TABLE OF CONTENTS

TABLE OF CONTENTS.....................................................................................................................................2

SAFETY .............................................................................................................................................................4

ELECTRICAL...............................................................................................................................................4

CARBON DIOXIDE (CO2)...........................................................................................................................4

GENERAL PRECAUTIONS.........................................................................................................................4

LEGAL ...............................................................................................................................................................4

SPECIFICATIONS .............................................................................................................................................5

GENERAL REQUIREMENTS – ALL DISPENSERS...................................................................................5

DISPENSER SPECIFIC REQUIREMENTS ................................................................................................5

DISPENSER SPECIFICATIONS.................................................................................................................5

INSTALLATION.................................................................................................................................................6

GENERAL LOCATION REQUIREMENTS........................................................................................................6

SELF CONTAINED REFRIGERATION MODELS.......................................................................................6

REMOTE CONDENSING MODELS............................................................................................................6

DISPENSER MOUNTING............................................................................................................................6

CONNECTING TO ELECTRICAL POWER.................................................................................................7

CONNECTING TO WATER SUPPLY .........................................................................................................7

CONNECTING TO CO2 SUPPLY...............................................................................................................7

CONNECTING TO SYRUP SUPPLY..........................................................................................................8

MENUS AND NAVIGATION..............................................................................................................................8

KEYPAD ......................................................................................................................................................8

HOME MENU...............................................................................................................................................9

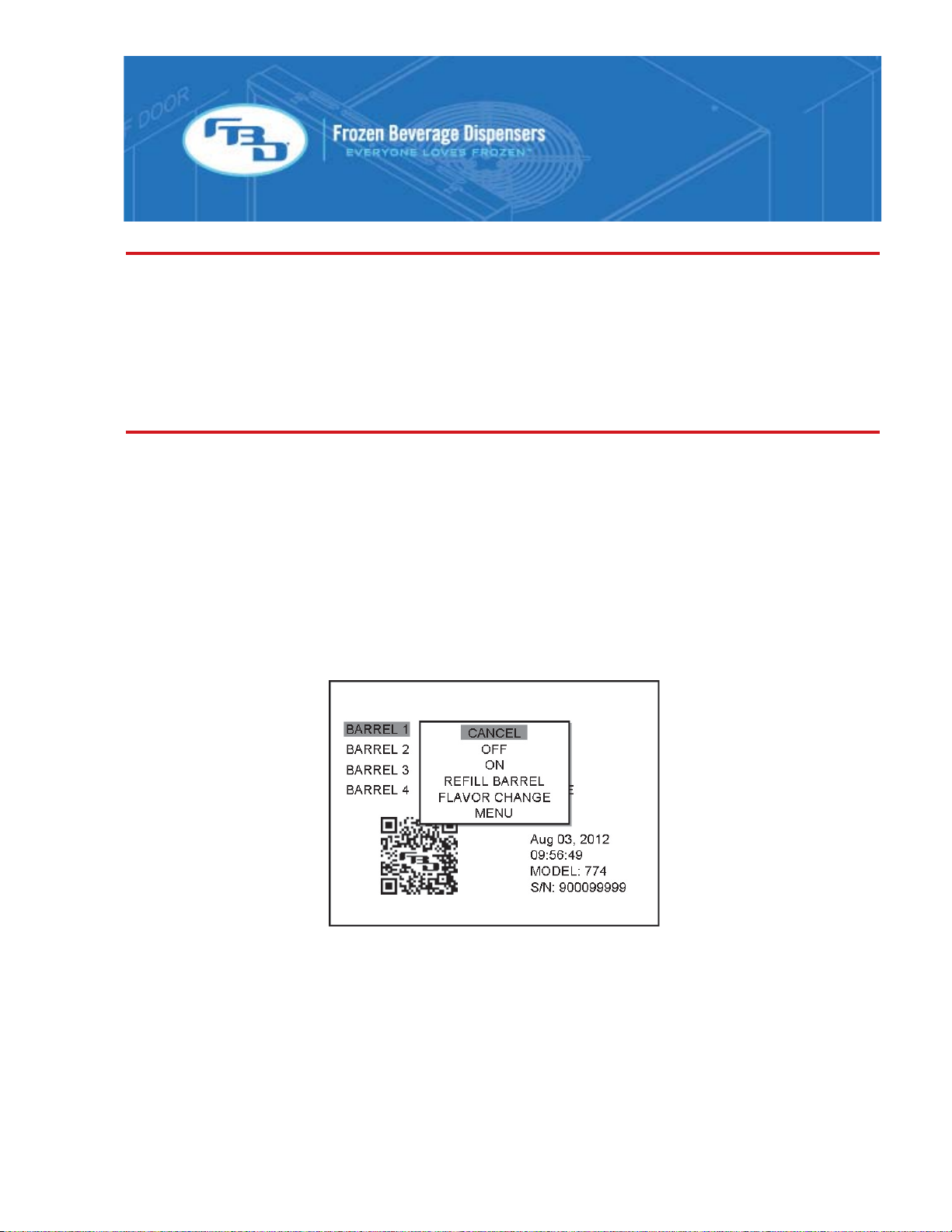

POPUP MENU.............................................................................................................................................9

MENU TREE..............................................................................................................................................10

MAIN MENU ..............................................................................................................................................11

READOUTS MENU ...................................................................................................................................11

FAULT CODES MENU..............................................................................................................................12

SERVICE MENUS.....................................................................................................................................12

MAINTENANCE OPTIONS MENU............................................................................................................13

SETTINGS MENU .....................................................................................................................................13

CLOCK AND SCHEDULE MENU..............................................................................................................14

DATE & TIME MENU.................................................................................................................................15

DEFROST SCHEDULE MENU .................................................................................................................15

AUTO DEFROST MENU...........................................................................................................................16

WAKE/SLEEP MENU................................................................................................................................16

MANUAL ON/OFF MENU..........................................................................................................................17

BEVTRAK MENU.......................................................................................................................................17

MODEM SETUP........................................................................................................................................18

MACHINE TOTALS MENU........................................................................................................................18

RESTORE FACTORY SETTINGS MENU.................................................................................................19

DIAGNOSTICS MENU...............................................................................................................................19

STARTING UP THE DISPENSER...................................................................................................................20

LEAK CHECK AND PRIME.......................................................................................................................20

INITIAL POWER UP..................................................................................................................................21

BRIXING....................................................................................................................................................21

FILLING BARREL AND STARTING..........................................................................................................23

DISPENSER OPERATION..............................................................................................................................24

FREEZE.....................................................................................................................................................24

OFF .........................................................................................................................................................24

DEFROST..................................................................................................................................................24

DRINK QUALITY .......................................................................................................................................24

DRINK TOO “FIRM” OR COLD.................................................................................................................24

2