it, automatically

assumes all the risks inherent to these sports and all the responsibilities for damages to yourself

or to third parties, accidents, injuries or death caused by using such products.

To fly with a paramotor/experimental aircraft/ULM always needs great attention. Be aware that

you fly at your own risk; always check if your machine is in good condition before use.

helvenco AG doesn’t assume any responsibility for damages caused by poor servicing or wrong

assembly.

Any modification on the standard AERO product made by any party other than helvenco AG can

make the product dangerous to be used and is on own risk.

Wrong mounted, bad balanced or unproportioned propellers can lead to serious damage of the

AERO1000/1500 products.

The engine can’t be used for acrobatic maneuverings.

Don’t use the AERO1000/1500 in bad weather conditions such as rain or snowfall.

Not limitative list of possible reasons leading to premature engine failures:

•Engine modifications not approved by helvenco AG.

•Carelessness, lack of servicing, accidents, installations or wrong maintenance.

•Accidental falls or engine drop or drop of its components.

•Improper use or misusage of the engine.

•Assembly of parts or components not specified for the engine use.

•Engine overheating or stop after long usage, beyond the term indicated by helvenco AG.

•Use of improper petrol or oils, presence of dirty parts or foreign bodies in the engine.

•Permanent/ too long running into the rpm limiter.

•Engine or parts deterioration because of improperly storage.

•Wrong engine assembly, including the use of not original helvenco AG parts.

•Damages to the engine caused by foreign bodies.

•Usage of wrong spark plugs.

•Not respecting the manual in general.

4

System installation

The system comes with 8 pre-installed silent blocks on the front plate. These are the fixation

points to install the AERO1000 system on your vehicle! You can change the position of the silent

blocks on the front plate. Below you find the dimension sheet!

The OEM must use an optional backup system (Ex. steel tie-wraps or tension strap) between

the AERO1000/1500 system and the frame it is attached to. If not, the user must contact the

OEM.

