Femtochrome FR-103MN User manual

FEMTOCHROME. RESEARCH, INC.

FR-103MN AUTOCORRELATOR

INSTRUCTION MANUAL

2123 4th Street Berkeley, California 94710 Tel (510) 644-1869 Fa (510) 644-0118

onnnil* to ^ h (3)fo n n tn ^ h rr% n n o r^r\m h tt r v //uaaAa/ fomtnr^hrnmA r.n m

TABLE OF CONTENTS

L Introduction

...............................................

.

2. Theory of Operation

..................................

.

3. Operating Instructions

a. Fundamental Characteristics

...........

b- lignment Procedure

......................

a lignment Hints

..............................

cL Wavelength Dependence

.................

e. Wide Scan Range/Scan Nonlinearity

f- Input Beam Polarization

................

g. Pulsewidth Calibration

......

.............

h. Major Optics lignment

.................

2

o 1 11 1 1

2

3

IX 1 X 1 A 1 A 1 A 1 L

Options

a. Crosscorrelation (/CC)

..........................................

b. Interferometric Option (flO)

......................

c. Fiber dapter (/F )

...............................................

.

d Fiber Coupled (/FC)

...............................................

e- Low Rep Rate Option (/LRR)

................................

f. Computer Data cquisition (/CD )

..........

g- VG Display Option (/VG )

............................

h- Extended Wavelength (IR) Options (/1000, /2000)

Spare Parts List

................................................

........

..

.

Warranty Information

The standard FR-103MN utilizes background-free (noncollinear) second harmonic generation

(SHG) for the measurement of the autocorrelation fimction of repetitive ultrashort laser pulses.

The unit can be set to crosscorrelate two synchronized pulses of different wavelengths.2

Collinear SHG (with background) with interferometric resolution is offered as an option(/IO),3

The Low Rep Rate Option4 (/LRR) renders the unit applicable for any rep rate (as low as 4Hz).

The optional Fiber dapter (/F ) or (/FC) facilitate easy alignment and repeatable connection of

fiber coupled beams. n optional /D board installed in the unit and its software (Computer

Data cquisition (/CD )),provides an interface (RS232) of the FR-103MN with a PC, resulting

in a complete pulsewidth monitoring system. lternatively,the NG option renders the unit

completely self-contained in a single package including a color TFT display.

1 For high resolution or best performance at a specific wavelength, a custom crystal

can be selected

2

3

See 3L Crosscorrelation

,

p. 14

See 4a. Interferometric Option, p. 16

See 4e. Low Rep Option, p.19

1. INTRO UCTION

The Model FR-103MN Rapid Scanning utocorrelator is a high resolution instrument for

continuous monitoring and display of femtosecond and picosecond laser pulses. While its

unprecedented resolution makes it ideal for fsec pulses from modelocked lasers with high peak

power,the instrument’s high sensitivity renders it perfectly suited also for long pulses with low

power. The operation ranges of the FR-103MN can be interchangeably selected as follows1:

FR-103MN/BBO (410-900 nm): BBO crystal (0.3 mm/60°)/VS Beamsplitter/VS PMT

FR-103MN/KDP (530-1070 nin): BBO crystal (0.3 mm/35°) ^S Beamsplitter/VS PMT

FR-103MN/IR (700-1800 nm): LiI03 crystal (1 mm/24°)/IR Beamsplitter/IR PMT

Note: The wavelength range of410-1800nm can be further extended into the IR region

optionally, by photodiode detector modules /1000 (1000-2000nm) and /2000 (2000-3000nm).

These options utilize the same optics as in the /IR version.

n appropriate set of fundamental blocking filters is included for each operating range.

The unique scanning mechanism6 of the FR-103MN provides a dispersion free scan range of

>60 psec with high linearity. Dispersion is eliminated through the exclusive use of high reflecting

metallic coated mirrors,with a focus in the nonlinear (NL) crystal obtained by means of a curved

mirror. The pulsewidth resolution is <5 fsec using an ultrathin (<0.05 mm) crystal.

