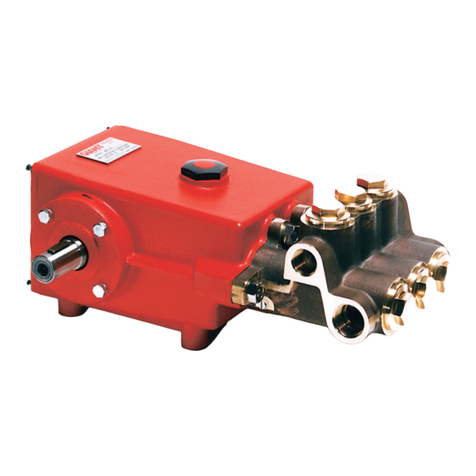

Federal Pump BGP Series Instruction manual

••••••••••••••

iIMPORTANT

READ ALL INSTRUCTIONS IN THIS MANUAL BEFORE OPERATING AND SERVING A PUMP

••••••••••••••

••••••••••••••

•••••••••••••• ••••••••••••••

••••••••••••••

INTRODUCTION

Compatible with Federal Pump’s OS, FSS, SBS,

TCS, and NPC simplex, and duplex control

system, these series can support 24/7 automatic

operation for standard pump service in

residential and commercial buildings.

Available in free standing and quick disconnect,

the product offering are also conveniently pre-

packaged in systems that provide the end user

with trouble and maintenance free operation

when designed, installed, and maintained

properly.

Sewage pumps provide for the lifting and

disposal of sewage and sewage related fluids

from retaining basins or concrete pits and are

pumped to city water disposal lines where these

fluids cannot drain under gravity conditions

alone. Typically located below grade, sewage

pumps provide building owners the ability to

design and locate restroom or other facilities

below ground that are serviced by these sewage

lift stations.