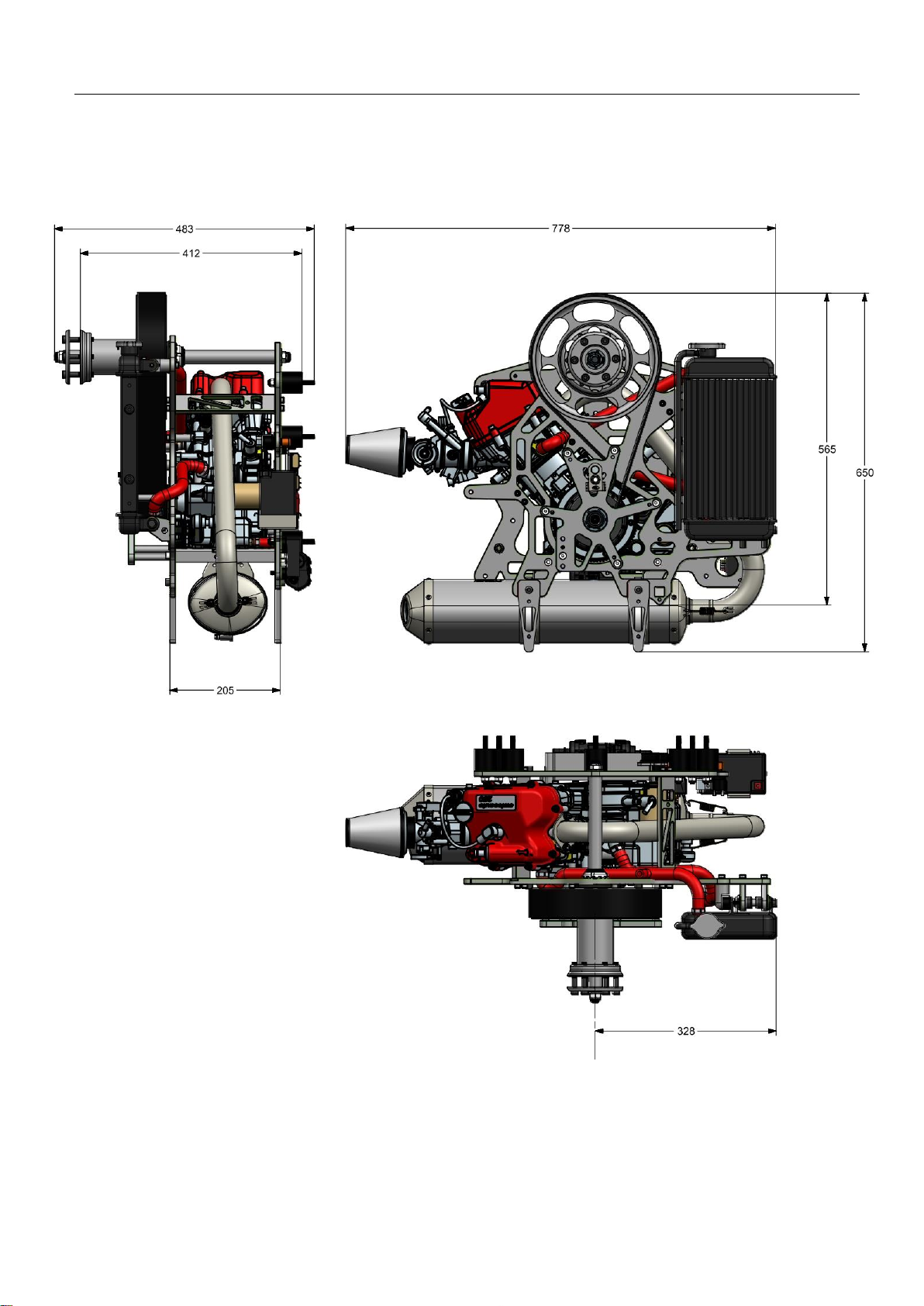

5

System dimensions

6

Engine preparation

Remove all plugs:

-Intake port

-Exhaust port

-Breather tube

7

Engine preparation

Place the system on the table as

shown.

Install the 2 feet and the exhaust

manifold.

Screw on the 2 self-locking M6 nuts.

Just tighten them a little bit so you can

still turn the manifold by hand.

Tighten them correctly after

installation of the exhaust muffler.

8

Engine preparation

Install the exhaust muffler.

Connect the 2 cradles with the silent

blocks below the engine mounts and

push the manifold into the exhaust

muffler.

Tighten all 4x M6 lock-nuts

Add the 2 exhaust springs

Finally tighten the 2 M6 lock-nuts at

the engine exhaust port.

9

Engine preparation

We have prepared installation points for the start/stop switch, the starter relais

and the ECU. You see them on the photos above. They are not installed!

Depending to the installation setup you have the choice to go to our positions or

to your own installation.

Install the other 2 feet. Now you can

place the engine upright.

Once the engine is installed on the

frame you can remove the feet.

