FE TP-E1U User manual

INR-SI47-1246a

- 1 -

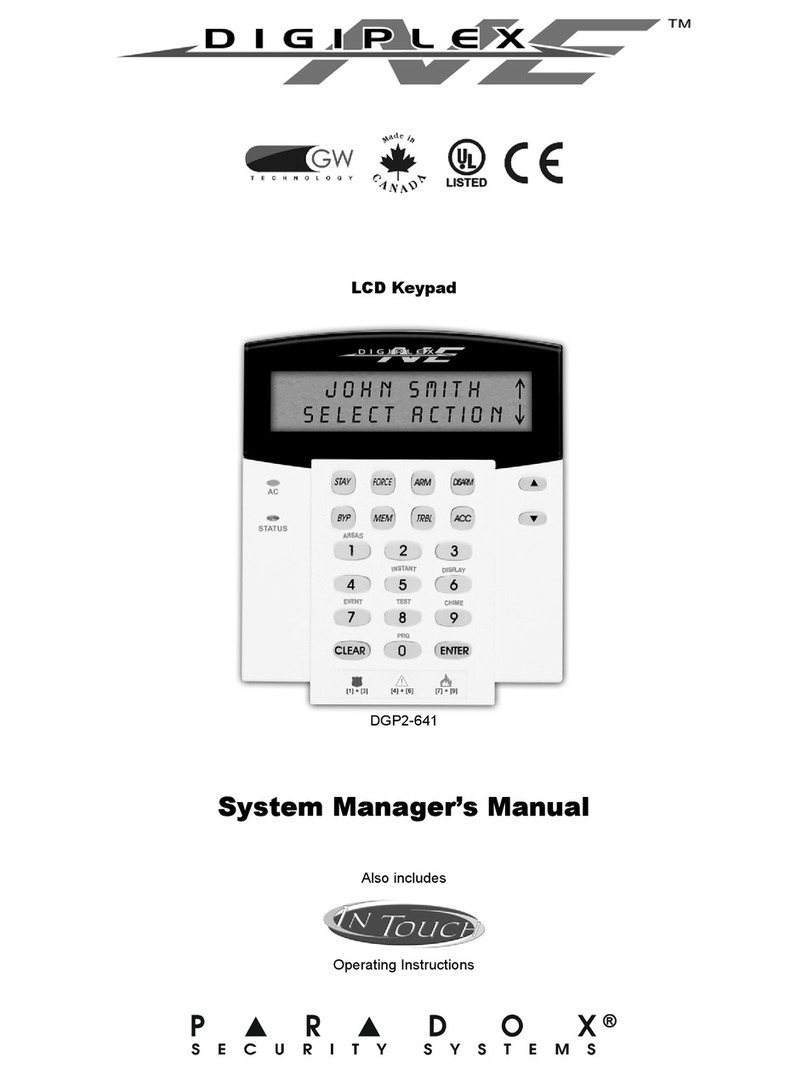

Installation Manual

Remote Keypad "TP-E1U"

Thank you for purchasing the remote keypad "TP-E1U." Using this keypad allows you to operate the

FRENIC-MEGA/Mini/Ace/VP/Lift series of inverters remotely and locally. To operate the inverter remotely, use a remote

operation extension cable (CB-5S, CB-3S or CB-1S) or commercially available LAN cable to connect the remote keypad to the

inverter. You can run and stop the motor, specify the function codes, monitor the running status, and perform data copying

(read the function code data from an inverter, copy (write) it into another inverter, or verify it).

1. Acceptance Inspection

Check the following:

(1) The package contains a remote keypad and its installation manual

(this book).

(2) There have been no problems during transportation. In particular, no

parts are damaged or have fallen out of place nor are there any

dents on the body.

(3) The model name "TP-E1U" is inscribed on the back of the remote

keypad as shown in Figure 1.

(4) In case of using this keypad for the FRENIC-Ace / VP / Lift series,

check the stamps under the model name, as shown in Figure 1.

The model which has "D" to “Z” of the first character of the stamps

allows to be applied for FRENIC-Ace / VP / Lift series.

Note that the data copy function is not available in FRENIC-Ace / VP /

Lift series if the first character of the stamps is "A" to "C".

