Feider Machines FM20V115-A User manual

ORIGINAL INSTRUCTIONS >EN

CORDLESS ANGLE GRINDER

FM20V115-A

USER GUIDE

CAUTION: READ THE INSTRUCTIONS BEFORE USING THE

MACHINE

CONCENTS

1.

INTENDED USE 3

2.

SAFETY INSTRUCTIONS 3

3.

SYMBOLES 8

4.

YOUR PRODUCT 9

5.

PACKAGE CONTENT LIST 11

6.

OPERATIONS 11

7.

CLEANING AND MAINTENANCE 14

8.

TECHNICAL DATA 15

9.

SERVICE DEPARTMENT 15

10.

STORAGE 15

11.

DISPOSAL 16

12.

DELARATION OF CONFORMITY 16

13.

WARRANTY 17

14.

PRODUCT FAILURE 18

15.

WARRANTY EXCLUSIONS 19

02

1.

INTENDED USE

This machine is developed for grinding and roughing of metal and stone. With correct accessories the

machine can also be used for brushing and sanding. It is not designed for commercial use.

WARNING! For your own safety, read this manual and the general safety instructions carefully

before using the appliance. Your power tool should only be given to other users together with

these instructions.

2.

SAFETY INSTRUCTIONS

2.1

GENERAL POWER TOOL SAFETY WARNINGS

WARNING Read all safety warnings, instructions, illustrations and specifications provided with

this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk

of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious personal injury.

03

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as a

dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g)If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power tool

will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from

the power tool before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g)Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery packs may

create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects, that can make a connection from one terminal to

another. Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may

exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature

above 130 °C may cause explosion.

04

NOTE The temperature „130 °C“ can be replaced by the temperature „265 °F“.

g) Follow all charging instructions and do not charge the battery pack or tool outside the

temperature range specified in the instructions. Charging improperly or at temperatures outside the

specified range may damage the battery and increase the risk of fire.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

and your hand or arm may be pulled into the spinning accessory.

k) Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged

give the operator an electric shock.

Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could

cutting accessory may contact hidden wiring or its own cord.

j) Hold the power tool by insulated gripping surfaces only, when performing an operation where the

injury beyond immediate area of operation.

personal protective equipment. Fragments of workpiece or of a broken accessory may fly away and cause

i) Keep bystanders a safe distance away from work area. Anyone entering the work area must wear

hearing loss.

filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause

stopping flying debris generated by various operations . The dust mask or respirator must be capable of

capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of

safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron

h) Wear personal protective equipment. Depending on application, use face shield, safety goggles or

Damaged accessories will normally break apart during this test time.

of the rotating accessory and run the power tool at maximum no-load speed for one minute.

After inspecting and installing an accessory, position yourself and bystanders away from the plane

wires. If power tool or accessory is dropped, inspect for damage or install an undamaged accessory.

for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or cracked

g) Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels

excessively and may cause loss of control.

Accessories that do not match the mounting hardware of the power tool will run out of balance, vibrate

mounted by flanges, the arbour hole of the accessory must fit the locating diameter of the flange.

f) Threaded mounting of accessories must match the grinder spindle thread. For accessories

your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

e) The outside diameter and the thickness of your accessory must be within the capacity rating of

power tool. Accessories running faster than their rated speed can break and fly apart.

d) The rated speed of the accessory must be at least equal to the maximum speed marked on the

operation.

manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe

c) Do not use accessories which are not specifically designed and recommended by the tool

hazard and cause personal injury.

performed with this power tool. Operations for which the power tool was not designed may create a

b) Operations such as sanding, wire brushing, polishing and cut-off tool are not recommended to be

below may result in electric shock, fire and/or serious injury.

illustrations and specifications provided with this power tool. Failure to follow all instructions listed

a) This power tool is intended to function as a grinder. Read all safety warnings, instructions,

Operations:

Safety Warnings Common for Grinding, Sanding, Wire Brushing, Polishing or Abrasive Cutting-Off

2.2 SAFETY INSTRUCTIONS FOR ALL OPERATIONS

05

l) Never lay the power tool down until the accessory has come to a complete stop. The spinning

accessory may grab the surface and pull the power tool out of your control.

m) Do not run the power tool while carrying it at your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the accessory into your body.

n) Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause electrical hazards.

o) Do not operate the power tool near flammable materials. Sparks could ignite these materials.

p) Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in

electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other

accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is

entering into the pinch point can dig into the surface of the material causing the wheel to climb out or kick out.

