FE TP-G1-?LS User manual

Instruction Manual

Multi-function Keypad "TP-G1-LS"

Thank you for purchasing our Multi-function Keypad TP-G1-CLS / TP-G1-ELS.

• This product is designed to remotely control the FRENIC-Lift series of inverters. Read through this

instruction manual and the FRENIC-Lift Instruction Manual, and be familiar with the handling procedure for

correct use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. Keep this manual in a safe place until the multi-function

keypad is discarded.

• For the usage of inverters and optional equipment, refer to the instruction manuals prepared for the

FRENIC-Lift series of inverters and its optional equipment.

Fuji Electric FA Components & Systems Co., Ltd. INR-SI47-1092b-E

Copyright © 2005 – 2007 Fuji Electric FAComponents & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA

Components & Systems Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Preface

Thank you for purchasing our multi-function keypad TP-G1-CLS / TP-G1-ELS.

By installing the multi-function keypad directly on a FRENIC-Lift as an attached keypad or connecting them to-

gether using an optional remote operation extension cable(CB-5S, CB-3S, or CB-1S, depending on the distance),

you can operate the inverter locally or remotely. In either mode, you can run and stop the motor, monitor the

running status, and set the function codes. In addition, you can perform "data copying": You can read function

code data from an inverter, copy (write) it into another inverter, or verify it.

Before installing and using the multi-function keypad, read through this manual in conjunction with the

FRENIC-Lift Instruction Manual (INR-SI47-1038-E) and familiarize yourself with its proper use. Improper use may

prevent normal operation or cause a failure or reduced life of the inverter.

The LCD on the multi-function keypad may display each function code name as “FUNCTION.” For the proper

function code name refer to the FRENIC-Lift Instruction Manual (INR-SI47-1038-E) and the FRENIC-Lift Ref-

erence Manual (INR-SI47-1068-E).

Related Publications

Listed below are other publications on the FRENIC-Lift to be consulted in conjunction with this manual as nec-

essary.

• FRENIC-Lift Instruction Manual (INR-SI47-1038-E)

• FRENIC-Lift Reference Manual (INR-SI47-1068-E)

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

About the ROM version of multi-function keypad

Please read manual (INR-SI47-1056-E) when ROM version of a multi-function keypad is 8510. It might be dif-

ferent from the content of the description of this manual.

Please refer to this Manual 3.4.6 Reading maintenance information Menu #5 "Maintenance Information" for the

confirm method of ROM version of multi-function keypad.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or maintenance

and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all safety infor-

mation and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

i

Operation

• Be sure to install the terminal block cover and the front cover before turning the power on. Do not re-

move the covers while power is applied.

Otherwise electric shock could occur.

• Do not operate switches/buttons with wet hands.

Doing so could cause electric shock.

• If the retry function has been selected, the inverter may automatically restart and drive the motor de-

pending on the cause of tripping. Design the machinery or equipment so that human safety is ensured

after restarting.

• Never make an alarm reset with the operation signal being on. Doing so will suddenly restart the in-

verter. Ensure that the operation signal is turned off beforehand.

Otherwise an accident could occur.

• If you set the function codes wrongly or without completely understanding this instruction manual, the

FRENIC-Lift Instruction Manual (INR-SI47-1038-E) and the FRENIC-Lift Reference Manual

(INR-SI47-1068-E), the motor may rotate with a torque or at a speed not permitted for the machine.

An accident or injuries could occur.

• Do not touch the inverter terminals while the power is applied to the inverter even if the inverter stops.

Doing so could cause electric shock.

Wiring

• Do not operate the switch with wet hands.

Doing so could cause electric shock.

• Before opening the cover of the inverter to install the multi-function keypad, turn the power off and wait

for at least five minutes. Further, make sure that the LED monitor is turned off, the charger indicator is

off, and the DC link bus voltage between the terminals P (+) and N (-) has dropped below the safe

voltage level (+25 VDC), using a circuit tester or another appropriate instrument.

Otherwise electric shock could occur.

• In general, the insulation property of the sleeve of the signal wire and that of the sheath of the signal

cable are not sufficient for high voltages. Therefore, if a signal wire or cable comes into direct contact

with a live part of the main circuit, the insulation may be broken, causing the signal wire to be exposed to

the high voltage of the main circuit. Be sure to keep all signal wires and cables away from live parts of

the main circuit.

