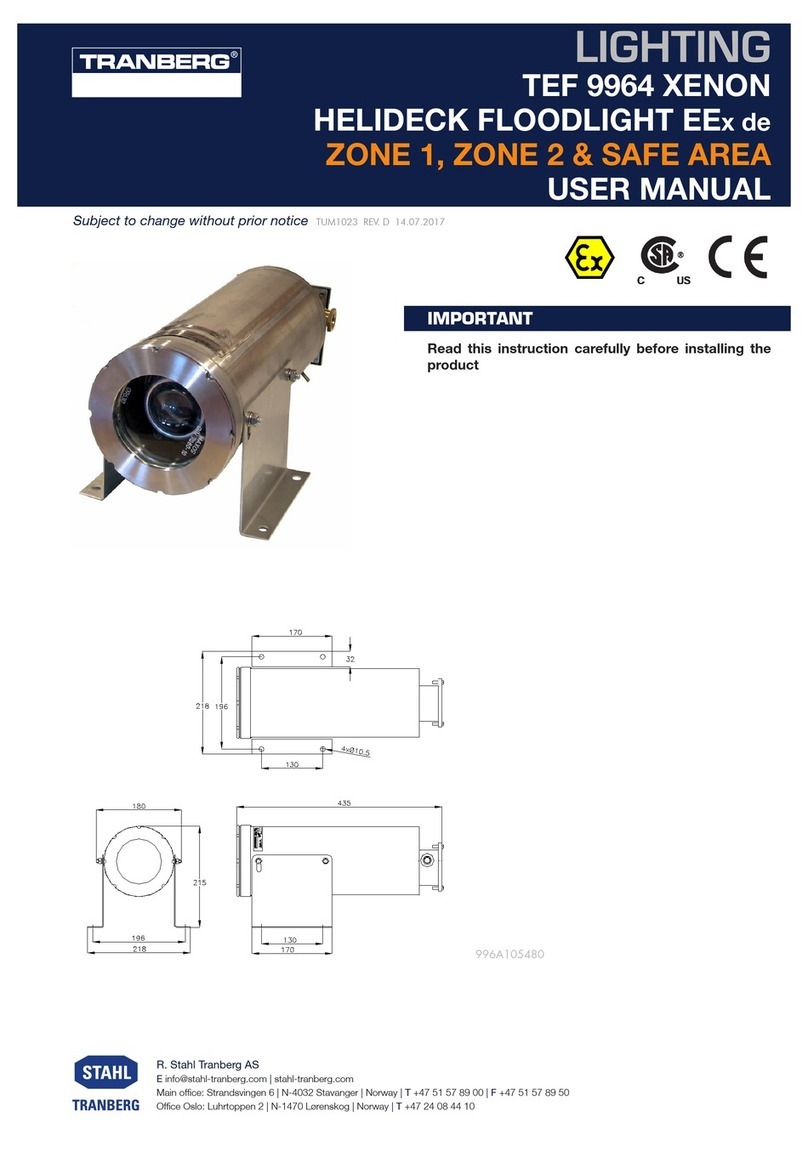

General Information

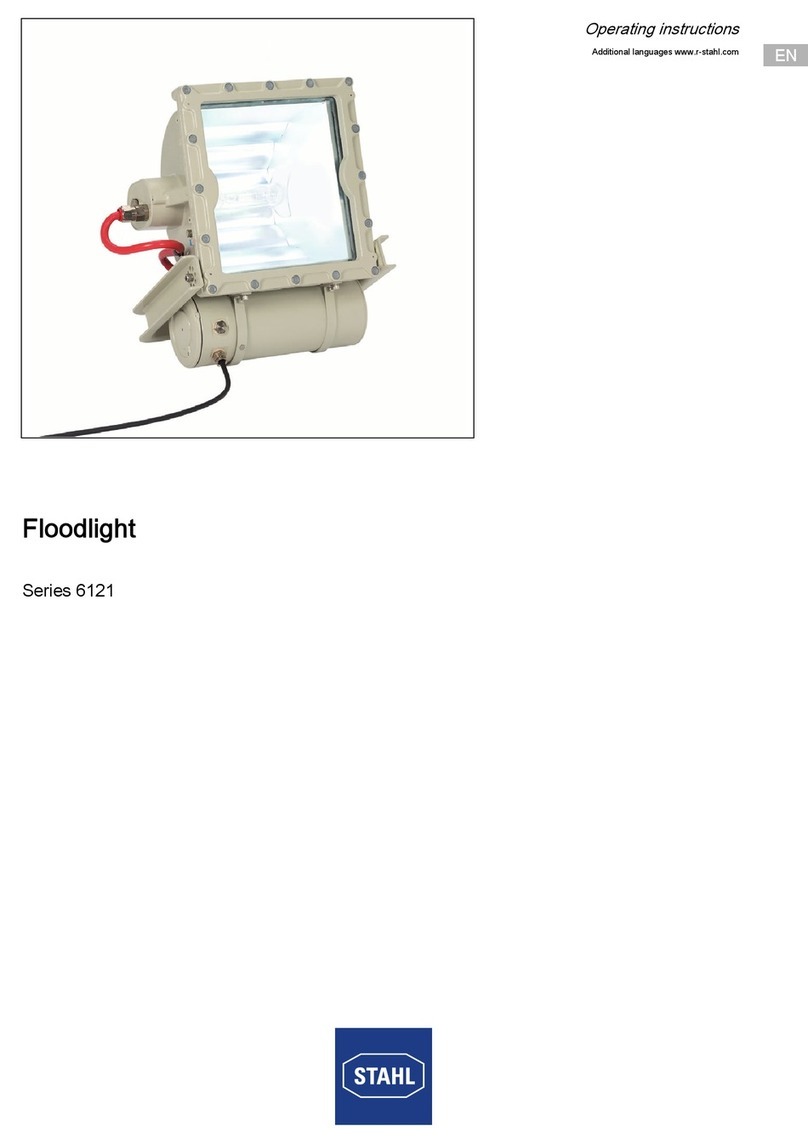

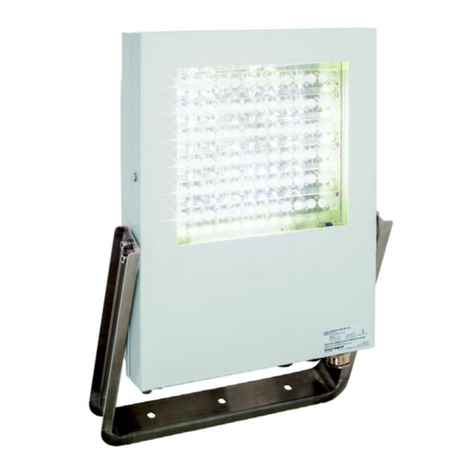

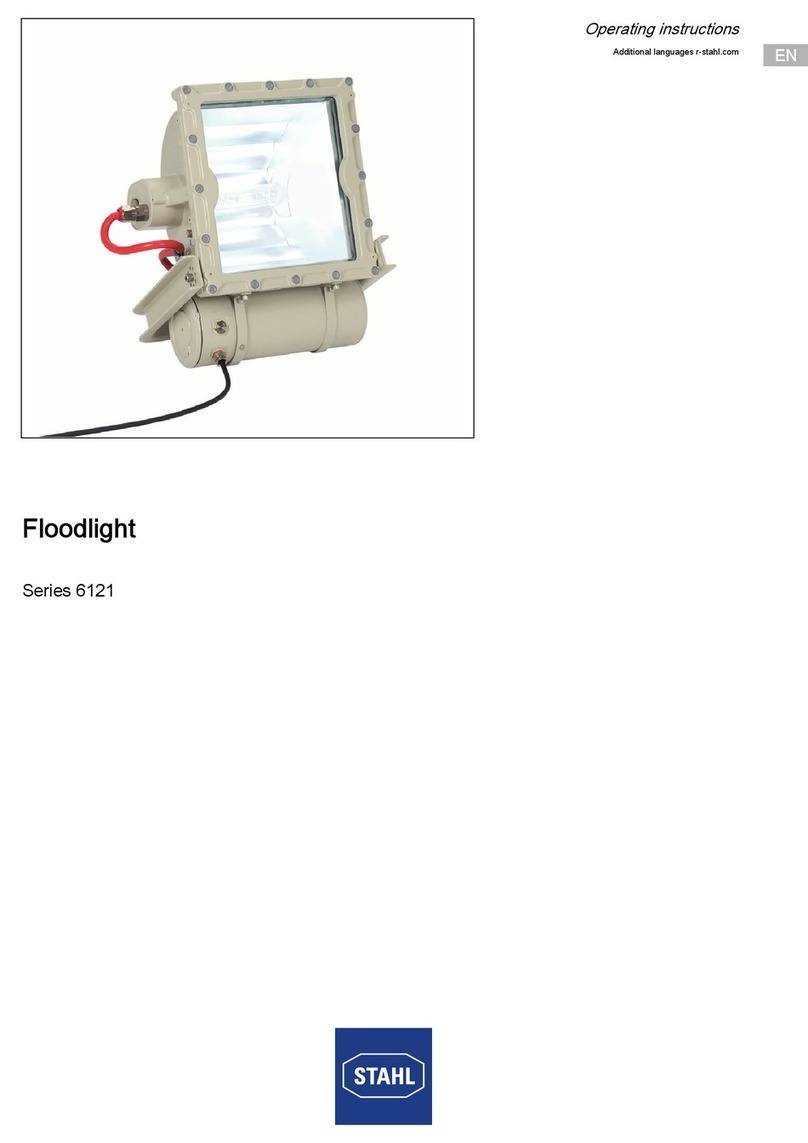

2Floodlight

Series 6521/4

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

Contents

1 General Information ............................................................................................2

1.1 Manufacturer .......................................................................................................2

1.2 Information regarding the operating instructions .................................................3

1.3 Conformity with standards and regulations .........................................................3

2 Explanation of the symbols .................................................................................3

2.1 Symbols in these operating instructions .............................................................3

2.2 Warning notes .....................................................................................................4

2.3 Symbols on the device ........................................................................................4

3 Safety notes ........................................................................................................4

3.1 Operating instructions storage ............................................................................4

3.2 Safe use ..............................................................................................................4

3.3 Intended Use .......................................................................................................5

3.4 Modifications and alterations ..............................................................................5

4 Function and device design ................................................................................5

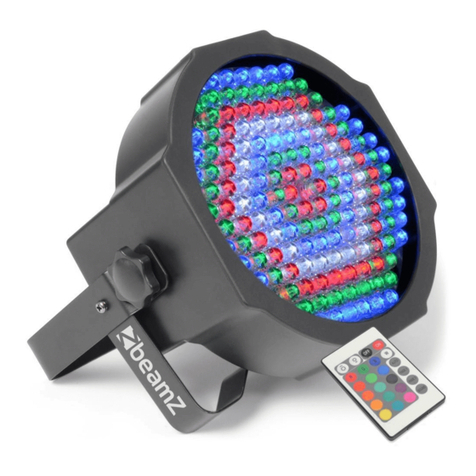

4.1 Function ..............................................................................................................5

