mounted dome down, condensation may occur in the conduit system. Use properly rated conduit

seals/drainstopreventmoisturefromenteringthexture.Threadthextureontothe3/4"pipe

and secure with the set screw.

Thedomeguard(Part#K8449090)maybeusedasanaccessory.Itismountedonthe154XST

usingthetwosupplied#8-32screws.Adjustthetensiononthescrewsuntilthedomeguardis

squarewiththehousing.

C. Electrical Connections.

WARNING

This is a four-wire device, and when installed, all four wires must be terminated. Failure to terminate

bothredandbothblackwireswillresultinashockorrehazard.

The 154XST unit is provided with four leads; two red, and two black. To achieve electrical

supervision, connect one red (+) lead to the positive side of the incoming power source and the

other red (+) lead to the outgoing power source. Likewise, connect one black (–) lead to the

negative side of the incoming power source, and the other black (–) lead to the negative side of

the outgoing power source.

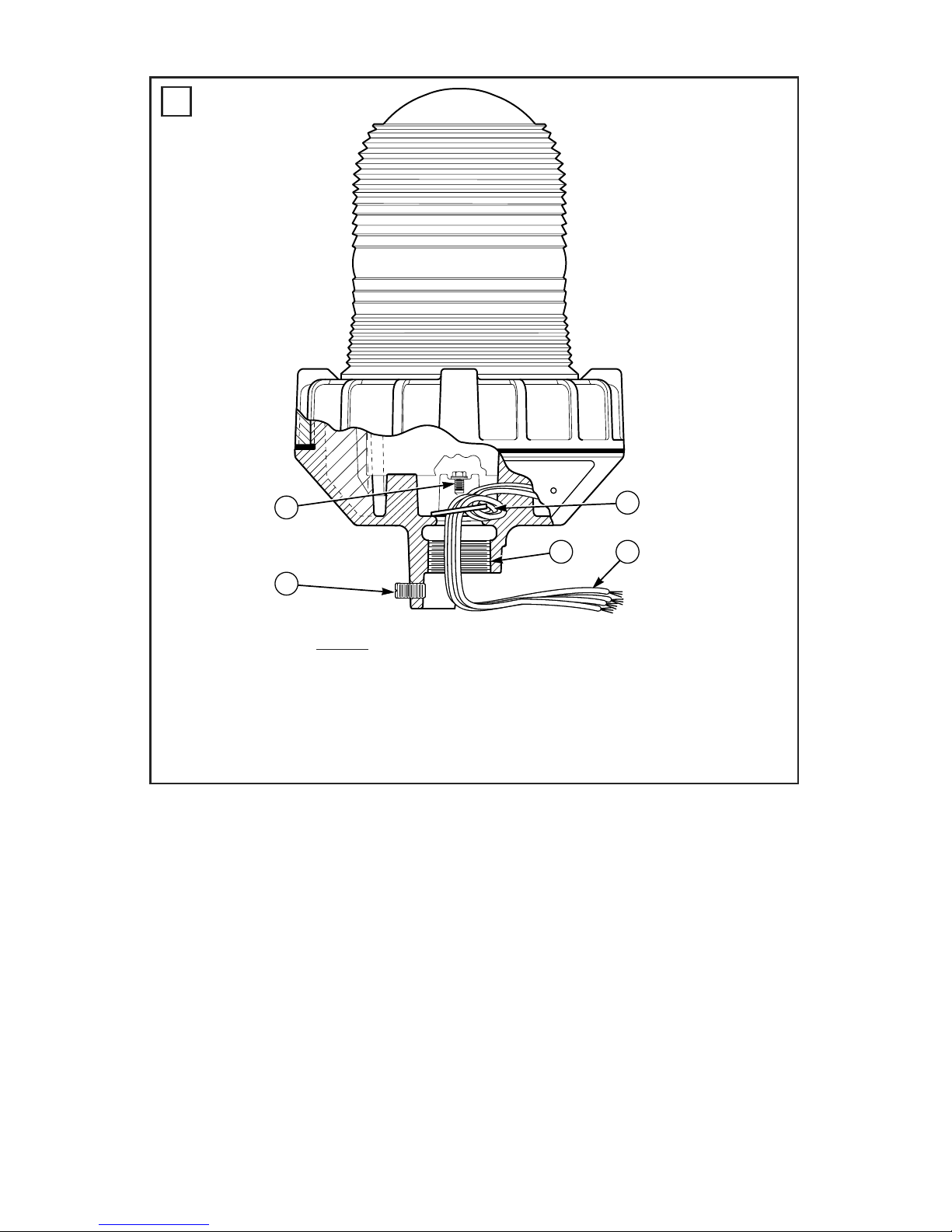

Ifrequired,thegreenscrewinthehousingisprovidedforconnectiontoanearthground(see

gure1).Togainaccesstothescrew,thepowersupplyassemblycanberemoved.Globe

removalisdescribedinparagraphIII.A.1.

NOTE

This unit is polarity sensitive, and may be damaged by incorrect electrical hookup. Polarity must be

observedforproperoperation.Inaddition,damagewillresultifthevoltageratingisexceeded.

III. MAINTENANCE.

WARNING

Topreventignitionofhazardousatmospheres,disconnectthexturefromthesupplycircuit

before opening. Keep tightly closed when in operation.