Otherwise, an accident or electric shock could occur.

ii

Disposal

• For disposal, treat the multi-function keypad as industrial waste.

Otherwise injuries could occur.

Others

• Never attempt to modify the multi-function keypad or inverter.

Doing so could cause electric shock or injuries.

GENERAL PRECAUTIONS

Drawings in this manual may be illustrated without covers or safety shields for explanation of detail parts.

Restore the covers and shields in the original state and observe the description in the manual before

starting operation.

How this manual is organized

This manual is made up of chapters 1 through 4

Chapter 1 BEFORE USING THE MULTI-FUNCTION KEYPAD

This chapter describes the points to check upon delivery and lists the inverters the multi-function keypad is de-

signed to interface with.

Chapter 2 INSTALLATION AND INTERCONNECTION

This chapter describes how to install the multi-function keypad and how to interconnect it with an inverter.

Chapter 3 OPERATION USING THE MULTI-FUNCTION KEYPAD

This chapter describes the operation of the inverter using the multi-function keypad. More specifically, this

chapter gives an overview of the inverter’s three operation modes (Running, Programming, and Alarm modes)

and describes how to run and stop the inverter/motor, set function code data, monitor running status, view

maintenance information and alarm data, and perform data copying.

Chapter 4 SPECIFICATIONS

This chapter lists the general specifications such as operating environments, communication specifications and

transmission specifications.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full effi-

ciency, as well as information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

iii

Table of Contents

Preface ........................................................................i

Safety precautions..............................................................i

How this manual is organized..............................................iii

Chapter 1 BEFORE USING THE MULTI-FUNCTION

KEYPAD.........................................................1-1

1.1 Acceptance Inspection...........................................1-1

1.2 Inverters with which the Multi-function Keypad

Interfaces taka....................................................... 1-1

Chapter 2 INSTALLATION AND INTERCONNECTION.. 2-1

2.1 Accessories and Parts Required for

Interconnection......................................................2-1

2.2 Installing the Multi-function Keypad.......................2-2

2.2.1 Three ways of installation/use.......................2-2

2.2.2 Installing the multi-function keypad............... 2-3

Chapter 3 OPERATION USING THE MULTI-FUNCTION

KEYPAD.........................................................3-1

3.1 Components on the Keypad ..................................3-1

3.2 Overview of Operation Modes...............................3-4

3.3 Running Mode.......................................................3-5

3.3.1 Running/stopping the motor.............................3-5

3.3.2 Setting the reference speed (pre-ramp)........... 3-7

3.3.3 Monitoring the running status

on the LED monitor.......................................3-8

3.4 Programming Mode...............................................3-9

3.4.1 Setting function codes

-- Menu #1 "Data Setting" --........................3-10

3.4.2 Setting up function codes quickly

-- Menu #0 "Quick Setup" --........................3-13

3.4.3 Checking changed function codes

-- Menu #2 "Data Checking" --...................3-13

3.4.4 Monitoring the running status

-- Menu #3 "Drive Monitoring" --..................3-14

3.4.5 Checking I/O signal status

-- Menu #4 "I/O Checking" --.......................3-16

3.4.6 Reading maintenance information

-- Menu #5 "Maintenance Information" -- .... 3-20

3.4.7 Reading alarm information

-- Menu #6 "Alarm Information" --................3-23

3.4.8 Viewing cause of alarm

-- Menu #7 "Alarm Cause" --.......................3-26

3.4.9 Data copying

-- Menu #8 "Data Copying" --......................3-28

3.4.10 Measuring load factor

-- Menu #9 "Load Factor Measurement" --..3-35

3.4.11 Changing function codes covered by Quick setup

-- Menu #10 "User Setting" --......................3-38

3.4.12 Performing communication debugging

-- Menu #11 "Communication Debugging" --3-39

3.5 Alarm Mode.........................................................3-40

3.6 Other Notes.........................................................3-42

3.6.1 Tuning motor parameters...............................3-42

3.6.2 Password protection...................................... 3-44

3.6.3 Connecting to other inverter series................3-47

Chapter 4 ...............................SPECIFICATIONS...................................................................................

