Fenner K Series Manual

www.fptgroup.com

Fenner is a registered Trade Mark of Fenner PLC

All Dimensions are in Millimetres unless otherwise stated

Head Office: Amber Way, Halesowen,West Midlands. B62 8WG

w w w . f p t g r o u p . c o m

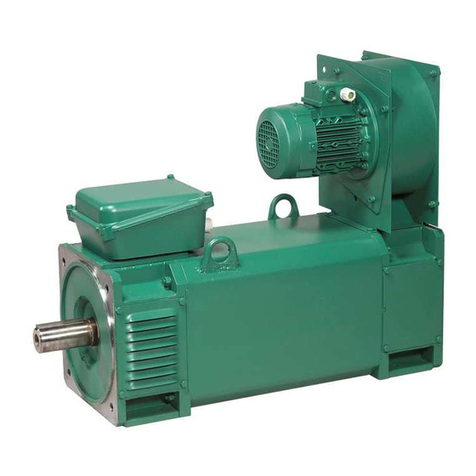

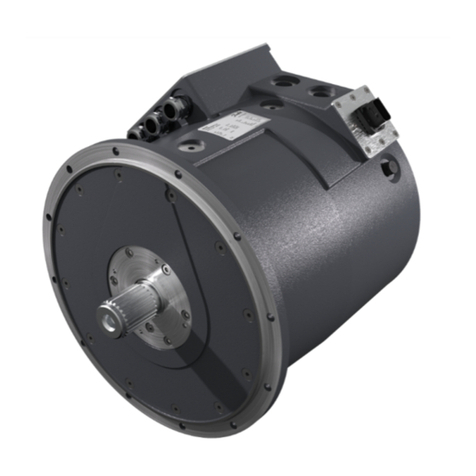

SERIES K

GEARMOTORS

Installation and Maintenance

RECOMMENDED OIL GRADES

4

IMPORTANT HEALTH & SAFETY

INSTALLATION LEAFLETS

Satisfactory performance depends on proper installation, lubrication

and maintenance. All instructions given in the installation leaflet must

be followed carefully.

LUBRICATION

Sizes 890 to 893 will be supplied with a quantity of EP mineral oil

(Shell Omala 320) for mounting position B3. Other mounting must

be specified on order. However if , as requested, the unit is sup-

plied without lubricant then the oil quantity is obtained from Tables

1 & 2. Sizes 894 to 898 are supplied without oil. Before running

they should be filled with an appropriate amount of the correct

lubricant shown in the tables 1 & 2, dependent on the mounting

position, see below.

WARNING Do not overfill as excess lubricant may cause over-

heating and leakage.

OIL CHANGES

Sizes 890, 891 and 892 are lubricated for life except when

the units are required to work in an explosive atmosphere

(94/9/EC Atex 100a Group II category 2 zones 1 & 21 & category

3 zones 2 & 22) See separate leaflet for recommendations.

All other sizes will require an oil change depending on the unit

operating temperature. Initial fill of oil should be changed in a new

gear unit after 1000 hours operation or one year or half the life in

the table opposite whichever is the soonest.

PERIODIC INSPECTION

Check oil level every 3000 hours or 6 months whichever is sooner

on sizes 893 to 898 and if necessary top up with the recommend-

ed grade of lubricant.

TABLE 2. LUBRICANT QUANTITY (LITRES)

QUINTUPLE REDUCTION

Mounting Position

Unit B3 V5 V6 B8 B7 B6

Size Primary Secondary Primary Secondary Primary Secondary Primary Secondary Primary Secondary Primary Secondary

