CIA-575-001 Rev 1.0

7 | P a g e

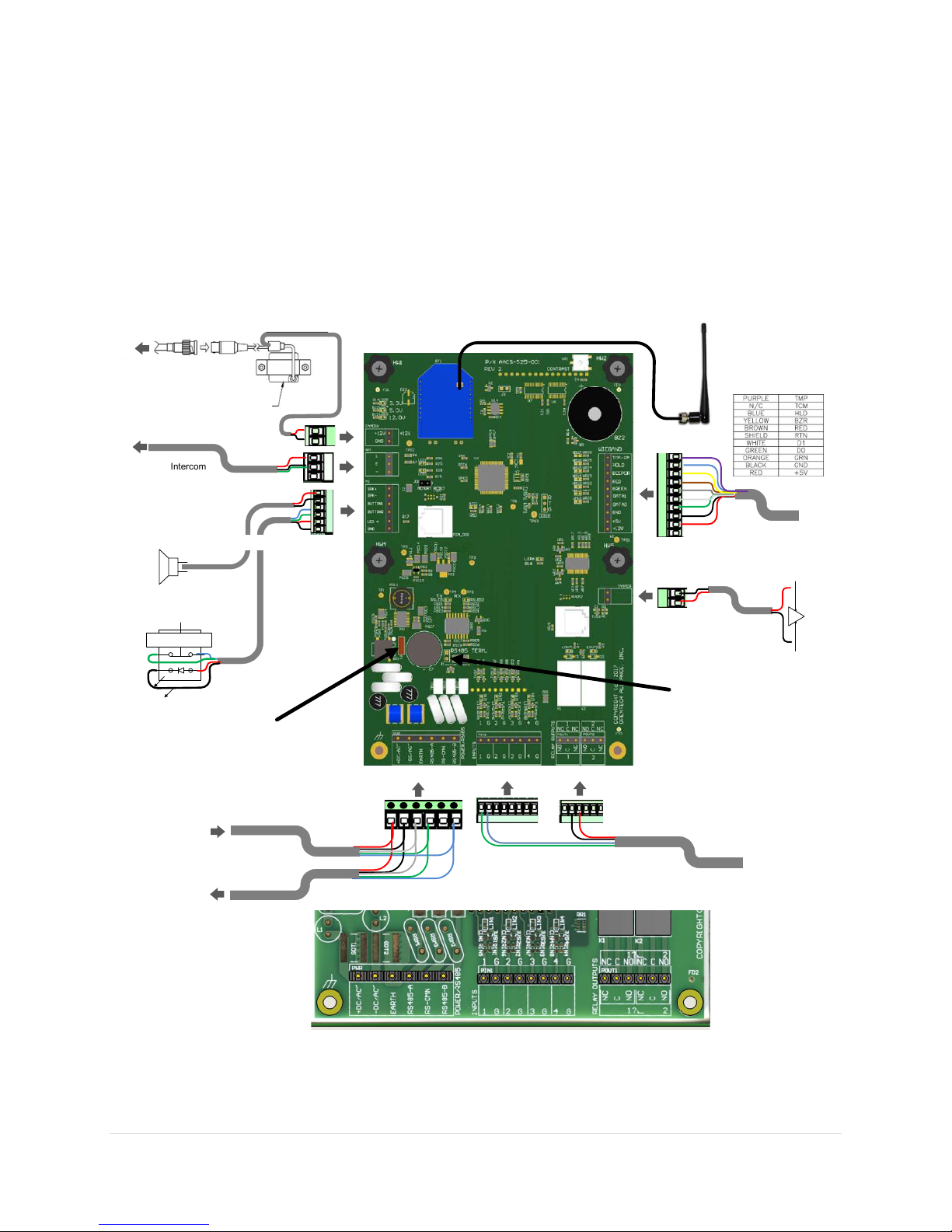

PWR/RS485: Power and RS485 data communication is done with a single connector and should be the

last connector to be attached as it may carry active power. We recommend that power and RS485 data

communications be via a single 18 AWG, 4-conductor shielded cable. The shield drain wire can be used

as the EARTH common wire. Do not connect more than two (2) RS485 cables to one PCB. All PCBs shall

be connected as an inline chain beginning with the controller and ending with the last device. The last

device shall have a “termination” jumper installed as shown in Figure 10. It is located next to the tall

capacitor as marked. All other devices shall have this jumper omitted.

These connectors have 6 pins.

DC + V (12-24VDC) ……… Required.. RED

DC – V (DC Common) …… Required.. BLK

EARTH ……………………... Recommended.. SHEILD

RS485-A ……………………. Required..

RS-CMN …………………… Optional if EARTH is connected,

RS-485-B …………………… Required

RS485 Limitations: A wired keypad can be located up to 4000 feet from the controller given proper

twisted pair cable with ground wire is used.