The wheel may either jump toward or away from the operator, depending on direction of the wheel’s

movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback or

torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper

precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may kickback over your hand.

c) Do not position your body in the area where power tool will move if kickback occurs. Kickback will

propel the tool in direction opposite to the wheel’s movement at the point of snagging.

d) Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent

kickback and loss of control.

⚫Check that the maximum speed indicated on the grinding disc corresponds to the maximum speed of

the machine. The speed of the machine must not exceed the value on the grinding disc.

⚫Make sure that the dimensions of the grinding disc correspond to the specifications of the machine.

⚫Make sure that the grinding disc has been mounted and fastened properly. Do not use reducing rings or

adapters to make the grinding disc fit properly.

⚫Treat and store grinding discs in conformance with the supplier’s instructions.

⚫Do not use the machine for grinding workpieces with a maximum thickness exceeding the maximum

grinding depth of the grinding disc.

⚫Do not use grinding discs for deburring.

⚫When grinding discs have to be mounted on the thread of the spindle, make sure that the spindle has

sufficient thread. Make sure that the spindle is sufficiently protected and does not touch the grinding

surface.

2.3 FURTHER SAFETY INSTRUCTIONS FOR ALL OPERATIONS

2.4 SPECIFIC SAFETY INSTRUCTIONS FOR ANGLE GRINDERS

06

⚫Before use, inspect the grinding disc for any damage. Do not use grinding discs which are cracked,

ripped or otherwise damaged.

⚫Before use, let the machine run idle for 30 seconds.

⚫Immediately switch off the machine in case of abnormal vibrations or occurrence of another defect.

Carefully inspect the machine and grinding disc before switching the machine on again.

⚫Make sure that sparks do not put people into danger or that they contact highly flammable substances.

⚫Make sure that the workpiece is sufficiently supported or clamped. Keep your hands away from the

surface to be cut.

⚫Always wear safety goggles and hearing protection. If desired or required also use another kind of

protection like for example an apron or helmet.

⚫Ensure that mounted wheels and points are fitted in accordance with the manufacturer’s instructions.

⚫Ensure that blotters are used when they are provided with the bonded abrasive product and when they

are required.

⚫If a guard is supplied with the tool never use the tool without such a guard.

⚫For tools intended to be fitted with threaded hole wheel, ensure that the thread in the wheel is long

enough to accept the spindle length.

⚫Ensure that ventilation openings are kept clear when working in dusty conditions.

Batteries

▪Never attempt to open for any reason.

▪Do not store in locations where the temperature may exceed 40°C (104°F).

▪Charge only at ambient temperatures between 4°C and 40°C

(39.2°F and 104°F).

▪Charge only using the charger provided with the tool.

▪Store your batteries in a cool dry place (5°C-20°C/41°F-68°F). Never store batteries in discharged

state.

▪It is better for Li-ion batteries to discharge and reload them regularly (at least 4 times a year). The

ideal charge for long-term storage of your Li-ion battery is 40% of capacity.

▪When disposing of batteries, follow the instructions given in the section “Protecting the

environment”.

▪Do not cause short circuits. If connection is made between the positive (+) and negative (-) terminal

directly or via accidental contact with metallic objects, the battery is short circuited and an intense

current will flow causing heat generation which may lead to casing rupture or fire.

▪Do not heat. If batteries are heated to above 100°C (212°F), sealing and insulating separators and

other polymer components may be damaged resulting in electrolyte leakage and/or internal short

circuiting leading to heat generation causing rupture or file. Moreover do not dispose of the

batteries in fire, explosion and/or intense burning may result.