890 0.7 0.8 0.7 1.0 0.7 1.0 0.7 1.3 1.0 1.7 1.1 1.0

891 0.7 1.0 0.7 1.3 0.7 1.3 0.7 1.7 1.0 2.1 1.1 1.3

892 0.8 1.5 0.8 1.85 0.8 1.85 0.8 2.4 1.4 3.1 1.5 1.9

893 0.8 1.7 0.8 2.8 0.8 2.8 0.8 3.3 1.4 4.2 1.5 2.9

894 0.8 3.5 0.8 5.8 0.8 5.8 0.8 9.1 1.4 10.4 1.5 9.1

895 1.6 4.5 1.6 9.3 1.6 6.2 1.6 9.1 1.9 10.4 2.5 9.1

896 1.6 8.8 1.6 15.0 1.6 15.0 1.6 17.5 1.9 20.9 2.5 16.3

897 2.8 14.0 2.8 24.0 2.8 24.0 2.8 28.6 3.2 33.0 4.9 25.6

898 2.8 22.0 2.8 36.0 2.8 36.0 2.8 41.0 3.2 49.0 4.9 35.9

Primary units are filled with Shell Omala 320 and are suitable for all ambient temperatures between 0 and 35 C.

TABLE 1. LUBRICANT QUANTITY (LITRES)

TRIPLE REDUCTION

890, 891 & 892 - fill with the correct quantity of lubricant.

893 to 898 - fill gearbox until oil escapes from level plug

Unit Mounting Position

Size B3 B6 B7 B8 V5 V6

890 0.8 1.0 1.7 1.3 1.0 1.0

891 1.0 1.3 2.2 1.7 1.3 1.3

892 1.5 1.9 3.1 2.4 1.85 1.9

893 1.7 2.9 4.2 3.3 2.8 2.8

894 3.5 5.8 8.7 6.8 5.8 5.8

895 4.5 9.1 10.5 9.1 8.0 8.0

896 8.8 16.3 21 17.5 15 15

897 14 25.5 33 28.6 24 2

898 22.0 36 49 41 36 36.0

All Quantities are approximate.

LUBRICANT TYPE TEMPERATURE RANGE

ISO Ambient Temperature °C

Viscosity -5°C to 20°C -30°C to 20°C 0°C to 35°C 20°C to 50°C

EP Mineral Oil 220 - 320 460

Synthetic Oil 1 - 220 220 320

Synthetic Oil 2 - 220 320 460

Synthetic Oil 1 = Polyalphaolein based.

Synthetic Oil 2 = Polyglycol basrd

Supplier Mineral Oils Containing Synthetic Lubricants Synthetic Lubricants

EP Additives Polyglycol Based Polyalphaolefin based

BP Energol GR-XP or XF Enersyn SG-XP Enersyn EPX

Castrol Alpha Max or SP Alphasyn PG Alphasyn EP or T

Esso Spartan EP Glycolube Spartan Synthetic EP

Fuchs Renogear V or WE Renolin PG Renogear SG

Mobil Mobilgear 600 Glygoyle Mobilgear SHC

Shell Omala or Omala F Tivela or Tivela S Omala HD

Texaco Meropa or Meropa WM Synlube CLP Pinnacle EP

Total Carter EP Carter SY Carter EP/HT

Rocol Sapphire Hi-Torque - -

Unit Operating Renewal Period (Hours)