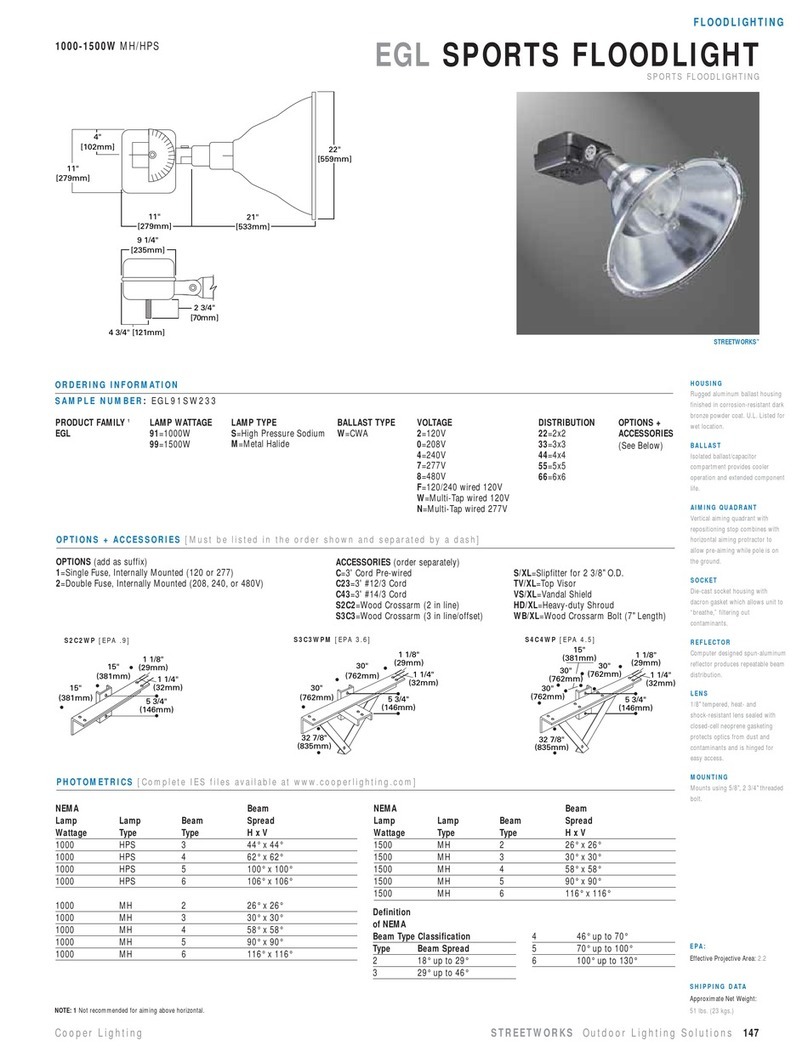

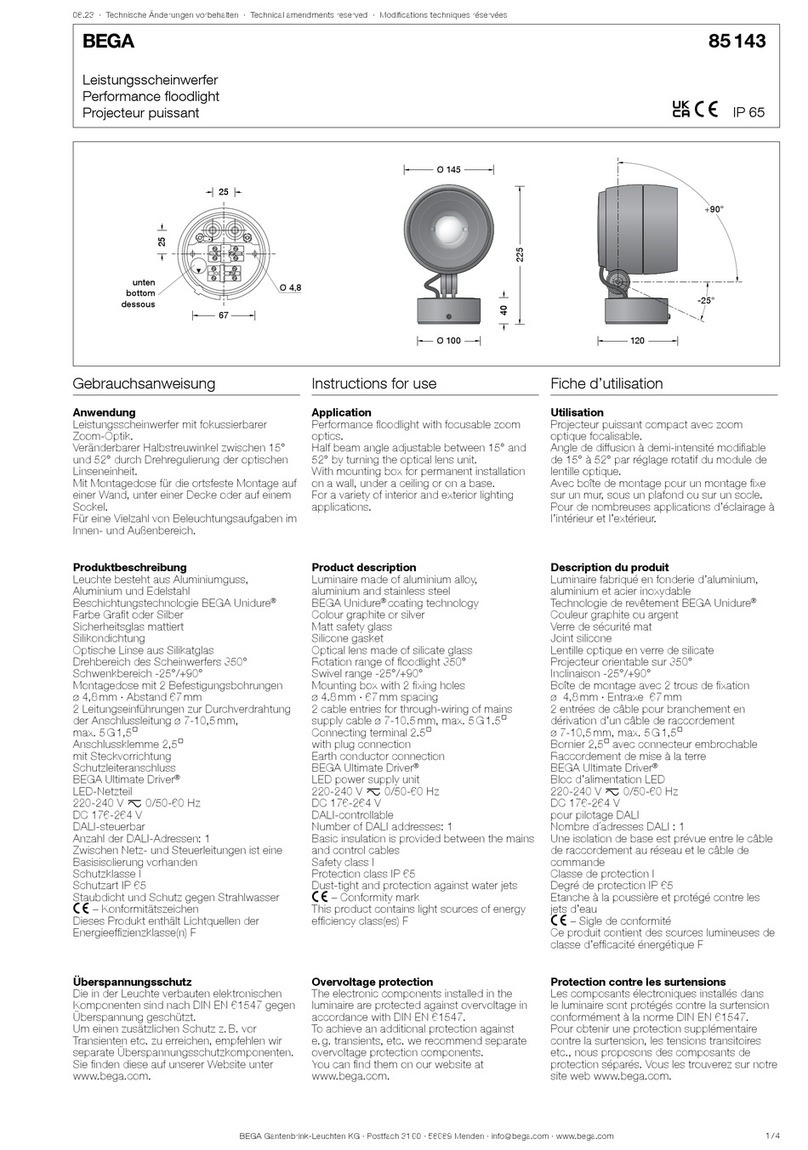

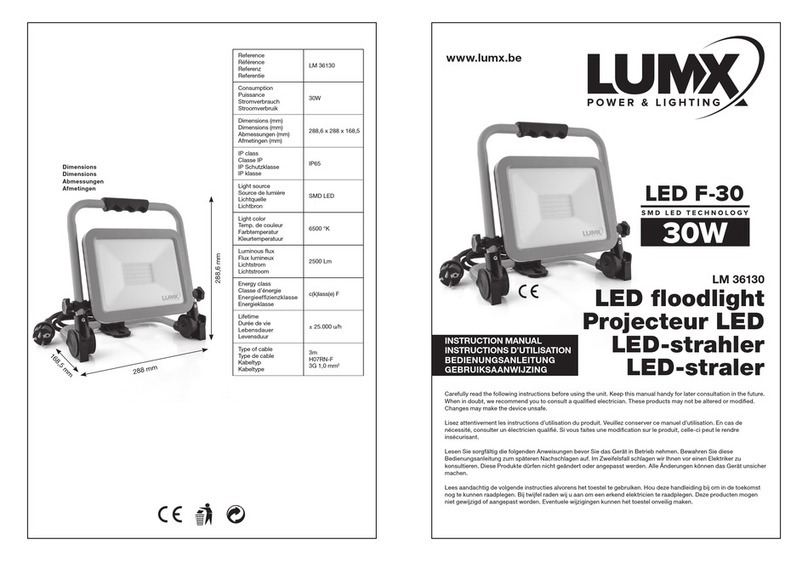

4.2 Device design .....................................................................................................6

5 Technical data .....................................................................................................7

6 Transport and storage .......................................................................................11

6.1 General .............................................................................................................11

