3|

INTRODUCTION

LEGAL INFORMATION

Chevrolet Performance is committed to providing

proven, innovative performance technology that is

truly More than just Power. Chevrolet Performance

Parts are engineered, developed and tested by the

factorytomeetyourexpectationsforfitandfunction.

Visitourwebsiteatwww.ChevroletPerformance.com

for the Chevrolet Performance Parts authorized

Center near you.

This book provides general information on components

and procedures that may be useful for engine break-in

andtechnicalinspection.Observeallsafetyprecautions

and warnings as needed. Wear eye protection and

appropriate protective clothing. When working

under or around the vehicle support it securely with

jack-stands. Use only the proper tools. Exercise

extreme caution when working with flammable

corrosive, and hazardous liquids and materials.

Some procedures require special equipment and

skills. If you do not have the appropriate training,

expertise, and tools to perform any part of the

installation then contact a professional.

This publication is intended to provide information

about your circle track engine and related components.

The publication also describes procedures and

modications that may be useful during the installation.

It is not intended to replace the comprehensive service

manuals or parts catalogs which cover General Motors

engines and components. Rather, it is designed to

provide supplemental information in areas of interest

and to do-it-yourself enthusiasts and mechanics.

This publication pertains to engines and vehicles

which are used off the public highways except where

specically noted otherwise. Federal law restricts the

removal of any part of a federally required emission

control system on motor vehicles. Further, many states

have enacted laws which prohibit tampering with

or modifying any required emission or noise control

system. Vehicles which are not operated on public

highways are generally exempt from most regulations.

As are some special interest and pre-emission vehicles.

The reader is strongly urged to check all applicable

local and state laws.

HISTORY

GM has a long history of providing the engine of choice

for circle track racing. The introduction of the small

block Chevy in 1955 started it all. Production parts

were durable, and the engines were plentiful. In the

1960’s, Chevrolet started producing HD parts for racing

activities and a whole industry was started.

Over time, the competitive nature of racing drove costs

increasingly higher and sanctioning bodies found it

increasingly difcult to police the competitors. In the

1990’s, several tracks and individuals took Chevrolet’s

successful crate engines designed for the street

and adapted them for circle track applications. The

potential for cost savings was tremendous.

