FATEK FBs-1HLC Installation manual

1

FBs-1HLC

Precision Load Cell Module

Operation manual

V1.1 06/07/2017

FATEK AUTOMATION CORP.

FATEK

2

Contents

Chapter 1 1HLC module introduction.......................................................................................................... 3

1.1

Module specification............................................................................................................................. 3

1.2

Module appearance and description.................................................................................................. 4

1.3

Application connections........................................................................................................................ 4

1.4

Communication interface between 1HLC and PLC:........................................................................ 6

1.5

1HLC application interface................................................................................................................... 6

1.5.1 Application interface contents and Modbus comparison table....................................................................6

1.5.2 Detailed description...........................................................................................................................................7

Chapter 2 Application examples.................................................................................................................. 8

2.1

Application connections........................................................................................................................ 8

2.2

Setting PLC communication parameters........................................................................................... 8

2.3

Ladder diagram programming............................................................................................................. 9

2.4

1HLC module calibration.................................................................................................................... 10

2.4.1 Zero-point calibration.......................................................................................................................................10

2.4.2 Full-span calibration.........................................................................................................................................10

2.4.3 Weight measuring............................................................................................................................................10

3

Chapter 1 1HLC module introduction

A load cell is formed by attaching a stress strain gauge to a metal elastic body. When the metal elastic

body is subjected to pressure or tensile force, the deformation of the elastic body is detected and

converted to an output voltage signal. PLC acquires data from 1HLC via the Modbus communication

protocol.

1.1

Module specification:

General specification

Supply voltage

DC 24V

Weight

127g

Operation temperature

-10°C to + 40°C (+14°F to + 104°F)

Operation humidity

85% relative humidity (non-condensing state)

Dimensions

90 (L) x 40 (W) x 80 (H) mm

Input signal and A/D conversion

A/D conversion method

24Bits △ Σ

A/D conversion speed

100 times/sec

Load cell excitation power

supply

DC 5V 5% , 120mA (for 8 350Ω load cells )

Max. measured voltage

-1mV ~ 39mV

Input sensitivity/resolution

Above 0.15V/D 1 / 60000 d

Digital

Status indicators

POWER、MD、ZERO、NET、GROSS

Memory

Calibration parameters and function settings are all saved to EEPROM

Features

1. Industrial-grade weight control design suitable for all kinds of extreme industrial environments

2. High noise-interference resistance; effectively suppresses interferences from power supplies,

electromagnetic waves, and wireless RF.