10

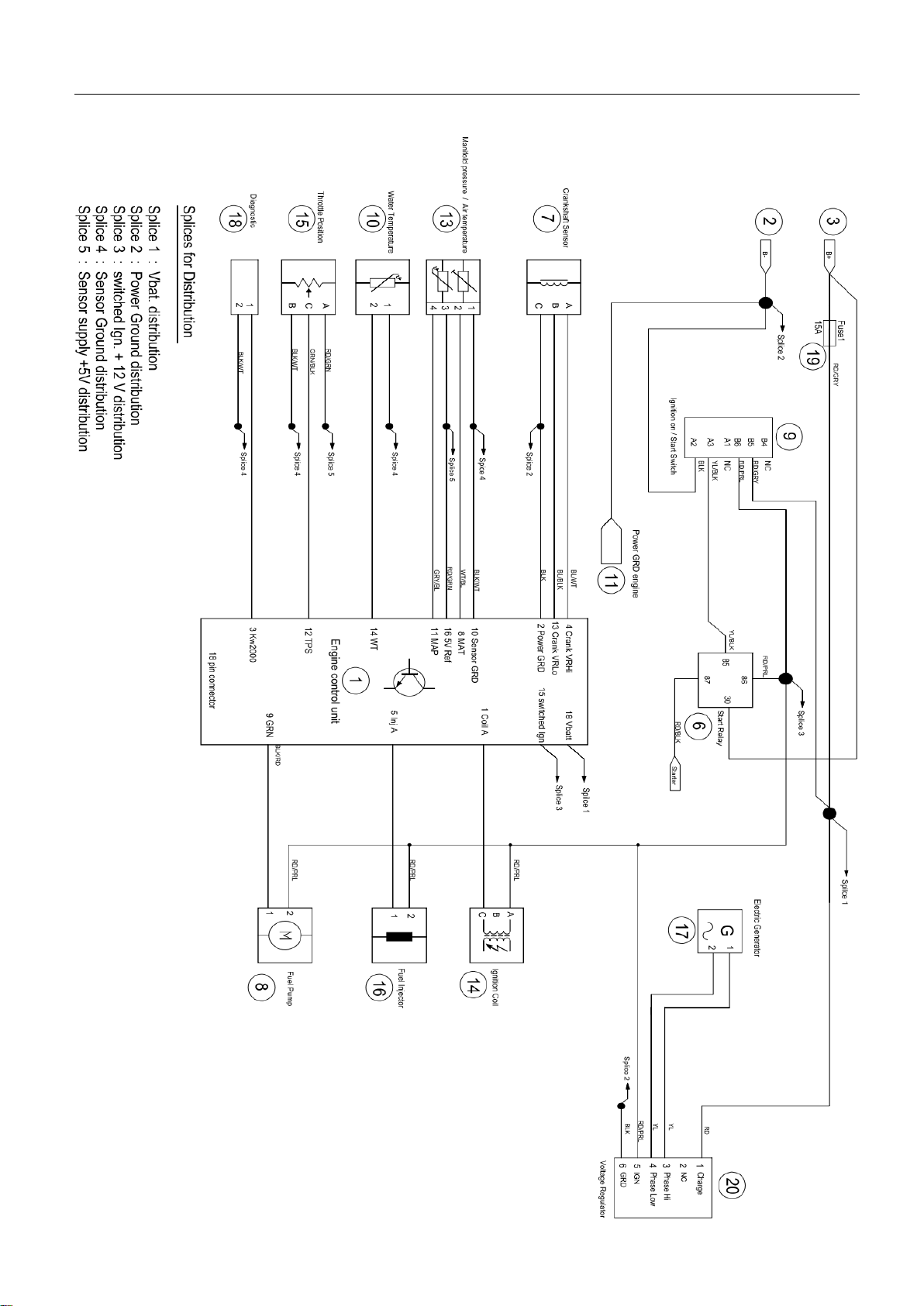

Wiring diagram

11

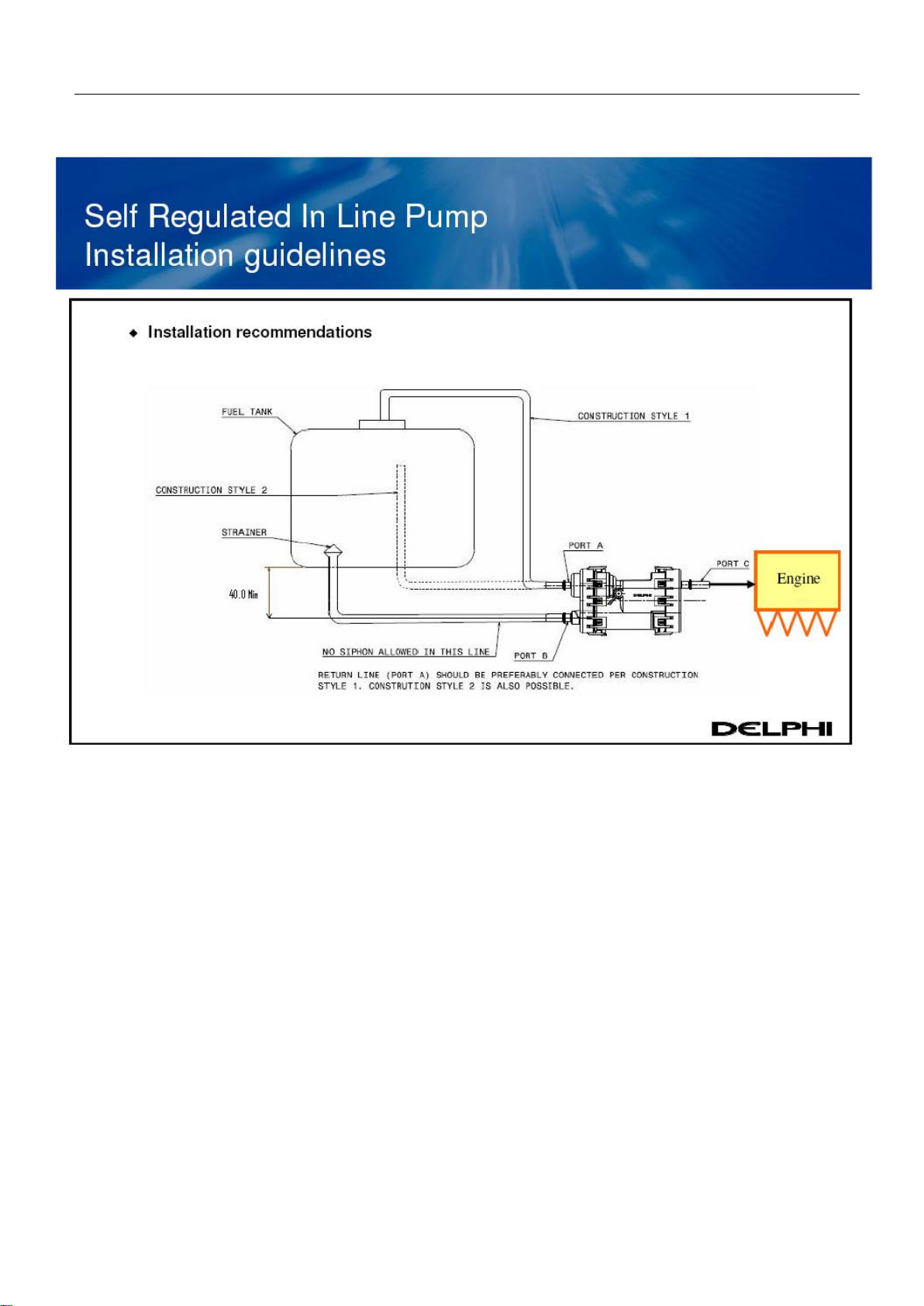

Fuel pump installation

The fuel pump isn’t self-bleeding!

Pump and all fuel hoses must be filled with fuel before running. Else the pump

gets damaged.

The pump must be installed below the fuel tank in the shown orientation!

To avoid engine stall, Port C must be higher or equal level with Port B!

Only use the quick release connectors that came along with the fuel pump.

The pump creates 2,5bar on the pressure line Port C! Only use the supplied

pressure hose and secure it on both sides with hose clamps to the connectors.

