Part No. SCAZ042891 1.3.4 5E&OE

Operating Instructions Scarab M6

TABLE OF CONTENTS

Para Title Page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -1

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0

HEALTH & SAFETY ADVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

OPERATING ADVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFETY PROPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

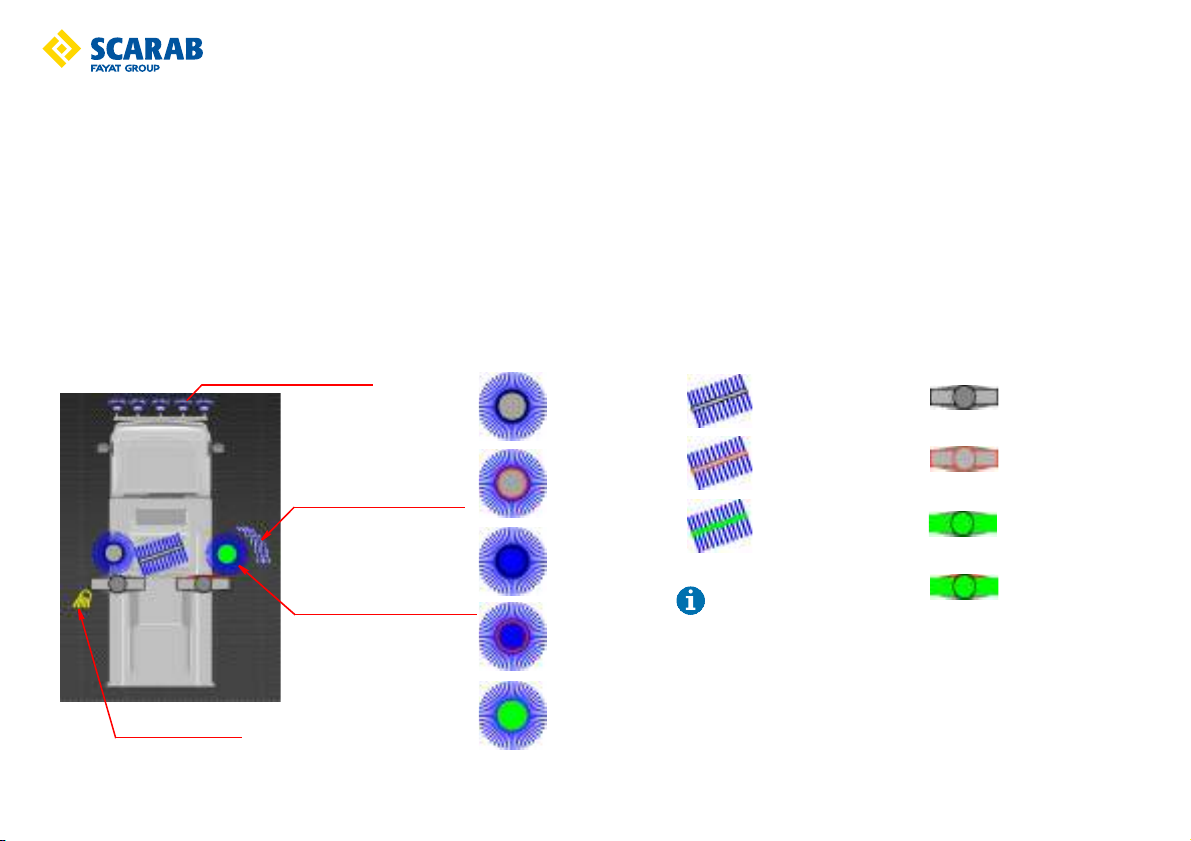

THE CANbus SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Main control panel switch functions . . . . . . . . . . . . . . . . . . . . . . . . .6

Auxiliary control panel switch functions . . . . . . . . . . . . . . . . . . . . . .7

Remote-control switch box functions . . . . . . . . . . . . . . . . . . . . . . . .8

THE LCD MONITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Additional controls & instruments . . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATING IN SWEEP MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Starting the auxiliary engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Suction fan boost setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sweeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exiting sweep mode/stopping the auxiliary engine . . . . . . . . . . . 13

DISCHARGING THE HOPPER (TIPPING) . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear Door Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rear Door Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

USING THE AUXILIARY HAND PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . 16

REAR-MOUNTED WANDER HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Para Title Page