3. Small volume and occupies little space; convenient for storage in control stations, high precision,

and superior performances

4. Adjustable digital filtering may effectively suppress vibrations generated in local environment

5. Flexible calibration schemes and automatic stability detection

6. Automatic zero-point tracking for effective suppressing of zero-point drift occurring in load cells

4

1.2

Module appearance and description

Expansion flat

cable connector

1.3

Application connections

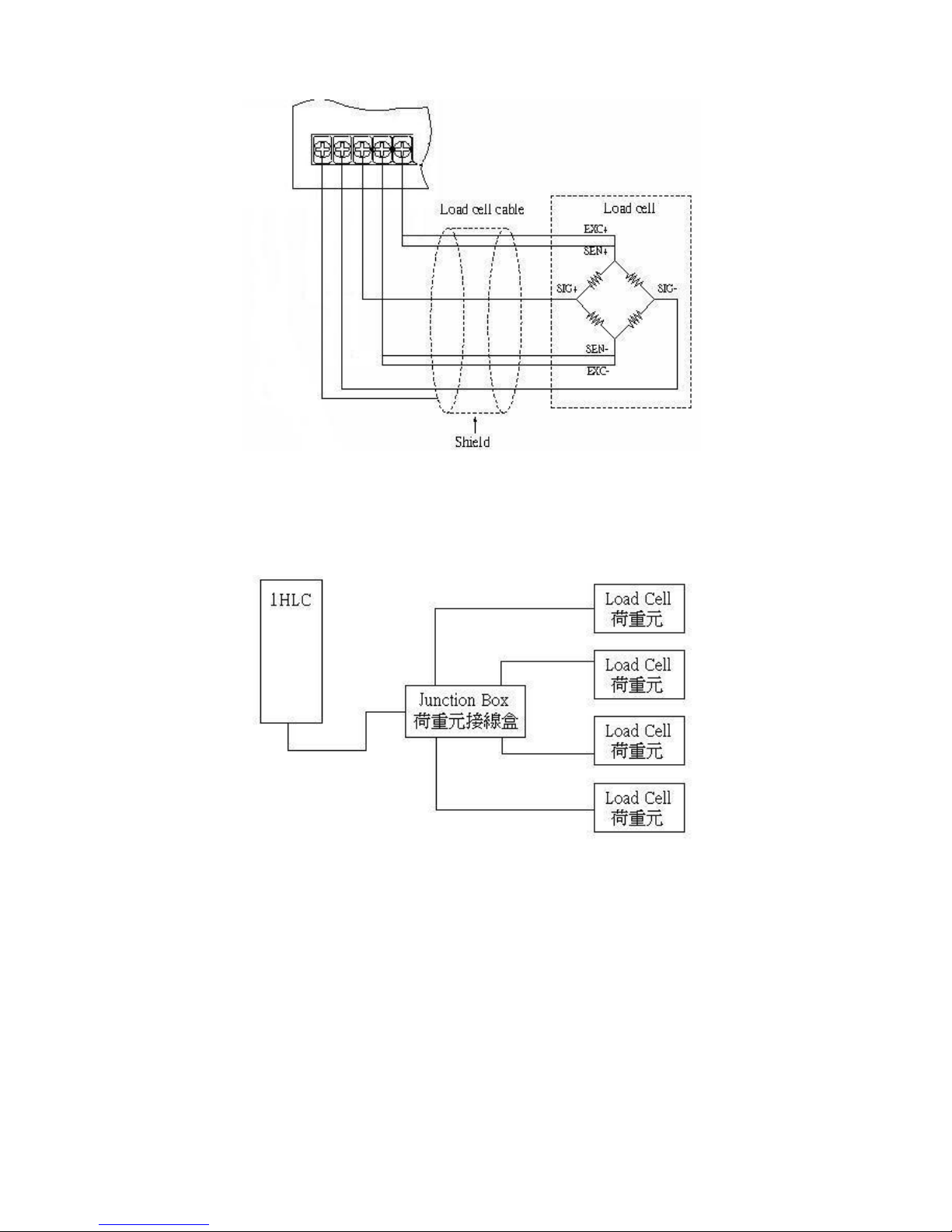

Four-line connection

EXC: Load cell excitation power supply

(DC 5V 5%)

24V power supply

Status flag indicator

NET: net weight indicator

GRS: gross weight indicator

MD: stable indicator

ZRO: zero-point indicator

PORT4

PORT3

NETGRS MD ZRO

POW

SIG: signal source

SIG

+

SIG

-

EXC

+

EXC

-

FG FG FG

FG

FBs-1HLC

Expansion port cover

Port3 connect to PLC

Port4 connect to expanded CMXXE module

(CMXXE module can only use port 4)

5

Six-line connection

Multiple-load-cell connection

6

IN (X )