▪Under extreme conditions, battery leakage may occur. When you notice liquid on the battery,

proceed as follows:

✓Carefully wipe the liquid off using a cloth. Avoid skin contact.

✓In case of skin or eye contact, follow the instructions below:

•Immediately rinse with water. Neutralize with a mild acid such as lemon juice or

vinegar.

•In case of eye contact, rinse abundantly with clean water for at least 10 minutes.

2.5SAFETY INSTRUCTIONS FOR BATTERIES AND CHARGER

07

Consult a physician.

Fire hazard! Avoid short-circuiting the contacts of a detached battery. Do not incinerate

the battery.

Charger

Only use the model of charger recommended. See the

technical data.

3.

SYMBOLS

Conforms to relevant safety standards

To reduce the risk of injury, the user must read and understand this manual

before using this product.

Wear eye protection.

Do not dispose of old appliances with domestic rubbish

.

08

4.

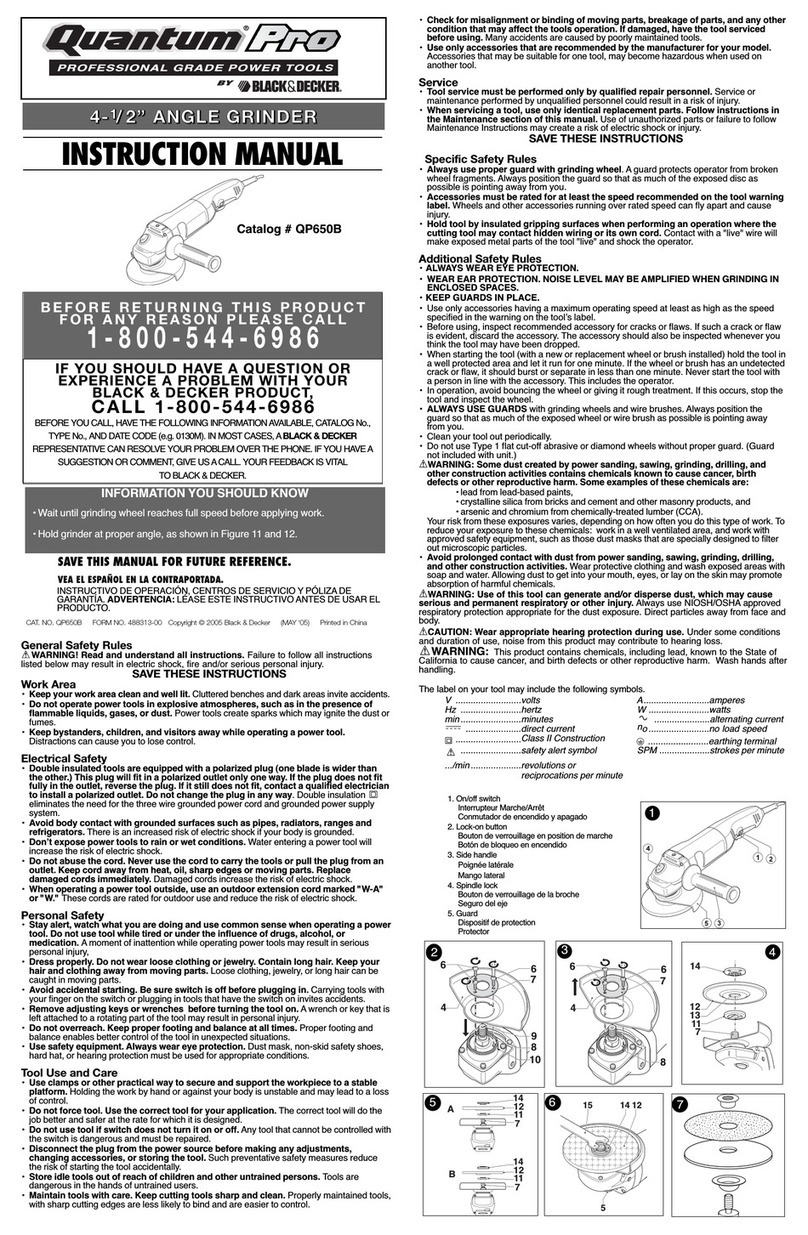

YOUR PRODUCT

1. Lock lever for protection guard

2. Spindle lock button

3. Main handle

4. On/Off switch

5. Air vents

6. Auxiliary handle

7. Guard

8. Grinding disc (not included)

9. Speed adjuster

10. Release button

11. Battery pack (Not included)

09

10

5.