12

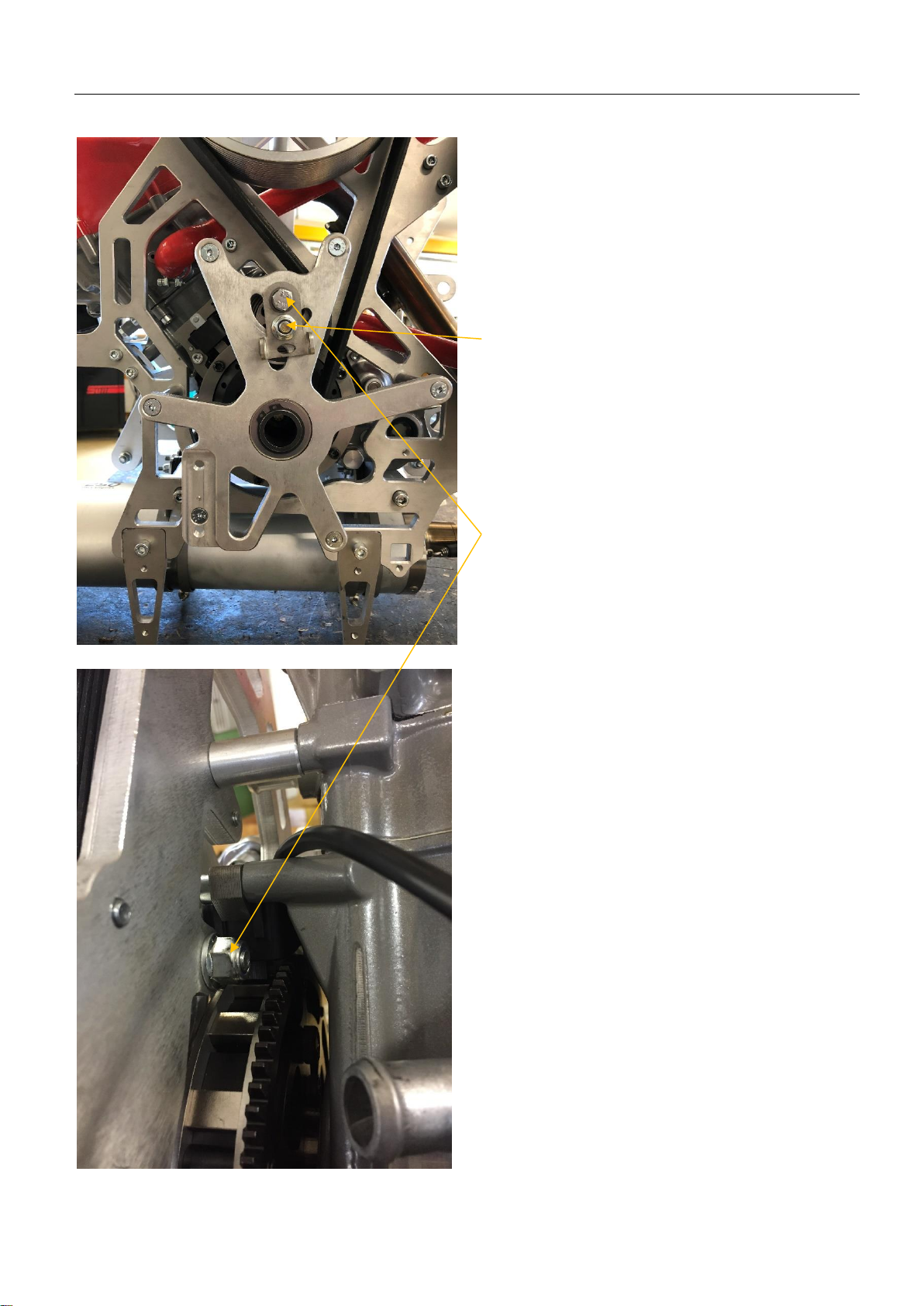

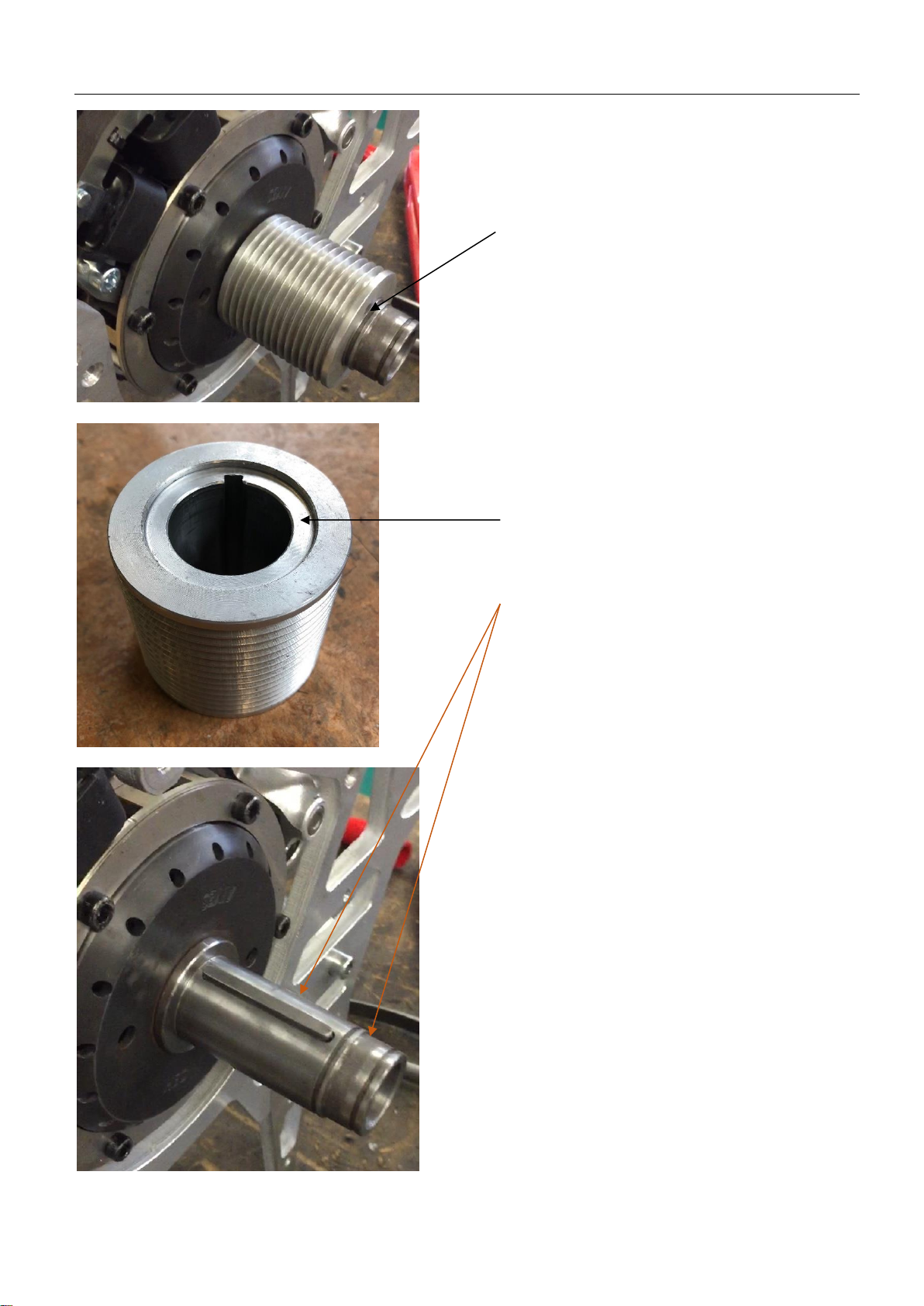

Exchange of PTO pulley

Unbolt the M8 self-locking nut

(Don’t remove)

Remove the M8 self-locking nut at the

back of engine back plate.