2. THEORY OF OPERATION

The FR-103MN utilizes the SHG method of the 1st kind in the conventional Michel son

Interferometer set-up of pulsewidth measurement.5 In the standard configuration, noncollinear

beams lead to the background-free autocorrelation measurement Repetitive linear delay

generation in one arm of the Michelson arrangement is introduced by a pair of parallel (//)

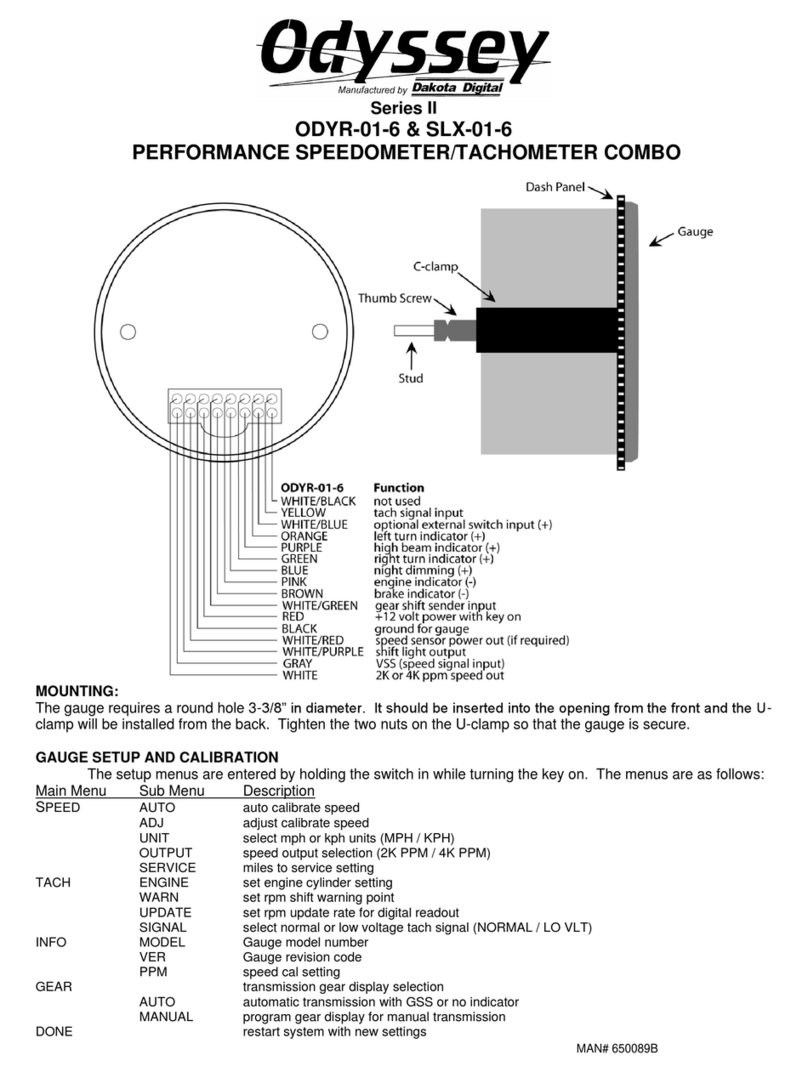

mirrors centered about a rotating axis.6 In the geometry of Figure 1,the rotation of the // mirror

assembly leads to an increase (or decrease) of path length for

汪

traversing beam.6 Thus,the

transmitted pulse train is delayed (or advanced) about the reference (zero delay) position. This

delay varies with time as a fixnction of the shaft’s rotation. For small angular changes, the delay

as a function of time is linear and given by6

T = { ^ . } t (1)

c v 1

where D is the distance between the // mirrors,f is the frequency of rotation,and c is the speed of

light.

Rotation of the // mirror assembly leads to a repetitive generation of linear delay which,used in

the described SHG configuration, provides a continuous display of the autocorrelation function

of the pulses on a conventional high impedance oscilloscope synchronized to this rotation.

5

6

E-P. Ippen and C,V. Shank, "Ultrashort Light Pulses/1 SX. Shapiro ed” New York:

Springer-Verlag (1977)

Yasa and R M mer,Optics Commun” V36,406 (1981)

The total scan range is given by6

^2d

I — c (2)

where d is the length of the scanning mirror.