Temp C Mineral Oil Synthetic Oil

75 or less 17000 or 3 Yrs 26000 or 3 Yrs

80 12000 or 3 Yrs 26000 or 3 Yrs

85 8500 or 3 Yrs 21000 or 3 Yrs

90 6000 or 2 Yrs 15000 or 3 Yrs

95 4200 or 17 Mths 10500 or 3 Yrs

100 3000 or 12 Mths 7500 or 2.5 Yrs

105 2100 or 8 Mths 6200 or 2 Yrs

110 1500 or 6 Mths 2100 or 18 Mths

OIL RENEWAL TABLE

www.fptgroup.com

Fenner is a registered Trade Mark of Fenner PLC

All Dimensions are in Millimetres unless otherwise stated

Head Office: Amber Way, Halesowen,West Midlands. B62 8WG

w w w . f p t g r o u p . c o m

SERIES K

GEARMOTORS

Installation and Maintenance 4

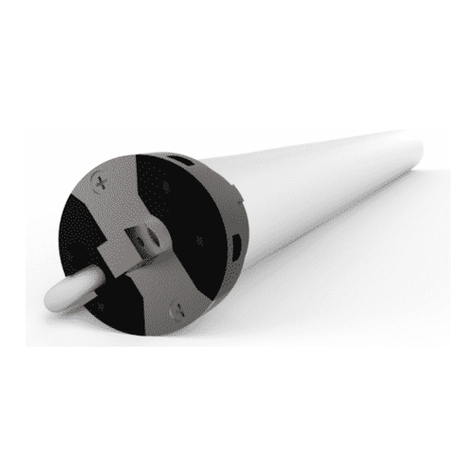

MOUNTING POSITIONS

Plug positions apply for sizes 893 and larger.

Ventilator/Filling Position Level Position Drain Position

SHAFT MOUNTING

Ensure that the shaft on to which the gear unit is to be mounted

and the gear unit bore are clean and free from burrs.

Liberally smear the shaft and bore with lubricants to aid

assembly and prevent fretting corrosion. Slide the unit on to the

driven shaft. Fit side fitting key. DO NOT USE TAPER OR TOP

FITTING KEY.

FOOT OR FLANGE MOUNTING

The Fenner series K is designed primarily as a shaft mounted

gearbox, however if a customer wishes to use the unit in the foot

mounted position all sizes have pre-cast feet built in to the gearcase

for mounting in the B3 position. Series K can also be used as a

flange mounted unit, standard output flanges area available as acces-

sories. Consult you local Authorised Distributor for details. Use the

tightening torques listed below for holding down bolts.

Clean shaft extensions and ventilator where fitted

The shafts of the unit and driven equipment should be in as perfect

alignment as possible. Fenaflex®couplings should be used when

shaft alignment cannot be assured and also when protection from

peak and vibrating torques are desirable. Ensure the base foundation/

flange mounting surface is flat*, vibration and torsionally rigid.

The drive should be mounted on a rigid support and bolted down

firmly using set screws to ISO grade 8.8 minimum. Ensure that ma-

chined mounting points are supported over their full area. If packing

is to be used, place either side of the mounting bolt. During the final

bolting down ensure the unit and/or baseplate are not distorted to

maximise unit performance.

For units mounted on bedplates, dowel two diagonally opposite feet

in to position.

Fit all guards required to comply with the factory acts, check the mo-

tor wiring for correct direction of rotation and check oil levels.

*Maximum permissible flatness error for mounting surface is 0.12mm.

MOTOR CONNECTIONS TO MAINS

Connection of the electric motor to the mains supply should be

made by a qualified person.The current rating of the motor will be

identified on the motor plate and correct sizing of the cables to

electrical regulations is essential.

STARTING UP

Prior to starting up the following procedure should be followed

1. Ensure Ventilator is fitted ( size 893 and above

2. Check Oil level (893 and above) top up if necessary

3. Ensure all safety devices are in place (i.e. guards fitted)

4. Remove any safety devices fitted to prevent machine rotation

Starting up should be performed or supervised by suitably quali-

fied personnel.

BREATHERS/MOUNTING POSITIONS

Sizes 890,891 & 892 are supplied for operation without breathers.

Size 893 is supplied for operation with a breather but to prevent

leakage during transit this unit is fitted with blanking plugs. It

is essential that when the unit is in its operating position the

relevant blanking plug is removed and replaced by the breather

plug (supplied) in the position indicated on the installation leaflet.

Sizes 894 to 898 are supplied for operation with a breather but are

despatched without oil.

It is essential that when the unit is in its operating position the

relevant blanking plug is removed and replaced by the breather

plug (supplied) in the position indicated on the installation leaflet.

1. Ensure Ventilator is fitted (size 893 and above)

2. Check Oil level (893 and above) top up if necessary

3. Ensure all safety devices are in place (i.e. guards fitted)

4. Remove any safety devices fitted to prevent machine rotation

Starting up should be performed or supervised by suitably quali-

fied personnel.