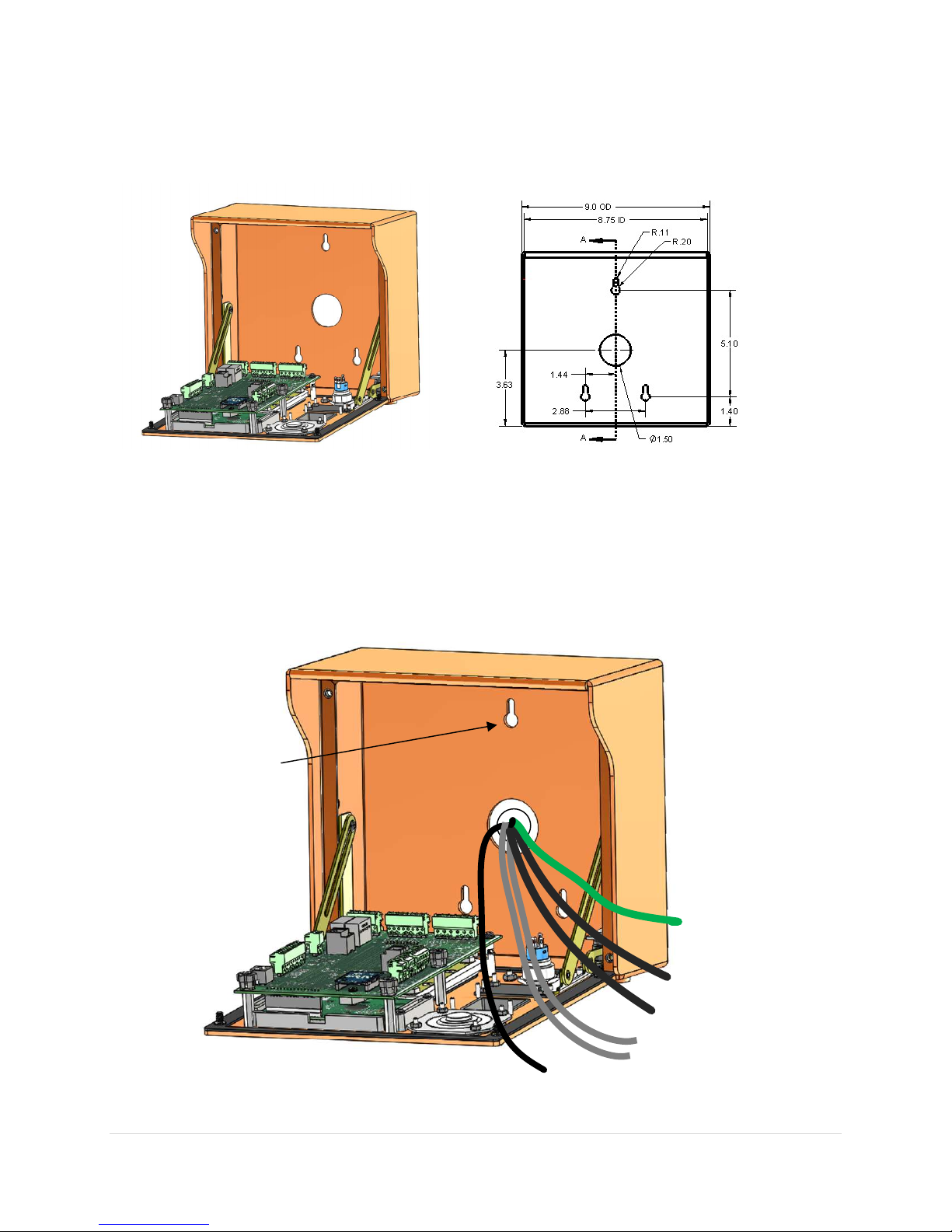

To properly terminate cables into connectors the following instructions apply.

1. Strip back the outer insulation and shield foil from both of the 18 AWG, 4-conductor, shielded cables

(coming from the controller or previous AI device in line and going out to the next AI device in line),

being careful not to cut the bare shield wire. Strip ¼ inch of insulation off the end of each of the

individual colored conductor wires.

2. Remove the terminal blocks from the keypad circuit board by sliding them up and off. The terminal

blocks may be somewhat difficult to remove as a tight electrical connection is necessary. If they are

tight, rock them slightly back and forth while lifting away from the board.

3. Insert wires into the desired connector. Where 2 wires are tied together ensure that both wires are

seated all the way inside the slot. Use a flathead precision screwdriver to tighten down the terminal

screw.

4. Verify that the terminal slot has tightened down on the copper wire and not on the rubber insulation.

There should be no copper wire showing outside of the terminal slot. Gently tug the wires to verify that

they are tightly held inside the terminal slot. Repeat this process with each of the remaining wire

connections as shown in Figure 10.

Wireless Communications (Optional): Wireless Communications (Optional): The Keypad can also

function without the RS485 wiring. In this case the XBEE or XBEE Pro 900 MHZ wireless module and an

RPSMA antenna must be installed on the system Gateway and on the Keypad to operate wirelessly. If the

keypad or relay unit is within wireless range of the Gateway the keypad will work in same fashion as with

RS485 connections. The range depends on the wireless module used, the antenna used, the RF

background level of the area (rural or urban) and the number of obstructions between devices. The XBEE

basic module range is up to 300ft unobstructed line of sight rural area. Typical obstructed range of XBEE

in urban areas is 100 ft. The XBEE Pro module range is up to 1 mile w/unobstructed rural line of sight.

500ft obstructed line of sight in urban areas is common for XBEE Pro. XBEE Pro transmitter modules are

recommended. This equipment option has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules.

This option has not been evaluated nor certified as part of UL294 level 2 nor CSA C22.2 No.205