Figure 1 Rotating Parallel (||) Mirrors

figure of nonlinearity over the full scan range is6

NL=d/4D (3)

In the standard configuration of the FR-103MN,the scan mirror has a size of d = 0.75n and the

mirrors are separated by a distance of D = 1.25”. The rotation frequency is f = 10 Hz. [f=5Hz

and 2.5Hz (or /LRR) are also selectable by a slide switch near the // mirrors.】 Hence, the

following numerical values follow from Equations (1)_(2):

T/t = 12.5 psec/msec [6,25ps/ms for 5Hz]

Tt = 75psec

3- OPERATING INSTRUCTIONS

3a. Fundamental Characteristics

The SHG autocorrelation function of an incoming train of ultrashort pulses is traced when the

SIGN L output of the FR-103 is input to a >20 MHz bandwidth (IM il) oscilloscope, triggered

externally by the TRIGGER output- The output signals and controls of the FR-103 are described

below.

G IN The high voltage applied to the PMT (photomultiplier) is varied over the range

of 0-1000 volts.

DEL Y The trigger pulse generated by a photointermpter is variably delayed using this

control. The introduced delay is in the range of 0.1-10 msec. This function can be

used to expand the time-base of the oscilloscope, for the observation of shorter

pulses. The smaller knob near this pot provides finer control of DEL Y.

SIGN L The SHG signal detected by the PMT is output through a preamplifier circuit.

The integration time of this circuit is selected by a five-position slide switch

(1 fsec — 1 psec),accessible on the back panel.

TRIGGER The trigger pulse from the photointerrupter (coupled to the motor) is output

through the delay circuit. The oscilloscope trigger channel should be set to:

EXT” NORM., and (+) SLOPE for proper synchronization. Initially, timebase

setting should be lmsec/div or 2msec/div.

TRIG. SELECT slide switch near the DEL Y pot on the front panel disables DEL Y

when set in Pos.#0. In Pos.#l & 2 the trigger DEL Y is functional*

Notes:

1 • In the factory setting of the FR-103MN,the TRIG SELECT switch is set to “0

and the autocorrelation trace peak occurs right at the (+) edge of the DEL Y

disabled trigger pulse,set about a central position of the full scan range. [The

reading of the T-stage micrometer for this setting is indicated on it.]

This is the normal recommended mode of operation.

SPEED SELECT slide switch,accessible inside the right back comer, selects 3 motor speeds

for the // mirror assembly: 10Hz/5Hz/2.5Hz. The calibration factor,given in

the manual for 10Hz,is proportional to the motor speed. E.g. for 5Hz,the

calibration factor is 6.25ps/ms.

Scan Range: >7 5 psec

Resolution9: <5 fsec

Delay Calibration Factor (T/t): 12.5 psec/msec( 10Hz). The exact value of this factor has a weak

dependence on the position of the pulse peak within the delay window (scan range).

Experimentally,the instrument is calibrated by micrometer translation of the comer

mirror,as described in Section 3g.

Sensitivity: Depending on the operation wavelength and the characteristics of the

NL crystal, an average input power (Pav) of a few mW is typically sufficient.

Using an optimal crystal,the noise equivalent signal level can be as low as

PpkPav= 0.2 x 1 O^W2, where Ppk is the peak power.

Minimum Pulse Repetition Rate: For pulse repetition rates <1 MHz, the autocorrelation trace

displays dips due to the vanishing of the signal between pulses. However,the trace

envelope corresponds to the autocorrelation function even for lower pulse repetition

rates. In general,a higher minimum pulse repetition rate is needed for shorter pulses,for

direct observation on a real time oscilloscope. For lower rep rates,/LRR needs to be

used.

The basic properties of the FR-103MN can be summarized as follows:

Resolution is limited only by the SHG crystal thickness,which is specified by the

customer* The standard crystal thickness is 0.3mm, giving a resolution of

〜

15fs. Using a

thinner (<0.05mm) crystal,a resolution <5fs can be achieved.