POW

RUN

ERR

TX RX

POW

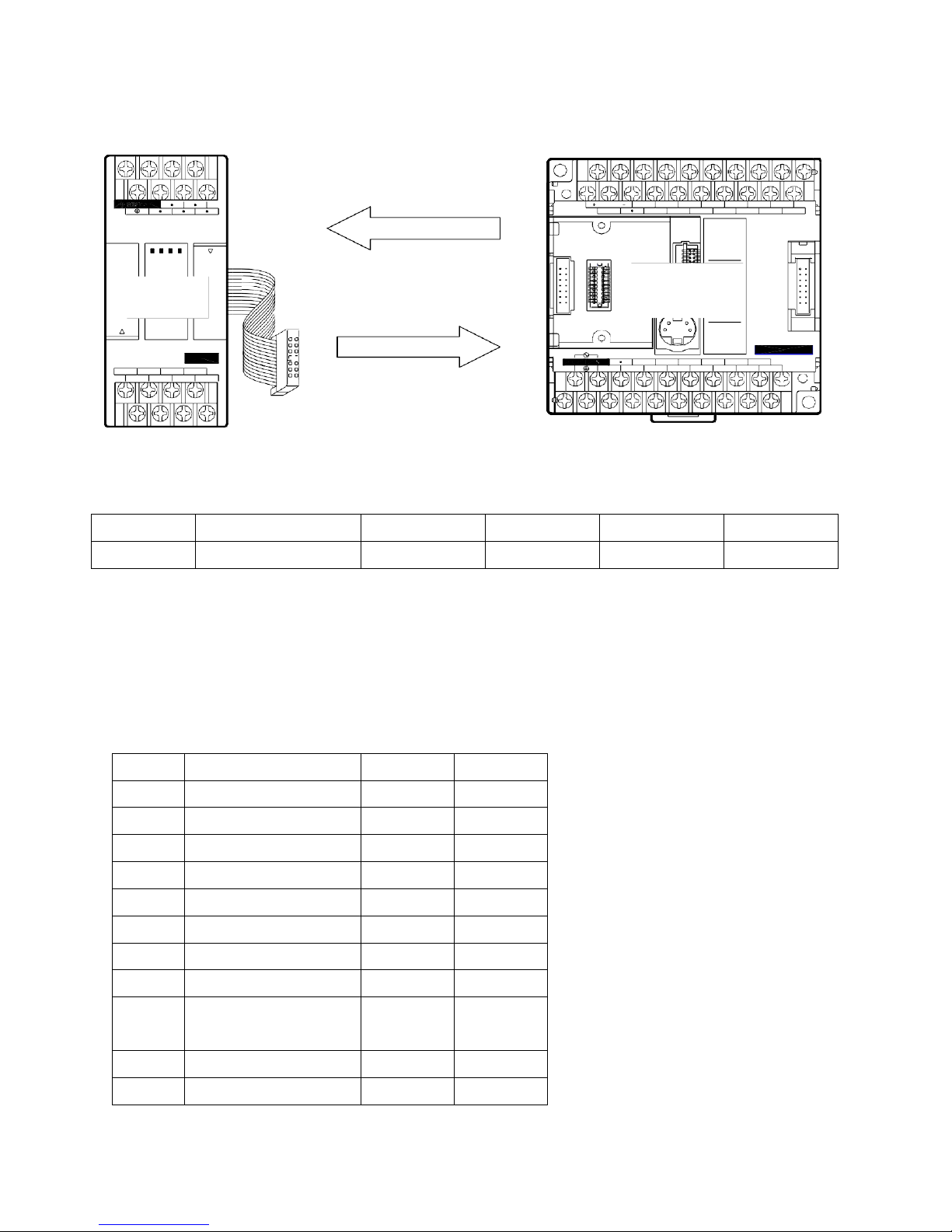

1.4

Communication interface between 1HLC and PLC:

PLC acquires data from 1HLC via the Modbus communication protocol.

max.

