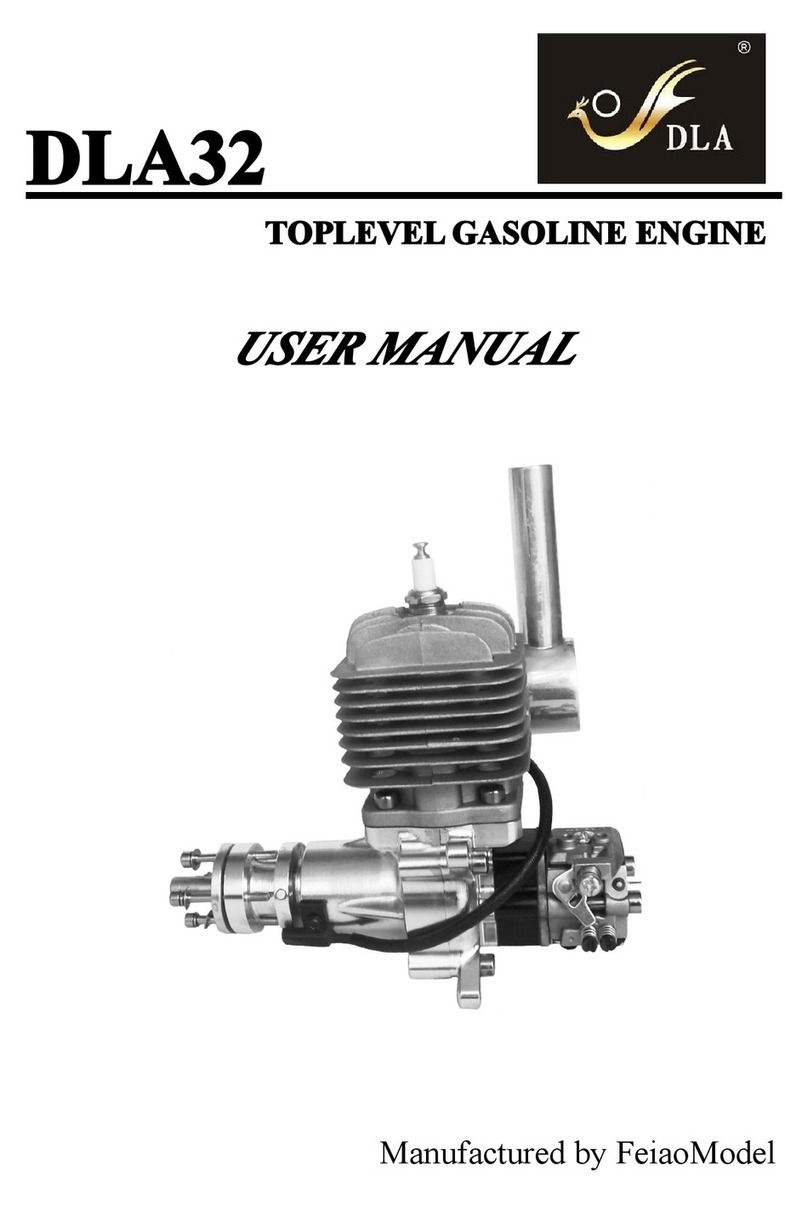

FeiaoModel DLA Series User manual

User Manual

Thanks for purchasing DLA series engines, please read all of

the instructions below before starting your engine, especially

the Safety Instructions.

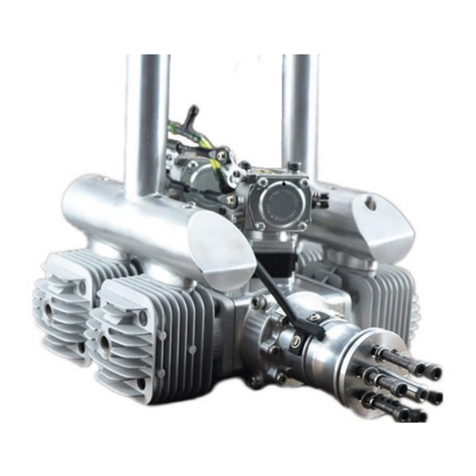

About DLA engines

Your DLA engine has been specifically designed, developed

and manufactured from proprietary components for giant scale

model, it is very powerful, extremely lightweight, easy to adjust

and operate, and should provide years of outstanding

performance.