3b. Alignment Procedure

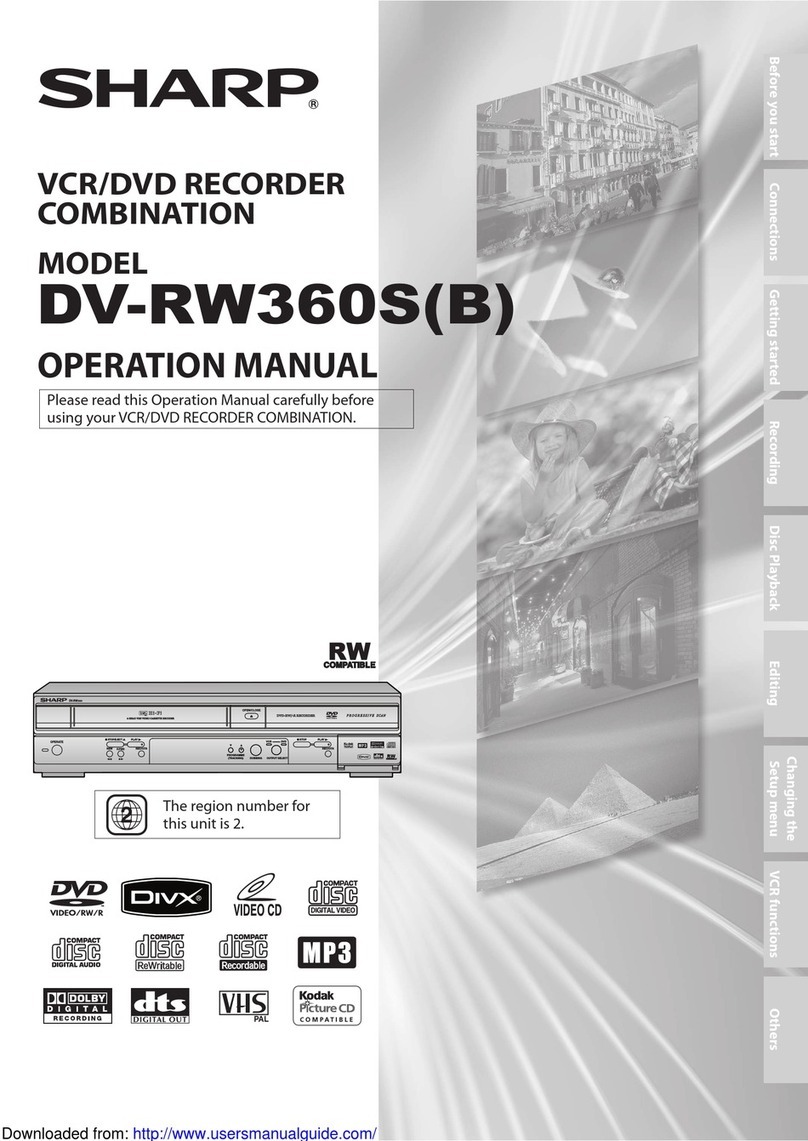

The standard optical schematic of the FR-103MN is sketched in Figures 2 and 3. [When

/FA(CC) Option is included, the alternate beam configuration described in section 4.a is

applied. In this case, the delayed and fixed beams described below are reversed. See

Sect.4a] The beams lie mainly in the horizontal plane through the centers of Ml and the input

aperture. Most of the optical components are factory aligned and need not be reset. Described

below,the adjustment of the FR.103MN for proper operation is straightforward.

<

Corner-fiiirror

retrorefledor

M2 Second

Harmonic

-* -

M1

Angle tuned

SKfG cry tal

Beam

plitter

><- M3

♦

Figure 2 FR-103MN Top View Schematic

SHG cry tal

Aperture Fundamental

blocking filter

Figure 3 FR-103MN Side View Schematic

(i) Direct the vertically polarized input beam through the center of the input aperture and orient

the FR-103 (by lateral movement and/or using the level adjustment knobs) such that the

incoming beam is incident on Ml slightly left of center (looking from the front side). The return

beam from the comer mirror will form a spot on Ml symmetrically displaced to the right by 6-7

mm. Typical positions of the beam spots are illustrated in Figure 4. Lateral movement of the

FR-103 will adjust the separation between the incident and return beams to an optimal value of

4_5mm.

M2

Incident

beam pot Return beam

pot from

comer mirror Beam pot

from rotating Beam pot from

corner mirror

mirror

Figure 4 Beam Spots on Ml and M2

(ii) When the described alignment is set,the retroreflected beam from the comer mirror

(fixed beam) forms a spot on the PMT housing displaced to the right of the aperture by typically

2 mm (vertical mark) and centered between the indicated horizontal marks,as depicted in Fig 5.

Note that the exact beam positions on Ml and M2 is not critical, and it is only required to

center the beam at the input aperture and adjust the FR-103 sideways and height-wise, so

that the fixed beam forms a spot at the PMT as shown in Fig.5.