40 0mA

24V OUT

S/S

X0 X2

X1

X4 X6

X3 X5 X7

X8 X10

X9

X12

X11 X13

PORT4

NET GRS MD ZRO

PORT3

Fun150

0 I 2 3

4 5 6 7

8 9 I0 II

I2 I3

Slave Modbus Protocol Master

OUT( Y )

FBs-1HLC

IN AC100~240V

Y1 Y2

0 I 2 3

4 5 6 7

8 9

Y4 Y5 Y6

FBs-24MCR2-AC

Y8

SIG

+

SIG

-

EXC

+

EXC

-

C0 Y0 C2 Y3 C4 C6 Y7 Y9

FG FG FG FG

Connect to PLC using Winproladder and change the PORT 3 communication parameters of

Winproladder. The communication parameters of 1HLC are fixed as follow:

1.5

1HLC application interface:

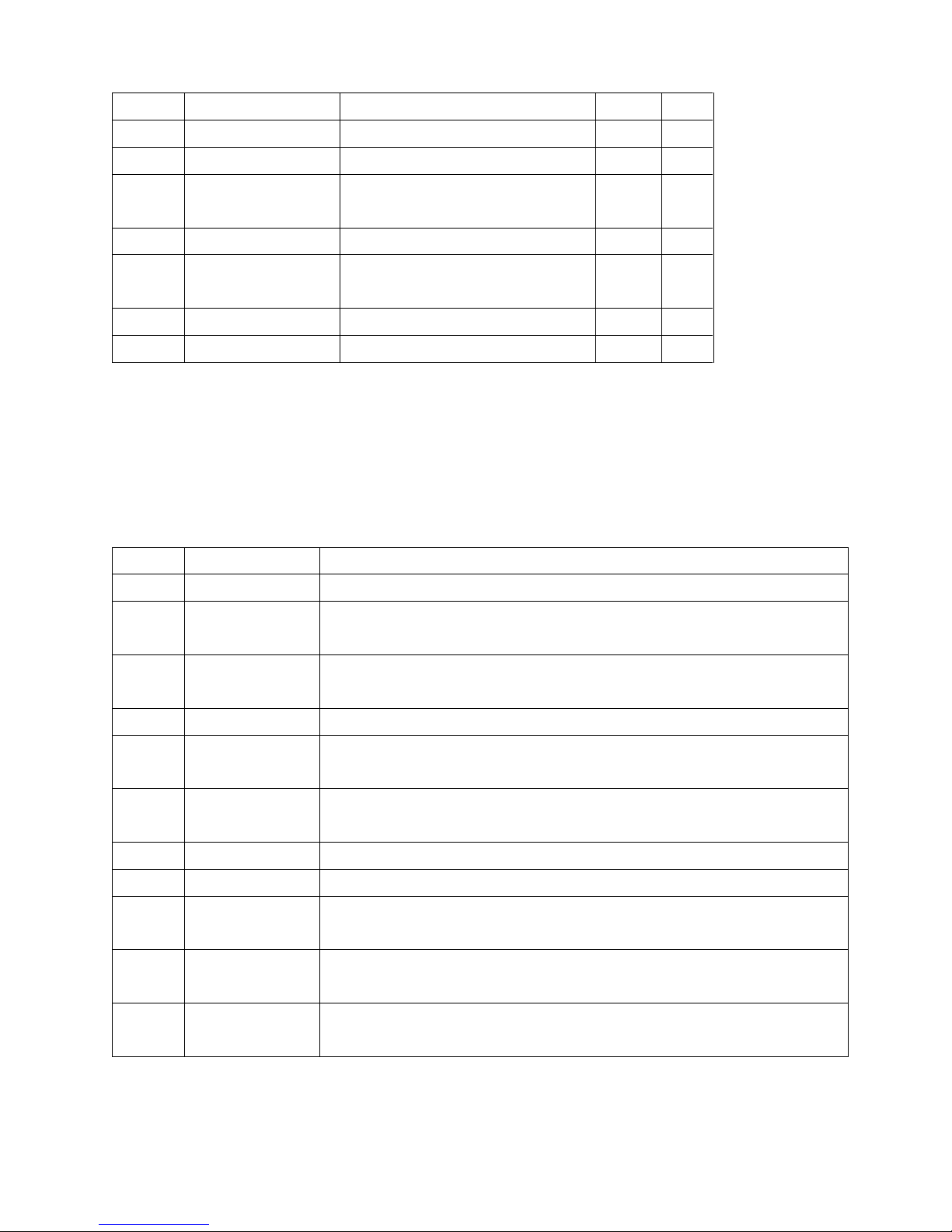

1.5.1 Application interface contents and Modbus comparison table

Status/Control bit

Address

Name

Length

R/W

000002

Overload flag

Bit

R

000005

Display gross weight flag

Bit

R

000006

Display net weight flag

Bit

R

000007

Zero-point flag

Bit

R

000008

Unstable flag

Bit

R

000257

Adjust to zero

Bit

W

000258

Deduction

Bit

W

000263

Clear deduction

Bit

W

000513

Zero-point calibration

input

Bit

W

000514

Full-span calibration input

Bit

W

000773

Save EEP

Bit

W

PORT

Connection speed

Parity bit

Data bit

Stop bit

format

Port3

19200

No

8

1

RTU

7

Status/Settings register

Address

Name

Settings

Length

R/W

402305

AD internal value

Word

R

402307

Display value

2Word

R

402567

SPAN calibration

weight

2Word

R

402561

Max. weight

2Word

R/W

401793

Calibration error

message

0~3

Word

R/W

402049

AD sampling frequency

0=100、1=50、2=25、3=12.5、4=6.25Hz

Word

R/W

402052

Min. scale

1,2,5,10,20,50

Word

R/W

1.5.2 Detailed description

Status/Control bit

Address

Name

Description

000002

Overload flag

Flag ON when the measured weight is higher than the max. weight

000005

Display gross

weight flag

Displayed measurement value includes package weight

000006

Display net weight

flag

Displayed measurement value is actual weight

000007

Zero-point flag

Gross weight is 0 when=1

000008

Unstable flag

Conditions of unstable tracking time and unstable tracking area may be set for the

devices maintaining stable values

000257

Adjust to zero