4.1 General Specifications...........................................4-1

4.2 Communication Specifications...............................4-2

4.3 Transmission Specifications...................................4-2

iv

Chapter 1 BEFORE USING THE MULTI-FUNCTION KEYPAD

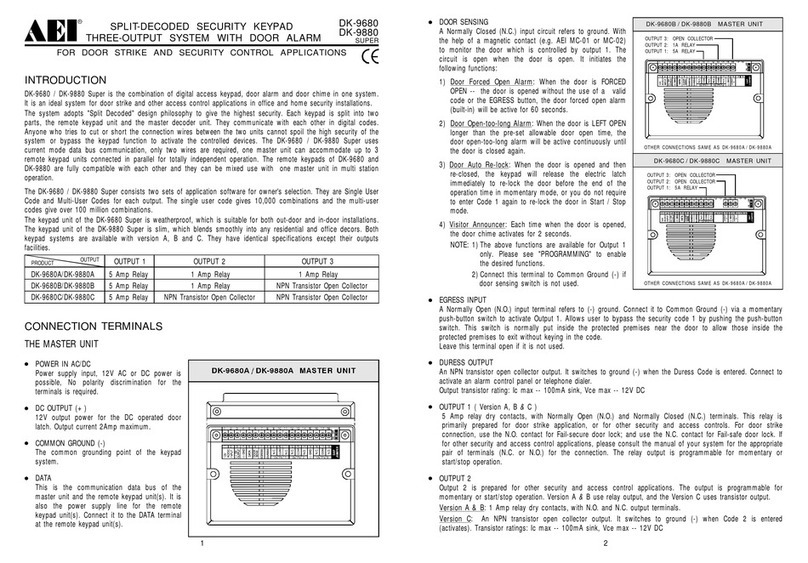

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) The package contains a multi-function keypad and the

following attached goods.

Attached goods

Multi-function keypad fixing screws

Instruction manual (this book)

(2) There have been no problems during transportation. In

particular, no parts are damaged or have fallen out of place

nor are there any dents on the body.

(3) The model name "TP-G1-CLS" or "TP-G1-ELS" is printed on

the back of the multi-function keypad as shown in Figure 1.1.

The language that can be displayed is different in each model

name.(Refer to the table below)

Model name Language that can be displayed

TP-G1-CLS Chinese, English, Japanese

TP-G1-ELS English, Japanese, German, French

Spanish, Italian

If you suspect the product is not working properly or if you have

any questions about your product, contact your Fuji Electric

representative.

Figure 1.1 Back of Multi-function Keypad

TP-G1-CLS / TP-G1-ELS

1.2 Inverters with which the Multi-function Keypad Interfaces

The multi-function keypad interfaces with the following Fuji inverters:

Series Type of inverter*Remarks

FRENIC-Lift FRNLM1S-2

FRNLM1S-4

(Each has its meaning as shown below,

represented by an alphanumeric character.)

No restriction is there for use of this product.

* Type of inverter

For the details of the Inverter type identification, refer to the FRENIC-Lift Instruction Manual

(INR-SI47-1038-E), Chapter 1, Section 1.1 "Acceptance Inspection."

1-1

Chapter 2 INSTALLATION AND INTERCONNECTION

2.1 Accessories and Parts Required for Interconnection

To install the multi-function keypad on the enclosure’s panel instead of the inverter, you need the following

accessories and parts:

Accessories/Parts Type or Specifications Remarks

Remote operation extension cable*1CB-5S, CB-3S, or CB-1S You have a choice of three lengths: 5 m, 3

m, and 1 m.

Screws

(for mounting the multi-function keypad) M3 x *2Provide 2 screws (to be provided by the

customer) beforehand.

*1: Alternatively, you can use an off-the-shelf 10BASE-T/100BASE-TX LAN cable (straight type) that meets the

ANSI/TIA/EIA-568A Category 5 standard (maximum length: 20 m).

Recommended LAN cable:

Manufacturer:Sanwa Supply, Co. Ltd.

Model:KB-10T5-01K (for 1 m)

KB-STP-01K (for 1 m) (shielded cable, EMC-compliant)

*2: Use the screws of the length just right for the panel. (See Figure 2.7.)

2-1

2.2 Installing the Multi-function Keypad

2.2.1 Three ways of installation/use

You can install the multi-function keypad in one of the following three ways:

Install it directly on the inverter (see Figure 2.1).

Install it on the front panel of enclosure (see Figure 2.2).