(iii) The beam from the delay arm of the Michelson Interferometer is retroreflected by the end

mirror M3, the control knobs of which are located on the right side of the FR-103. On

攀

retroreflection,this beam overlaps with the fixed beam in the crystal and forms a spot on the

PMT housing symmetrically displaced to the left of the aperture. (Figure 5)

Spot from Fundamental

delayed beam / blocking filter (inside)

PMT

Hou ing

Entrance aperture

for 2nd harmonic

Spot from

fixed beam

Figure 5 Front View of PMT Housing

(iv) lignment of M2 is controlled by three fine adjustment screws. Two of these,

orthogonally about the central one,render vertical and horizontal tilts. The central screw causes

mirror translation and thereby focus adjustment. The factory set controls of M2 should not need

to be readjusted. i

(v) Vertical alignment of the beam spots is easily accomplished using the levelling knobs of

the instrument. If tiie beam from the retroreflector is low (or high), then raise (or lower) the

back. (Figure 6)

Lower Back Raise Back

Beam spot from

corner mirror

Figure 6 Vertical lignment of the Beam Spot

(vi) Lateral movement of the FR-103 (while maintaining centering of the incoming beam at

the input aperture) adjusts the beam spacing at the PMT housing. (Figure 7) Optimal adjustment

will locate the two beam spots w/ 4-5mm in between, on either side of the aperture.

Sideway movement

adju t thi pacing

Figure 7 Horizontal lignment of the Beam Spot

(vii) The 2nd harmonic is generated (when the NL crystal is phase matched by angle tuning

,

i.e. rotation of the front panel micrometer) in the direction bisecting the two beam paths,and

therefore is incident on the PMT aperture.

(viii) The SHG crystals are generally hygroscopic. For maximum resolution,the crystals are

provided without windows but with single layer MgF2 R coatings which yield good protection

against exposure to H20. desiccator is also provided as a cover,for long term reliability of the

NL crystal. During an experiment, the desiccator is removed and placed beside the crystal

assembly- When the unit in not in use,this cover should be kept on the crystal to minimize its

exposure to humidity and dust. The desiccant must be periodically replaced as necessary.

(ix) The beamsplitter and Ml alignments are factory set and need not be readjusted unless a

major misalignment occurs. In such

迁

case,refer to Section 3h.

(x) filter transmitting the second harmonic and attenuating the fundamental is placed inside

the screw-on stub containing the aperture, on the PMT housing. It may be necessary to change

this filter if a major change of wavelength takes place. The unit is supplied with a standard set of

filters covering the wavelength range of operation.

3c. Alignment Hints

s described in the previous section,the factory set controls of the optical elements (Ml

,

M2 and

Beamsplitter) do not need to be readjusted. In order to obtain the autocorrelation ( C) signal,it

is only necessary to have (i) a vertical input polarization

,

(ii) NL crystal micrometer adjusted for

the correct phasematching angle and (iii)beams overlap in the crystal (which is adjustable by the

two large external knobs on the right hand side (RHS) which control M3). If the signal is not

easily observed,with the input beam is properly aligned as described in Sec.3b” the steps below

should be followed:

(1) Ensure that the input polarization is vertical and proper fundamental blocking filter for the

wavelength of operation is installed behind the PMT aperture stub. If provided,remove the IR

sensor cap off the PMT aperture.

(2) Using the horizontal control of M3 ( RHS top knob) steer the delayed beam directly into the

PMT aperture. Use lms/div

,

EXT, NORM, trigger w/ (+)SLOPE on the scope. With some G IN

on (depending on the input level) and adjusting the crystal micrometer, a square signal (about

6ms) should be observed at the correct phasematching angle. The (+) edge of the DEL Y

DIS BLED [“0"] is about the center of this observed scan range. 、

[ t this step,depending on the PMT response at the fundamental operation wavelength and the

duty cycle of the pulses, there may be some linear response (signal independent of the ciystal

angle) which may need to be further filtered out with an additional external fundamental blocking

filter. Such a linear response will also be observed if the IR sensor cap provided (which

upconverts the fundamental) is kept on the PMT aperture.]

(3) If a fiber coupled beam is being used (w/FA), it is necessary to control input

polarization for vertical, simultaneously with the phase matching angle.

(4) Once this square SHG signal (vanishing outside a narrow range of the x’tal micrometer) is

observed, adjust and fix input polarization at maximum signal. Note the micrometer reading,

(5) Move the delayed beam to its proper position (left side of the PMT aperture, symmetrical to

the fixed beam spot),using the horizontal M3 control knob on the RHS.

