1

TABLE OF CONTENTS

1. SAFETY ........................................................................................................................................................3

1.1 ELECTRICAL .......................................................................................................................................3

1.2 CARBON DIOXIDE (CO2)...................................................................................................................3

1.3 GENERAL PRECAUTIONS ................................................................................................................3

2. UNIT IN STORAGE......................................................................................................................................3

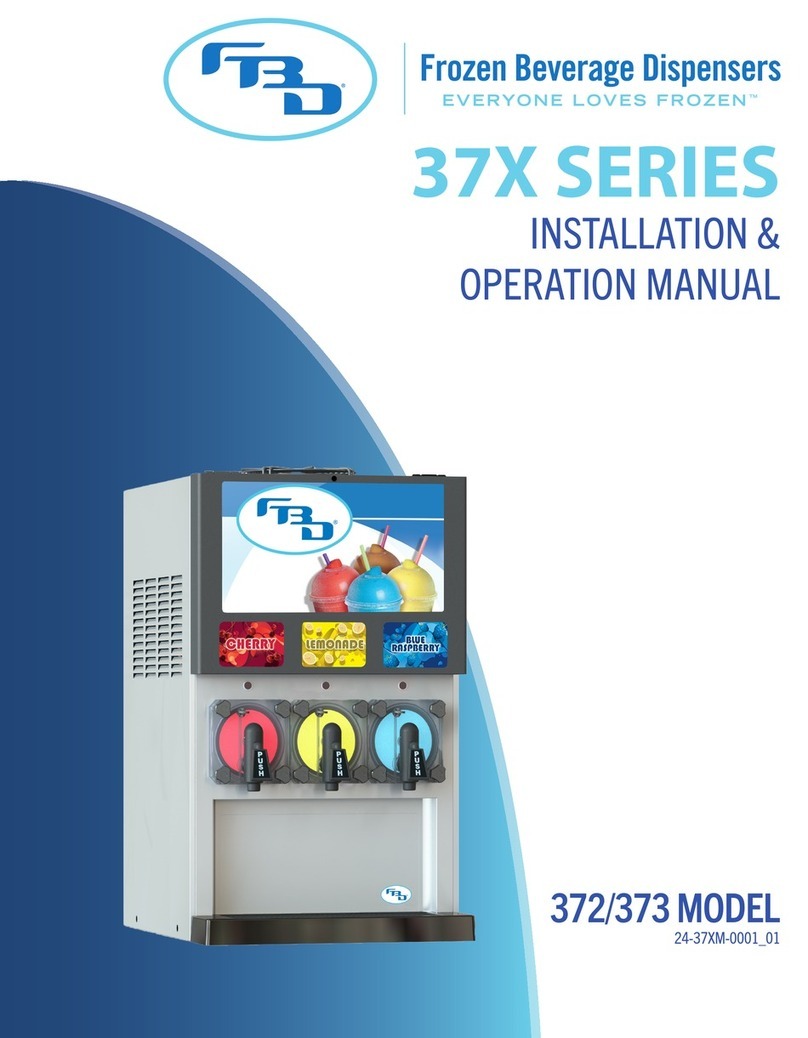

3. SPECIFICATIONS .......................................................................................................................................4

3.1 GENERAL REQUIREMENTS .............................................................................................................4

3.2 ELECTRICAL REQUIREMENTS........................................................................................................4

3.3 DIMENSION AND WEIGHT SPECIFICATIONS ...............................................................................4

4. RECEIVING AND UNPACKING DISPENSER ..........................................................................................5

4.1 RECEIVING..........................................................................................................................................5

4.2 UNPACKING ........................................................................................................................................5

5. INSTALLATION............................................................................................................................................5

5.1 GENERAL LOCATION REQUIREMENTS.........................................................................................5

5.2 SELF-CONTAINED REFRIGERATION MODELS.............................................................................5

5.3 DISPENSER MOUNTING ...................................................................................................................6

5.4 CONNECTING TO ELECTRICAL POWER .......................................................................................6

5.5 CONNECTING TO WATER SUPPLY ................................................................................................7

5.6 CONNECTING TO CO2SUPPLY.......................................................................................................7

5.7 CONNECTING TO SYRUP SUPPLY.................................................................................................8

5.8 LONG TUBING RUNS.........................................................................................................................8

6. STARTING UP THE DISPENSER ..............................................................................................................9

6.1 LEAK CHECK.......................................................................................................................................9