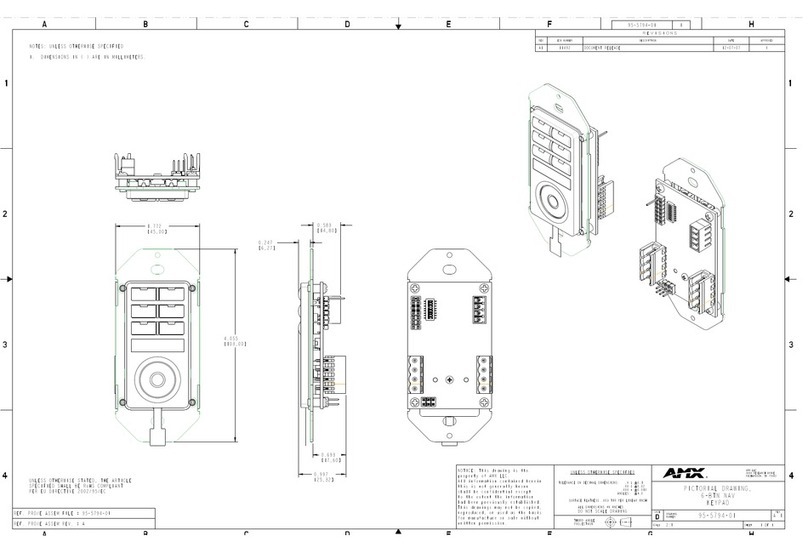

Figure 1 Back of Remote Keypad

If you suspect the product is not working properly or if you have any questions about your product, contact your Fuji Electric

representative.

2. Inverters with which the Remote Keypad Interfaces

The remote keypad "TP-E1U" interfaces with the following Fuji inverters:

Type of inverter Series name Remarks

FRN G1- FRENIC-MEGA

FRN C2- FRENIC-Mini

FRN E2- FRENIC-Ace The data copy function is valid in the remote keypad which

has the first character of the stamps "D" to "Z" under the

model name on the back of the keypad. (Refer in Figure 1)

FRN F2- FRENIC-VP

FRN LM2- FRENIC-Lift

3. Installation and Connection

To mount the remote keypad to the panel and other devices except inverters, use a remote operation extension cable

(CB-5S, CB-3S or CB-1S) or commercially available LAN cable.

(1) Parts required for connection

In addition to the inverter, the following parts are required.

Parts name Model Remarks

Remote operation extension cable

(Note 1) CB-5S, CB-3S and CB-1S Three types available in length of 5 m, 3 m, and

1 m

Fixing screw M3(Note 2) Two screws (prepared by the customer)

(Note 1) When using a commercially available LAN cable, select a 10BASE-T/100BASE-TX straight type cable compliant

with US ANSI/TIA/EIA-568A Category 5. (Less than 20 m)

Recommended LAN cable (for 1 m) Manufacturer : Sanwa Supply Inc.

Model : KB-10T5-01K

KB-STP-01K (Shielded LAN cable, EMC-compliant)

(Note 2) Use screws with the length suitable for the wall thickness of the panel. (Please refer to Figure 2.3)

(2) Installation procedure

After finishing the wiring for the inverter, proceed to the following steps. Turn OFF the inverter power.

Stamps

First character

Model name

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

-2 -

Figure 2.1 Mounting a Remote Keypad on the Panel Figure 2.2 Mounting a Remote Keypad on the inverter

(In case of FRENIC-MEGA series)

Mounting the remote keypad on the panel (Figure 2.3)

Cut the panel out for a single square area and perforate two screw holes on the panel wall as shown in Figure 2.3.

Figure 2.3 External Dimensions, Dimensions of Square Cut-out and Screw Holes

Mount the remote keypad onto the panel

wall with 2 screws.

(Recommended tightening torque: 0.7 N·m)

Using a remote operation extension cable or commercially

available LAN cable, connect the remote keypad to the

inverter (insert one end of the cable into the RJ-45 connector

on the remote keypad and the other end into that on the

inverter).

Figure 2.4 Mounting the Remote Keypad Figure 2.5 Connecting the Remote Keypad to the Inverter

with the Remote Operation Extension Cable or

LAN Cable(In case of FRENIC-MEGA,Lift series)

RJ-45 connector Panel

M3

(To be provided

by the customer)

RJ-45 connector

(Remote keypad)

RJ-45 connector

(Inverter unit)

Panel

Remote operation extension cable

or LAN cable

Remote keypad

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

- 3 -

Figure 2.6 Connecting the Remote Keypad to the Inverter

with the Remote Operation Extension Cable or

LAN Cable(In case of FRENIC-Mini series)

Figure 2.7 Connecting the Remote Keypad to the Inverter with

the Remote Operation Extension Cable or LAN

Cable(In case of FRENIC-Ace,VP series)

Mounting the remote keypad on the inverter (Figure 2.8)

Mount the remote keypad on the inverter unit in the direction of arrows and . (In case of FRENIC MEGA series)

Figure 2.8 Mounting the remote keypad on the inverter

(In case of FRENIC-MEGA series)

4. General Specifications

(1) Operating environment

For FRENIC-MEGA or Mini series, refer to their Instruction Manual, Chapter 2, Section 2.1 "Operating Environment."