10

(6) Turn the x’tal micrometer counterclockwise slightly (about half a turn)-

(7) Carefully readjust the two RHS external knobs of M3 (which steer the delayed beam vertically

and horizontally), until the C signal is observed. t this step,the beams overlap in the NL x’tal

is to be obtained and an incremental step by step procedure may need to be carried out. The C

trace peak will appear within the ~6ms window defined by the square pulse observed in step(2)?

depending on the setting of the comer-mirror T-stage micrometer.

(8) That the correct C signal is being observed should be checked by (i) vanishing of the signal

outside a narrow range of the NL x’tal mike,and (ii) vanishing of the signal when the fixed beam

is blocked (by means of e.g* a piece of paper in front of the comer-mirror T-stage).

(9) Once the C signal is observed, x’tal micrometer, the two RHS knobs and input polarization

should be readjusted for a maximum signal The T-stage micrometer can be adjusted to center the

trace peak within the

〜

6ms scan range.

3d. Wavelength ependence

The phase matching angle for the NL crystal,for any given wavelength,is adjustable by the front

panel micrometer. The rotational stage the NL crystal is mounted on allows a wide range of

angles, and provides for a single standard NL crystal to readily angle tune over its entire

wavelength range.

3e. Wide Scan Range/Scan Nonlinearity

The delay range of the FR-103MN is proportional to the mirror size used in the // mirror

assembly. For long pulsewidths, the effect of scan nonlinearity needs to be taken into account The

pulse delay,as the // mirrors rotate,is a sinusoidal function of the rotation angle (time), and linear

only for small angles. It can be shown that6, to 3rd order,the pulsewidth measured must be

multiplied by the factor [l^CFWHM/lOO)2^], where FWHM is the foil width at half max of the

trace measured in msecs,to yield the actual pulsewidth. Therefore,even for a pulsewidth as long

as 25 psec (FWHM = 5 msec),the pulsewidth measurement error due to scan nonlinearity is

<0.5%.

3f. Input Beam Polarization

The FR-103 is set for a vertical input beam polarization. [It is also possible to convert the unit for

use w/ a horizontal input polarization' However, this is not recommended, since

迁

horizontally

polarized input beam is incident on the pellicle beamsplitter as P-polarized. This orientation

results in lower beam intensities incident on the crystal,since in general,the reflectance of the

beamsplitter is lower for P-polarization than S-polarization (vertical input polarization). The 2nd

harmonic generated for horizontal input polarization is therefore as much as ten times less than for

vertical input beam polarization,this factor being wavelength dependent. Please consult factory

for operation w/ a horizontal input polarization.]