PACKAGE CONTENT LIST

◼Remove all packaging materials.

◼Remove remaining packaging and packing inserts (if included).

◼Check that the package contents are complete.

◼Check the appliance, the power cord, the power plug of charger and all accessories for transportation

damage or not.

◼Keep the packaging materials as far as possible until the end of the warranty period. Then take it to your

local waste disposal system.

WARNING! Packaging materials are not toys! Children must not play with plastic bags! There

is a danger of suffocation!

1 x angle grinder

1 x auxiliary handle

1 x pin spanner

1 x instruction manual

Note: If any parts are missing or damaged, please contact your dealer.

6.

OPERATION

6.1 CHARGING THE BATTERY PACK

NOTE: The battery and charger not delivered in package, you can buy Buider battery platform 1

which used for full range.

1). Take the battery pack out of the equipment. Do this by pressing the side pushlock buttons.

2). Check that your mains voltage is the same as that marked on the rating plate of the battery charger.

Insert the power plug of the charger into the socket outlet. The RED LED will then begin to light.

3). Insert the battery pack into the battery charger .then the red LED on charger will begin to Green flash

light.

4). You will find a label with “Charger indicator” of the LED indicator on the charger.

The battery pack can become a little warm during the charging. This is normal.

If the battery pack fails to charge, check:

⚫Voltage at the power socket

⚫Whether there is good contact at the charging contacts.

⚫Whether the battery pack is warm or not, The battery protection system will not allow the battery to be

charged if the battery temperature is over 40℃ after use, allow the battery pack to cool to room

temperature before commencing with the charging.

If the battery pack still fails to charge, send the charging unit and the battery pack to our customer service

center.

To ensure that the battery pack provides long service, you should take care to recharge it promptly. You must

recharge the battery pack when you notice that the power of the cordless vacuum drops. Never allow the

battery pack to become fully discharged. This will cause it to develop a defect.

Battery capacity indicator

Press the switch for the battery capacity indicator . The battery capacity indicator shows the charge status of

the battery using 4 LEDs as following:

All 4 LEDs are lit:

The battery is fully charged.

3 LED(s) are lit:

11

The battery has approx 75% remaining charge.

2 LED(s) are lit:

The battery has approx 50% remaining charge.

1 LED is lit:

The battery will be empty soon, please recharge the battery.

6.2 CHARGER INDICATOR

Indicator status

Explanations and actions

Ready for use

The charger is connected to the mains and is ready for use; there is no battery pack

in the charger.

Charging

The charger is charging the battery pack in charge mode.

Battery pack is full of charge.

Charging is finished and battery pack in the charger.

The temperature of battery is too high or too low, the charger is under protection

status. The charging function can be recovered after the temperature is normal.

Unrecoverable battery malfunction.

6.3 INSERTING AND REMOVING THE BATTERY.

WARNING: Before making any adjustments ensure the drill is switched off with the direction

of rotation selector in the center position

1. Remove the battery: press the battery release latch in and at the same time pull the battery pack off.

2. To insert the battery, push the battery pack onto the contacts of the tool.

6.4 FITTING THE AUXILIARY HANDLE (FIG. 1)

The auxiliary handle (6) can be attached to the angle grinder in 3 different positions: left and right and top of

head.

6.5 ASSEMBLY THE PROTECTIVE GUARD (FIG. 2 –3)

1. Loosen the clip of the protective guard (7) by pulling lock lever of protective guard (1) outward.

12

2. Turn the protective guard so that uncovered part of the disc is as far apart as possible from the hand on

main handle (3).