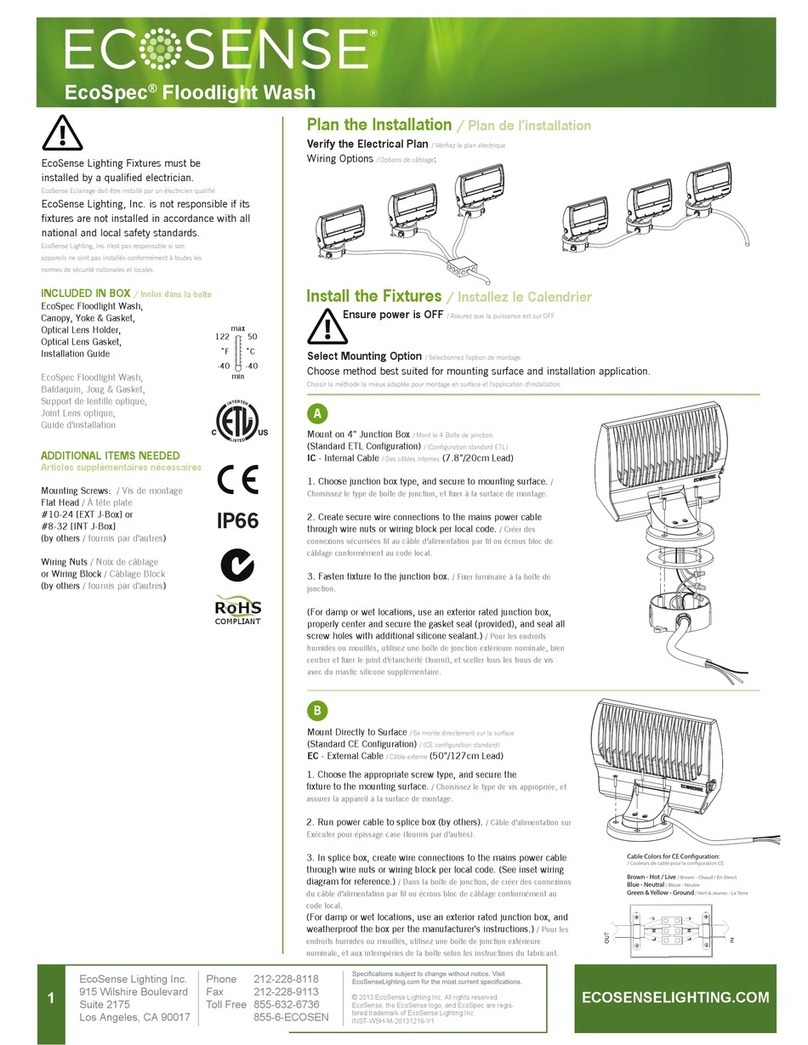

7 Mounting and installation ..................................................................................12

7.1 Dimensions / fastening dimensions ..................................................................12

7.2 Mounting / dismounting, operating position ......................................................13

7.3 Installation .........................................................................................................14

8 Commissioning .................................................................................................15

9 Operation ..........................................................................................................16

9.1 Troubleshooting ................................................................................................16

10 Maintenance and repair ....................................................................................17

10.1 Maintenance .....................................................................................................17

10.2 Repair ...............................................................................................................20

10.3 Returning the device .........................................................................................20

11 Disposal ............................................................................................................21

12 Accessories and Spare parts ...........................................................................21

1 General Information

1.1 Manufacturer

R. Stahl Schaltgeräte GmbH

Am Bahnhof 30

74638 Waldenburg

Germany

R. STAHL (P) LTD., Plot No. - 5

Malrosapuram Road, Sengundram Indl. Area

Singaperumal Koil, Kancheepuram Dist.,

Tamil Nadu Ð 603 204, INDIA

Phone:

Fax:

Internet:

E-mail:

+49 7942 943-0

+49 7942 943-4333

www.stahl-ex.com

Phone:

Fax:

Internet:

E-mail:

+91 44-30 600 600

+91 44-30 600 700

www.rstahl.net