Feltest Caliper Profiler User manual

Feltest Caliper Profiler

Instruction Manual

2

1. Table of contents

Page

2. Declaration of conformity 3

3. Safety instructions 4

3.1 Intended use 4

3.2 Safety precautions 4

4. About the instrument 5

4.1 Names of parts 6

4.2 Specifications 6

4.3 Working principle 7

5. Measuring 7

5.1 Finding a good position 7

5.2 Measuring procedure 8

5.3 Feltest Caliper Profiler memory navigation 9

5.4 Feltest Caliper Profiler PC communication 10

6. Interpretation of the results on forming fabrics 11

7. Interpretation of the results on press felts 12

7.1 Judging the condition of a felt 13

7.2 Sources of error 15

8. Maintenance 15

8.1 Accuracy and calibration 16

8.2 Service 16

Appendix A felt compaction table for felt “new weights 17

Appendix B felt compaction curves high-speed machines 19

Appendix C felt compaction curve for Yankee tissue felts 19

3

2. Declaration of conformity

The product “Feltest Caliper Profiler” is conform to the following directive:

89/336/EEC of 03.05.1989, EMC directive

The following Generic Standards have been used to show compliance

with this EMC Directive:

a) Emission : NEN-EN 50081-1 January 1994

b) Immunity : NEN-EN 50082-2 June 1995

Signed on May 1st 2004,

M.F. Lensvelt

Managing Director

Postal address:

Feltest Equipment BV

Postbus 205

NL-6960 AE Eerbeek

The Netherlands

4

3. Safety instructions

3.1 Intended use

The Feltest Caliper Profiler is intended only to measure the caliper of

forming fabrics and press felts on running paper machines and is not

intended, nor suitable to be used on any other object nor for any other

application.

Do not measure running dryer screens or similar products.

The seam of these products could snatch the instrument out of ones hands,

which might cause severe injuries and/or costly damage.

Use the instrument only as intended and according to this manual!

3.2 Safety precautions

• Before using the instrument, read this manual

carefully, it contains important safety information.

If you not fully understand this manual, please

contact Feltest. Store this manual with the

instrument, easy to find for users.

•Do not make measurements close to in-going nips.

You or the instrument could be grabbed into the

machine, which might cause severe injuries and/or

costly damages.

• Do not measure fabrics or press felts with damages.

Before starting measurements, check with the (other)

staff if holes or damaged edges are known and check

for signs of defects yourself. If there are any damages

or if you have any doubt; Do not measure !

• Do not push the inside corner of the Caliper Profiler

against the edge of the fabric or felt.

Irregular edges could snatch the instrument

out of your hands.

5

• Before starting a measurement, make sure you posi-

tion yourself in a stable position on a stable base.

• Always hold the instrument with two hands during

the complete measurement procedure, to avoid the

tool being snatched out of your hands.

• Do not bend over into the machine.

If you must, lean against a safety fence after checking its stability first.

• Do not ignore or remove safety constructions.

• Always follow the safety instructions that apply for the location

Please note:

Doing measurements on running paper machines is potentially

dangerous and requires alertness, concentration and common

sense.

The instruments of Feltest Equipment B.V. are designed and constructed

to be as safe as possible for their intended use. Nevertheless, it is the

user's responsibility to actually use the instruments in a safe way.

Feltest Equipment B.V. cannot be held responsible or liable in any way for

suffered injuries or damages that occurred while using their instruments.

4. About the instrument

The instrument contains high precision parts and therefore must

be treated with care.

The instrument is protected against dust and spray water.

However, avoid submerging the instrument in water and

avoid strong mechanical shocks.

6

4.1 Names of parts

1. Anvil

2. Probe

3. Pushbutton (del pos, p+)

push short -> higher memory position

push long to delete the current

memory position

4. Pushbutton (del mem, p-)

push short -> lower memory position

push long to clear all memory

positions

5. Display

6. Pushbutton (min, max, avg)

push for the statistical functions.

7. Pushbutton (ⱷ, set zero)

push short to turn the instrument on/off

push long to set zero

8. Red indication LED

9. Connector for communication to a

computer

10. Trigger

11. Battery container

12. Front handgrip

4.2 Specifications

measuring units

mil / mm

measuring range

0 –5 mm

accuracy

± 0,01 mm

length x height x thickness

431 x 130 x 27 mm

weight

1,7 kg

sampling rate

5 –25 Hz

protection

IP64

battery type

Alkaline 9 Volt, size PP3

7

4.3 Working principle

The working principle is as follows: a variable resistor is

mechanically connected with the upper probe. Opening the mouth

gives a change in the electric resistance, which is transformed into

mils (1/1000 of an inch) or millimeters and shown on the display.

The sampling rate can be set between 5-25 times per second.

The values shown on the display are dampened to avoid a rapidly

changing and therefore unreadable display.