And for FRENIC-Ace series, refer to its Instruction Manual, Chapter 1, Subsection 1.3.1 "Operating Environment."

(2) Operation method

Refer to the FRENIC-MEGA, Mini, Ace, VP or Lift series Instruction Manual, Chapter 3 "OPERATION USING THE

KEYPAD."

For data copy, refer to the following description.

(3) Copying data -- Menu #7 "Data Copying" --

Menu #7 "Data Copying" is used to read function code data out of an inverter for storing it in the keypad or writing it into

another inverter. It is also used to verify the function code data stored in the keypad with the one configured in the inverter.

The keypad serves as a temporary storage media.

In addition, using Menu #7 allows you to store the running status information in the keypad, detach the keypad from the

inverter, connect it to a PC running FRENIC Loader at an office or off-site place, and check the inverter running status

without removing the inverter itself.

To store the inverter running status information into the keypad, use "Read data" (

read

) or "Read inverter running

information" (

chec

) function. For details on how to connect the keypad to a PC and check the inverter running status

information stored in the keypad, refer to the FRENIC Loader Instruction Manual.

Figure 3 shows the menu transition in Menu #7 "Data Copying." The keypad can hold function code data for a single

inverter.

Table 1 below lists details of the data copying functions.

It is not possible to copy the function code data between different type of inverter (e.g. Mini series and Ace series) .

err

is blinking, if the data is copied between different type of inverter.

RJ-45 connector

(Remote keypad)

RJ-45 connector

(Inverter unit)

Panel

Remote operation extension cable

or LAN cable

Remote keypad

RJ-45 connector

(Remote keypad)

RJ-45 connector

(Inverter unit)

Panel

Remote operation extension cable

or LAN cable

Remote keypad

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

-4 -

Figure 3 Menu Transition in Menu #7 "Data Copying"

Basic keying operation

(1) Turn the inverter ON. It automatically enters Running mode. In that mode, press the key to switch to Programming

mode. The function selection menu appears.

(2) Use the and keys to display "Data Copying" (

'cpy

).

(3) Press the key to proceed to the list of data copying functions (e.g.

read

).

(4) Use the and keys to select the desired function, then press the key to execute the selected function.

(e.g.

read

will blink.)

(5) When the selected function has been completed,

end

appears. Press the key to return to the list of data copying

functions. Press the key again to return to the menu.

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

- 5 -

Table 1 shows the details of the data copying functions.

Table 1 List of Data Copying Functions

Display on

LED Monitor Function Description

read

Read data Reads the function code data out of the inverter’s memory and stores it into the keypad

memory.

Also reads out inverter’s current running status information which can be checked by

FRENIC Loader, such as information of I/O, system, alarm, and running status.

Pressing the key during a read operation (when

read

is blinking) immediately aborts

the operation and displays

err

(blinking).

If this happens, the entire contents of the memory of the keypad will be completely cleared.

copy

Write data Writes data stored in the keypad memory into the inverter’s memory.

If you press the key during a write operation (when

copy

is blinking), the write

operation that is under way will be aborted and

err

will appear (blinking).

If this happens, the contents of the inverter’s memory (i.e., function code data) have been

partly updated and remain partly old. Therefore, do not operate the inverter.

Instead, perform initialization or rewrite the entire data.

If this function does not work, refer to "If data copying does not work".

ueri

Verify data Verifies (collates) the data stored in the keypad memory with that in the inverter's

memory.

If any mismatch is detected, the verify operation will be aborted, with the function code in

disagreement displayed blinking. Pressing the key again causes the verification to

continue from the next function code.

Pressing the key during a verify operation (when

ueri

is blinking) immediately aborts

the operation and displays

err

(blinking).

err

appears blinking also when the keypad does not contain any valid data.

proT

Enable Data

protection

Enables the Data protection of data stored in the keypad’s memory.

In this state, you cannot read any data stored in the inverter’s memory, but can write

data into the memory and verify data in the memory.