13

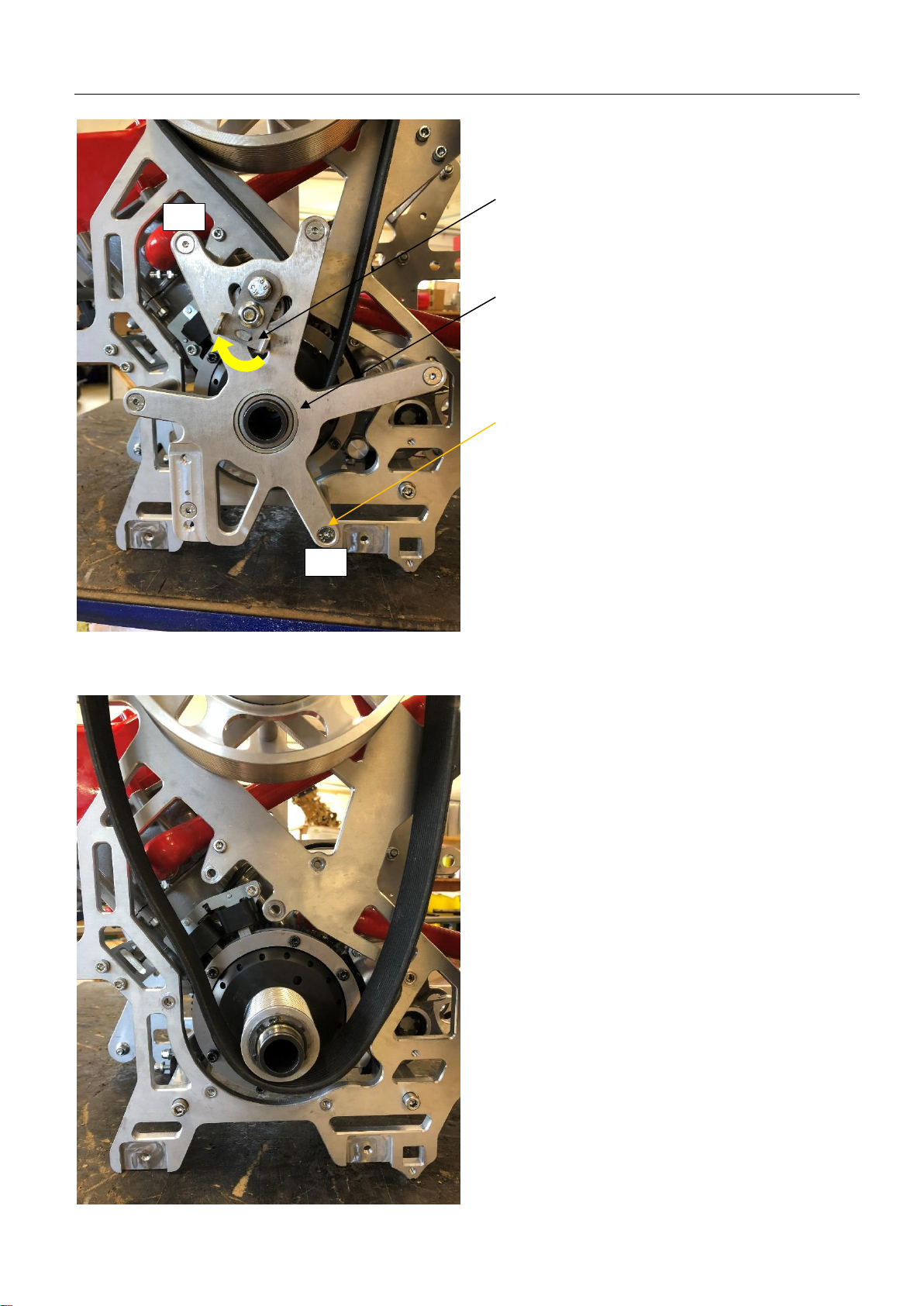

Exchange of PTO pulley

Release the belt tension by moving

the belt tensioner lever.

Remove the circlip and the distance

shim from the PTO shaft.

Remove all 6x M6 screws from the

PTO support plate.

ATTENTION!

Hold the distance sleeves when

remove the 6x M6 screws else the

will drop!

At re-installation of the PTO plate:

For correct outlining, always

tighten first screw #1 & #2 before

all others!

Remove the PTO support plate incl.

belt tensioner.

Remove the belt.

#1

#2

14

Exchange of PTO pulley

Remove the circlip and the distance

shim from the PTO shaft.

Remove the pulley and add the new

one.

ATTENTION! For correct belt

alignment mount the offset at the

pulley to engine side.

Always put anti-seize grease or

copper grease on the PTO shaft

before adding the pulley and PTO

plate.

Re-mount distance shim and circlip.

Install the PTO support plate inclusive

the belt tensioner.

Add the 6x M6 screws inclusive its

distance sleeves.