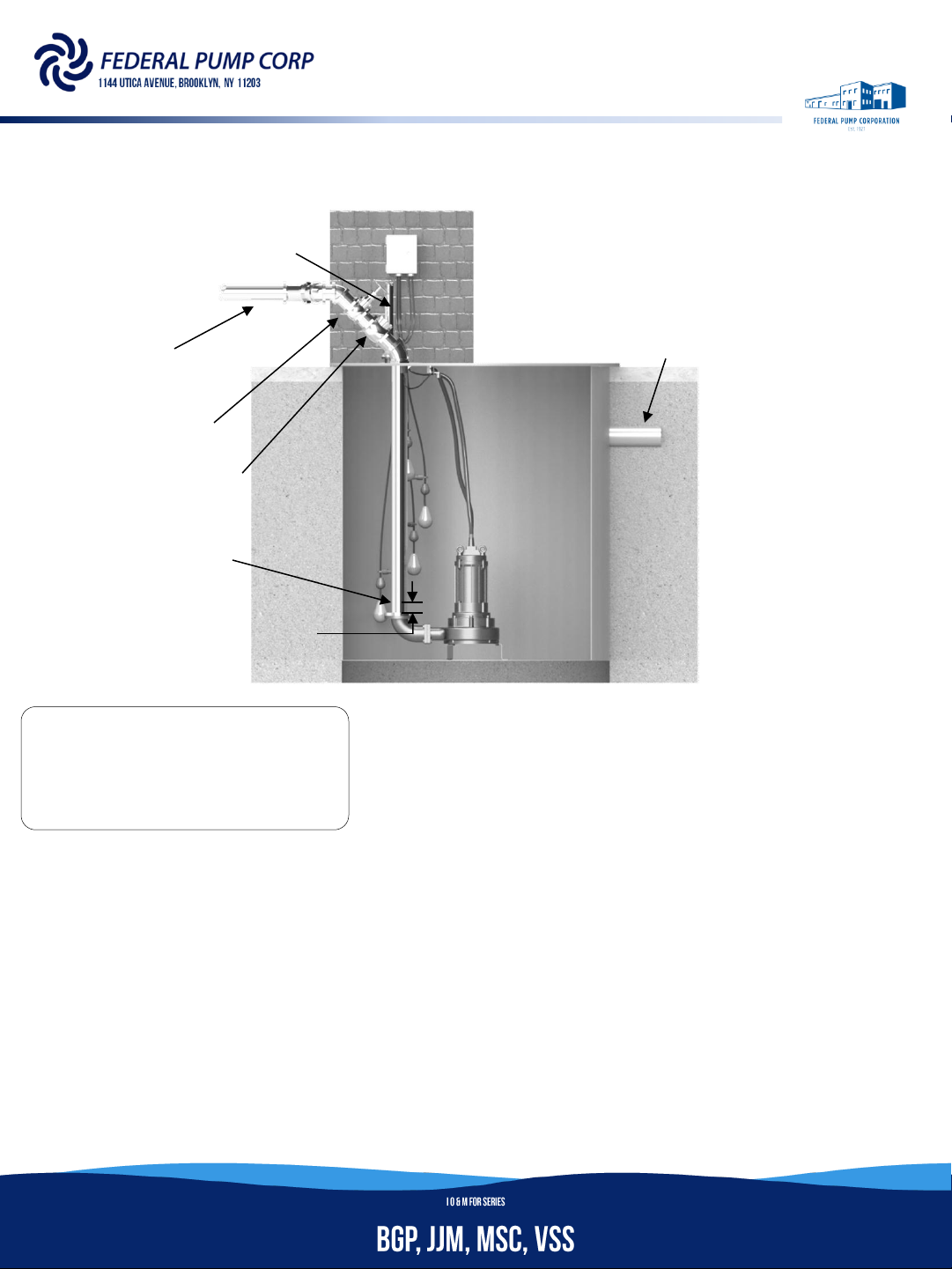

TYPICAL PRE-PACKAGED DUPLEX

SEWAGE SYSTEM SHOWN WITH

FRAME, COVER AND BASIN.

(VALVING AND NOT INCLUDED)

2

DISCHARGE

VENT

INLET

GATE VALVE

CHECK VALVE

Drill 1/8” Dia. Vent hole

to prevent air lock

6.00”

3

Before installation, read the following instructions

carefully. Failure to follow instruction and safety

information could cause serious bodily injury,

death and/or property damage. Each Federal

Pump product is carefully inspected to insure

proper performance. Closely following these

instructions will eliminate potential operating

problems, assuring years of trouble-free service.

IDANGER: "Danger" indicates an imminently

hazardous situation which, if not avoided, WILL

result in death or serious injury.

IWARNING: "Warning" indicates an imminently

hazardous situation which, if not avoided, MAY

result in death or serious injury.

ICAUTION: "Caution" indicates a potentially

hazardous situation which, if not avoided, MAY

result in minor or moderate injury.

IMPORTANT!!! –Federal Pump is not responsible

for losses, injury or death resulting from failure to

observe these safety precautions, misuse, abuse

or misapplication of the pump(s) or equipment.

ALL RETURNED PRODUCTS MUST BE

CLEANED, SANITIZED, OR

DECONTAMINATED PRIOR TO SHIPMENT, TO

INSURE EMPLOYEES WILL NOT BE EXPOSED TO

HEALTH HAZARDS IN HANDLING SAID MATIERAL.

ALL APPLICABLE LAWS AND REGULATIONS SHALL

APPLY.

IWARNING: Installation, wiring, and junction

connections must be in accordance with the

National Electric Code and all applicable state and

local codes. Requirements may vary depending on

usage and location.

IWARNING: Installation and servicing is to be

conducted by qualified personnel only.

Keep clear of suction and discharge

openings. Do not insert fingers in pump

suction with power connected; the rotating cutter

and /or impeller can cause serious injury.

Always wear eye protection when working

on pumps. Do not wear loose clothing that

may become entangled in moving parts.

IDANGER: Pump build up heat

and pressure during operation.

Allow time for pumps to cool before handling or

servicing the pump or any accessory items

associated with or near the pump.

This pump is not intended for use in

swimming pools or water installations

where there is human contact with pumped fluid.

There is a risk of electric shock. To reduce risk of

electric shock, always disconnect pump from

power source before handling any aspect of the

pumping system. LOCK OUT POWER AND TAG.

GENERAL SAFETY INFORMATION

U

`

`

ab

H

••••••••••••••

4

IWARNING: Do not use this pump in water over

104˚F. Do not exceed manufacturer’s

recommended maximum performance, as this

could cause the motor to overheat.

IDANGER: Do not lift, carry or hang pump by the

electrical cables. Damage to the electrical cables

can cause shock, burns, or death. Never handle

connected power cords with wet hands. Use

appropriate lifting device.

IWARNING: Ground Fault Circuit Interrupter

(GFCI) to be used with plug-in type power cord.

IWARNING: Sump and sewage pumps often

handle materials which could cause illness or

disease. Wear adequate protective clothing when

working on a used pump or piping. Never enter a

basin after it has been used.

IDANGER: Failure to permanently ground the

pump, motor and controls before connecting to

power can cause shock, burns, or death.

IDANGER: These pumps are not to be installed

in locations classified as hazardous in accordance

with the National Electric Code, ANSI/NFPA 70.