Upon pressing the key the inverter immediately displays

err

.

chec

(*)

Read inverter

running

information

Reads out inverter’s current running status information that can be checked by

FRENIC Loader, such as information of I/O, system, alarm, and running status, excluding

function code data.

Use this command when the function code data saved in the PC should not be overwritten

and it is necessary to keep the previous data.

Pressing the key during a read operation (

chec

blinking) immediately aborts

the operation and displays

err

(blinking).

To get out of the error state indicated by a blinking

err

or

cper

, press the key.

When

cper

is blinking, it indicates that the function code number does not match. But in this case the function

codes which are consistent completely can continue copying after pressing key.

While

cper

is blinking, pressing key changes display to flashing of

err

.

(*)

A

ce(E2S) series of ROM version number less than 500 or Lift(LM2) series does not support “

chec

”.

Data protection

You can protect data saved in the keypad from unexpected modifications. Enabling the data protection that was disabled

changes the display

read

on the "Data Copying" function list to

proT

, and prohibits data reading from the inverter.

To enable or disable the data protection, follow the steps below.

(1) Select the "Data Copying" (

'cpy

) on the function selection menu in Programming mode.

(2) When the

'cpy

is displayed, holding the key down for at least 5 seconds alternates data protection status between

enabled or disabled.

For switching the data protection status, be sure to hold the key down for at least 5 seconds. Once the key is

released within 5 seconds, press the key to go back to the

' cpy

display and perform the keying operation

again.