Function to set or adjust the displayed value to zero when there is no load

when=1

000258

Deduction

Deduce the package weight of the load on the tray when=1

000263

Clear deduction

Clear the package weight deduction and display gross weight when=1

000513

Zero-point

calibration input

Zero-point button to be set during calibration when=1

000514

Full-span calibration

input

SPAN weight button to be set during calibration when=1 (SPANcalibration weight

should be set first)

000773

Save EEP

Save settings in EEPROM and automatically read previously saved settings at

power-on when=1

8

Status/Settings register

Address

Name

Description

402305

AD internal value

Value of scale analog signal voltage converted for internal calculations of the

scale.

402307

Display value

Actual measured weight after specification calibration and weight calibration.

402567

SPAN calibration

weight

Weight of known standardized weight in calibration.

402561

Max. weight

Set maximum weight of scale and display overload flag if exceeding the max.

weight.

401793

Calibration error

message

0 : normal

1

: AD abnormal

2

: weight calibration earlier than prerequisite calibration (e.g., SPAN1<ZERO)

3 : weight calibration precision higher than 0.1uV/D

Chapter 2 Application examples

2.1

Application connections

Complete the hardware wiring connection first; please refer to the hardware equipment and

connection scheme in below.

Hardware: FBs-24MC*1, FBs-1HLC*1, and scale*1

1.

Connect 1HLC cable to the left (communication) expansion port ofPLC.

2.

The 4 lines of the scale are connected to EXC+, EXC-, SIG+, and SIG- of 1HLC.

24V power supply

1HLC

24MC

9

2.2

Setting PLC communication parameters

Connect to PLC using Winproladder (24MC in this example) and change the PORT 3 communication

parameters of Winproladder. The communication parameters of 1HLC are fixed as follow:

PORT

Connection

speed

Parity bit

Data bit

Stop bit

format

Port3

19200

No

8

1

RTU

2.3

Ladder diagram programming

1. Establish FUN150 in the ladder diagram of Winproladder and use FUN150 Modbus to transmit data

from 1HLC.