3. Fix the protection guard by pushing the lock lever inwards (the protective guard should no longer be able

to move).

NOTE: If the protective guard can not be fixed firmly by the lock lever (1), use a hexagon wrench to

tighten the hexagon nut.

6.6 REPLACING THE GRINDING DISC (FIG. 4 –5)

Beware –a disc which has been used may be very hot!

◼Depress and hold down the spindle lock button (2) to secure the spindle.

◼Turn the shaft until it locks.

◼Remove the outer flange (a) and backing flange (b) by using the two-hole spanner provided.

◼Fit the desired disc (8) on the spindle and replace the outer flange and backing flange. Release the

spindle lock.

Important! Only ever press the spindle lock when the motor and grinding spindle are at a

standstill!

You must keep the spindle lock pressed while you change the wheel !

For grinding wheels up to approx. 3 mm thick, screw on the flange nut with the flat side facing the grinding

wheel.

6.7 SWITCHING ON / OFF (FIG. 6)

Before engage the ON/OFF switch button, check that the grinding disc is properly fitted and

run smoothly, the outer flange is well tightened.

◼Connect the battery pack onto the angle grinder body.

◼To switch on the angle grinder, push the On/Off switch(4) to the right a little and then forward to catch

the lock-fixed slot.

◼When you press the switch “O”, the tool returns off.

◼Do not let go of grinder until it has stopped running.

6.8 SPEED ADJUSTMENT

◼This tools with 6 positions for speed adjustment, max speed 8500/min, you can choose the speed what

you want.

The wheel continues to rotate after the tool is switched off.

6.9 OPERATON MODES

Grinding

Hold the handle (3) and auxiliary handle (6) firmly and switch on. Avoid blocking the ventilation slots with

your hand, as this may cause the grinder to overheat. Let the disc reach full speed. Apply the grinder to the

13

7. CLEANING AND MAINTENANCE

7.1 CLEANING

7.2 LUBRICATION

item.

Maximum effect is achieved when the grinder is held at an

angle of 15-30°in relation to the item. Move the grinder

gently along the item. Give the grinder time to work. It is

rarely necessary to press the disc hard against the surface

to be worked. Sparks can occur in the motor compartment

during use. This is normal and does not mean the grinder is

defective. Switch off the grinder after use.

FLANGE ARRANGEMENTS WHEN USING GRINDING WHEELS

Flange arrangements when using a depressed centre or straight grinding wheel.

1 Clamping flange

2 Flange nut

Always disconnect the battery pack from the angle grinder before making any adjustment or

attaching any accessories.

⚫

⚫

⚫

⚫

Never use solvents such as petrol, alcohol, ammonia water, etc. These solvents may damage

the plastic parts.

⚫The machine does not require any specific lubrication.

ee from dust and dirt.

14

8.

TECHNICAL DATA

Rated voltage (direct current)

20V d.c.

Rotation speed

4000-8500/min

Max. disc diameter:

Ø 115mm

Drive spindle thread:

M 14

Battery type

Recommendation of battery to use:

Model: FBA20U2 or FBA20U4

20V d.c. 2Ah or 4Ah

Charger type

Recommendation of charger to use:

Model: FFC20EU

Input 220-240V~ 50/60Hz,0.6Amax

Output 20V d.c., 2A

Sound pressure level

LpA 81.4 dB(A), K= 3 dB(A)

Sound power level

LwA 92.4 dB(A), K= 3 dB(A)

Ah,AG(Vibrations):

< 2.5 m/s2; K: 1,5 m/s2

Information

The declared vibration total value has been measured in accordance with a standard test method

and may be used for comparing one tool with another;

The declared vibration total value may also be used in a preliminary assessment of exposure.

Warning

that the vibration emission during actual use of the power tool can differ from the declared total

value depending on the ways in which the tool is used; and

of the need to identify safety measures to protect the operator that are based on an estimation of

exposure in the actual conditions of use (taking account of all parts of the operating cycle such as

the times when the tool is switched off and when it is running idle in addition to the trigger time).