Ceiling Mounted (B8)

Left Hand Wall Mounting (B6)

Vertical Mounting Shaft Up (V6) Flange Mounting Shaft Up (V3)

Vertical Mounting Shaft Down (V5) Shaft Down Flange Mounting (V1)

Right Hand Wall Mounting (B7)

Standard Floor Mounted (B3)

Set Screw Foot & Output Motors to

Size Flange Bolts Gearhead

Torque (Nm)

M6 10 10

M8 25 18

M10 50 37

M12 85 64

M16 200 150

M20 350 260

M24 610 -

M30 1220 -

M36 2150 -

SERIES K - GEARBOXES

8

284 Drive Design & Maintenance Manual - FEN01/10

Dimensions Motorised

SIZE a a2 a3 b b0 c e f f0 h h1 k n n0 o

890 100 28 32 110 115 11 120 143 152 100 16 38 38 60

891 120 35 37 130 130 16 145 168 171 112 13 38 40 75

892 130 30 45 130 150 15 157 170 192 132 5 40 40 83

893 140 30 45 120 160 20 170 176 208 140 13 For k 55 48 90

894 165 40 55 150 200 27 200 210 263 180 25 dimensions 60 55 105

895 180 55 70 180 233 30 230 256 309 212 15 see facing 76 76 120

896 240 75 75 240 295 35 290 340 395 265 10 page 100 100 150

897 270 95 95 280 360 40 340 390 455 315 41 110 115 175

898 330 115 110 350 420 45 400 470 540 375 65 120 120 205

SIZE p3 q q1 s v2 v4 w7 y z D m m1 m2 m3 T U v3

890 167 63 159 11 76 - 63 140 0.0 30 52.5 120 105 30.3 33.5 8 M10X50L

891 187 71 179 11 76 - 78 140 2.5 35 66.0 150 132 35.3 38.5 10 M12X55L

892 217 80 219 14 91 - 87 180 4.5 40 73.0 166 142 40.3 43.5 12 M16X70L

893 233 90 229 14 91 - 94 180 5.0 40 80.0 180 156 40.3 43.5 12 M16X70L

894 288 112 265 18 91 - 109 212 5.0 50 92.5 210 183 50.5 54.0 14 M16X70L

895 341 132 330 23 115 - 124 250 5.0 60 105.0 240 210 60.5 64.5 18 M20X80L

896 420 160 355 27 115 - 154 300 5.0 70 132.5 300 270 70.5 75.0 20 M20X80L

897 513 200 423 34 140 155 180 360 5.0 80 155.0 350 313 80.5 85.5 22 M20X80L

898 590 225 476 39 140 155 210 400 5.0 100 180.0 410 373 100.5 106.5 28 M24X110L

TRIPLE REDUCTION

QUINTUPLE REDUCTION

* for motor dimensions

see page 307

* for motor dimensions

see page 307

Section

SERIES K - GEARBOXES

8

GEARBOXES

FEN01/10 - Drive Design & Maintenance Manual 285

Dimensions Motorised

Motor Frame Dimension k

Size 890 891 892 893 894 895 896 897 898

63 442 470 535 555 614 728 789

71 446 474 539 559 618 731 795

80A 459 487 552 572 631 749 813 952 1078

90S 469 497 562 582 641 759 823 962 1088

100L 458 486 551 571 630 786 850 973 1099

112M 458 486 551 571 630 786 850 973 1099

132SA 785 849 996 1122

160M 1004 1130

Motor Frame Dimension k

Size 890 891 892 893 894 895 896 897 898

63 256 284 311 331

71 260 288 317 337

80 273 301 335 355 414 506 570

90 283 311 345 365 424 509 573

100 246 300 372 392 435 515 579 670 796

112 231 300 372 392 435 515 579 670 796

132 372 391 458 515 579 670 796

160 466 545 614 705 789

180 614 705 789

200 614 705 789

225 641 732 816

250 988

280 988

TRIPLE REDUCTION DIMENSIONS

QUINTUPLE REDUCTION DIMENSIONS

Section

SERIES K - GEARBOXES

8

GEARBOXES

FEN01/10 - Drive Design & Maintenance Manual 299

Extended Output Shaft *

SIZE Ø d i2 L L11 L12 o t u v

890 25.015 / 25.002 50 50 3 40 134.0 28.0 8 M10 x 1.5, 22 Deep

891 30.015 / 30.002 60 60 3 50 175.0 33.0 8 M12 x 1.75, 28 Deep

892 35.018 / 35.002 70 70 3 60 176.0 38.0 10 M16 x 2, 36 Deep

893 40.018 / 40.002 80 80 3 70 210.0 43.0 12 M16 x 2, 36 Deep

894 50.018 / 50.002 100 100 3 80 242.0 53.5 14 M16 x 2, 36 Deep

895 60.030 / 60.011 120 120 3 100 285.0 64.0 18 M20 x 2.5, 42 Deep

896 70.030 / 70.011 140 140 3 110 341.0 74.5 20 M20 x 2.5, 42 Deep

897 90.035 / 90.013 170 170 5 140 405.5 95.0 25 M20 x 2.5, 42 Deep

898 110.035 / 110.013 210 210 5 180 475.5 116.0 28 M24 x 3, 55 Deep

* It is recommended that when using a B5 output flange and output shaft, the extended version is used