Use X0 to control M102 and X1 to control M103 because M102 is the zero-point calibration control

coil (000513) and M103 is the full-span calibration control coil (000514) from the Modbus Master

table in step 2.

2. Register addresses to be read or written are set in the Modbus Master table; for the register

addresses of the slave please refer to 【1.5.1 Application interface contents and Modbus

comparison table】.

10

2.4

1HLC module calibration

Module calibration allows the subsequently measured values to be more precise. The registers and

connections in the calibration steps have already been converted by step 2 【Modbus Master Table】

in section 2.3 and the detailed corresponding registers are described in this section.

2.4.1

Zero-point calibration

Confirm that the tray or tank scale is empty and execute zero-point calibration input (X0 from 0 to 1); if

successful, the display value register DR500 (Modbus register 402307) will be zero. If not, confirm

whether the zero-point calibration operation is correct. Subsequently, set the status of X0 of zero-point

calibration back to 0 or else the display value will remain at 0 when measuring.

2.4.2

Full-span calibration

Place object of known weight (standardized weight) on the tray or tank scale and input the weight of

the object of known weight to the SPAN calibration weight register DR504 (Modbus register 402567);

after the displayed value is stable, execute SPAN calibration input (X1 from 0 to 1). The display value

register DR500 (Modbus register 402307) will be the same as DR504 (Modbus register 402567).

Subsequently, set X1 from 1 to 0 and remove the object of known weight (standardized weight);

measurements of objects may then begin.

Note: if register DR504 (Modbus register 402567) is zero then the display value register DR500

(Modbus register 402307) will remain zero when measuring weights.

2.4.3

Weight measuring

Place object on the tray and the display value register DR500 (Modbus register 402307) will display

the weight of the object according to the standard of the known weight in full-span calibration.