IWARNING: The Uniform Plumbing Code (UPC)

states that sewage systems shall have an audio

and visual alarm that signals a malfunction of the

systems, that are required to reduce the potential

for property damage.

IMPORTANT!!! –Prior to installation, record

Performance(GPM,TDH), Model Number, Record

Number, Full Load Amp, Voltage, Phase, and HP

from the pump name plate for future reference.

Also record the site voltage and current readings

at equipment startup. Use the table below for

record keeping. Refer to the pump series for

performance data and dimension. The series can

be found as the first group of letters in the “Model

Number”. Contact the factory or local

representative with Record Number for assistance

if needed.

NAME PLATE

GPM: TDH:

Model Number:

Record Number:

Full Load Amp:

Voltage: Phase: HP:

□Oil Fill Motor Design

□Air Fill Motor Design

STARTUP

Voltage:

Amp Draw:

1 Phase L-N:

3 Phase L 1-2:

L 2-3:

L 3-1:

GENERAL SAFETY INFORMATION

••••••••••••••

5

RECOMMENDATIONS

RECEIVING: Immediately upon receipt of the

shipment, inspect and check with the packing list

and report to the transportation company’s local

agent of any damage or shortage. Inspect carton

and wrappings before discarding. Parts and

accessories may sometimes be wrapped

individually and packed in the carton. Should you

find the plastic wrapping removed or damaged

upon the arrival of the equipment, note the

incident on the carrier’s Bill of Lading.

STORAGE: The plastic wrapping is not meant as

mean to protect the equipment from the

environment during storage. If the pump is

received sometime in advance of when it can be

put into use, it should be inspected, rewrapped or

re-boxed and stored in a dry location. If the pump

is to be stored for a long period of time, rotate the

pump shaft periodically to protect the bearings.

Units should not be stored where temperatures

will be below 20˚F or above 100˚F.

CONTROLS: 3 Phase, pump only, and non-115Volt

pump models require a separate approved pump

control device or panel for automatic operation.

Be sure that the electrical specification of the

control selected properly match the electrical

specifications of the pump.

SUBMERGENCE: The pump should always be

operated in the submerged condition. The

minimum liquid level should never be less than

above the pump’s volute. The recommended

liquid level would be the height of the pump to

assist with motor cooling.

VENT HOLE: The discharge piping of the pump

should always be drilled with a vent hole(⅛”Ø) at

a height of 6”above the pump discharge to

prevent air locking.

••••••••••••••

6

INSTALLATION

IWARNING: Under no circumstances should

power or sensing cable be pulled while the pump

is being transported or installed. Attach a chain or

rope to the grip or lugging bolt to install the

pump. (certain models of pump will be provided

with stainless steel lift cable)

1. This pump must not be installed on its side or

operated in a dry condition. Ensure that it is

installed upright on a secure base.

2. Install the pump at a location in the tank

where there is the least turbulence.

3. If there is a flow of liquid inside the tank,

support the piping where appropriate. Install

piping so that air will not be entrapped. If

piping must be installed in such a way that

air pockets are unavoidable, install an air

release valve wherever such air pockets are

most likely to develop.

INSTALLATION: These pumps are recommended

for use in a concrete pit or basin. The basin or lift

station shall be sealed and vented in accordance

with local plumbing codes. This pump is designed

to pump grey water, non-explosive and non-

corrosive liquids, and shall NOT be installed in

locations classified as hazardous in accordance

with the National Electrical Code (NEC)

ANSI/NFPA 70 or Canadian Electric Code (CEC).

The minimum depth should be at least 42”. Check

the pump catalog for minimum basin diameter.

These are the minimum requirements. The pump

should never be installed in a trench, ditch, or

hole with a dirt bottom. The legs will into the dirt

and the suction will become plugged.

1. EXCAVATION: Excavate the hole large enough

to accommodate basin, back fill material, &

adequate working space. A minimum of 8”

diametrical clearance around the tank is

recommended. Never place basin directly in

contact with rocks or other sharp objects.

Prepare the bottom of the excavated hole

with at least 6”of back fill material or

concrete pad. Place only fine ⅛” to ¾” pea

gravel or ⅛” to ½” washed, crushed stone as

back fill material. Do not use sand or native

soil as backfill. Properly compact underneath

the basin to provide a solid level base that can

support the weight of the filled basin. Check

base to insure it is level. Anchor if necessary.

2. INLET CONNECTION & INITIAL BACKFILL: Only

fine pea gravel or washed, crushed stone

should be used around the bottom of the

basin to hold it in place. Concrete may be

poured around basin bottom if ballast is

required for buoyancy. Do not use sand or

native soil as backfill. Make the inlet

connection as required for your basin. Do not

install more than 1 inlet connection per basin.