When the instrument undergoes temperature chances

(e.g. a relatively dry press felt, generates a lot of friction and

therefore heat during the measurement), there will be a zero-shift.

Therefore the instrument needs some time to adjust to this new

temperature (i.e. the metal parts need to expand) before the most

accurate results can be acquired.

The distance that the instrument is moved into the fabric or felt can

be read from the linear scale on the housing.

The trigger has two functions:

When pulled, the mouth opens.

When pushed, the recording of data into the memory starts/stops

5. Measuring

5.1 Finding a good position

A safe and stable position is of the utmost importance for safety.

If there are several safe positions to measure,

select one on the following criteria:

General:

Measure only on the return-run,

were the fabric/felt runs without paper.

8

Press felts only:

The caliper must be measured within the sheet's run, preferably

close after the press nip, before any showers or felt conditioning

(see chapter: Interpretation of the results).

5.2 Measuring procedure

Note: For press felts the measurement is only of value when the felt

has been running for at least 1 hour under a steady press load!

1. Switch the instrument on by pushing the (ⱷ, set zero)

button shortly.

2. Check if the display reads "0.00 mm" with closed and clean probes.

Set zero by pushing the (ⱷ, set zero) button more than 2 seconds.

When the display shows "set zero", release the button.

Note: Due to temperature differences the zero may shift.

Check the zero setting before each measurement.

3. Open the mouth of the instrument by pulling the trigger

and move the instrument into the running fabric or felt.

Do not let the inner corner of the instruments

mouth touch the edge of the fabric or felt!

Keep the instrument perpendicular to the

fabric or felt and release the trigger quietly.

4. Slightly push the instrument upward to make

sure that the probe has free movement.

After 2 seconds a stable result is achieved.

5. Pushing the trigger will start the red indicator

LED flashing and the recording of the test

results into the next available memory position.

9

6. To make a caliper profile or to measure the thinnest or thickest

spot, move the instrument slowly towards the edge of the fabric

or felt. When the probe goes over the edge of the fabric or felt,

the data recording will stop automatically the red indicator

stops flashing.

Note:

For press felts it isn’t always needed to make a caliper profile.

In that case keep the instrument steady and after a few seconds

switch off the data recording by pushing the trigger again. Open

the mouth by pulling the trigger and remove the instrument.

7. Check the zero setting.

If, due to temperature differences during measuring, zero has

shifted more than ± 0.03 mm, the measurement must be

discarded; set zero and execute a new measurement.

8. To display the lowest/highest and the average value, press

button (min, max, avg) several times. Pressing the button once

more will show the current value again.

9. Pressing the (ⱷ, set zero) button shortly will turn off the instrument.

5.3 Feltest Caliper Profiler memory navigation

Every time a recording is started, automatically a new memory

position is created.

Shortly push p+ button or p- button to navigate up or down through

the memory positions.

When the del pos button is pushed longer than 2 seconds

the current memory position will be deleted.

As long as the display reads p xx delete? (xx = memory position) it is

still possible to cancel by releasing the button.

A deleted position is shown by –xx instead of p xx.

10

Note: Deleting a position doesn’t create free memory space

for new positions !

When the del mem button is pushed longer than 2 seconds, all

stored memory positions are deleted and all memory space comes

available for new measurements.

5.4 Feltest Caliper Profiler PC communication

To capture the measured data from a Caliper Profiler to a

computer, or to chance its settings, you first have to install the

application Feltest Service (FS)from included CD-ROM.

A manual and a help file are enclosed in the software.

When the Caliper Profiler is connected to the computer's USB-port

for the first time, the system might require the installation of

drivers from the CD-ROM.

When the Caliper Profiler is connected to a computer, start FS

and press the "Auto-search" button on the tab "Set-up Profiler".

Available settings:

name

description

range

default

measure-

ments /

second

number of

measurements stored in

memory per second

5 - 25 Hz

10

auto-off

level

when measurements

drop below ….mm/mil

recording stops

0.1-1.5 mm

3.9 –59 mil

0,15

dimension

unit

measuring in millimeters

or

mils (1/1000”)

mm / mil

mm

11

6. Interpretation of the results on forming fabrics

The high accuracy of Feltest Caliper Profilers has the advantage that

even small dynamic changes in the forming fabric can be measured.

For example, due to high fabric tension the caliper can decrease up

to 0.04 mm in SSB fabrics. And even more on single and double

layer forming fabrics.

To get a feeling for the degree of caliper change due to fabric

tension, measure the same fabric at two positions with different

tension. For example just after the drive roll (relatively low fabric

tension) and at a safe distance before the breast roll (relatively high

fabric tension).

Most suppliers of forming fabrics recommend a minimum caliper

for their products. Usually the thinnest spot determines when a

forming fabric must be replaced.

