TABLE OF CONTENTS

SPECIFICATIONS...................................................................................................................................COVER

TABLE OF CONTENTS......................................................................................................................................i

SAFETY PRECAUTIONS ..................................................................................................................................ii

1. PREPARING THE LOCATION ....................................................................................................................1

1.1 LOCATION REQUIREMENTS ...........................................................................................................1

1.2 ADDITIONAL REQUIREMENTS........................................................................................................1

2. RECEIVING AND UNPACKING UNIT.........................................................................................................1

2.1 RECEIVING........................................................................................................................................1

2.2 UNPACKING ......................................................................................................................................1

3. INSTALLING THE UNIT..............................................................................................................................1

3.1 FLUSH MOUNTING...........................................................................................................................1

3.2 ROLL AROUND CART.......................................................................................................................2

4. CONNECTING TO ELECTRICAL POWER ................................................................................................2

5. CONNECTING WATER, CO2, AND SYRUP SUPPLIES ............................................................................3

5.1 WATER SUPPLY................................................................................................................................3

5.2 CO2SUPPLY......................................................................................................................................3

5.3 SYRUP SUPPLY................................................................................................................................4

6. STARTING THE UNIT .................................................................................................................................4

6.1 INITIAL POWER-UP...........................................................................................................................4

6.2 BRIXING.............................................................................................................................................5

6.3 FILLING THE CHAMBER...................................................................................................................6

CRITICAL REGULATOR AND FLOW CONTROL SETTINGS.........................................................................7

7. OPERATION OF THE DISPENSER............................................................................................................7