3. FINAL BACKFILL: Fill basin with water before

backfilling. Only fine pea gravel or washed,

crushed stone is recommended. Do not use

sand or native soil as backfill. Back fill to 4”to

6”around the entire periphery of the basin.

Compact back fill material in 12”lifts.

ICAUTION: If burial depth is greater than basin

height, consult factory representative to assure

structural integrity is not compromised.

Reinforcement may be required

ICAUTION: In freezing conditions, back fill

material must be dry and free of ice.

••••••••••••••

7

INSTALLATION

DISCHARGE PIPING: Discharge piping should be as

short as possible and sized no smaller than the

pump’s discharge size. Do not reduce the

discharge pipe size below that which is provided

on the pump. Both check valves and a shut-off

valve are recommended for each pump. The

check valve is used to prevent backflow into the

pit. If a swing check valve is used, it is

recommended to be installed at a 45°agree with

the pivot pin on top. The shut-off valve is used to

manually stop system flow during pump testing

and servicing.

ELECTRICAL CONNECTIONS:

1. POWER CABLE: The power cable mounted to

the pump must not be modified in any way

except for shortening or splicing to a specific

applications. 1 Phase pumps are provided with

a 3 wire power cord, and 3 Phase pumps are

provided with a 4 wire power cord. Connect

the green wire to ground. Under no

circumstances should the green wire be

connected to the power supply. Every pump

must be grounded. DO NOT USE THE POWER

CABLE TO LIFE PUMP. Do not use an

extension cord for 1 Phase pump(s). Always

wire the pump as indicated on the wiring

diagram inside the control panel

2. OVERLOAD PROTECTION: On submersible

motors, an in-panel overload protector is

needed to act as an overheating protector and

operates on the combined effect of

temperature and current. This means that the

overload protector will trip out and shut the

pump off if the windings become too hot, or

the load current passing through them

becomes too high. (IMPORTANT!!! –The

overload in the panel should NOT

automatically reset and start the pump up

after the motor cools.) In the event of an

overload, the source of this condition should

be determined and corrected immediately.

IWARNING: Never let the end of the cable

contact water

IWARNING: If the cable is extended, do not

immerse the splice in water

ICAUTION: Fasten the cable to the discharge

piping with zip tie

ICAUTION: Install the power cable so that it will

not overheat. Overheating is typically caused by

coiling the cable and exposing it to direct sunlight.

IMPORTANT!!! Always rely on a Certified

Electrician for installation

••••••••••••••

8

INSTALLATION

LIQUID LEVEL CONTROL (1Ph/230V & 3Ph):

Refer to the figure 1 which shows a typical

installation of (2) 1 phase 230 volt and 3 Phase

pump at all voltage using (3) level control switches

(SW1, SW2, SW3) and (1) high water alarm switch

(SW4) mounted to the style 1 pilot device with a

duplex control panel. The level control and high

water alarm float should have adequate clearance

so they cannot hang up in their swing and that the

pump is completely submerged when the level

controls are in the “OFF” mode. By adjusting the

cord tether the control levels can be changed.

Figure 1

••••••••••••••

9

OPERATION

PRE-OPERATION: After completing installation,

perform the following prior to contacting Federal

Pump’s local representative for equipment start

up:

1. CHECK VOLTAGE AND PHASE: Compare the

voltage and phase information stamped on

the pump name plate.

2. CHECK PUMP ROTATION: Improper motor

rotation can result in poor pump performance

and can damage the motor and/or pump.

Incorrect rotation for 1Phase pumps is

unlikely. If the rotation is incorrect contact

factory.

3. NAME PLATE: Record the information from

the pump name plate for future reference.

4. INSULTATION TEST: An insulation (megger)

test should be performance on the motor

before the pump is put into service. The

resistance values, voltage, and current should

be recorded.

5. PUMP-DOWN TEST: Be sure pump has been

properly wired, lowered into the basin or lift

station. Check the system by filling the pit with

liquid and allowing the pump to operate

through its pumping cycle if control system is

ready. Otherwise, test the pump on “HAND”

or manual position (make sure the liquid level

does not get pump below the top of the pump

volute. The time needed to empty the system

(pump-down time) along with the volume of

water, should be recorded. Pump are typically

designed to operate up to 20 cycles an hour.