This spot often can be found within 30 cm from the wire edge;

because of wear caused by the edges of foils, poorly positioned

stops on suction boxes, etc. etc..

Rest potential [%] = caliper(run) –caliper(min) x 100%

caliper(min)

Note:

Above calculation doesn’t take into account from which side the

fabric has lost material. Usually forming fabrics have more material

at the machine side to withstand abrasion; The warp, which gives

the fabric it’s strength, is usually located on the paper side. Hence,

a caliper decrease is much more serious if the material is lost on the

paper side then when it would be lost from the roll side! Visual

inspection during a stop is required.

12

7. Interpretation of the results on press felts

When the felt goes through the nip, it’s compressed and afterwards

it will expand back.

During the lifetime of the felt this expansion will decrease and the

felt becomes compacted.

Compacted felts absorb less water than non-compacted felts.

Therefore the caliper of the felt should be judged in conjunction

with the felt weight.

h = caliper (height) of the felt (mm)

s = solid (non-absorbing) part of the felt (mm)

v = void (absorbing) part of the felt (mm)

F = actual weight of 1m2felt (g/m2)

ρ= density of press felt (approx. 1.14 for PA) (g/cm3)

s =

COMPACTION =

* 100% =

* 11.4%

WATER STORAGE CAPACITY [g/m2] = 1000 *

- F

13

In Appendix-A you can look up storage capacity at different

compaction percentages for felt types with different “new

weights”

To interpret the compaction into day’s life, graphics of various

positions at high-speed machines ( V > 900 m/min ) are added as

Appendix-B and Appendix-C.

Note: These graphics are an average of many different

measurements on many different paper machines

with many different felt types from many different

suppliers. It is recommended to develop such a curve

for each specific position of your machine.

7.1 Judging the condition of a felt

The caliper (h) is measured with the Feltest Caliper Profiler and is

therefore known. When the water content is also measured with

a felt moisture meter, it can be converted into felt void (v).

Comparison of the measured water content to the theoretical

storage capacity of a felt, generates interesting information in

regard to the felt’s condition.

Measured water content < Theoretical storage capacity

If the actual water content is less than the storage capacity,

the felt is not fully saturated.

For “nip-dewatering machines”this indicates that the felt is bulky

and that the de-watering over the nip is not optimal.

It could mean that felt is not yet 'run in'.

For “Uhle box dewatering machines”this is quite a normal situation

for a felt in a good condition.

Measured water content > Theoretical storage capacity

If the actual water content is larger than the storage capacity,

the felt contains more water than that there is theoretically space

for. The answer to this impossibility is to be found in the use of the

wrong current felt weight and/or re-wetting of the felt after the nip.

14

The actual water content is best measured at

the same position as where the caliper was

measured.

Water from the felt conditioning system can

have an influence. Therefore try to measure

right after the nip and certainly before the felt

conditioning.

If there is much re-wetting of the felt at the press nip exit, the

measurement shows more water than there was in the mid-nip,

therefore wrongly indicating felt wear.

Hence it’s important to know which kind of press roll is used (blind

drilled rolls cause more re-wetting than grooved or suction rolls)

Blind drilled press roll Grooved press roll

Low speed machines like board machines usually have considerable

re-wetting of the felt. This makes wear-calculation extremely

difficult.

Estimation of current felt weight (Fcurrent)

in fast running / nip dewatering machines:

Fcurrent = (1000 * h - water content) * 1.14 * re-wetting factor

(indicative) re-wetting factor for suction roll at high speed: 1.05

(indicative) re-wetting factor for for tissue felts: 1.16

15

Note: To establish representative values for the re-wetting factor

compare the actual weight from lab reports which are

made later to the calculated Fcurrent

7.2 Sources of error

• wrong felt weight is being used, due to wrong data or because

the felt has lost weight.

In particular in combination with CaCO3a loss of weight of the

felt of 15 to 20% due to wear is common. In case of a very high

calculated compaction (> 85%) it’s likely that the felt has lost

fibers -> A low water content and high airspeeds at the Uhle

boxes can confirm this.

• The measured caliper was affected by some local wear,

for instance caused by a suction box edge -> measure again

• The measurement was done outside the sheet’s run -> measure

again

• No ‘set zero’ performed just before the measurement.

The temperature difference between a 1st press position in the

basement and a 3rd press position near the drying hood can be

substantial -> set zero, and measure again

8. Maintenance

Cleaning

For accurate measurements the two stainless steel probes must be

cleaned with a cloth or tissue. The aluminum frame and the

polycarbonate display window can be cleaned with a humid cloth

and, if necessary, some mild detergent.

16

Battery change

When the battery needs to be replaced, a low bat warning is shown

in the display for a few seconds when the instrument is switched

on.