Use it remotely in your hand (see Figure 2.3).

For FRN□□□LM1S-4□

Figure 2.1 Installing Multi-function Keypad Directly on Inverter

Figure 2.2 Installing Multi-function Keypad on Enclosure Figure 2.3 Using Multi-function Keypad

remotely in Your Hand

2-2

2.2.2 Installing the multi-function keypad

After completion of interconnection, follow the next steps to install the multi-function keypad in place. Be sure to

turn off the power of the inverter beforehand.

Installing the multi-function keypad directly on the inverter

Remove the blind cover mounted on the inverter.

Pull the blind cover toward you while holding down the hook (as directed by the arrows in Figure 2.4

below).

Figure 2.4 Removing the Blind Cover

Mount the multi-function keypad onto the inverter.

Put the multi-function keypad in the original slot while engaging its bottom latches with the holes (as shown

below), and push it onto the case of the inverter (arrow ) while holding it downward (against the terminal

block cover) (arrow ).

Figure 2.5 Mounting the Multi-function Keypad

2-3

Protection from abnormal vibration: for inverters with capacity of 22 kW or less

In an environment with large ambient vibrations, the inverter may be exposed to them, causing abnormal

vibrations on the multi-function keypad. If this happens, remove the terminal block cover and the front cover,

then secure the multi-function keypad to the inverter with the attached screw (Two). After that, reinstall those

covers.

For the procedures for removing the covers, refer to the FRENIC-Lift Instruction Manual

(INR-SI47-1038-E), Chapter 2, Section 2.3.1 "Removing and mounting the terminal block (TB) cover and

the front cover."

Figure 2.6 Fixing the Multi-function Keypad

2-4

Installing the multi-function keypad on the enclosure panel

Cut the panel out for a single square area and perforate two screw holes in the panel of the enclosure as

shown in Figure 2.7.

Model name

Figure 2.7 Dimensions of Square Cut-out and Screw Holes

2-5

Mount the multi-function keypad onto the enclosure with 2 screws as shown in Figure 2.8. (Recommended

tightening torque: 0.7 N•m)

Figure 2.8 Mounting Multi-function Keypad

Remove the blind cover mounted on the inverter (see Figure 2.4) and, using a remote operation extension

cable or a LAN cable, interconnect the multi-function keypad and the inverter (insert one end of the cable

into the RS485 port with RJ-45 connector on the multi-function keypad and the other end into that on the

inverter) (See Figure 2.9.).

Figure 2.9 Connecting Multi-function Keypad to the Inverter with Remote

Operation Extension Cable or an off-the-shelf LAN Cable

Using the multi-function keypad in hand

Follow step of "Installing the multi-function keypad on the enclosure panel" above.

2-6

Chapter 3 OPERATION USING THE MULTI-FUNCTION KEYPAD

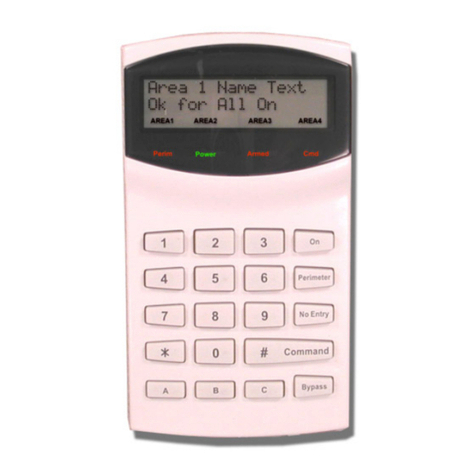

3.1 Components on the Keypad

The keypad allows you to start and stop the motor, view various data including maintenance information and

alarm information, set function codes, monitor I/O signal status, copy data, and calculate the load factor.

7-segment

LED monitor

Program key

Indicator indexes

DOWN key

Stop key

UP key Function/Data key

Run forward key

Run reverse key

Reset key

Shift key

Remote/Local

key

LED indicator

LCD monitor

3-1

Table 3.1 Overview of Keypad Functions

Item Monitors and Keys Functions

Five-digit, 7-segment LED monitor which displays the following according to the

operation modes:

In Running mode: Running status information (reference speed (final),

output current and voltage, etc.)

In Programming mode: Same as above.

In Alarm mode: Alarm code, which identifies the cause of an alarm if

the protective function is activated.

