FeiaoModel DLA232 User manual

This manual suits for next models

1

Other FeiaoModel Engine manuals

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA116i2 User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

FeiaoModel DLA Series User manual

FeiaoModel

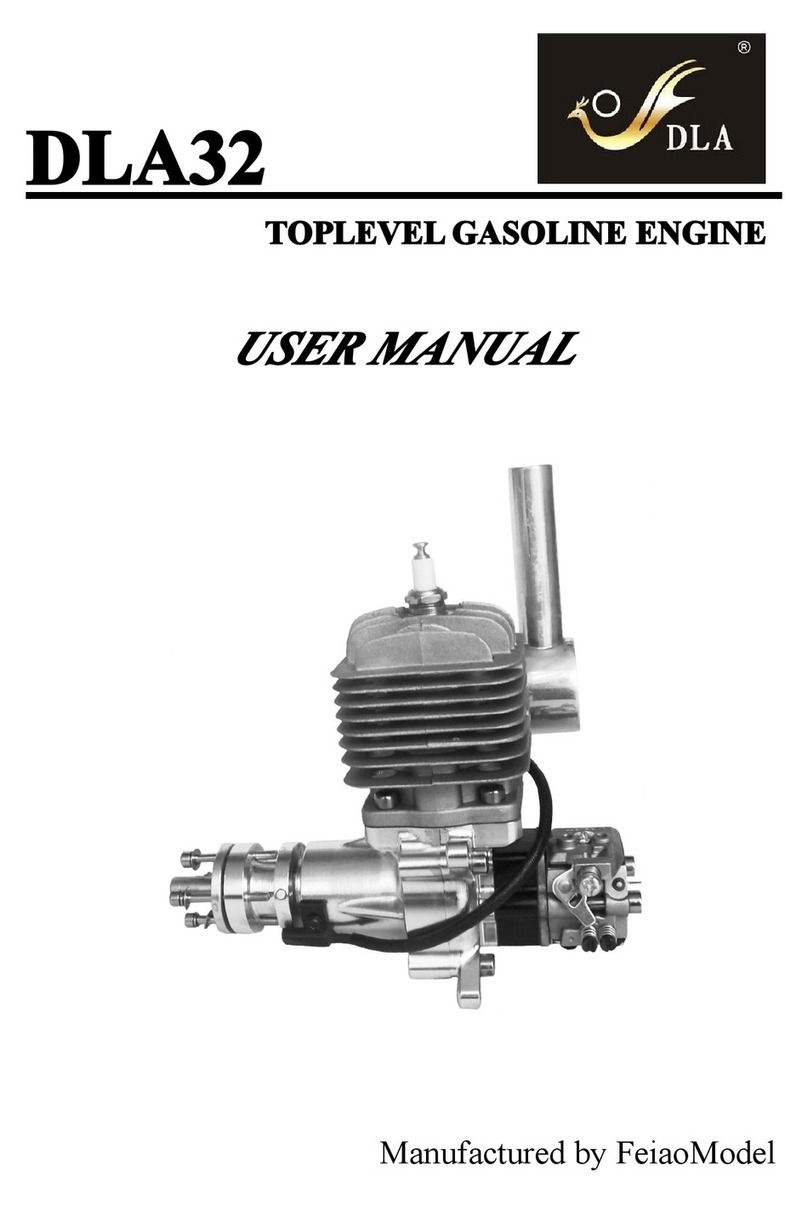

FeiaoModel DLA32 User manual

FeiaoModel

FeiaoModel DLA Series User manual

Popular Engine manuals by other brands

de Gier

de Gier GXP10 Installation instruction

PCM

PCM 2006 5.0L MPI Owner's operation and maintenance manual

Oriental motor

Oriental motor AR Series operating manual

Oriental motor

Oriental motor K II Series operating manual

Power Fist

Power Fist 8601676 user manual

Oriental motor

Oriental motor DGII Series operating manual

Oriental motor

Oriental motor K Series quick start guide

Oriental motor

Oriental motor PK Series operating manual

Ezgo

Ezgo Engine Shop rebuild manual

woodmizer

woodmizer LT70 Series Safety, Operation, Maintenance & Parts Manual

Vanguard

Vanguard 610000 Operator's manual

Ebmpapst

Ebmpapst M3G112-GA32-51 operating instructions