Wear hearing protection.

9.

SERVICE DEPARTMENT

Damaged switches must be replaced by our after-sales service department.

10.

STORAGE

◼Thoroughly clean the whole machine and its accessories.

◼Store it out of the reach of children, in a stable and secure position, in a cool and dry place, avoid too

high and too low temperatures.

◼Protect it from exposure to direct sunlight. Keep it in the dark, if possible.

◼Don’t keep it in plastic bags to avoid humidity build-up.

15

11.

DISPOSAL

Electrical products should not be discarded with household products. According to the European

Directive 2012/19/EU on waste electrical and electronic equipment and its implementation into national law,

electrical products used must be collected separately and disposed of at collection points provided for this

purpose. Talk with your local authorities or dealer for advice on recycling.

BATTERY PACK

This product contains Lithium-Ion. In order to preserve natural resources, please recycle or dispose of your

batteries properly. State, federal, or regional laws may prohibit the disposal of Lithium-Ion batteries with

ordinary garbage. Consult the relevant waste authorities for information on available recycling or disposal

options.

12.

DELARATION OF CONFORMITY

BUILDER SAS

32, rue Aristide Bergès - ZI 31270 Cugnaux - France, declares that,

Product: Angle Grinder 20V

Trademark: Feider

Model: FM20V115-A

Serial number: 20211004469-20211004968

is in conformity with the essential requirements and other relevant provisions of the applicable European

Directives, based on the application of European harmonized standards. Any unauthorized modification of

the apparatus voids this declaration.

European Directives (including, if applicable, their amendments up to the date of signature);

RoHS directive 2011/65/EU + (EU) 2015/863

2014/30/EU

2006/42/EC

LVD Directive 2014/35/UE

European harmonized standards

EN 60745-1:2009+A11:2010

EN60745-2-3:2011+A2:2013+A11:2014+A12:2014+A13:2015

EN55014-1:2017; EN55014-2 :2015

Cugnaux, 06/09/2021

Philippe MARIE / PDG

Responsible of the technical file: M. Olivier Patriarca

16

13. WARRANTY

WARRANTY

The manufacturer guarantees the product against defects in material and workmanship for a period of 2

years from the date of the original purchase. The warranty only applies if the product is for household use.

The warranty does not cover breakdowns due to normal wear and tear.

The manufacturer agrees to replace parts identifed as defective by the designated distributor. The

manufacturer does not accept responsibility for the replacement of the machine, in whole or in part , and/or

ensuing damage.

The warranty does not cover breakdowns due to:

•

insufcient maintenance.

•

abnormal assembly, adjustment or operations of the product.

•

parts subject to normal wear and tear.

The warranty does not extend to:

•

shipping and packaging costs.

•

using the tool for a purpose other than that for which it was designed.

•

the use and maintenance of the machine done in a manner not described in the user manual.

Due to our policy of continuous product improvement, we reserve the right to alter or change specifcations

without notice. Consequently, the product may be diferent from the information contained therein, but a

modifcation will be undertaken without notice if it is recognized as an improvement of the preceding

characteristic.

READ THE MANUAL CAREFULLY BEFORE USING THE MACHINE.

When ordering spare parts, please indicate the part number or code, you can fnd this in the spare parts list

in this manual. Keep the purchase receipt; without it, the warranty is invalid. To help you with your product,

we invite you to contact us by phone or via our website:

•+33 (0)9.70.75.30.30

•

https://services.swap-europe.com/contact

You must create a "ticket" via the web platform.

•

Register or create your account.

•

Indicate the reference of the tool.

•

Choose the subject of your request.

•

Describe your problem.

•

Attach these fles: invoice or sales receipt, photo

of the identifcation plate (serial number), photo

of the part you need (for example: pins on the

transformer plug which are broken).

17

14. PRODUCT FAILURE

WHAT TO DO IF MY MACHINE BREAKS DOWN?