LCD monitor which displays the following according to the operation modes:

In Running mode: Running status information

In Programming mode: Menus, function codes and their data

In Alarm mode: Alarm code, which identifies the cause of an alarm if

the protective function is activated.

7-segment

LED

monitor

and LCD

monitor

In Running mode, these indexes show the unit of the number displayed on the

7-segment LED monitor and the running status information on the LCD monitor.

For details, see the next page.

Indicator indexes

Switches the operation modes of the inverter.

Shifts the cursor to the right when entering a number.

Pressing this key after removing the cause of an alarm will switch the inverter to

Running mode.

This key is used to reset settings or screen transition.

UP and DOWN keys. These keys are used to select the setting items or change

the function code data.

and

Program-

ming keys Function/Data key. This key switches the operation as follows:

In Running mode: Pressing this key switches the information to be

displayed concerning the status of the inverter

(reference speed (final), output current and voltage,

etc.).

In Programming mode: Pressing this key displays the function code and

establishes the newly entered data.

In Alarm mode: Pressing this key displays the details of the problem

indicated by the alarm code that has appeared on the

LED monitor.

Starts running the motor in the forward direction. (in local mode only).

Starts running the motor in the reverse direction. (in local mode only).

Stops the motor. (in local mode only)

Operation

keys

Holding down this key for more than 1 second toggles between Local and Remote

modes.

LED

indicator Lights while a run command is supplied to the inverter.

3-2

Items Displayed on LED Indicators

Type Symbol Information, Condition, and Status

Reference speed (final)*1and reference speed (pre-ramp) *1Hz

A Output current

V Output voltage

% Reference torque, reference torque bias, torque bias balance adjustment

value and torque bias gain adjustment value

Reference speed (final)*1, reference speed (pre-ramp) *1 and motor speedr/min

m/min Reference speed (final)*1, reference speed (pre-ramp) *1 and elevator speed

kW Input power

Unit of number

displayed on

LED monitor

X10 Data exceeding 99,999

min Not applicable

sec Not applicable

PID Torque bias balance adjustment and torque bias gain adjustment.

FWD Running in forward direction

REV Running in reverse direction

Running status

STOP Stopped state (No output or detected speed “0”)

REM Remote mode

LOC Local mode

COMM Via communication (RS485-1, CAN)

JOG Jogging mode

Run command

source

HAND Via keypad (Lights also in local mode)

*1Function code C21 provides a choice of units--r/min, m/min, and Hz.

The speed-frequency conversion formulas are given below.

P01

[Hz]

×120×

F03

L31

=[m/min]

P01

[Hz]

×120=[r/min]

3-3

3.2 Overview of Operation Modes

FRENIC-Lift features the following three operation modes:

Running mode: This mode allows you to enter run/stop commands in regular operation. You can also

monitor the running status in real time.

Programming mode: This mode allows you to set function code data and check a variety of information

relating to the inverter status and maintenance.

Alarm mode: If an alarm condition arises, the inverter automatically enters the Alarm mode. In this

mode, you can view the corresponding alarm code* and its related information on the

LED and LCD monitors.

Alarm code represents the type of alarms that have been triggered by the protection function. For details, refer to

the FRENIC-Lift Instruction Manual (INR-SI47-1038-E), Chapter 8, Section 8.5 "Protection Features."

Figure 3.1 shows the status transition of the inverter between these three operation modes.

Figure 3.1 Status Transition between Operation Modes

3-4

3.3 Running Mode

When the inverter is turned on, it automatically enters Running mode. In Running mode, you can:

[ 1 ] Run or stop the motor (in local mode only),

[ 2 ] Set the reference speed (pre-ramp) (in local mode only), and

[ 3 ] Monitor the running status (e.g., reference speed (final), output current, etc.)

3.3.1 Running/stopping the motor

In local mode, pressing the or key starts running the motor in the forward or reverse direction,

respectively. Pressing the key decelerates the motor to stop. This keypad operation is enabled only in

Running and Programming modes.

Figure 3.2 Rotational Direction of Motor

Note) The rotational direction of IEC-compliant motor is opposite to the one shown here.

Displaying the running status on the LCD monitor

When function code E45 data (LCD monitor item selection) is set to "0"

(1)

The LCD monitor displays the running status, the rotational direction, and the operation guide.