11

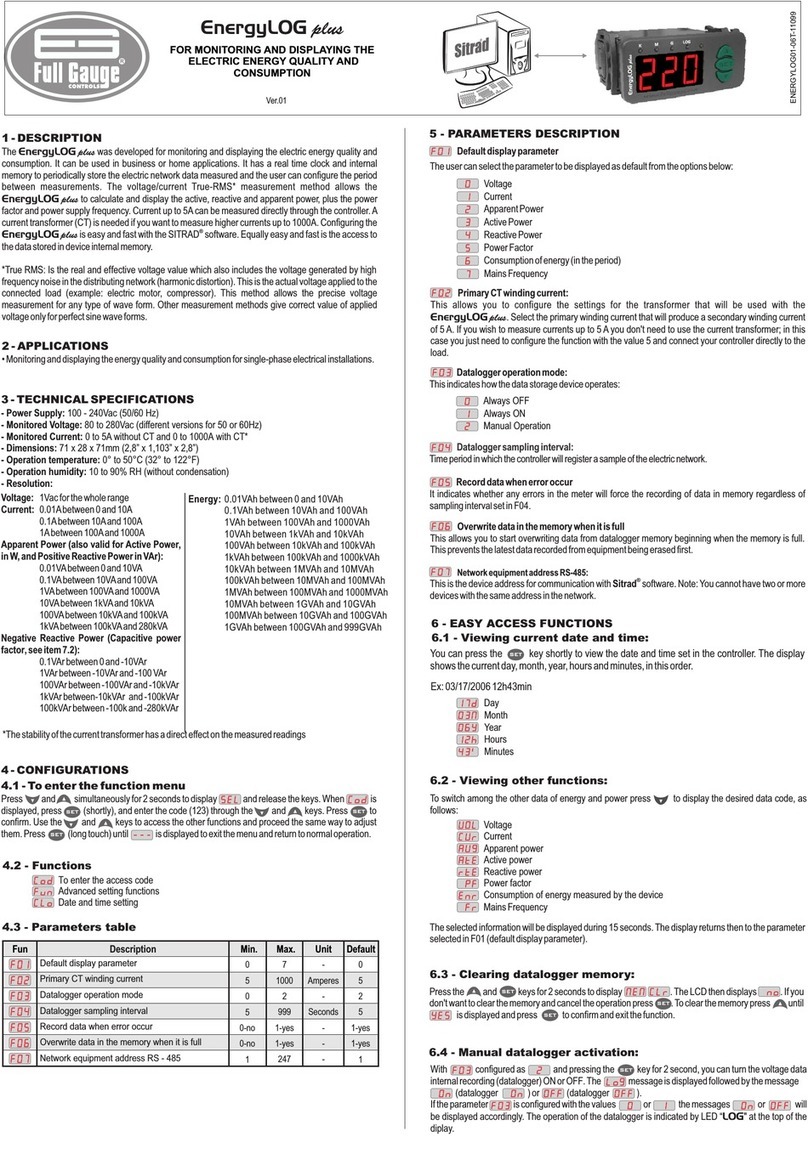

3g. Pulsewidth Calibration

Calibration of the FR-103 can be determined by translation of the micrometer driven retroreflector

stage in the stationary aniL For a given translation x,the corresponding shift s in the position of

the trace peak (Figure 8) yields the calibration factor using the conversion formula

T 2

—=

-----

(psec/msec) ⑶

t 0.3^

where x is in mm and s is in msec. The result will be found to be close to the theoretically

calculated value of 7.5 psec/msec. However, there is a weak dependence of the calibration factor

on the position of the pulse peak within the scan range. Therefore,the exact experimental

calibration factor must be determined by the translation of the comer-mirror forward and

backward about a given measurement position and the mean value of the two corresponding

calibration factors determined must be used.

_ ( —

Figure 8 Comer Mirror Translation x (mm) and trace shift s (msec)

The conversion from the FWHM autocorrelation trace width ( T) to the FWHM pulsewidth ( t)

is a function of the assumed pulse shape. In Table 1

,

t/ T is given for commonly used pulse

shapes.

Pulse Shape t/ T

Hyperbolic Secant Sech2 (1.763t/ t)

Gaussian Exp [-2.77 (t/ t)2]

Single-Sided Exponential

0.648

0,707

0.5

Table !• Relationship between autocorrelation width and pulsewidth for various pulse shapes.

3h. Major Optics Alignment

Realignment of the pellicle beamsplitter (PBS) and the fold mirror Ml may be necessary if either

component has been moved.

Fold Mirror (Ml) Alignment

(i) Direct the input beam,using the level adjustment knobs and/or lateral movement of the

FR-103, such that it is incident on Ml slightly to the left of center as depicted in Figure 4.

(ii) Using a small screwdriver, carefully adjust the vertical and horizontal control screws on

M1 such that the return beam from the comer mirror forms a spot at a symmetrically opposite

position, as depicted in Figure 4.

Beamsplitter Alignment

The ultrathin (

〜

l^xm) pellicle beamsplitter used in the FR-103 must be handled with extreme

caution. THE PBS CANNOT BE CLEANE BY CONVENTIONAL METHO S. Keeping

the plastic cover over the PBS mount when the unit is not in use will minimize the accumulation

of dust on the pellicle surfaces,eliminating the need for cleaning. If absolutely necessary, a gentle

flow of dry air can be tried.

lignment of the PBS is achieved as follows: With the input beam properly directed and Ml

correctly aligned, the beam returned by the comer mirror should form a spot on M2 as described

in Figure 4. djustment of this beam position is controlled by the horizontal and vertical tilts of

the PBS. Vertical control is reached from above using a screwdriver. Horizontal control is

achieved by loosening two 4-40 screws holding the PBS mount and readjusting it. The return

beam retroreflected from the // mirrors can be blocked out during this procedure. When the rotor

is set in a scan position and M3 is properly adjusted for retroreflection (by means of the external

right side panel knobs),the delayed beam forms a symmetrical spot on M2. (Figure 4) The focus

mirror vertical and horizontal controls (on the left side panel) may need to be readjusted to set the

two beams symmetrical about the PMT aperture.