USING THE DUST SUPPRESSION SYSTEM . . . . . . . . . . . . . . . . . . . . . . .18

Filling the water tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Using the low pressure water system . . . . . . . . . . . . . . . . . . . . . . .18

USING THE HIGH-PRESSURE WATER SYSTEM (OPTION) . . . . . . . . . . .19

Retractable hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

CLEARING A BLOCKAGE IN THE SUCTION PATH . . . . . . . . . . . . . . . . . .20

RECOMMENDED OPERATOR’S ROUTINE MAINTENANCE . . . . . . . . . .22

KEY MAINTENANCE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cleaning the suction fan and screen . . . . . . . . . . . . . . . . . . . . . . . .23

Auxiliary engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Engine oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Engine coolant level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Hydraulic oil tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Suction nozzle clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Side brushes & skirts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Removing & cleaning the water pump element(s) . . . . . . . . . . . .28

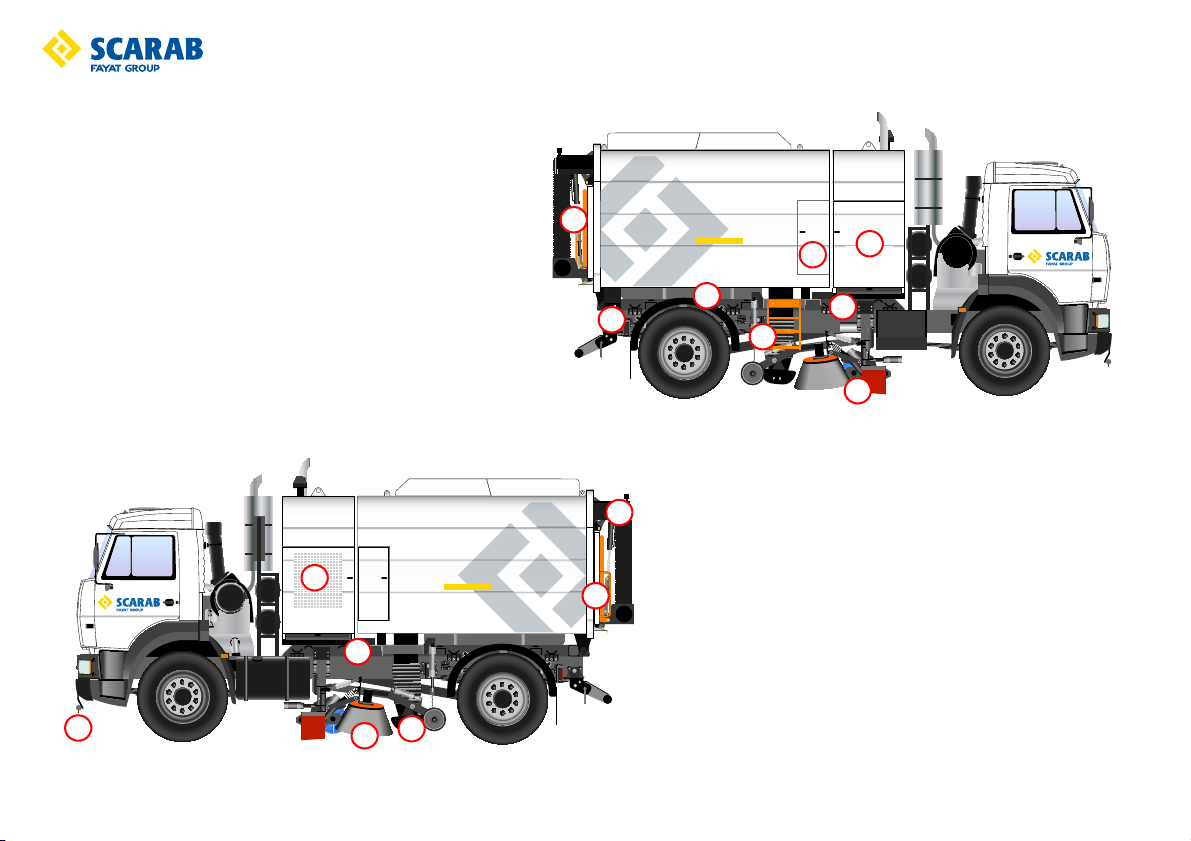

Manual greasing & lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

LCD MONITOR - OPTIONS SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Button function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Screen menu description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

OPERATOR’S NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38