Fit the M8 self-locking nut at the back

of engine back plate.

Tighten the 6x M6 with following

torque: 10Nm / 7,37 ft-lb

15

Clutch drum position

For correct alignment of the clutch

drum use a screw driver and pull out

the PTO shaft as shown.

It should easily move ± 0,5mm / 0,02

inches.

Now you can add the distance shim

and the circlip.

16

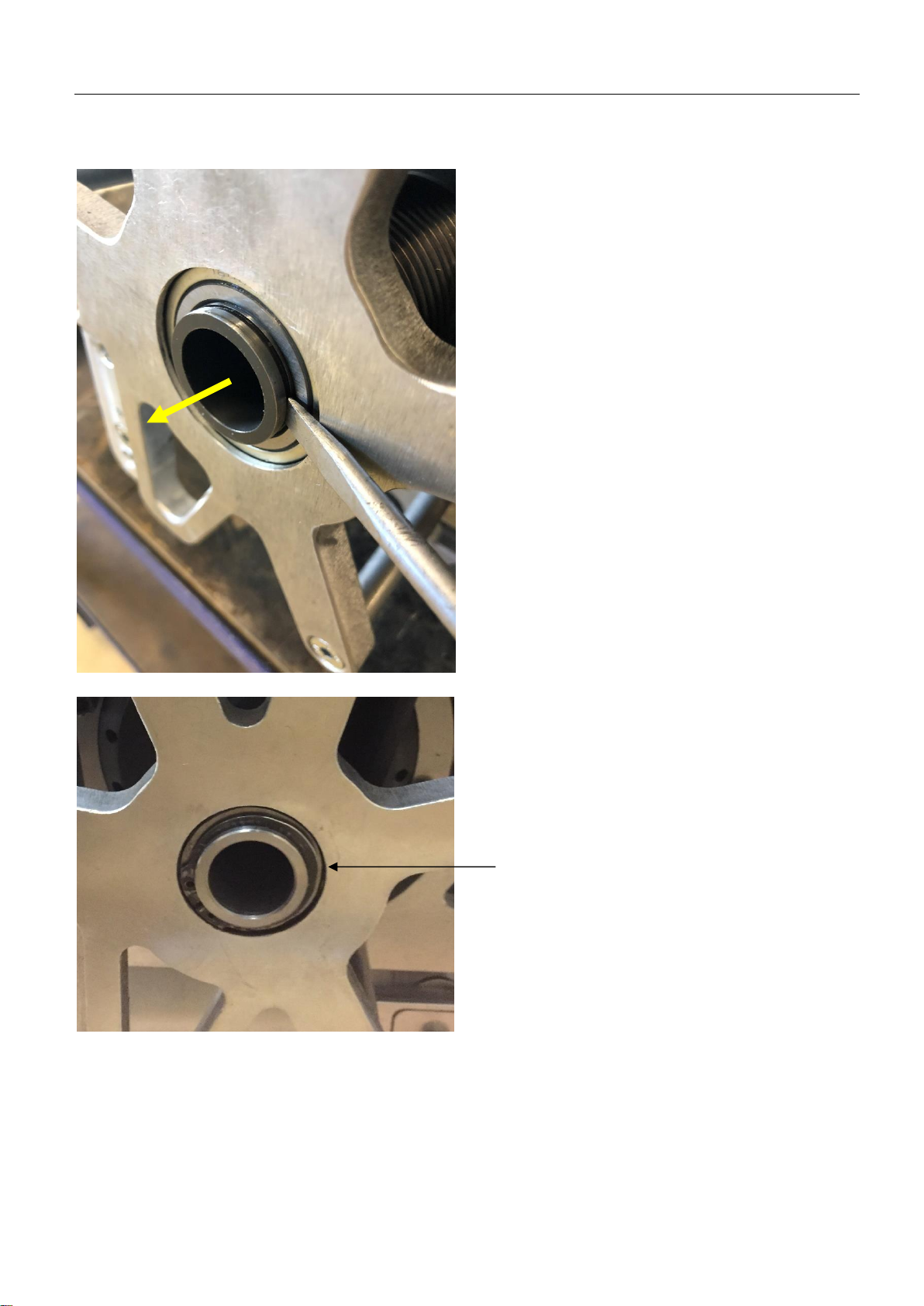

Exchange of propeller pulley

Remove the clip, unbolt the M12 self-

locking nut.

Remove washer and the black

pressure bush.

Now it is possible to remove the

complete propeller hub from the shaft

by pulling.

17

Exchange of propeller pulley

Remove the circlip and the distance

shim on the back of the propeller hub.

Attention! Circlip is curved; the

circlip must give an axial force to

the shim!