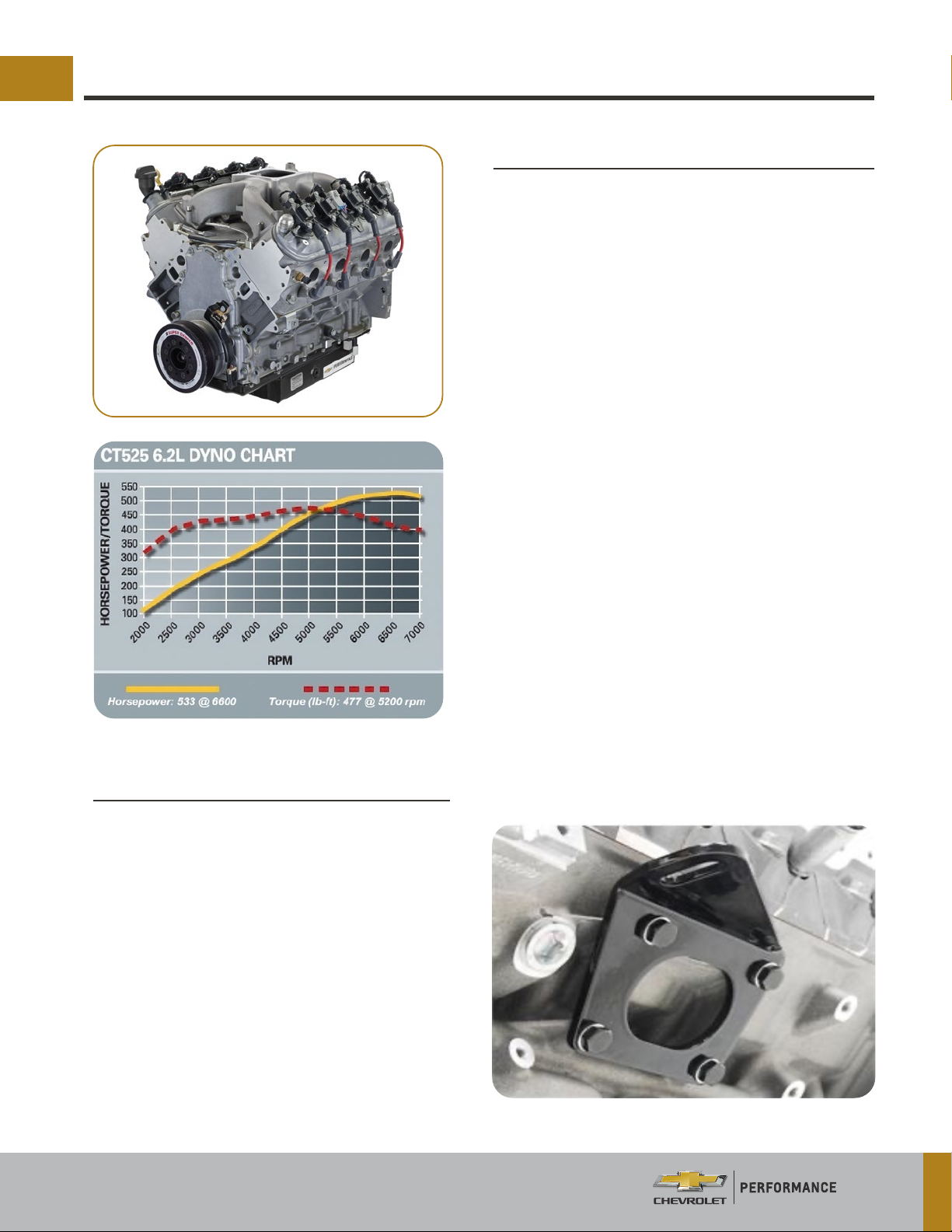

Based on the success of the 3 traditional Gen0/1 Small

BlockCTengines,GMRacingandChevroletPerformance

Parts engineers have developed a modern production

engine into a circle track race motor. The base engine

for the CT 525 comes from the highly successful latest

generation of the LS engine family, the 6.2L LS3 Gen 4

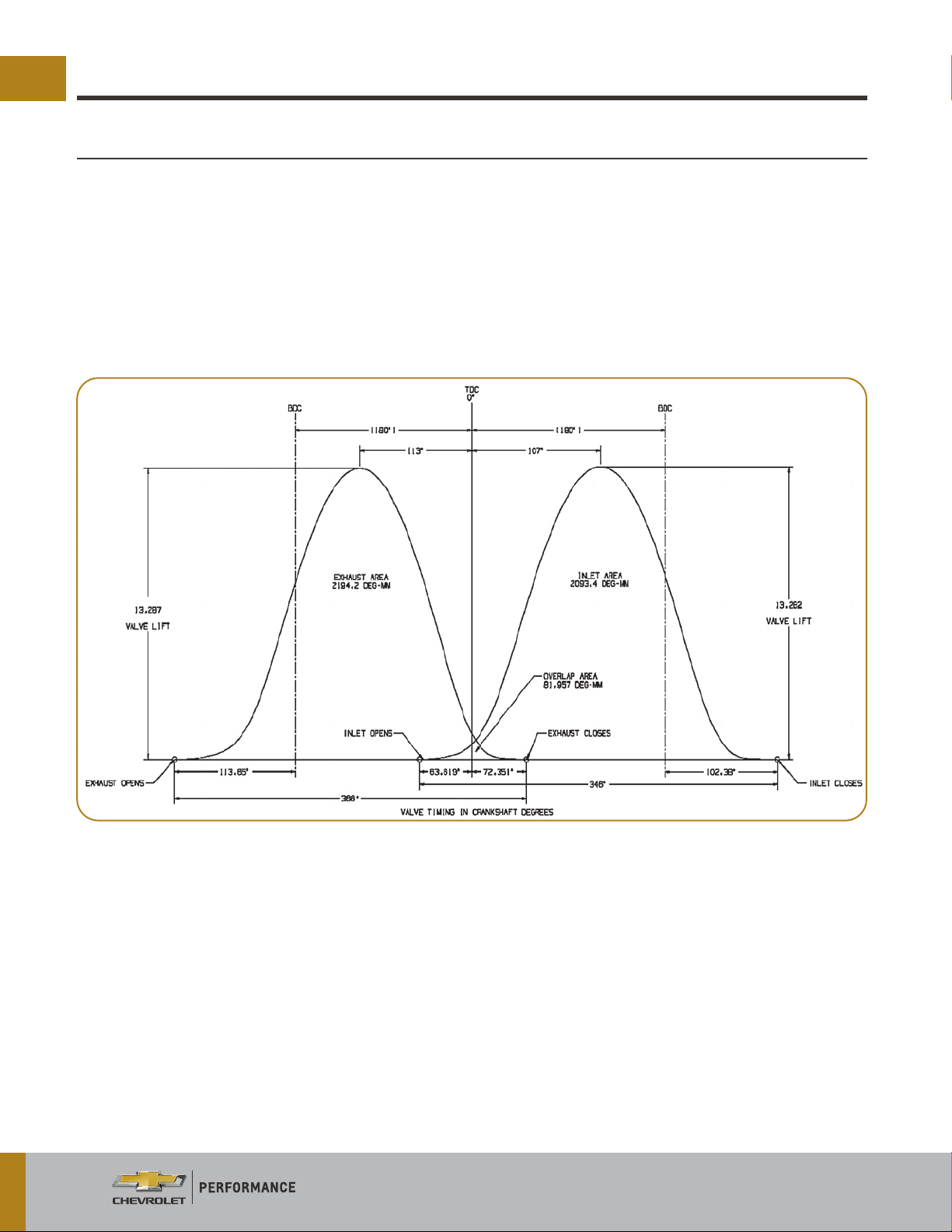

V-8. This engine is then up-tted with a Circle Track

Racing Oil Pan, Open Plenum Carbureted 4 barrel Intake

Manifold, ASA Camshaft, and a Ported Left side Valve

Cover for breathers.

Each engine is assembled with all new parts on a

production line to keep costs down. The engines then

are up-tted with special oil pans, valve covers and

sealing bolts. Factory sealing of the engines are one of

the keys to the success of the program as this makes it

difcult to tamper with the engine and helps maintain

equality among the competitors. If used as directed,

the engines should provide several seasons of use with

minimal maintenance.