SIZE Øa1 a4 Øb1 c1 Øe1 f1 h M Øs1

890 160 144.0 110 j6 10 130 3.5 100 45° 9

891 200 190.0 130 j6 12 165 3.5 112 45° 11

892 250 189.0 180 j6 16 215 4.0 132 45° 14

893 250 220.0 180 j6 18 215 4.0 140 45° 14

894 300 247.0 230 j6 18 265 4.0 180 45° 14

895 350 285.0 250 h6 18 300 5.0 212 45° 18

896 450 351.0 350 h6 20 400 5.0 265 22.5° 18

897 450 410.5 350 h6 22 400 5.0 315 22.5° 18

898 450 470.5 350 h6 22 400 5.0 375 22.5° 18

øe1

M

8 Holes

s1 dia

a4

h

B5 Output Flange on Left

u

f1

i2

c1

o

øb1

øa1

L

L12 L11

B5 Output Flange on Right

Tapped Hole

v

t

ød

u

Output Shaft

SIZES 890 TO 895

SIZES 896 TO 899

B5 FLANGE DIMENSIONS

øe1

M

4 Holes

s1 dia

B5 FLANGE DIMENSIONS

EXTENDED OUTPUT SHAFT DIMENSIONS

Accessories

SERIES K - GEARBOXES

8

300 Drive Design & Maintenance Manual - FEN01/10

Unit Single Extension Double Extension Single Extension * B5 Output Torque

Size Output Shaft Output Shaft Extended Output Shaft Flange Arm

890 890A9700 890A9800 890A9900 871A9900 890A9600

891 891A9700 891A9800 891A9900 872A9900 891A9600

892 892A9700 892A9800 892A9900 892A9300 892A9600

893 893A9700 893A9800 893A9900 893A9300 893A9600

894 894A9700 894A9800 894A9900 894A9300 894A9600

895 883A9700 895A9800 895A9900 875A9900 895A9600

896 884A9700 896A9800 896A9900 876A9900 896A9600

897 885A9700 897A9800 897A9900 877A9900 897A9600

898 898A9700 898A9800 898A9900 877A9900 898A9600

øQ

øe5

F7

22. 5o

22.5 o

22.5 o

22.5 o

22.5 o

22. 5o

f F

o2 o2

ør

øR

Male spigot

890 - 894

Female recess

895 - 898

B14 FLANGE DIMENSIONS

890, 891 & 895

øe5

øQ

30o

30o

30o

30o

892

ACCESSORY PRODUCT CODES

Size Øe5 F7 o2 Q Ør h7 ØR H7 Spigot f Recess F

SPIGOT Ø

890 107 PCD 6 HOLES M8 X 1.25, 12 DEEP 55 122 85 - 2.5 -

891 130 PCD 6 HOLES M8 X 1.25, 12 DEEP 70 146 105 - 2.5 -

892 125 PCD 6 HOLES M10 X 1.5, 17 DEEP 75 150 105 - 3.0 -

893 150 PCD 6 HOLES M10 X 1.5, 17 DEEP 83 180 130 - 3.5 -

894 150 PCD 8 HOLES M10 X 1.5, 17 DEEP 95 180 130 - 6.0 -

895 195 PCD 6 HOLES M12 X 1.75, 20 DEEP 115 220 - 150 - 5

896 230 PCD 5 HOLES M16 X 2.0, 27 DEEP 145 260 - 180 - 6

897 280 PCD 8 HOLES M16 X 2.0, 27 DEEP 170 310 - 210 - 7

898 280 PCD 9 HOLES M16 X 2.0, 27 DEEP 200 310 - 210 - 7

øe5

øQ

45o

45o

893

øe5

øQ

45o