(The lower indicators show the running status and run command source. For the upper ones, see Section

3.3.3.)

Figure 3.3 Display of Running Status

The running status and the rotational direction are displayed as listed in Table 3.2.

Table 3.2 Running Status and Rotational Direction

Status/Direction Display Meaning

RUN A run command is present or the inverter is driving the motor.

Running status STOP A run command is not present and the inverter is stopped.

FWD Forward rotation being commanded.

Rotational direction REV Reverse rotation being commanded.

Blank The inverter is stopped (output shut down) or running at zero speed.

3-5

(2) When function code E45 data (LCD monitor item selection) is set to "1"

The LCD monitor displays the reference speed (final), output current, and reference torque in a bar chart.

(The lower indicators show the running status and run command source. For the upper ones, see Section

3.3.3.)

The full scale (maximum value) for each item is as follows:

Reference speed (final): Maximum speed

Output current: 200% of inverter rated current

Reference torque: 200% of motor rated torque

Figure 3.4 Bar Chart

Switching between remote and local modes

The inverter can be operated either in remote or local mode. In remote mode, which applies to normal operation,

the inverter is driven under the control of the data settings stored in the inverter, whereas in local mode, which

applies to maintenance operation, it is separated from the control system and is driven manually under the

control of the keypad.

•Remote mode: The run and speed command sources are determined by source switching signals including

function codes and communications link operation signal. The keypad cannot be used as a

command source.

•Local mode: The keypad is enabled as a run and speed command source, regardless of the settings

specified by function codes. The keypad takes precedence over a communications link

operation signal or other command sources.

Holding down the key for at least one second switches between remote and local modes. Switching to

remote mode turns on the lower indicator above the REM index, and switching to local mode, above the LOC

index.

When the mode is switched from remote to local, the reference speed (pre-ramp) specified in remote mode is

automatically inherited. Further, if the run command is ON at the time of the switching, the inverter automatically

turns on such a run command in the keypad that carries over the rotational direction.

Figure 3.5 Transition between Remote and Local Modes

In local mode, operation (such as issuing run or speed command) on the remote side is disabled. Do not switch from

remote to local mode while the motor is loaded.

Accidents or injuries may result.

3-6

3.3.2 Setting the reference speed (pre-ramp)

You can set the reference speed (pre-ramp) in frequency (Hz) with the / keys on the keypad in local

mode.

Using / keys in local mode

/

(1) Switch the keypad to Running mode. This is because in Programming or Alarm mode, the keys

are disabled to set the reference speed (pre-ramp).

(2) Press the / keys to display the reference speed (pre-ramp) on the LCD monitor with the lowermost

digit blinking.

Figure 3.6 Setting the Speed Command in Local Mode

(3) The newly specified speed is not automatically saved in the inverter, so specify the speed again if necessary

when you restart the inverter.

•When the speed monitor is selected (E43 = 0), the reference speed (pre-ramp) can be specified

with the

/ keys.

•E48 specifies the speed-monitoring formats (unit). For details about the LED monitor, refer to

Section 3.3.3.

•When you start accessing the reference speed (pre-ramp) with the / keys, the lowest digit

on the display will blink and start changing. As you are holding down the key, blinking will gradually

move to the upper digit places and the upper digits will be changeable.

•Pressing the key moves the changeable digit place (blinking) and thus allows you to change

upper digits easily.

Table 3.3 Available Speed Command Sources

Symbol Command source Symbol Command source

HAND Keypad MULTI Multistep speed command

Analog speed command

(Not reversible) Analog speed command

(Reversible)