SEQUENCE OF OPERATION: For Federal Pump’s

Since Federal Pump offers a multitude of liquid

level controls, please refer to their (OS, FSS, SBS,

TCS, NPC) corresponding IOM manual for

sequence of operation

••••••••••••••

10

OPERATION

TROUBSHOOTING CHART: Always disconnect the pump from the power source before handling

inspections or repairs .

HCAUTION: Risk of electric shock

`DANGER: Keep clear of suction and discharge openings. Do not insert fingers in pump with power

connected; the rotating cutter and /or impeller can cause serious injury.

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Pump will not run

1.

Poor electrical connection, blown fuse(s), tripped

breaker or other interruption of power; improper

power supply

2.

Motor or switch inoperative (go to manual

operation)

2a.

Float movement restricted

2b.

Switch will not activate pump or is defective

2c.

Defective or damaged motor

3.

Insufficient liquid level

16.

Liquid temperature exceeding pump operation

range

1.

Check all electrical connections for security. Have electrician measure current in

motor leads, if current is within ±20% of locked rotor Amps, impeller is probably

locked. If current is 0, overload may be tripped on a single phase pump. Remove

power, allow pump to cool, then re-check current

2a.

Reposition pump or clean basin as required to provide adequate clearance for float

2b.

Disconnect level control. Set ohmmeter for low range, such as 100 ohms full scale

and connect to level control leads. Actuate level control manually and check to see

that ohmmeter shows zero ohms for closed switch, and full scale for open switch.

2c.

Check winding insulation and winding resistance. If check is outside of range, dry and

re-check. If still defective, replace per maintenance instruction for the pump series.

3.

Mark sure liquid level is above the pump

4. Re

-check all sizing calculations to determine proper pump sizing

5. Check discharge line for restrictions, including ice if line passes through or into cold

areas.

6.

Remove and examine check valve for proper installation and freedom of operation

7. Open valve

8. Check impeller for free of operation, security and condition. Clean impeller cavity

and inlet of any obstruction

9.

Loosen flange or union slightly to allow trapped air to escape at the discharge piping

slowing while the pump is on “HAND”. Clean vent hole

10.

Check rotation. If power supply is three phase, reverse any (2) of (3) power supply

leads on the motor end of the starter or VFD to ensure proper impeller rotation

11.

Repair fixtures as required to eliminate leakage

12.

Check pump temperature limits and fluid temperature

13.

Replace portion of discharge pipe with flexible connector or tighten existing piping

14.

Turn to automatic position

15.

Check for leaks around basin inlet and outlets

16.

Check temperature of the liquid inside the pit. Quench the basin with a hose to 70˚F,

and let it cool down before turning the pump on. Add a dedicated quench line to the

system to keep the pump from overheating

Pump

will not turn off

2a.

Float movement restricted

2b.

Switch will not activate pump or is defective

4.

Excessive inflow or pump not properly sized for

application

9.

Pump may be air locked causing pump not to flow

14.

H-O-A switch on panel is in “HAND” position

Pump hums but doesn’t run

1.

Incorrect low voltage

8.

Impeller jammed or loose on shaft, or inlet plugged

Pump delivers

insufficient capacity

1.

Incorrect low voltage

4.

Excessive inflow or pump not properly sized for

application

5.

Discharge restricted

6.

Check valve partially closed or installed backwards

7.

Shut-off valve closed

8. Impeller jammed or loose on shaft, or inlet plugged

9.

Pump may be air locked causing pump not to flow

10.

Piping fixtures leaking or discharge before the

nozzle

Pump cycles too frequently or runs

periodically when fixtures are not in use

6.

Check valve partially closed or installed backwards

11.

Fixtures are leaking

15. Ground water entering basin

Pump shuts off and

turns on

independent of switch, (trips thermal

overload protector). CAUTION! Pump

may start unexpectedly. Disconnect

power supply.

1.

Incorrect low voltage

4.

Excessive inflow or pump not properly sized for

application

8. Impeller jammed or loose on shaft, or inlet plugged

12. Excessive water temperature (internal protection

only)

Pump operates noisily or vibrates

excessively

2c.

Worn bearings, motor shaft bent

5.

Debris in impeller cavity or broken impeller

10.

Pump running backwards

13.

Piping attachments to building structure too loose

or rigid.

NOTE: Federal Pump assumes no responsibility for damage or injury due to disassembly in the field. Disassembly of the pumps or supplied accessories other than at Federal Pump or its

authorized service centers, automatically void warranty on the equipment

••••••••••••••

11

MAINTENANCE

INSPECTION: Schedule to check pressure, output,

voltage, current, and other specifications on a bi-

annual basis. If unusual readings are found, and

correct as soon as possible.