45o

45o

45o

894

øe5

øQ

30o

30o

30o

30o

896

øe5

øQ

36o

36o

36o

18o

18o

18o

18o

897

øe5

øQ

36o

36o

36o

18o

18o

18o

18o

898

* For use with B5 Output flange

Accessories

SERIES K - GEARBOXES

8

294 Drive Design & Maintenance Manual - FEN01/10

SIZE a a2 a3 b b0 c e f f0 g2* h h1 k* n n0 o p3 q q1 T2* s w7 z

890 100 28 32 110 115 11 120 143 152 140 100 16 333 38 38 60 167 63 159 111 11 63 0.0

891 120 35 37 130 130 16 145 168 171 140 112 13 361 38 40 75 187 71 179 111 11 78 2.5

892 130 30 45 130 150 15 157 170 192 180 132 5 410 40 40 83 217 80 219 111 14 87 4.5

893 140 30 45 120 160 20 170 176 208 180 140 13 430 55 48 90 233 90 229 111 14 94 5.0

894 165 40 55 150 200 27 200 210 263 212 180 25 492 60 55 105 288 112 265 115 18 109 5.0

895 180 55 70 180 233 30 230 256 309 250 212 15 622 76 76 120 341 132 330 160 23 124 5.0

896 240 75 75 240 295 35 290 340 395 300 265 10 710 100 100 150 420 160 355 195 27 154 5.0

897 270 95 95 280 360 40 340 390 455 360 315 41 856 110 115 175 513 200 423 233 34 180 5.0

898 330 115 110 350 420 45 400 470 540 400 375 65 987 120 120 205 590 225 476 286 39 210 5.0

*Dimensions relate to triple reduction, see quintuple reduction table on facing page for quintuple reduction dimensions

TRIPLE REDUCTION

QUINTUPLE REDUCTION

Non Motorised Dimensions

SERIES K - GEARBOXES

8

302 Drive Design & Maintenance Manual - FEN01/10

Satisfactory performance depends on proper

installation, lubrication and maintenance. All

instructions given in the installation leaflet

must be followed carefully.

Shaft Mounting

Ensure that the shaft on to which the gear

unit is to be mounted and the gear unit

bore are clean and free from burrs.

Liberally smear the shaft and bore with

lubricants to aid assembly and prevent

fretting corrosion. Slide the unit on to the

driven shaft. Fit side fitting key. DO NOT

USE TAPER OR TOP FITTING KEY.

Foot Mounting

Mount the unit securely to a rigid struc-

ture. Fit the output extension shaft as

required. Use flexible couplings such as

Fenaflex for shaft to shaft connections and

ensure that shaft misalignment is within

the coupling's capacity. When a pulley or

sprocket is fitted to either shaft, mount it

as close as possible to the gearcase.