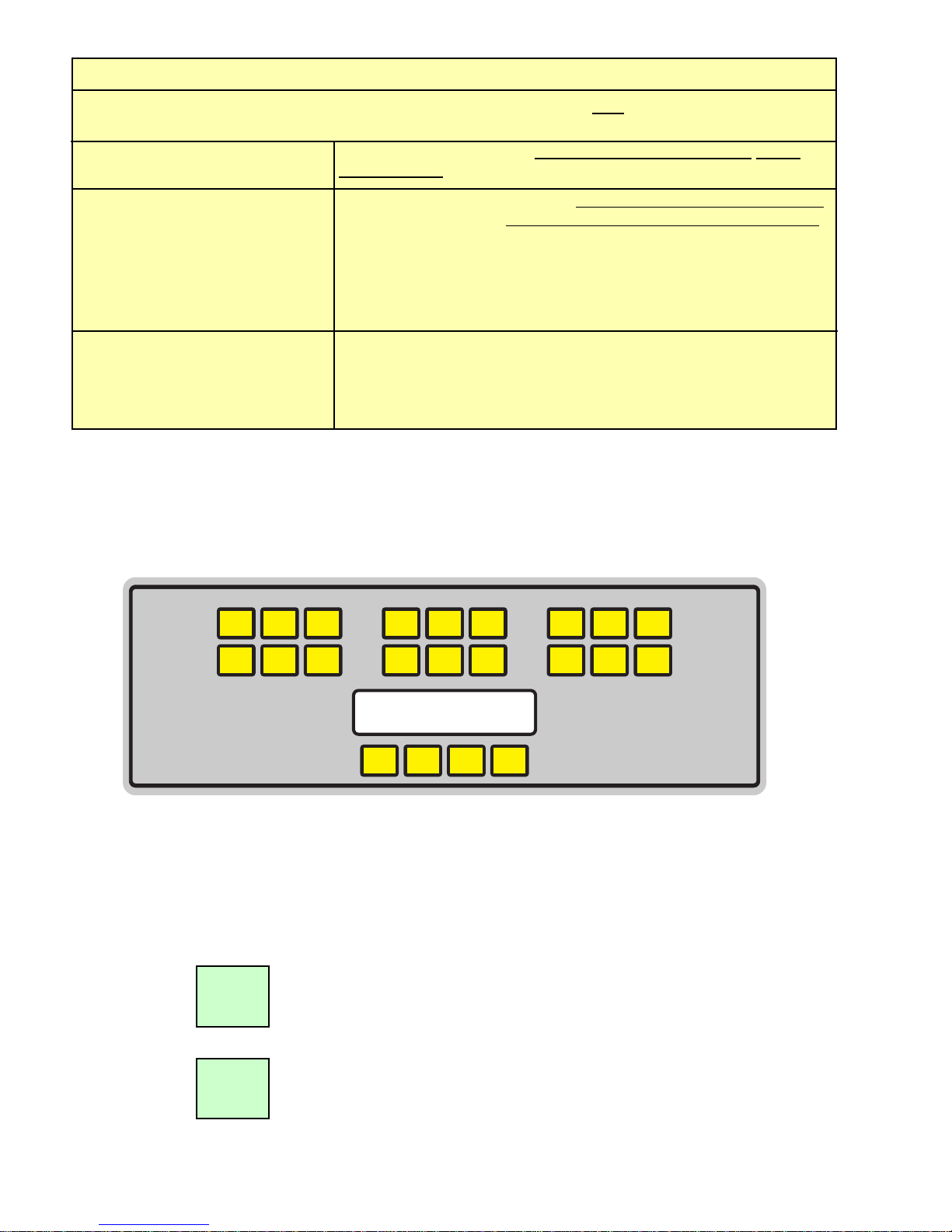

7.1 OPERATING ELECTRONIC CONTROLS.........................................................................................7

7.2 MACHINE ACCESS .........................................................................................................................11

7.3 MACHINE SETTINGS......................................................................................................................12

7.4 READOUTS......................................................................................................................................13

8. CLEANING AND SANITIZING THE UNIT ................................................................................................13

8.1 GENERAL INFORMATION ..............................................................................................................13

8.2 REQUIRED CLEANING EQUIPMENT.............................................................................................14

8.3 DAILY CLEANING OF THE UNIT....................................................................................................14

8.4 SANITIZING THE SYRUP SYSTEMS .............................................................................................14

9. BASICS OF OPERATION .........................................................................................................................15

9.1 MAKING ADJUSTMENTS TO THE FBD553D.................................................................................15

10. CHANGING FACTORY SET “LEVEL CONTROL” ..................................................................................16

10.1 BEFORE CHANGING “LEVEL CONTROL” SETTINGS..................................................................16

10.2 DRINK TOO HARD AND COLD.......................................................................................................17

10.3 DRINK TOO LIQUID ........................................................................................................................17

10.4 CHANGING THE DEFAULT LEVEL CONTROL SETTING .............................................................18

11. CHANGING FACTORY THAW AND FREEZE SETTINGS.......................................................................18

11.1 BEFORE CHANGING THAW AND FREEZE SETTINGS................................................................18

11.2 CHANGING THAW AND FREEZE SETTINGS................................................................................19

12. BEVTRAK OPERATION............................................................................................................................19

12.1 NAVIGATING THE BEVTRAK MENU..............................................................................................19

12.2 NORMAL OPERATION....................................................................................................................20

13. CRITICAL INFORMATION ........................................................................................................................20

13.1 DEFROST AND RUN TIME DELAY.................................................................................................20

13.2 CHAMBERS 90% FULL ON INITIAL SET UP .................................................................................20

13.3 LINE VOLTAGE DROP ....................................................................................................................21

13.4 LONG TUBING RUNS .....................................................................................................................21

14. TROUBLESHOOTING GUIDE..................................................................................................................21

MECHANICAL............................................................................................................................................21

ELECTRICAL.............................................................................................................................................23

ELECTRONIC CONTROLS.......................................................................................................................25

REFRIGERATION......................................................................................................................................25

DRINK QUALITY........................................................................................................................................27

LCD DISPLAY ERROR MESSAGES.........................................................................................................29

LCD DISPLAY MESSAGES.............................................................................................................................32

LCD DISPLAY ERROR MESSAGES ..............................................................................................................33

WARNING LIGHTS..........................................................................................................................................33

i