(If wrong assembled the circlip is

loose)

Push the propeller pulley away from

the hub.

Now you can exchange the pulley.

ATTENTION:

Remove the 6 rubbers from the old

pulley and install them into the new

one.

Lubricate the rubbers and the bolts

before assembly by using white

grease.

Push the new pulley on the hub!

The bolts must be positioned into

the rubbers!

Re-mount the distance shim and the

circlip.

Ensure the circlip is correctly

fixated into the groove!

18

Exchange of propeller pulley

Push the propeller hub back on the

propeller shaft.

Use white grease to lubricate the

inner ring of the oil seal before

mounting.

ATTENTION:

Don’t forget to install the black

distance sleeve into the hub before

adding the shim and the M12 self-

locking nut.

Tighten the M12 with following torque:

20Nm / 15 ft-lb

Add the clip

19

Belt tension

Place the M8 self-locking nut at the

back of engine back plate. Don’t

tighten it yet.

Use a screw driver and place it into

the tensioner lever as shown.

Push the lever down to tighten the

belt. (The tension is OK when the belt

in the center between both pulleys

can be twisted between 90° & 45°)

Once the belt tension is set tighten

the M8 lock-nut.

Remove the screw driver and tighten

the M8 bolt with the self-locking nut

on the back plate.

Tighten the M8 with following torque:

24Nm / 17,7 ft-lb

20

EFI installation guide

Push the throttle body on the intake

port and tighten the clamp. (Use the

clamp from the carb rubber)

Put on the air filter on the throttle body

and use the supplied hose to connect

the engine breather tube with the air

filter.

Cut the tube to correct length.

ATTENTION: Be sure there is no

blocking in this breather tube to

avoid engine failure!

Connect the engine ground cable to

the engine or the aluminium frame.

Connect the water temperature

sensor.

Connect the crank trigger sensor.

This manual suits for next models

1

Table of contents

Popular Engine manuals by other brands

Crusader

Crusader 5.7L Carburetor Owner's operation and maintenance manual

Vanguard

Vanguard 490000 Operator's manual

Oriental motor

Oriental motor US Series operating manual

Oriental motor

Oriental motor BLV Series operating manual

Oriental motor

Oriental motor BLH Series operating manual

Vanguard

Vanguard 350000 Operator's manual

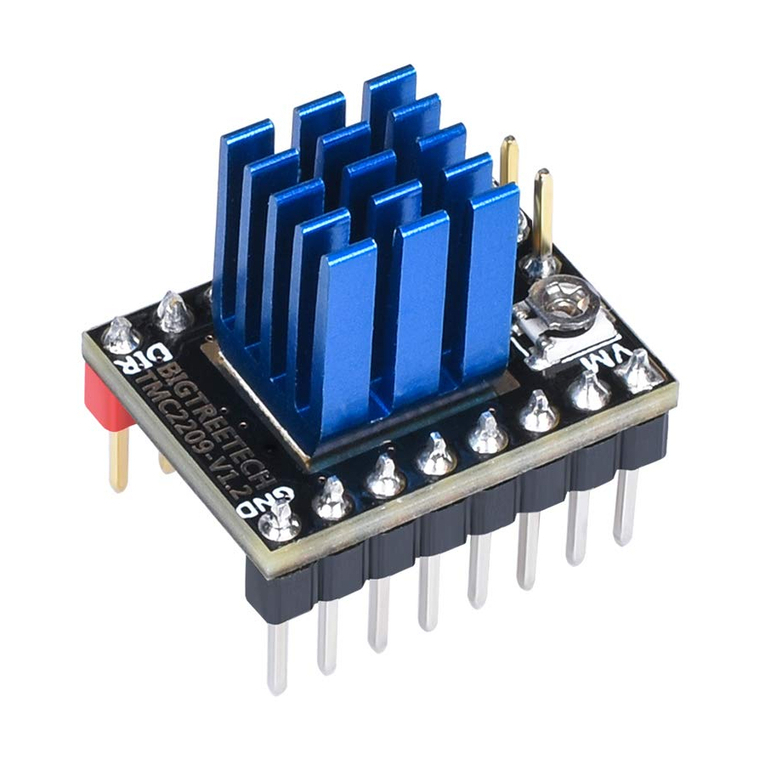

BIG TREE TECH

BIG TREE TECH TMC2209-V1.2 manual

Oriental motor

Oriental motor SPR II Series operating manual

E-MAG

E-MAG LYCOMING 200-6XL Series Installation and operating guide

woodmizer

woodmizer G26 Safety, Operation, Maintenance & Parts Manual

Oriental motor

Oriental motor World K Series operating manual

Oriental motor

Oriental motor PKP Series operating manual