When fitting or removing drive compo-

nents do not hammer on shaft as this will

damage the bearings, Fenner Taper Lock

bushes permit easy fixing and dismantling

without undue force.

LUBRICATION

Sizes 890 to 893 will be supplied with a

quantity of EP mineral oil (Shell Omala 320)

for mounting position B3. Other mountings

must be specified on order. However if ,

as requested, the unit is supplied without

lubricant then the oil quantity is obtained

from Tables 1 & 2. Sizes 894 to 898 are

supplied without oil. Before running they

should be filled with an appropriate amount

of the correct lubricant shown in tables 1

& 2, dependent on the mounting position,

see below.

WARNING Do not overfill as excess lubri-

cant may cause overheating and leakage.

Oil Changes

Sizes 890, 891 and 892 are lubricated for

life except when the units are required to

work in an explosive atmosphere. (94/9/EC

Atex 100a Group II category 2 zones 1 &21

& category 3 zones 2 & 22). See separate

leaflet for recommendations. All other sizes

will require an oil change depending on the

unit operating temperature. Initial fill of oil

should be changed in a new gear unit after

1000 hours operation or one year or half

the life in the table below whichever is the

soonest.

Temperature Limitations

The standard lubricant is suitable for opera-

tion in ambient temperatures of 0 to 35°C,

outside of this consult your local Author-

ised Distributor.

BREATHERS/MOUNTING POSITIONS

Sizes 890,891 & 892 are supplied for op-

eration without breathers.

Size 893 is supplied for operation with a

breather but to prevent leakage during

transit this unit is fitted with blanking plugs.

It is essential that when the unit is in its op-

erating position the relevant blanking plug

is removed and replaced by the breather

plug (supplied) in the position indicated on

the installation leaflet.

Sizes 894 to 898 are supplied for operation

with a breather but are despatched without oil.

It is essential that when the unit is in its op-

erating position the relevant blanking plug

is removed and replaced by the breather

plug (supplied) in the position indicated on

the installation leaflet.

STARTING UP

Prior to starting up the following procedure

should be followed

Ensure Ventilator is fitted (size 893 and

1.

above)

Check Oil level (893 and above) top up

2.

if necessary

Ensure all safety devices are in place

3.

(i.e. guards fitted)

Remove any safety devices fitted to

4.

prevent machine rotation

Starting up should be performed or super-

vised by suitably qualified personnel.

MOUNTING POSITIONS

Plug positions apply for sizes 893 and larger. Ventilator/Filling Position Level Position Drain Position

Installation and Maintenance

Ceiling Mounted (B8)

Standard Floor Mounted (B3)

Right Hand Wall Mounting (B7) Left Hand Wall Mounting (B6)

Vertical Mounting Shaft Up (V6) Flange Mounting Shaft Up (V3) Vertical Mounting Shaft Down (V5) Shaft Down Flange Mounting (V1)

Unit Op Renewal Period (Hours)

Temp °C Mineral Oil Synthetic Oil

75 or less 17000 or 3 yrs 26000 or 3 yrs

80 12000 or 3 yrs 26000 or 3 yrs

85 8500 or 3 yrs 21000 or 3 yrs

90 6000 or 2 yrs 15000 or 3 yrs

95 4200 or 17 mths 10500 or 3 yrs

100 3000 or 12 mths 7500 or 2.5 yrs

105 2100 or 8 mths 6200 or 2 yrs

110 1500 or 6 mths 2100 or 18 mths

† † *

† Gear units for use in mounting

positions B6 and B7 should only be

selected with overall ratios greater than

or equal to those shown in the table

below.

* Mounting positions B6 are not

recommended for geared motors.

Please consult your local authorised

distributor.