Unscrew the front plate of the battery container and replace the 9-

Volt (size PP3) battery. Before putting back the front plate, check if

the rubber seal around the battery container is still on its place and

in good condition. Tighten the two screws with medium force.

8.1 Accuracy and calibration

A little wear on the two probes doesn’t influence the

± 0.01 mm accuracy within 0.50 to 5.00 mm range of a

Feltest Caliper Profiler.

More extensive wear (flattened surfaces of the probes)

will result in too high caliper values:

• when the instrument is not kept exactly perpendicular to

the fabric or felt (misalignment),

• because the worn upper probe will be pushed a little less

into press felts

8.2 Service

When the accuracy seems out of specification, the instrument

needs to be send to

Feltest Equipment BV for service and re-calibration.

Please add a problem description in English or German language

and send it properly packed and insured to Feltest Equipment BV.

The actual address can be found on www.feltest.com.

17

Appendix-A(1/2) Felt compaction table felt “new weights” 900 –1350 g/m2

900

950

1000

1050

1100

1150

1200

1250

1300

1350

caliper

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

comp.

st.cap.

1,10

72

311

76

267

80

223

84

179

88

135

92

91

96

47

100

4

104

-40

108

-84

1,11

71

321

75

277

79

233

83

189

87

145

91

101

95

57

99

14

103

-30

107

-74

1,12

70

331

74

287

78

243

82

199

86

155

90

111

94

67

98

24

102

-20

106

-64

1,13

70

341

74

297

78

253

82

209

85

165

89

121

93

77

97

34

101

-10

105

-54

1,14

69

351

73

307

77

263

81

219

85

175

88

131

92

87

96

44

100

0

104

-44

1,15

69

361

72

317

76

273

80

229

84

185

88

141

92

97

95

54

99

10

103

-34

1,16

68

371

72

327

76

283

79

239

83

195

87

151

91

107

95

64

98

20

102

-24

1,17

67

381

71

337

75

293

79

249

82

205

86

161

90

117

94

74

97

30

101

-14

1,18

67

391

71

347

74

303

78

259

82

215

85

171

89

127

93

84

97

40

100

-4

1,19

66

401

70

357

74

313

77

269

81

225

85

181

88

137

92

94

96

50

100

6

1,20

66

411

69

367

73

323

77

279

80

235

84

191

88

147

91

104

95

60

99

16

1,21

65

421

69

377

72

333

76

289

80

245

83

201

87

157

91

114

94

70

98

26

1,22

65

431

68

387

72

343

75

299

79

255

83

211

86

167

90

124

93

80

97

36

1,23

64

441

68

397

71

353

75

309

78

265

82

221

86

177

89

134

93

90

96

46

1,24

64

451

67

407

71

363

74

319

78

275

81

231

85

187

88

144

92

100

96

56

1,25

63

461

67

417

70

373

74

329

77

285

81

241

84

197

88

154

91

110

95

66

1,26

63

471

66

427

70

383

73

339

77

295

80

251

84

207

87

164

91

120

94

76

1,27

62

481

66

437

69

393

73

349

76

305

79

261

83

217

86

174

90

130

93

86

1,28

62

491

65

447

69

403

72

359

75

315

79

271

82

227

86

184

89

140

93

96

1,29

61

501

65

457

68

413

71

369

75

325

78

281

82

237

85

194

88

150

92

106

1,30

61

511

64

467

67

423

71

379

74

335

78

291

81

247

84

204

88

160

91

116

1,31

60

521

64

477

67

433

70

389

74

345

77

301

80

257

84

214

87

170

90

126

1,32

60

531

63

487

66

443

70

399

73

355

76

311

80

267

83

224

86

180

90

136

1,33

59

541

63

497

66

453

69

409

73

365

76

321

79

277

82

234

86

190

89

146

1,34

59

551

62

507

65

463

69

419

72

375

75

331

79

287

82

244

85

200

88

156

1,35

58

561

62

517

65

473

68

429

71

385

75

341

78

297

81

254

84

210

88

166

1,36

58

571

61

527

64

483

68

439

71

395

74

351

77

307

81

264

84

220

87

176

1,37

58

581

61

537

64

493

67

449

70

405

74

361

77

317

80

274

83

230

86

186

1,38

57

591

60

547

64

503

67

459

70

415

73

371

76

327

79

284

83

240

86

196

1,39

57

601

60

557

63

513

66

469

69

425

73

381

76

337

79

294

82

250

85

206

1,40

56

611

60

567