Table of contents

Other FATEK Control Unit manuals

Popular Control Unit manuals by other brands

Eizo

Eizo JC-100 user manual

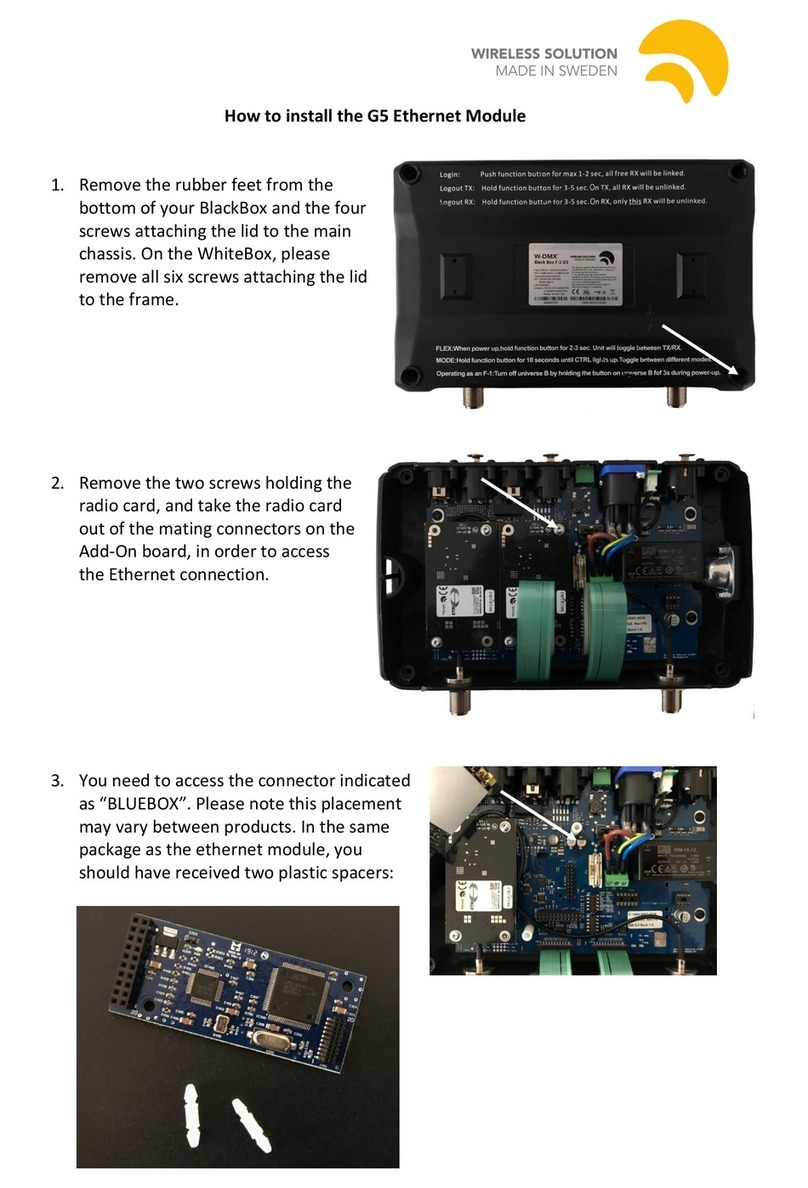

Wireless Solution

Wireless Solution W-DMX G5 How to install

Pickering

Pickering PXI 40-795-001 user manual

acorn controls

acorn controls TEMPFLOW TZV Installation, operation and maintenance instructions

Bardiani

Bardiani BBZS5 Operating and maintenance instructions

GF