1. DAILY INSPECTIONS: Check current daily. If the

amp draw fluctuation is great, even though its

within the limits of pump rating, foreign

objects may be clogging the pump. If the

amount of liquid discharged falls suddenly,

said objects may block the suction inlet.

2. MONTHLY INSPECTIONS: Measure the

insulation resistance. The value should be

more than 1M ohm. If resistance starts to fall

rapidly even with an initial indication of over

1M ohm, this may be an indication of damage

or defect and repair work would be required.

3. ANNUAL INSPECTIONS: To extend the service

life of the mechanical seal, replace the oil in

the mechanical seal chamber (for applicable

SERIES) once a year. Water mixed with the oil

or cloudy textures are indications of a

defective mechanical seal requiring

replacement. When replacing the oil, lay the

pump on its side with filler plug on top. Inject

suitable amount of oil. Not every pump has an

oil chamber. Refer to sectional view for

details.

4. 3-5 YEAR INSPECTIONS: Conduct an overhaul

on the pump. These intervals will preclude the

possibility of future trouble.

5. COOLING OIL INSPECTION: Anytime the pump

removed from operation, the cooling oil in the

motor housing should be checked visually for

oil level and contamination. To check oil, set

unit upright, remove pipe plug from housing,

and inspect the oil in the housing to make

sure it is clean and clear (light amber in color

and free from suspended particles). Milky

white oil indicates the presence of water. Oil

level should be just above the motor when

pump is in vertical position.

SERVICE: No periodic lubrication is required.

Perform the following checks every time a pump

is removed from operation or when pump

performance deteriorates:

1. Inspect motor chamber for oil level and

contamination

2. Inspect impeller and body for excessive build-

up of clogging

3. Inspect motor, bearings, and shaft seal for

wear or leakage

OIL TESTING: Test the cooling oil using the

following steps

1. Drain oil into a clean, dry container by placing

pump on its side, and removing pipe plug from

housing.

2. Check oil for contamination using an oil tester

with a range to 30kV breakdown.

3. If oil is found to be clean and uncontaminated

(measuring above 15kV), refill the housing

with the same oil

4. If oil is found to be contaminated (measuring

15kV or below), the pump must be carefully

inspected for leaks at the shaft seal, cable

assembly, gaskets, and pipe plug. To help

locate the leak(s), perform a “soap bubble”

leak test

5. After leak is repaired, dispose of old oil

properly, and refill with new oil.

••••••••••••••

12

MAINTENANCE

PRESSURE TEST (IF OIL HAS BEEN DRAINED):

Remove pipe plug from housing. Apply pipe

sealant to pressure gauge assembly and tighten

into hole. Pressure motor housing to 10 PSI. Use

solution around the sealed areas and inspect

joints for air bubbles

If, after five minutes, the pressure is still holding

contact, and no bubbles are observed, slowly

bleed the pressure and remove the gauge

assembly, and replace oil. All leak(s) must be

located and repaired if pressure does not hold.

PRESSURE TEST (IF OIL HAS NOT BEEN DRAINED):

Oil should be at normal level. Remove pipe plug

from housing. Apply pipe sealant to pressure

gauge assembly and tighten into hold. Pressurize

motor housing to 10 PSI. Use soap solution

around the sealed areas above the oil level and

inspect joints for air bubbles. For sealed areas

below oil level, leaks will seep oil. If, after five

minutes, the pressure is still holding constant, and

no bubbles, oil seepages is observed, slowly bleed

the pressure and remove the gauge assembly, and

replace oil. All leak(s) must be located and

repaired if pressure does not hold.

PRESSURE TEST (AIR FILL MOTOR)

Remove pipe plug from housing. Apply pipe

sealant to pressure gauge assembly and tighten

into hold. Pressurize housing to 10 PSI. Use soap

solution around the sealed areas to inspect joins

for air bubbles. If, after five minutes, the pressure

is still holding constant, and no bubbles, slowly

bleed the pressure and remove the gauge

assembly, and replace pipe plug. All leak(s) must

be located and repaired if pressure does not hold.

ICAUTION: Pressure builds up extremely quickly

due to the limited space inside the pump housing.

Too much pressure will damage mechanical seal.

DO NOT exceed 10 PSI

OIL REPLACEMENT: Set unit upright and refill with

new cooling oil as per table below. Fill to just

above motor, but below capacitor(1Phase motor)

as an air must remain in the top of the housing to

compensate for oil’s thermal expansion. Apply

pipe thread compound to threads of pipe plug

then assemble it to housing.

DANGER: DO NOT overfill oil.

Overfilling of housing with oil will

create excessive and dangerous hydraulic pressure

which can destroy the pump and create a hazard.