63

523

66

479

69

435

72

391

75

347

78

304

81

260

85

216

1,41

56

621

59

577

62

533

65

489

68

445

72

401

75

357

78

314

81

270

84

226

1,42

56

631

59

587

62

543

65

499

68

455

71

411

74

367

77

324

80

280

83

236

1,43

55

641

58

597

61

553

64

509

67

465

71

421

74

377

77

334

80

290

83

246

1,44

55

651

58

607

61

563

64

519

67

475

70

431

73

387

76

344

79

300

82

256

1,45

54

661

57

617

60

573

64

529

67

485

70

441

73

397

76

354

79

310

82

266

1,46

54

671

57

627

60

583

63

539

66

495

69

451

72

407

75

364

78

320

81

276

1,47

54

681

57

637

60

593

63

549

66

505

69

461

72

417

75

374

78

330

81

286

1,48

53

691

56

647

59

603

62

559

65

515

68

471

71

427

74

384

77

340

80

296

1,49

53

701

56

657

59

613

62

569

65

525

68

481

71

437

74

394

77

350

79

306

1,50

53

711

56

667

58

623

61

579

64

535

67

491

70

447

73

404

76

360

79

316

1,51

52

721

55

677

58

633

61

589

64

545

67

501

70

457

73

414

76

370

78

326

1,52

52

731

55

687

58

643

61

599

63

555

66

511

69

467

72

424

75

380

78

336

1,53

52

741

54

697

57

653

60

609

63

565

66

521

69

477

72

434

75

390

77

346

1,54

51

751

54

707

57

663

60

619

63

575

66

531

68

487

71

444

74

400

77

356

1,55

51

761

54

717

57

673

59

629

62

585

65

541

68

497

71

454

74

410

76

366

1,56

51

771

53

727

56

683

59

639

62

595

65

551

67

507

70

464

73

420

76

376

1,57

50

781

53

737

56

693

59

649

61

605

64

561

67

517

70

474

73

430

75

386

1,58

50

791

53

747

56

703

58

659

61

615

64

571

67

527

69

484

72

440

75

396

1,59

50

801

52

757

55

713

58

669

61

625

63

581

66

537

69

494

72

450

74

406

1,60

49

811

52

767

55

723

58

679

60

635

63

591

66

547

69

504

71

460

74

416

1,61

49

821

52

777

54

733

57

689

60

645

63

601

65

557

68

514

71

470

74

426

1,62

49

831

51

787

54

743

57

699

60

655

62

611

65

567

68

524

70

480

73

436

1,63

48

841

51

797

54

753

57

709

59

665

62

621

65

577

67

534

70

490

73

446

1,64

48

851

51

807

53

763

56

719

59

675

62

631

64

587

67

544

70

500

72

456

1,65

48

861

51

817

53

773

56

729

58

685

61

641

64

597

66

554

69

510

72

466

1,66

48

871

50

827

53

783

55

739

58

695

61

651

63

607

66

564

69

520

71

476

1,67

47

881

50

837

53

793

55

749

58

705

60

661

63

617

66

574

68

530

71

486

1,68

47

891

50

847

52

803

55

759

57

715

60

671

63

627

65

584

68

540

70

496

1,69

47

901

49

857

52

813

55

769

57

725

60

681

62

637

65

594

67

550

70

506

1,70

46

911

49

867

52

823

54

779

57

735

59

691

62

647

64

604

67

560

70

516

1,71

46

921

49

877

51

833

54

789

56

745

59

701

62

657

64

614

67

570

69

526

1,72

46

931

48

887

51

843

54

799

56

755

59

711

61

667

64

624

66

580

69

536

1,73

46

941

48

897

51

853

53

809

56

765

58

721

61

677

63

634

66

590

68

546

1,74

45

951

48

907

50

863

53

819

55

775

58

731

60

687

63

644

66

600

68

556

1,75

45

961

48

917

50

873

53

829

55

785

58

741

60

697

63

654

65

610

68

566

1,76

45

971

47

927

50

883

52

839

55

795

57

751

60

707

62

664

65

620

67

576

1,77

45

981

47

937

50

893

52

849

55

805

57

761

59

717

62

674

64

630

67

586

1,78

44

991

47

947

49

903

52

859

54

815

57

771

59

727

62

684

64

640

67

596

1,79

44

1001

47

957

49

913

51

869

54

825

56

781

59

737

61

694

64

650

66

606

1,80

44

1011

46

967

49

923

51

879

54

835

56

791

58

747

61

704

63

660

66

616

18

Appendix-A(2/2) Felt compaction table felt “new weights” 1150-1600 g/m2

cali-

1150

1200

1250

1300

1350

1400

1450

1500

1550

1600

per

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

comp.

st.

cap.