GF JRG 5195.025 Installation and operation instructions

GEM

GEM B52 operating instructions

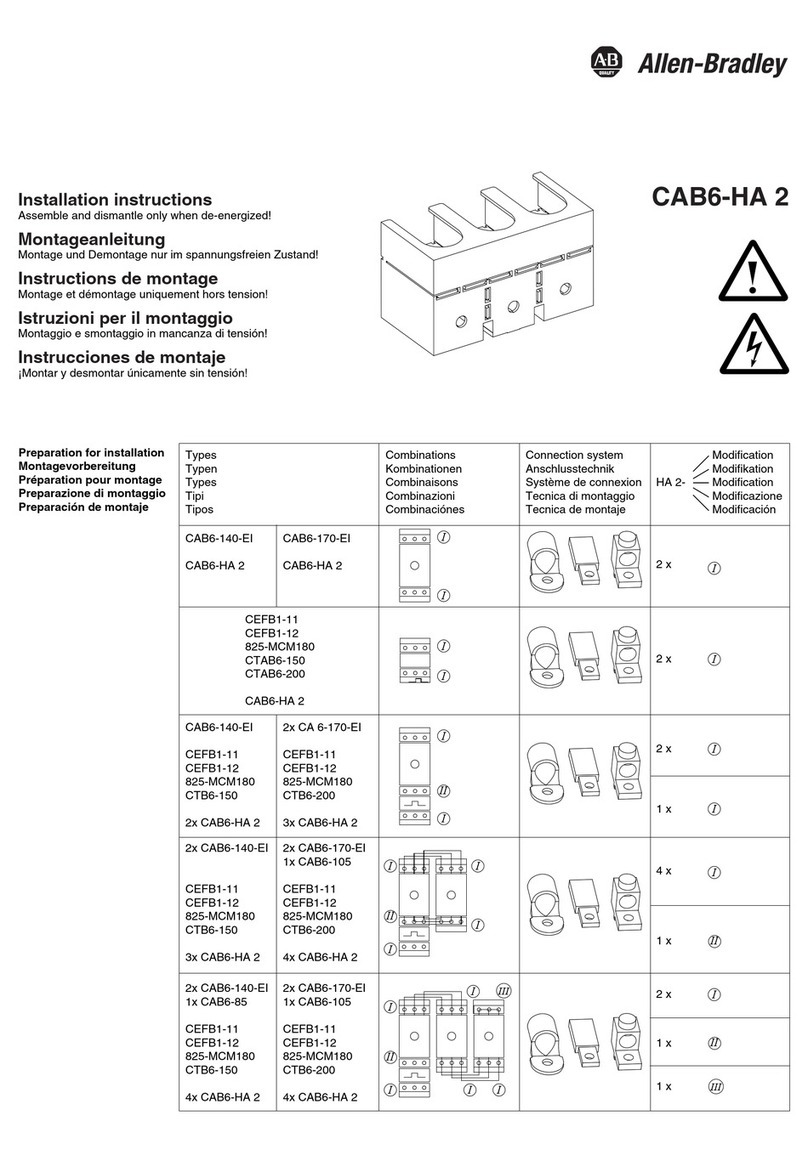

Allen-Bradley

Allen-Bradley CAB6-HA 2 installation instructions

Ducati

Ducati CTR32 instruction manual

Vanderbilt

Vanderbilt ACTpro IOM Installation and configuration instructions

Nibco

Nibco T-103-HC Installation and maintenance guide

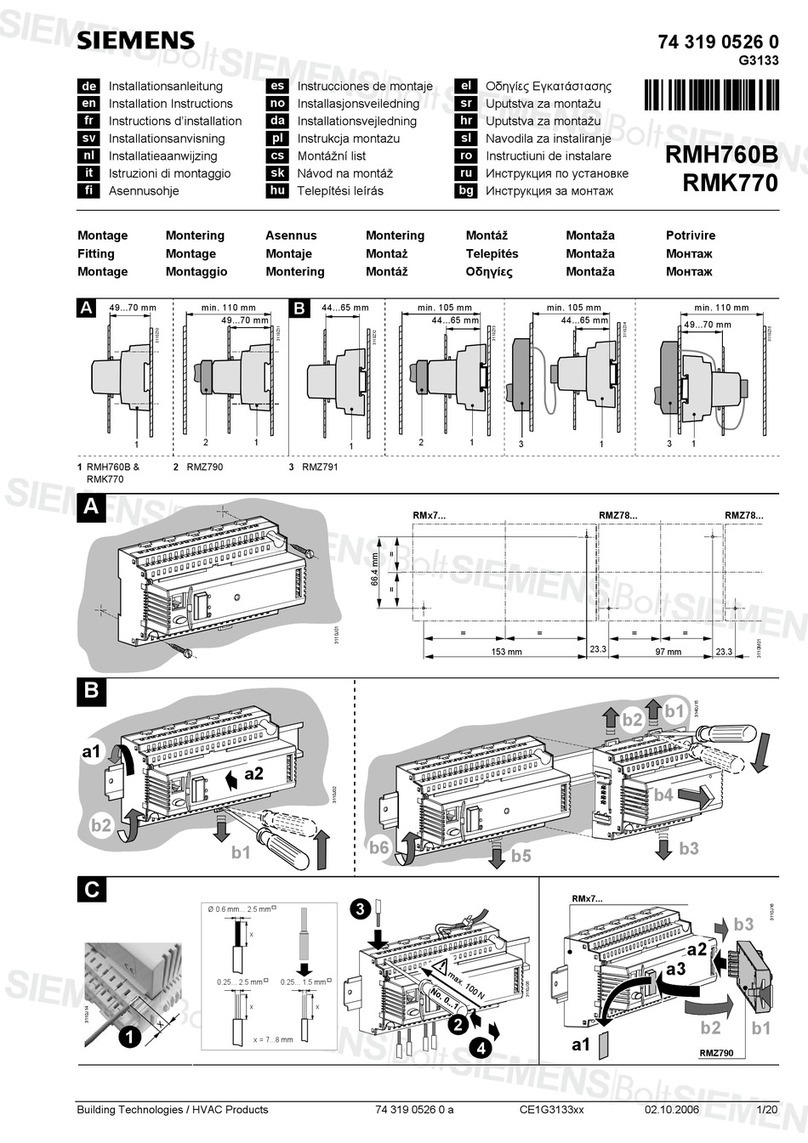

Siemens

Siemens RMH760B installation instructions