The main components of the engine, such us the spark plug,

ignition system, bearing and carburetor are all imported from

world famous brands. The crankcases which are machined

from aluminum alloy make the engines wear and damage

resistant. Besides excellent fit and finish, precise bearing

alignment is insured, which is critical to engine performance.

The reliable auto advancing, CDI ignition system insures easy

starting and excellent performance. This ignition provides a

powerful spark, yet is fully shielded to insure protection from

R/F noise

TECHNICAL DATA

Performance:

38HP

RPM speed: 1200-5800rpm/min.

90Kg Pulling Force/1000meters Altitude

Propeller:36*10,38*8,34*8,34*12,for36*10,36*12

(recommended)

Spark Plug: DLA CM6

Parameter:

Exhaust Amount: 360CC

Diameter stroke: 53mm*41mm

Ratio of compression: 8.6:1

Lubrication Ratio:25:1~30:1 (Trial Run), 40:1~50:1(Normal

Flying)

Weight: Main engine: 7280g Exhaust pipe: 240g Ignition:

180g*2 standoffs: 22*4g

Safety Instructions before starting engines

WARNING!

This engine is not a toy! Serious injury and /or death can

occur from its misuse! READ and become familiar with this

entire instruction manual. LEARN the engine's applications,

limitations, and possible hazards. DLA is not responsible

for any loss, injury or damage resulting from the use of its

products.

1. Keep all spectators at least 30 feet away from the engine

while operating the engine.

2. Do not put anything (e.g. fingers, body parts, objects, et al)

into the rotating propeller

3. Wear proper apparel. Do not wear loose clothing, gloves,

neckties, jewelry, or neck straps ,which may get caught in

the moving propeller.

4. Always wear eye protection when starting the engine.

5. Inspect engine mount bolts and firewall integrity before

operating the motor.

6. Turn off the engine before making any adjustments.

7. Always use the proper size and well-conditioned propeller.

8. Always use the correct length propeller bolts and make sure

they are tight before every flight. (Screw thread-locking

glue is necessary)

9. Remember to keep engine fuel in a safe place, away from

any sparks, excessive heat, or anything which could ignite

the fuel. Remember that gasoline/mixture is highly

flammable and must be handled with extreme caution. Do not

smoke while running or operating the engine.

10. Do not run the engine near loose material such as dirt,

gravel, power cords, ropes, sand, etc. Loose material can

be drawn into the turning prop causing injury or damage.

Engine installation

1. Make sure each engine comes with a firewall mounting plate

drilled with four holes for #10 size screws.

2. A spacer is needed to keep the cooling fins away from the

firewall where the firewall is larger than the engine plate.

3. In order to make sure the engine does not speed excessively

without a positive control installed, throttle return springs

must be left in place.

4. After you have connected the return spring to the throttle

servo you may unhook it(do not remove it), since it acts as

a spacer for the butterfly. The butterfly will work loose by

removing the return spring.

5. The ignition battery should be mounted externally, near the

cowl, at least twelve inches from the receiver or throttle servo

that connects to the receiver.

6. The carburetor needs at least 1 1/2" (38mm) of clearance

between the intake and the bottom of the cowl. If there is less

than 1 1/2", make an opening in the cowl below the

carburetor at least as large as the carburetor intake diameter.

7. A long, narrow, screw driver is recommended to drill small

holes in the cowl for adjusting the needle valves, since the

carburetor must often be adjusted differently with the cowl on

as compared to off.

8. The engines are equipped with a diaphragm pump carburetor

making tank location not critical relative to the carburetors

fuel entry position. Place the tank on the aircraft’s center of

gravity (CG). Then aircraft trim changes during flight will not

be necessary from a full to an empty tank

FUEL:

Clean petrol 93# is strongly recommended for your DLA

engines. Lubrication Ratio of trial Run is 25:1~30:1, while

normal flying is 40:1~50:1, Higher-octane fuel will not generate

more power and may cause the engine to run slower and

overheat.

Note: Damage caused by fuel additives, such as nitro,

over-lean carburetor settings, over-advanced timing and

over-heating are not covered under warranty.

Ignition system

DLA Ignition details:

• The red cable is positive (+), while the black is negative (-).

• Working voltage: 6.6V~8.4V (7.4V ,2S Li-Po battery is

recommended)

• Please connect Li-Po battery to DLA ignition directly.

• It is important to achieve the correct coordination of the

sensor(s) to the magnets for fitting a new ignition.

•Four cylinder engine containing 2 ignitions and 2 sensors.