Overfilling oil voids equipment warranty

ib

Cooling Oil

Recommended Supplier/Grade

BP Enerpar SE100

Conoco Pale Parafin 22

Mobile D.T.E Oil Light

Shell Transformer-10

Texaco Diala-Oil-AX

••••••••••••••

13

MAINTENANCE

DISASSEMBLY: When disassembling pump, have a

piece of cardboard or wooden board ready to

place the different parts on as you work. Do not

pile parts on top of each other. They should be

laid out neatly in rows. The O-ring and gasket

cannot be reused once they are removed. Have

replacement parts ready prior to disassembly.

Disassemble in the order shown below, while

referring to the sectional view in the equipment

catalog. Always disconnect power prior to

dissembling the pump.

1. IMPELLER & VOLUTE:

a) Remove cap screws, volute and gasket.

b) Clean and examine impeller for cracks

or chips, and replace if required. To

remove impeller, place a flathead

screwdriver in the slot at the end of

the shaft to hold the shaft stationary

while unscrewing.

c) Where applicable, check v-ring and

remove if damaged.

2. POWER CORD & MOTOR:

a) Place pump upright on blocks to avoid

resting unit on shaft.

b) Remove pipe plug and drain oil from

housing.

c) Remove gland nut and washer from

the motor housing, and slide power

cord up along with washers and

grommet.

d) Pull cord through and disconnect the

wires from the terminals on power

cord. Be sure to note wire connections

for reassembly.

e) Disconnect cable leads from motor

leads and remove motor housing and

O-ring. Always replace O-ring and

gasket once removed.

f) For single phase motors, check motor

capacitor with an Ohmmeter by first

grounding the capacitor by placing a

screwdriver across both terminals. If

the Ohmmeter reading moves to

infinity then drifts back, the capacitor

is in working condition. Otherwise,

replace the capacitor.

g) Inspect motor winding for shorts, and

check resistance valves. Check rotor for

wear and damages. If rotor or the

stator windings are defective or

damaged, the complete motor must be

replaced.

3. MECHANICAL SEAL:

a) Where applicable, remove seal plate.

b) Carefully remove mechanical seal

without scratching sliding surface

c) Inspect for signs of uneven wear

pattern on stationary members, chips

and scratches on either seal faces.

Replace the complete seal if any part is

damaged. DO NOT interchange seal

components. Replace the entire shaft

seal.

4. BEARING:

a) Examine bearing and replace if worn.

Remove bearing from shaft using a

wheel puller, if replacement is

required.

••••••••••••••

14

MAINTENANCE

ASSEMBLY: All parts must be clean before

reassembly. Handle seal parts with extreme care.

DO NOT damage lapped surfaces. Reassemble in

reverse order of disassembly. Be careful of the

following:

1. During reassembly, periodically. rotate the

impeller by hand and check for smooth

rotation. If rotation is not smooth, check for

alignments in the bearing, and scratches on

the seal faces.

2. Upon completion of reassembly, rotate the

impeller by hand from the pump suction, and

check that it rotates smoothly without

touching the suction plate before operating

the pump.

O-rings, shaft seals, gaskets, and other pump

components are available as kits from the factory

and representatives.

••••••••••••••

15

NOTES

••••••••••••••

Federal Pump Corporation

Factory Warranty

Equipment or parts manufactured by Federal Pump Corporation (“Seller”) which fail to function

properly because of defects in material or workmanship and which are returned to Seller with

shipping charges prepaid, within one year from date of shipment (invoice date) will be repaired

or replaced by Seller, FOB the factory, at Seller’s expense. Equipment or parts furnished by

Seller, but manufactured by others (such as motors, switches, control panels, etc.) are the

responsibility of the manufacturer under its warranty, if any, and Buyer’s sole recourse will be

to such manufacturer. If Seller determines that the failure to function properly (of equipment

or parts returned) is not due to defective material or workmanship but rather to misapplication

or mishandling after receipt by Buyer, Seller will repair or replace the equipment or parts upon