ANALOGNR ANALOG_R

RS485-1 Via RS485 communications link LOADER Via FRENIC Loader

JOG Jogging operation CAN Via CAN communications link

3-7

This manual suits for next models

2

Table of contents

Other FE Keypad manuals

Popular Keypad manuals by other brands

Upgrading everyday security

Upgrading everyday security EL-2620 introduction

Xantech

Xantech MRC44KP installation instructions

Bosch

Bosch DS7446KP user guide

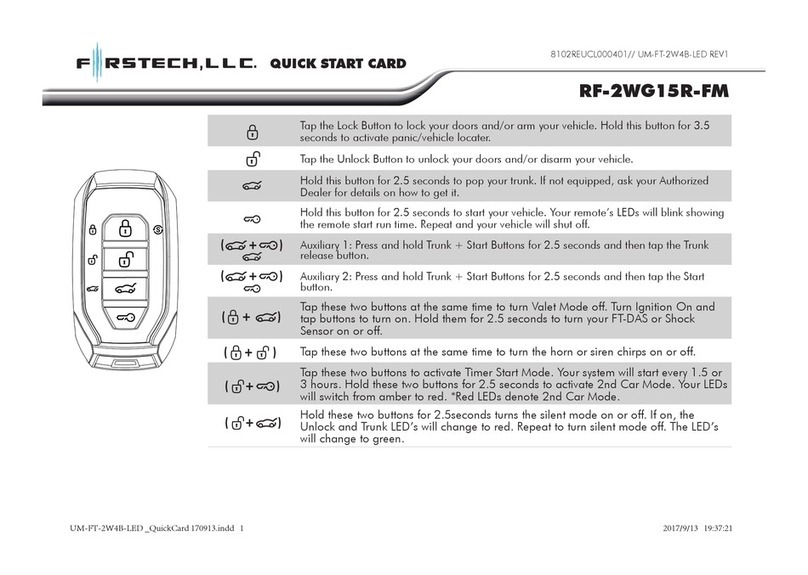

CompuSTAR

CompuSTAR RF-2WG15R-FM Quick start card

Alarm Controls Corporation

Alarm Controls Corporation KP-100 operating instructions

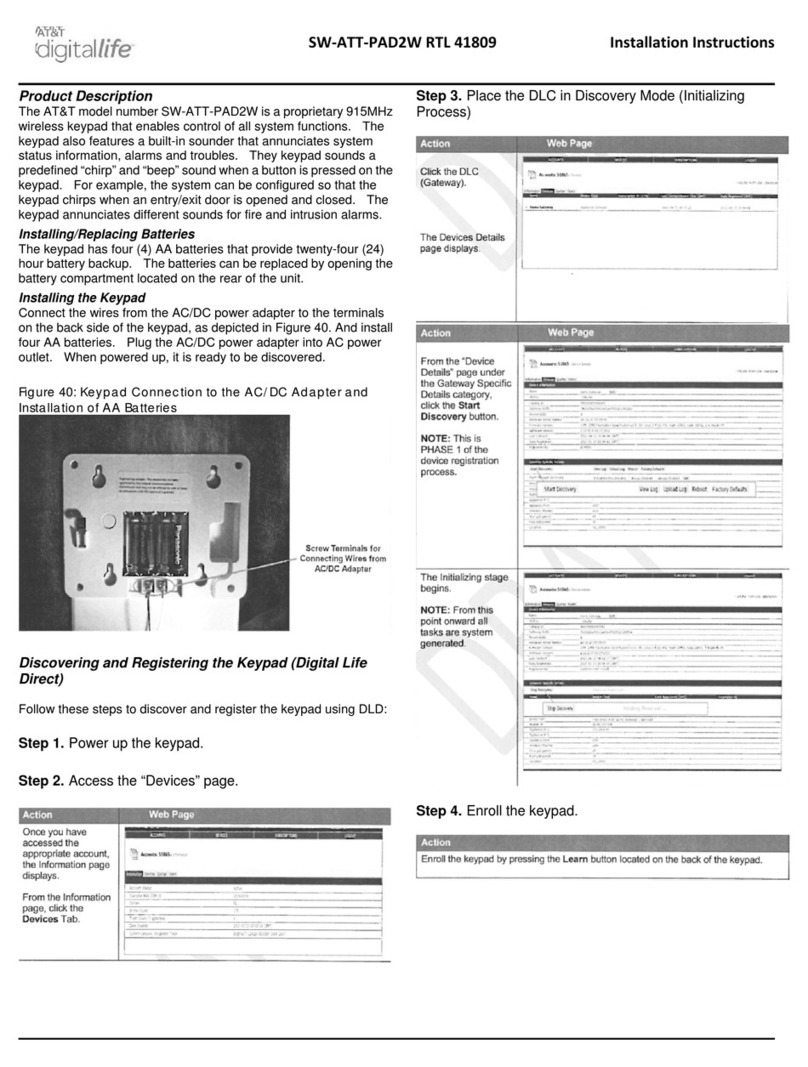

AT&T

AT&T Digital Life SW-ATT-PAD2W installation instructions