1,60

63

591

66

547

69

504

71

460

74

416

77

372

79

328

82

284

85

240

88

196

1,61

63

601

65

557

68

514

71

470

74

426

76

382

79

338

82

294

84

250

87

206

1,62

62

611

65

567

68

524

70

480

73

436

76

392

79

348

81

304

84

260

87

216

1,63

62

621

65

577

67

534

70

490

73

446

75

402

78

358

81

314

83

270

86

226

1,64

62

631

64

587

67

544

70

500

72

456

75

412

78

368

80

324

83

280

86

236

1,65

61

641

64

597

66

554

69

510

72

466

74

422

77

378

80

334

82

290

85

246

1,66

61

651

63

607

66

564

69

520

71

476

74

432

77

388

79

344

82

300

85

256

1,67

60

661

63

617

66

574

68

530

71

486

74

442

76

398

79

354

81

310

84

266

1,68

60

671

63

627

65

584

68

540

70

496

73

452

76

408

78

364

81

320

84

276

1,69

60

681

62

637

65

594

67

550

70

506

73

462

75

418

78

374

80

330

83

286

1,70

59

691

62

647

64

604

67

560

70

516

72

472

75

428

77

384

80

340

83

296

1,71

59

701

62

657

64

614

67

570

69

526

72

482

74

438

77

394

80

350

82

306

1,72

59

711

61

667

64

624

66

580

69

536

71

492

74

448

76

404

79

360

82

316

1,73

58

721

61

677

63

634

66

590

68

546

71

502

74

458

76

414

79

370

81

326

1,74

58

731

60

687

63

644

66

600

68

556

71

512

73

468

76

424

78

380

81

336

1,75

58

741

60

697

63

654

65

610

68

566

70

522

73

478

75

434

78

390

80

346

1,76

57

751

60

707

62

664

65

620

67

576

70

532

72

488

75

444

77

400

80

356

1,77

57

761

59

717

62

674

64

630

67

586

69

542

72

498

74

454

77

410

79

366

1,78

57

771

59

727

62

684

64

640

67

596

69

552

71

508

74

464

76

420

79

376

1,79

56

781

59

737

61

694

64

650

66

606

69

562

71

518

74

474

76

430

78

386

1,80

56

791

58

747

61

704

63

660

66

616

68

572

71

528

73

484

76

440

78

396

1,81

56

801

58

757

61

714

63

670

65

626

68

582

70

538

73

494

75

450

78

406

1,82

55

811

58

767

60

724

63

680

65

636

67

592

70

548

72

504

75

460

77

416

1,83

55

821

58

777

60

734

62

690

65

646

67

602

70

558

72

514

74

470

77

426

1,84

55

831

57

787

60

744

62

700

64

656

67

612

69

568

72

524

74

480

76

436

1,85

55

841

57

797

59

754

62

710

64

666

66

622

69

578

71

534

73

490

76

446

1,86

54

851

57

807

59

764

61

720

64

676

66

632

68

588

71

544

73

500

75

456

1,87

54

861

56

817

59

774

61

730

63

686

66

642

68

598

70

554

73

510

75

466

1,88

54

871

56

827

58

784

61

740

63

696

65

652

68

608

70

564

72

520

75

476

1,89

53

881

56

837

58

794

60

750

63

706

65

662

67

618

70

574

72

530

74

486

1,90

53

891

55

847

58

804

60

760

62

716

65

672

67

628

69

584

72

540

74

496

1,91

53

901

55

857

57

814

60

770

62

726

64

682

67

638

69

594

71

550

73

506

1,92

53

911

55

867

57

824

59

780

62

736

64

692

66

648

69

604

71

560

73

516

1,93

52

921

55

877

57

834

59

790

61

746

64

702

66

658

68

614

70

570

73

526

1,94

52

931

54

887

57

844

59

800

61

756

63

712

66

668

68

624

70

580

72

536

1,95

52

941

54

897

56

854

58

810

61

766

63

722

65

678

67

634

70

590

72

546

1,96

51

951

54

907

56

864

58

820

60

776

63

732

65

688

67