If you bought your product in a store:

a)

Empty the fuel tank if your product has one.

b)

Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

the repairer will refuse the machine.

Go to the store with the complete machine and with the receipt or invoice.

If you bought your product on a website:

a)

Empty the fuel tank if your product has one.

b)

Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

the repairer will refuse the machine.

c)

Create a SWAP-Europe service ticket on the site: https://services.swap-europe.com When making the

request on SWAP-Europe, you must attach the invoice and the photo of the nameplate (serial number).

d)

Contact the repair station to make sure it is available before dropping of the machine.

Go to the repair station with the complete machine packed, accompanied by the purchase invoice and the

station support sheet downloadable after the service request is completed on the SWAP-Europe site

For machines with engine failure from manufacturers BRIGGS & STRATTON, HONDA and RATO, please

refer to the following instructions.

Repairs will be done by approved engine manufacturers of these manufacturers, see their site:

•

http://www.briggsandstratton.com/eu/fr

•

http://www.honda-engines-eu.com/fr/service-network-page;jsessionid=5EE8456CF39CD572AA2AEEDFD

290CDAE

•

https://www.rato-europe.com/it/service-network

Please keep your original packaging to allow for after-sales service returns or pack your machine

with a similar cardboard box of the same dimensions.

For any question concerning our after-sales service you can make a request on our website https://

services.swap-europe.com

Our hotline remains available at +33 (9) 70 75 30 30.

18

15. WARRANTY EXCLUSIONS

THE WARRANTY DOES NOT COVER:

•

Start-up and setting up of the product.

•

Damage resulting from normal wear and tear of the product.

•

Damage resulting from improper use of the product.

•

Damage resulting from assembly or start-up not in accordance with the user manual.

•

Breakdowns related to carburetion beyond 90 days and fouling of carburetors.

•

Periodic and standard maintenance events.

•

Actions of modifcation and dismantling that directly void the warranty.

•

Products whose original authentication marking (brand, serial number) has been degraded, altered or

withdrawn.

•

Replacement of consumables.

•

The use of non-original parts.

•

Breakage of parts following impacts or projections.

•

Accessories breakdowns.

•

Defects and their consequences linked to any external cause.

•

Loss of components and loss due to insufcient screwing.

•

Cutting components and any damage related to the loosening of parts.

•

Overload or overheating.

•

Poor power supply quality: faulty voltage, voltage error, etc.

•

Damages resulting from the deprivation of enjoyment of the product during the time necessary for repairs

and more generally the costs related to the immobilization of the product.

•

The costs of a second opinion established by a third party following an estimate by a SWAP-Europe repair

station

•

The use of a product which would show a defect or a breakage which was not the subject of an immediate

report and/or repair with the services of SWAP-Europe.

•

Deterioration linked to transport and storage*.

•

Launchers beyond 90 days.

•

Oil, petrol, grease.

•

Damages related to the use of non-compliant fuels or lubricants.

* In accordance with transport legislation, damage related to transport must be declared to carriers within 48

hours maximum after observation by registered letter with acknowledgement of receipt.

This document is a supplement to your notice, a non-exhaustive list.

Attention: all orders must be checked in the presence of the delivery person. In case of refusal by the

delivery person, it you must simply refuse the delivery and notify your refusal.

Reminder: the reserves do not exclude the notifcation by registered letter with acknowledgement within 72

hours.

Information:

Thermal devices must be wintered each season (service available on the SWAP-Europe site). Batteries must

be charged before being stored.

19

BUILDER SAS

32, rue Aristide Bergès - ZI 31270 Cugnaux - France

MADE IN PRC

Table of contents

Other Feider Machines Grinder manuals

Popular Grinder manuals by other brands

Quantum

Quantum Pro QP650B instruction manual

Ayce

Ayce NC800AG-125 Operator's manual

Makita

Makita DGD800 instruction manual

Milwaukee

Milwaukee M18 FSAG115XB Original instructions

Parkside

Parkside PDOS 200 B2 Translation of the original instructions

Cornwell Tools

Cornwell Tools CAT420HDG operating instructions