Input Speed (rpm)

Unit Size 1000 1500 1800 >1800

890-895 All All All

896 All 11:1 14:1

897 11:1 20:1 25:1

898 16:1 32:1 36:1

Consult you local

distributor

Section

SERIES K - GEARBOXES

8

GEARBOXES

FEN01/10 - Drive Design & Maintenance Manual 303

LUBRICANT TYPE TEMPERATURE RANGE

Mounting Position

Unit B3 V5/V1 V6/V3 B8 B7 B6

Size Primary Secondary Primary Secondary Primary Secondary Primary Secondary Primary Secondary Primary Secondary

890 0.5 0.5 0.6 0.7 0.8 0.8 0.8 1.0 0.7 1.2 1.0 0.9

891 0.5 0.7 0.6 0.9 0.8 1.1 0.8 1.3 0.7 1.7 1.0 1.2

892 0.8 1.1 0.7 1.5 1.2 1.7 1.2 1.9 1.1 2.5 1.4 2.0

893 0.8 1.5 0.7 1.8 1.2 2.8 1.2 2.7 1.1 3.6 1.4 2.6

894 0.8 2.7 0.7 3.6 1.2 4.0 1.2 4.5 1.1 5.7 1.4 4.5

895 1.5 4.4 1.6 3.7 1.8 7.6 1.8 7.5 2.0 9.6 2.6 7.6

896 1.5 9.3 1.6 8.3 1.8 18.0 1.8 17.0 2.0 21.0 2.6 16.0

897 2.6 15.0 2.7 15.0 2.9 28.0 3.0 30.0 3.2 34.0 4.7 24.0

898 2.6 23.0 2.7 27.0 2.9 33.0 3.0 39.0 3.2 50.0 4.7 35.0

Unit Mounting Position

Size B3 V6/V3 V5/V1 B8 B7 B6

890 0.5 0.8 0.7 1.0 1.2 0.9

891 0.7 1.1 0.9 1.3 1.7 1.2

892 1.1 1.7 1.5 1.9 2.5 2.0

893 1.5 2.8 1.8 2.7 3.6 2.6

894 2.7 4.0 3.6 4.5 5.7 4.5

895 4.4 7.6 3.7 7.5 9.6 7.6

896 9.3 18.0 8.3 17.0 21.0 16.0

897 15.0 28.0 15.0 30.0 34.0 24.0

898 23.0 33.0 27.0 39.0 50.0 35.0

TABLE 1 LUBRICATION QUANTITY (LITRES) TRIPLE REDUCTION

TABLE 2 LUBRICATION QUANTITY (LITRES) QUINTUPLE REDUCTION

890, 891 & 892 if supplied without lubricant, fill with the correct amount as indicated in

the table below. 893 - 898 - fill gearbox until oil escapes from level plug.

Installation and Maintenance

ISO Ambient Temperature °C

Viscosity -5°C to 20°C -30°C to 20°C 0°C to 35°C 20°C to 50°C

EP Mineral Oil 220 - 320 460

Synthetic Oil 1 - 220 220 320

Synthetic Oil 2 - 220 320 460

Synthetic Oil 1 = Polyalphaolein based.

Synthetic Oil 2 = Polyglycol basrd

Supplier Mineral Oils Containing EP Synthetic Lubricants Synthetic Lubricants

Additives Polyglycol Based Polyalphaolefin based

BP Energol GR-XP or XF Enersyn SG-XP Enersyn EPX

Castrol Alpha Max or SP Alphasyn PG Alphasyn EP or T

Esso Spartan EP Glycolube Spartan Synthetic EP

Fuchs Renogear V or WE Renolin PG Renogear SG

Mobil Mobilgear 600 Glygoyle Mobilgear SHC

Shell Omala or Omala F Tivela or Tivela S Omala HD

Texaco Meropa or Meropa WM Synlube CLP Pinnacle EP

Total Carter EP Carter SY Carter EP/HT

Rocol Sapphire Hi-Torque - -

RECOMMENDED OIL GRADES

Table of contents