644

69

600

72

556

1,97

51

961

53

917

56

874

58

830

60

786

62

742

65

698

67

654

69

610

71

566

1,98

51

971

53

927

55

884

58

840

60

796

62

752

64

708

66

664

69

620

71

576

1,99

51

981

53

937

55

894

57

850

60

806

62

762

64

718

66

674

68

630

71

586

2,00

50

991

53

947

55

904

57

860

59

816

61

772

64

728

66

684

68

640

70

596

2,01

50

1001

52

957

55

914

57

870

59

826

61

782

63

738

65

694

68

650

70

606

2,02

50

1011

52

967

54

924

56

880

59

836

61

792

63

748

65

704

67

660

69

616

2,03

50

1021

52

977

54

934

56

890

58

846

60

802

63

758

65

714

67

670

69

626

2,04

49

1031

52

987

54

944

56

900

58

856

60

812

62

768

64

724

67

680

69

636

2,05

49

1041

51

997

53

954

56

910

58

866

60

822

62

778

64

734

66

690

68

646

2,06

49

1051

51

1007

53

964

55

920

57

876

60

832

62

788

64

744

66

700

68

656

2,07

49

1061

51

1017

53

974

55

930

57

886

59

842

61

798

64

754

66

710

68

666

2,08

48

1071

51

1027

53

984

55

940

57

896

59

852

61

808

63

764

65

720

67

676

2,09

48

1081

50

1037

52

994

55

950

57

906

59

862

61

818

63

774

65

730

67

686

2,10

48

1091

50

1047

52

1004

54

960

56

916

58

872

61

828

63

784

65

740

67

696

2,11

48

1101

50

1057

52

1014

54

970

56

926

58

882

60

838

62

794

64

750

67

706

2,12

48

1111

50

1067

52

1024

54

980

56

936

58

892

60

848

62

804

64

760

66

716

2,13

47

1121

49

1077

51

1034

54

990

56

946

58

902

60

858

62

814

64

770

66

726

2,14

47

1131

49

1087

51

1044

53

1000

55

956

57

912

59

868

61

824

64

780

66

736

2,15

47

1141

49

1097

51

1054

53

1010

55

966

57

922

59

878

61

834

63

790

65

746

2,16

47

1151

49

1107

51

1064

53

1020

55

976

57

932

59

888

61

844

63

800

65

756

2,17

46

1161

49

1117

51

1074

53

1030

55

986

57

942

59

898

61

854

63

810

65

766

2,18

46

1171

48

1127

50

1084

52

1040

54

996

56

952

58

908

60

864

62

820

64

776

2,19

46

1181

48

1137

50

1094

52

1050

54

1006

56

962

58

918

60

874

62

830

64

786

2,20

46

1191

48

1147

50

1104

52

1060

54

1016

56

972

58

928

60

884

62

840

64

796

2,21

46

1201

48

1157

50

1114

52

1070

54

1026

56

982

58

938

60

894

62

850

64

806

2,22

45

1211

47

1167

49

1124

51

1080

53

1036

55

992

57

948

59

904

61

860

63

816

2,23

45

1221

47

1177

49

1134

51

1090

53

1046

55

1002

57

958

59

914

61

870

63

826

2,24

45

1231

47

1187

49

1144

51

1100

53

1056

55

1012

57

968

59

924

61

880

63

836

2,25

45

1241

47

1197

49

1154

51

1110

53

1066

55

1022

57

978

58

934

60

890

62

846

2,26

45

1251

47

1207

49

1164

50

1120

52

1076

54

1032

56

988

58

944

60

900

62

856

2,27

44

1261

46

1217

48

1174

50

1130

52

1086

54

1042

56

998

58

954

60

910

62

866

2,28

44

1271

46

1227

48

1184

50

1140

52

1096

54

1052

56

1008

58

964

60

920

62

876

2,29

44

1281

46

1237

48

1194

50

1150

52

1106

54

1062

56

1018

57

974

59

930

61

886

2,30

44

1291

46

1247

48

1204

50

1160

51

1116

53

1072

55

1028

57

984

59

940

61

896

19

Appendix-B Compaction% vs Life days Yankee

day’s life

Appendix-C Compaction% vs Life days Yankee pick up felts (tissue)