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

-6 -

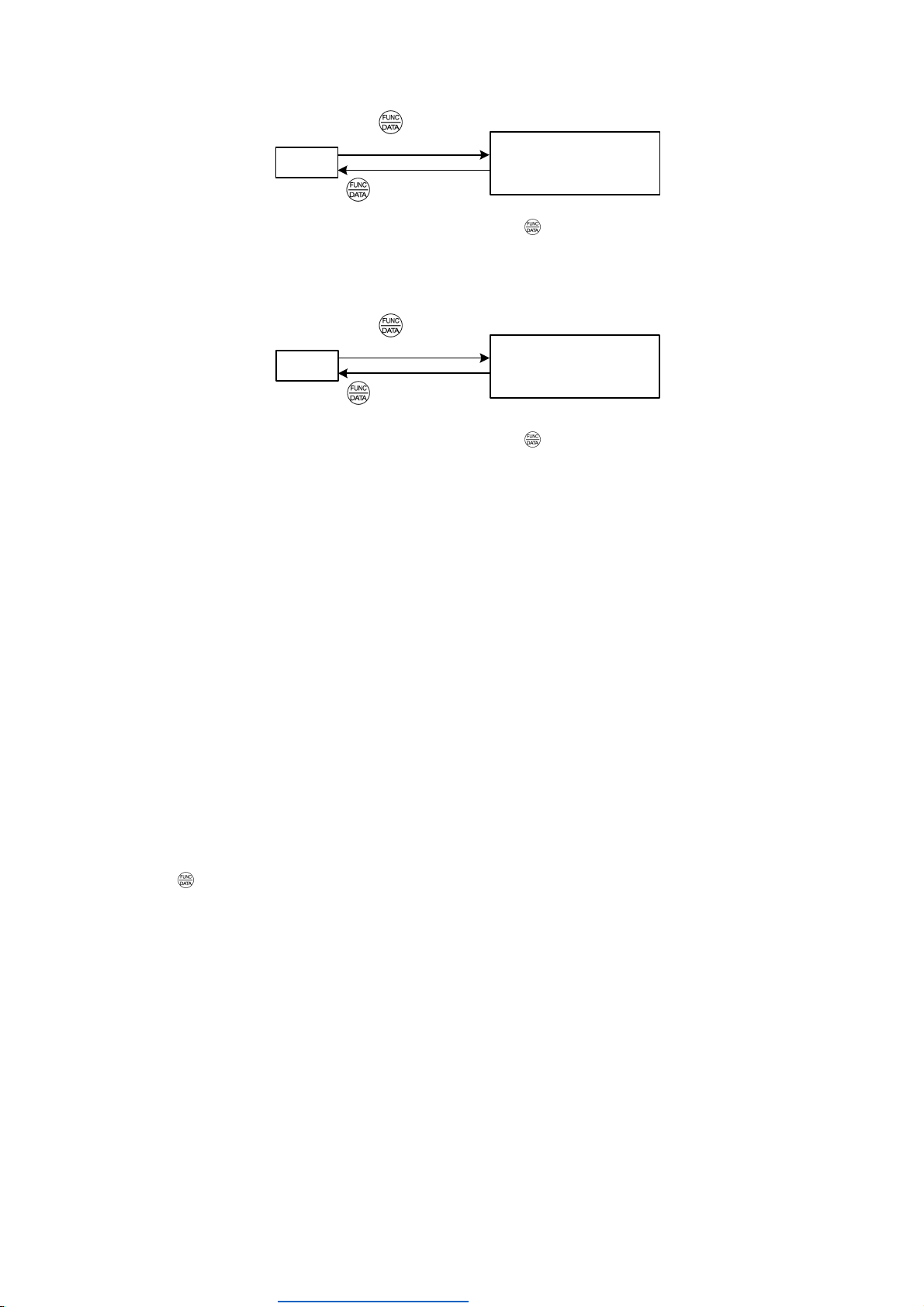

• Disabling the enabled data protection

'cpy

read proT

(Displayed item changes.)

⇒

Hold key down

for at least 5 seconds.

While running the "Data Copying" (

'cpy

)function, holding down the key for 5 seconds or more displays

read

after

displaying

proT

for 5 seconds to complete disabling the data protection.

• Enabling the disabled data protection

'cpy

read

proT

(Displayed item changes.)

⇒

Hold key down

for at least 5 seconds.

While running the "Data Copying" (

'cpy

) function, holding down the key for 5 seconds or more displays

proT

after

displaying

read

for 5 seconds to complete enabling the data protection.

The followings are restrictions and special notes concerning "Data Copying."

If data copying does not work

Check whether

err

or

cper

is blinking.

(1) If

err

is blinking (a write error), any of the following problems has arisen:

• No data exists in the keypad memory. (No data read operation has been performed since shipment, or a data read

operation has been aborted.)

• Data stored in the keypad memory contains any error.

• The models of copy source and destination inverters are different.

• A data write operation has been performed while the inverter is running.

• The copy destination inverter is data-protected. (Function code F00 = 1)

• In the copy destination inverter, the "Enable write from keypad" command WE-KP is OFF.

• A Read data operation has been performed for the inverter whose data protection was enabled.

(2) If

cper

is blinking, any of the following problems has arisen:

• The function codes stored in the keypad and ones registered in the inverter are not compatible with each other. (Either of

the two may have been revised or upgraded in a non-standard or incompatible manner. Consult your Fuji Electric

representative.)

• If the inverter type is the same

cper

has occurs by the software versions mismatch.

Pressing key can continue copying. But added function codes according to upgrade can not be copied.

• If the inverter type is different or special products for special customers

Do not copy since the function codes are not compatible between inverters.

(3)

ercl

is blinking, when the mismatch of the number of function code for customizable logic occurs at

ueri

(Verify):

(FRENIC-Ace,VP or Lift series has

ercl

detecting function.)

• In FRENIC-Ace series,

ercl

is blinking if a customer will copy the function codes relating to customizable logic in an

inverter which has the ROM version number 300 or later (has function codes for 200 steps) to TP-E1U and verify whether

they matches the codes of another inverter which has the ROM version number less than 300 (has function codes for

100 steps) and vice versa. In FRENIC-VP or Lift series, it works similar behaviour regardless of the ROM version.

(4) Some models have the password function. If the password has been set, it prevents the copy operation.

For more information, please refer to the instruction manual or user's manual for an each model.

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

- 7 -

(4) USB Connectivity

The keypad has a USB port (mini B connector) on its face. To connect a USB cable, open the USB port cover as shown

below.

Connecting the inverter to a PC with a USB cable enables remote control from FRENIC Loader. On the PC running

FRENIC Loader, it is possible to edit, check, manage, and monitor the function code data in real-time, to start or stop the

inverter, and to monitor the running or alarm status of the inverter.

Do not connect or disconnect the USB cable to the USB port on the keypad during the data copying.

For the instructions on how to use the FRENIC Loader, refer to the FRENIC Loader Instruction Manual(INR-SI47-1526□,

INR-SI47-1549□-E).

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

INR-SI47-1246a

-8 -

Fuji Electric Co., Ltd.

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome, Shinagawa-ku, Tokyo, 141-0032, Japan

Phone: +81 3 5435 7058 Fax: +81 3 5435 7420

URL http://www.fujielectric.com/

Dealers Industrial Equipment -- Visit https://DealersElectric.com or call (908) 688-1966 for all of your electric motor & VFD needs!

Table of contents

Other FE Keypad manuals