13

4.0PTI0NS

4a« Crosscorrelation

The FR-103MN can readily be used to crosscorrelate ultrashort pulses from two separate beams*

The second beam for crosscorrelation (CC) is introduced thru,the center of the opening in the

right side plate.( fiber adapter [/F (CC)] can be installed at this port, also.)

Note: The zero position of relative delay (ZPD) needs to be externally adjusted For the

midrange of the comer-mirror T-stage,the pathlength to the crystal for the 2nd beam is

about 50mm longer than the middle position of the scan range for the 1st beam,measured

from their respective entrance faces of the FR-103MN-[ Externally,the pathlength for the

1st beam should be longer by this amount (

〜

50mm)].

The FR-103MN can be set for crosscorrelation,as follows:

(i) The first beam is incident at the front aperture with the unit aligned as for autocorrelation ( C)

(position [1] of comer mirror in Figure 9 below).

【2】

m

2nd beam

Fixed 1 t beam

(autocorrelation) [1] Fixed 2nd beam

(cro correlation) [2]

€

---------------------------------------------------------------------

Delayed 1 t beam< r

/ v/

Tran mitted 1 t

beam (not u ed) [2]

BeamSpIitter

Retroreflected

delayed 1 t beam

1 st beam

Figure 9 FR-103MN Schematic of Crosscorrelation Operation

(ii) The comer mirror is tiien shifted by

〜

1/4” to position [2] such that the first beam is transmitted

at the back side of ML The second beam is introduced (after removing the plug) through the

aperture on the Right Side Panel,in a direction opposite but parallel to the first (with a shift of

〜

1/4"),such that it is translated by the comer mirror to traverse the first beam’s path in

autocorrelation.

14

5. Set the integration time constant switch to 1 fsec, and the motor speed to lowest (2JHz).

6. Fringe resolved autocorrelation will now be observed,when the retroreflecting mirror on the

// mirrors side is properly aligned using the control knobs on the Right Side Panel,

7. The beams can be given a small vertical deflection off the perfect retroreflection condition.

This prevents feedback to the laser without affecting interferometric operation. The beams going

back towards the laser form secondary spots on the semi-closed variable input aperture of the FR-

103 • These beams (from the two Michelson amis) should be set to overlap above or below the

main incident beam which enters the center of the input aperture.

j

8. Since the 1 fsec position has low gain and integration, sufficiently fiigh beam power may be

needed, depending on the pulsewidth^ wavelength^ and crystal type. small percentage of the

output of a typical modelocked Ti

辆

Sapphire laser is usually sufficient using the KDP crystal.*

»

9. When the comer-minor is installed back for noncollinear (backgromiiPfiree) operation,it should

be positioned such that the edge of its mount lines up with a scratch marked on the T-stage.

1.The FR-103 is aligned for the standard noncollinear (background free autocorrelation)

operation, with the retroreflecting comer mirror in its proper position on the translation stage.

. -

2.The comer-mirror is then removed and the Interferometric Option is mounted on the T-stage,

广

using mounting threads closest to the micrometer driving it. lignment screws of the /IO mount

are accessible from the Left Side Panel through two l/4ff holes.

3- lign the interferometric plane mirror to retroreflect the incident beam [factory aligned].The

beams from the two arms of the Michelson will then be overlapping and collinearly incident on

the NL crystal.

4. Direct the common spot of the two beams into the PMT aperture using the focus mirror

horizontal adjustment screw. Effective filtering of the fundamental is more critical in this mode

since the fiindamental is not spatially blocked out as in the noncollinear operation. It may be

necessary to use an additional fundamental blocking filter externally,depending on wavelength.

4b. Interferometric Option (/IO)

Table of contents

Popular Measuring Instrument manuals by other brands

Dewetron

Dewetron DEWE-CAM-GIGE-SPLIT-01 Technical reference manual

VWR

VWR MD 8000 L operating manual

palintest

palintest MICRO 500 operating instructions

Endress+Hauser

Endress+Hauser Proline t-mass 65 operating instructions

ElektroPhysik

ElektroPhysik QuintSonic 7 Technical manual and operating instructions

PCB Piezotronics

PCB Piezotronics P357A09/NC Installation and operating manual