day’s life

40

45

50

55

60

65

70

75

80

85

90

020 40 60 80 100

1st VN press, bottom

Suction pick up

2nd VN press

3rd / 4th VN press

40

45

50

55

60

65

70

75

80

85

90

020 40 60 80 100

Other manuals for Caliper Profiler

1

Table of contents

Popular Measuring Instrument manuals by other brands

Challenger Optics

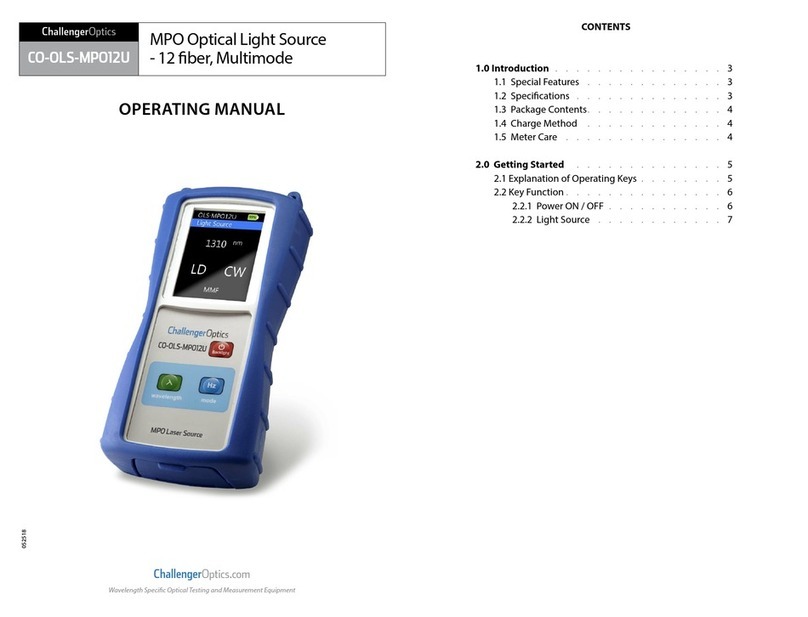

Challenger Optics CO-OLS-MP012 operating manual

WhisperPower

WhisperPower WBM Modular Smart Shunt installation manual

Aqualytic

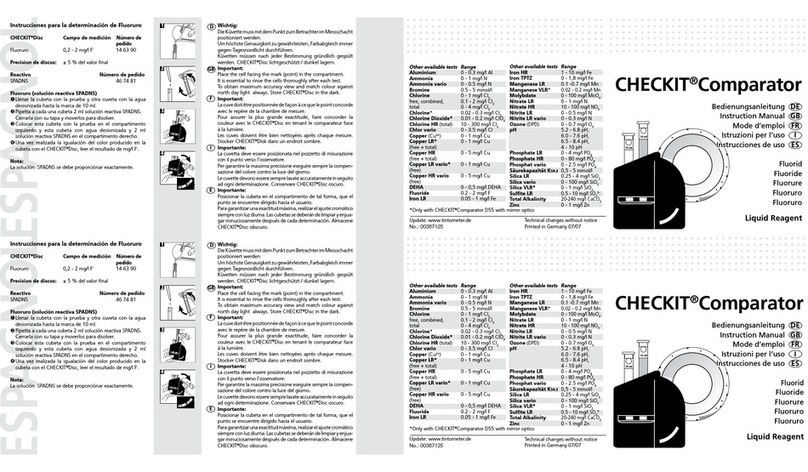

Aqualytic CHECKIT Comparator instruction manual

Challenger Optics

Challenger Optics CO-OLS-MPO12U operating manual

Electronics International Inc

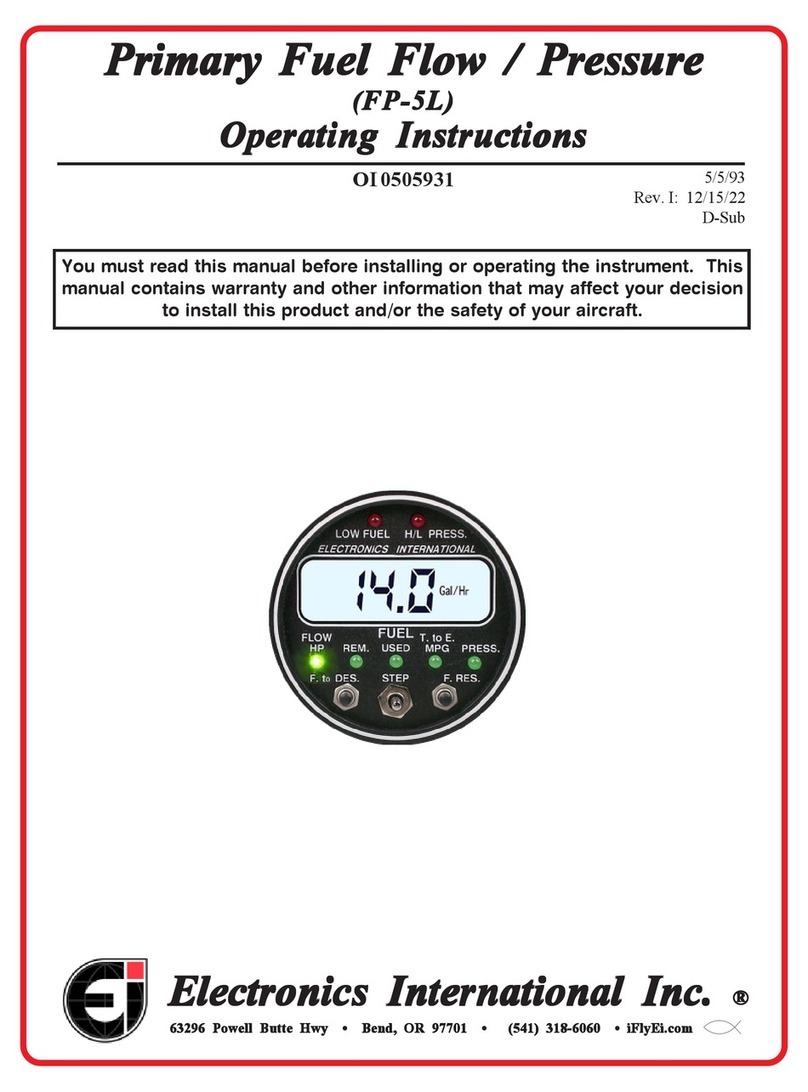

Electronics International Inc FP-5L operating instructions

Digistar

Digistar EZ 320 Operation & installation manual