Buyer’s authorization, and bill Buyer for material and labor required for the repair or

replacement. The forgoing sets forth Seller’s only warranty with respect to, and Seller’s entire

liability, for any claim or damages whatsoever arising out of the supplying of the equipment

hereunder or its use. The foregoing warranty is made by Seller and accepted by the person to

whom Seller’s applicable invoice is directed (“Buyer”) in lieu of all other warranties, express or

implied, of Seller and in lieu of all other obligations or liabilities of Seller. No other

representation or warranty on the part of seller, express or implied, shall apply to the

equipment supplied hereunder or referred to herein, or to its performance, all such other

warranties (including any warranty of merchantability or fitness for any purpose) being hereby

disclaimed. In no event will Seller be responsible for loss of business or profits or any other

similar or dissimilar consequential or incidental damages or losses. If warranty repairs or

replacements of parts are to be accomplished locally in lieu at Seller’s factory, they must be

agreed to in writing, by Seller in advance of the work being done, and with the exact cost of the

work stated in a letter of authorization from Seller. No expenses incurred will be paid by Seller

unless so agreed to in advance. Seller’s standard warranty extends for twelve months from

date of shipment. If the standard warranty is to be extended to eighteen months from date of

shipment, add 6% to the purchase price of the equipment. If the standard warranty is to be

extended to twenty-four months from the date of shipment, add 12% to the purchase price of

the equipment. If the standard warranty is to be extended to thirty months from date of

shipment, add 18% to the purchase price of the equipment. If the standard warranty is to be

extended to thirty-six months from date of shipment, add 24% to the purchase price of the

equipment. Extended warranties are effective only if the equipment is properly stored and

adequately protected from weather, excessive condensation, atmospheric conditions and

physical damage, and only if the equipment has been properly installed and not misused or

mishandled.

If you have a claim under the provision of the warranty, contact Federal

Pump Corporation or your local authorized representative.

This manual suits for next models

7

Table of contents

Popular Water Pump manuals by other brands

Giant

Giant MP Series Operating instructions/ repair and service manual

Burks

Burks BPV Series Installation and operation manual

BOC Edwards

BOC Edwards STP-A2203 Series instruction manual

Agilent Technologies

Agilent Technologies TPS-mobile 9698400 user manual

Warren rupp

Warren rupp WR10 operating instructions

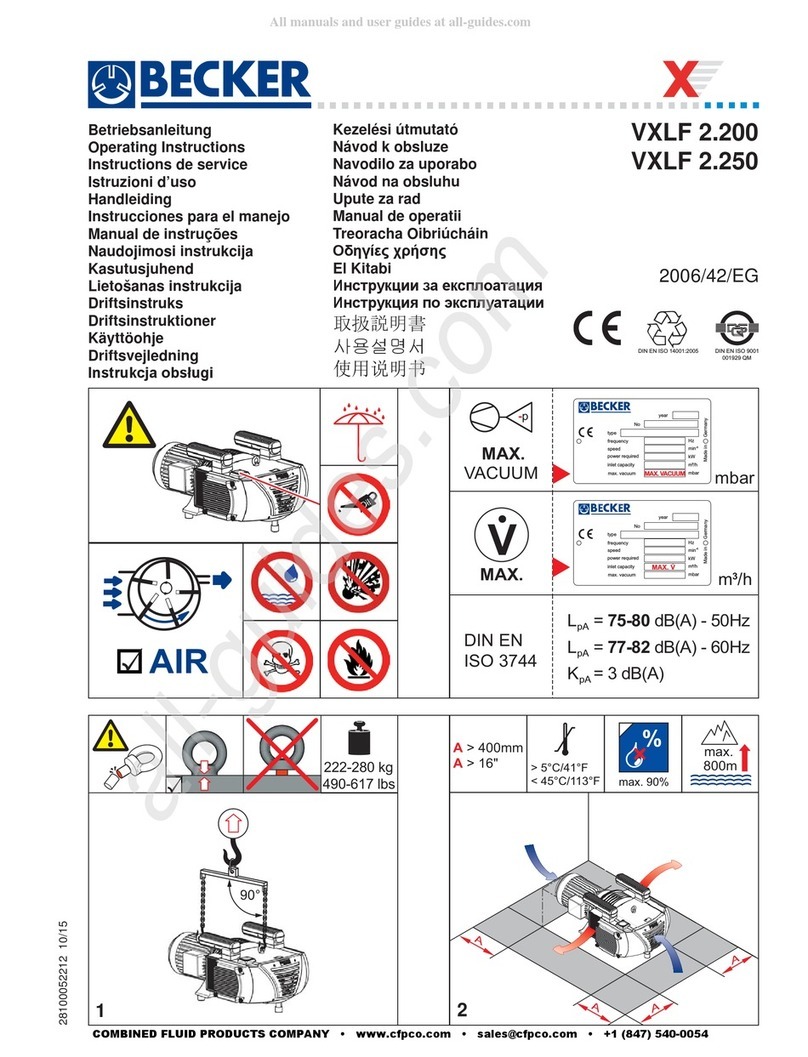

Becker

Becker VXLF 2.200 operating instructions