One sensor is marked ”F”, it must be connected with the

ignition, which is working for front two cylinders. Another

sensor is marked “R” , it must be connected with the

ignition, which is working for rear two cylinders.

The propeller selection and installation

Make sure the prop, spinner and prop bolts before each

flight! Loose prop bolts allow prop movement which will

shear the bolts.

Selection:

• The following props are recommended: 36*10,36*12

• Only use propeller sizes that are recommended above for

your engine

• The propeller blades must be of the same length.

Installation:

• You must use a drill press to drill your propeller from the rear.

• A drill guide is recommended, but the propeller washer can be

used as a drill template. (Fix the propeller washer onto the

propeller in the center-bore using a bolt and nut.)

• Keep your propeller balanced.

•Screw thread-locking glue is necessary

Engine starting procedure

1. Fill the tank with fresh filtered fuel.

2. Insure that your receiver and ignition batteries are charged,

your receiver and transmitter are on, and that your throttle is

set to low.

3. Close the choke and turn on the ignition switch.

4. Rubber stick is recommended to start the engine.

5. Begin flipping the prop through its compression stroke until

the engine fires.

6. Wait for the propeller to stop spinning, turn off the ignition,

and open the choke(s)

7. Switch the ignition back on and flip the propeller again until

the engine starts

8. Warm up the engine for 15 or 20 seconds before advancing

the throttle.

Carburetor Tuning and Care

The use of a tachometer is highly recommended. And, again,

never adjust the needles while the engine is running!

Tuning

1. Using the tachometer tune the engine for maximum power

with the high needle (H).

2. Using the tachometer again: richen the high needle (H) until

the engine runs 100-200 RPM less than the maximum RPM.

Now you should richen slightly on the high needle (H).

Keep the engine run at idle for 60 seconds. Insure that the idle

RPM to be constant. If the low needle (L) is too rich, it may

happen that idle RPM drops until the engine stops;. Lean the

low needle (L) until a constant idle RPM is achieved.

Check the transition with a quick throttle advance. It should

sound like it is making quick steady power.

3. Needle adjustment advice

Care:

Your carburetor screen will need to be cleaned with clean

gasoline and blow off with compressed air after every flight.

Check the choke and throttle plates for tightness.

Trouble Shooting

Problem1. The engine is flooded.

Solution:

Remove the spark plug; turn the engine to a position where the

fuel runs out and clean it.

Check the connections of spark plug, screws, restart the engine,

if it failed to start again, please send it back to After-sale service

center for repair.

Problem2. The engine starts after being choked but then stops

soon after.

Solution:

The low needle on the carburetor is probably too lean.

Adjust the Low End needle until you achieve a smooth idle and

a reliable transition to high throttle. Generally if the motor

stutters or coughs in the mid range or when the throttle is

advanced, the low end needle is too rich and possibly even the

high end needle.

Problem3. The engine runs rough and is vibrating strongly.

Solution:

Balance the propeller. Check the ignition timing. Check your

plumbing for air/fuel leaks

Check your spark plug for carbon and check the spark plug gap.

Check the engine mount to be sure it is rigid. Check to make

sure the engine is mounted on a level surface so that crankcase

is free of tension.

Check the engine and propeller bolts.

Problem4. The engine doesn't reach a normal RPM at full

throttle.

Solution:

Check:

A. The carburetor settings.

B. See if the propeller is too large.

C. See if the engine is overheating.

D. The ignition timing.

E. The spark plug for defect.

Verify:

A. you have the correct muffler system.

B. you have the correct gasoline, oil, and have mixed them with

the correct ratio.

DLA WARRANTY POLICY

DLA engines include a limited TWO YEAR WARRANTY ON

MATERIALS AND WORKMANSHIP to the original purchaser.

This warranty does not cover the following:

•Damage caused by improper handling, operation,

modifications, or maintenance.

• Damage caused by a crash.

• Damage caused by using improper fuel or additives.

• Damage incurred during transit to After Service Center.

Company: Shandong Feiao Aircraft Engine Co., Ltd.

Address: No.2 Research and development Building,NO.177

High-tech 6th Road, Donggang District, Rizhao

Shandong, China

Tel : 0086-633-7968381/7968386

Fax : 0086-633-7968386

www.dlaengine.com / www.feiaomodel.net

Other manuals for DLA Series

5

This manual suits for next models

1

Table of contents

Other FeiaoModel Engine manuals

FeiaoModel

FeiaoModel DLA32 User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA232 User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA116i2 User manual

FeiaoModel

FeiaoModel DLA Series User manual