SAFETY MESSAGE TO MAINTENANCE PERSONNEL

Listed below are some important safety instructions and precautions you should follow:

• Readandunderstandallinstructionsbeforeoperatingthissystem.

• Anymaintenancetothelightsystemmustbedonewiththepowerturnedoff.

• Anymaintenancetothelightsystemmustbeperformedbyatrainedelectricianinaccordancewith

NEC Guidelines and local codes.

• Neveraltertheunitinanymanner.Safetyinhazardouslocationsmaybeendangeredifadditional

openingsorotheralterationsaremadeinunitsspecicallydesignedforuseintheselocations.

• Thenameplate,whichmaycontaincautionaryorotherinformationofimportancetomaintenance

personnel,shouldnotbeobscuredifexteriorofhousingsusedinhazardouslocationsarepainted.

• Brokenglobescanleadtoexplosionswhichcouldresultinseriousinjuryordeath.Iftheglobeis

damaged in any way, the complete globe assembly MUST be replaced.

• Theonlyelectricalcomponentstobereplacedbythecustomeraretheashtubeandthecircuit

board assembly.

A. Flash Tube Replacement.

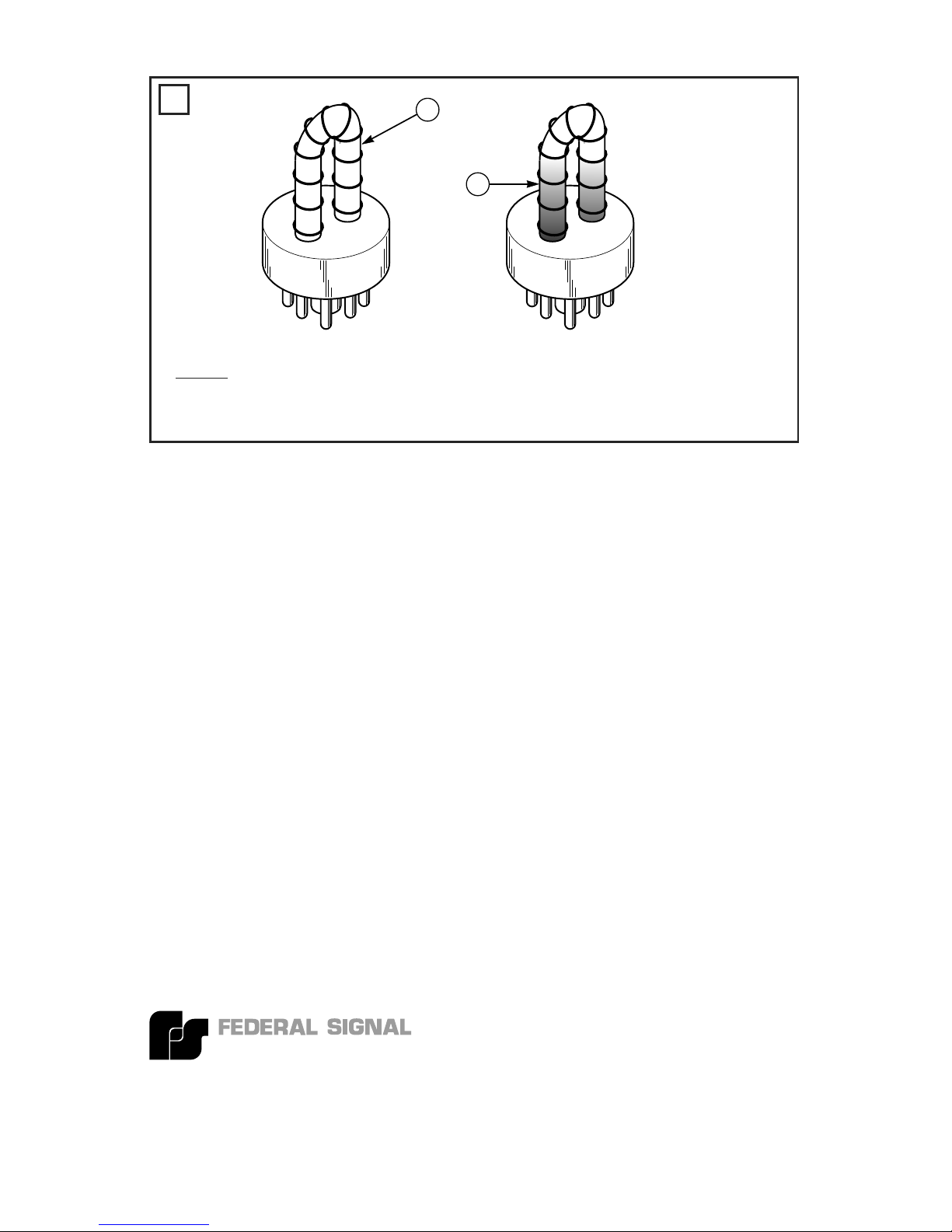

Asstrobelightsareused,theashtubesbegintodarken,causingthelightoutputtodecrease.

Thisdarkeningischaracteristicofashtubes.Darkeningwillbeginnearthebaseofthetube

andprogressupward.Also,asashtubesage,theymayhaveatendencytomisre(notre

periodically).

Afterextendedoperation,occasionallycheckforashtubedegradation.Shouldtheashtube

misre,haveanoticeabledecreaseinlightoutput,glowcontinuouslyordarkentoapoint

beyondthatshowningure2,itshouldbereplaced.

-2-