6.2 INITIAL POWER UP ............................................................................................................................9

6.3 CO2PURGE .......................................................................................................................................10

6.4 BRIXING .............................................................................................................................................10

6.5 FILLING BARREL ..............................................................................................................................12

7. DISPENSER OPERATION........................................................................................................................13

7.1 BRIX ....................................................................................................................................................13

7.2 EXPANSION.......................................................................................................................................13

7.3 REGULATED CO2INJECTION PRESSURE ..................................................................................14

7.4 THAW AND FREEZE SETTINGS.....................................................................................................14

7.5 NO DEFROST TIME BLOCK............................................................................................................14

7.6 SETTING WAKE/SLEEP TIMES ......................................................................................................15

7.7 DRINK QUALITY................................................................................................................................15

7.8 DRINK TOO "FIRM" OR COLD.........................................................................................................15

7.9 DRINK TOO LIQUID ..........................................................................................................................15

7.10 DEFROSTING ..................................................................................................................................16

7.11 BARRELS 90% FULL ON INITIAL SET-UP...................................................................................16

7.12 FREEZE ............................................................................................................................................16

7.13 OFF ...................................................................................................................................................16

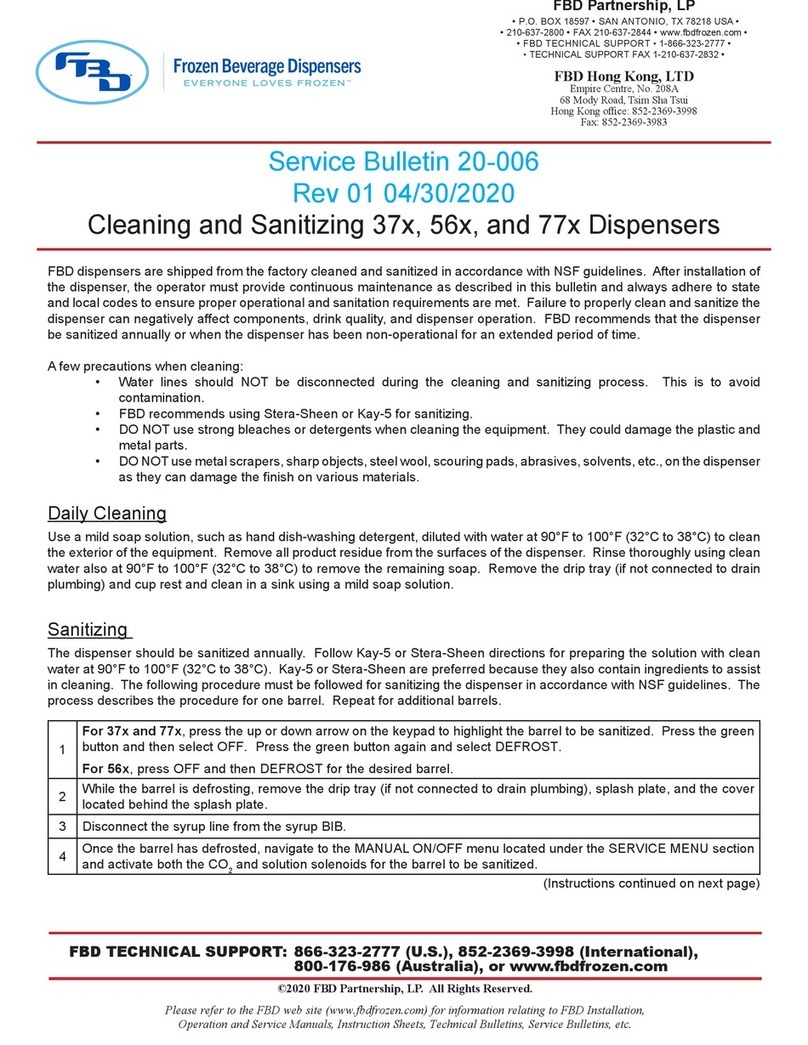

8. CLEANING AND SANITIZING THE UNIT...............................................................................................17

8.1 GENERAL INFORMATION ...............................................................................................................17

8.2 DAILY CLEANING .............................................................................................................................17

8.3 SANITIZING .......................................................................................................................................19

9. ROUTINE MAINTENANCE .......................................................................................................................19

9.1 AIR FILTER CLEANING....................................................................................................................19

9.2 REAR SEAL REPLACEMENT ..........................................................................................................20