Fenwal FLS-02EC User manual

ES1666 K10

Instruction Manual &

Technical Bulletin of

Explosion-proof Photoelectric Smoke Detector

FLS-02EC(-H2)

Thank you very much for purchasing. This

Instruction manual contains the important points in

preventing accidents and how to handle it. Please do

read thoroughly and comprehend this manual.

After reading it, please keep it in a convenient place

for reference.

1/13

ES1666

Contents

1. OVERVIEW ................................................................................................................................ 3

2. FEATURE................................................................................................................................... 3

3. SPECIFICATION ....................................................................................................................... 3

4. STRUCTURE.............................................................................................................................. 4

5. OPERATION .............................................................................................................................. 5

5.1. Status LED ............................................................................................................................. 5

5.2. Relay ....................................................................................................................................... 5

5.3. Automatic Test Function......................................................................................................... 5

6. INSTALLATION......................................................................................................................... 5

6.1. Installation Environments...................................................................................................... 6

6.2. Mounting................................................................................................................................. 6

6.3. Wiring ..................................................................................................................................... 7

6.3.1. Specification .................................................................................................................... 7

6.3.2. Procedure......................................................................................................................... 7

7. MAINTENANCE AND INSPECTION ......................................................................................10

8. ORDERING INFORMATION....................................................................................................11

9. CONTACT US............................................................................................................................11

2/13

ES1666

Warranty Period and Warranty Scope

【Warranty Period】

Warranty of the product is valid for only malfunctions occurring in the course of normal and correct

use of the product as per the Instructions Manual, and warranty period is 1 (one) year after the

product is delivered to the consignee specified at the time of order placement.

【Warranty Scope】

For the malfunctions occurring in the product due to reasons attributable to the supplier in the

aforementioned warranty period, supplier will repair the returned product at its own responsibility.

However, the following cases are excluded from the warranty scope.

1. Malfunctions and loss due to fire, earthquake, flood, lightning, and other natural disasters.

2. Malfunctions and loss due to inappropriate handling during movement and transportation at

customer’s side after the product delivery.

3. Root cause of the malfunction is not attributable to the product.

4. Malfunction and loss due incorrect use of the product, or if repair, remodeling, erroneous

connection etc by other vendor.

5. Wear and tear of relay connections, and life span of relay parts due to welding.

Also, warranty here refers to warranty for the delivered product only, and does not cover damages

resulting from the malfunction of the product.

3/13

ES1666

1. OVERVIEW

FLS-02EC(-H2) Explosin Proof Smoke Detector has Division and Zone explosion-proof ratings. This

detector is a sensor of the smoke using the scattered light, detecting the scattering of the light

reflected by the smoke. There are light emitter (Infrared LED) and the detector (photo-diode) inside,

the former emits the light through the lens, and the latter detects the light scattered by smoke to

detect the smoke in the hazardous area. This detector outputs include a localized LED, and relays.

An example of the installation location of this detector is as follows:

Battery rooms

Combustible storage facilities

Chemical plants

Engine room, etc

2. FEATURE

Since the structure is pressure-resistant, explosion-proof, it can be fitted in a hazardous area

It also tolerates the hydrogen explosion.

FM Approved for use in Class I, Division 2 hazardous locations. and FM Approvals for smoke

detector.

IECEx & ATEX Zone approved

LED provides detector status.

3. SPECIFICATION

Type

(Standard) FLS-02EC

(Hydrogen gas compatible) FLS-02EC-H2

Electronic

specification

Rating

DC24V,5mA(Standby),10mA(Alarm)

Range of the voltage

DC24V±10%

Alarm Level

1.8 to 3.1 %/ft

Status LED

Color : Red

Normal : Blinks once in 10 seconds

Alarm : Blinks once in 2 seconds

Trouble : Light out

Output Relay

Alarm Relay : Form A, DC24V 1A.

Trouble Relay:Form B, DC24V 1A.

Range of the

temperature

Operating

0 to +50 degree C

Storge

-20 to +70 degree C

Range of the operation

humidity

30 to 85 %RH (no condensation)

Mechanical

specification

external dimensions

136×136×100

material

aluminum alloy (ADC12)

color

Black

Weight

Approx 3kg

Certification

For complete approval details, refer to the

Appendix A.

4/13

ES1666

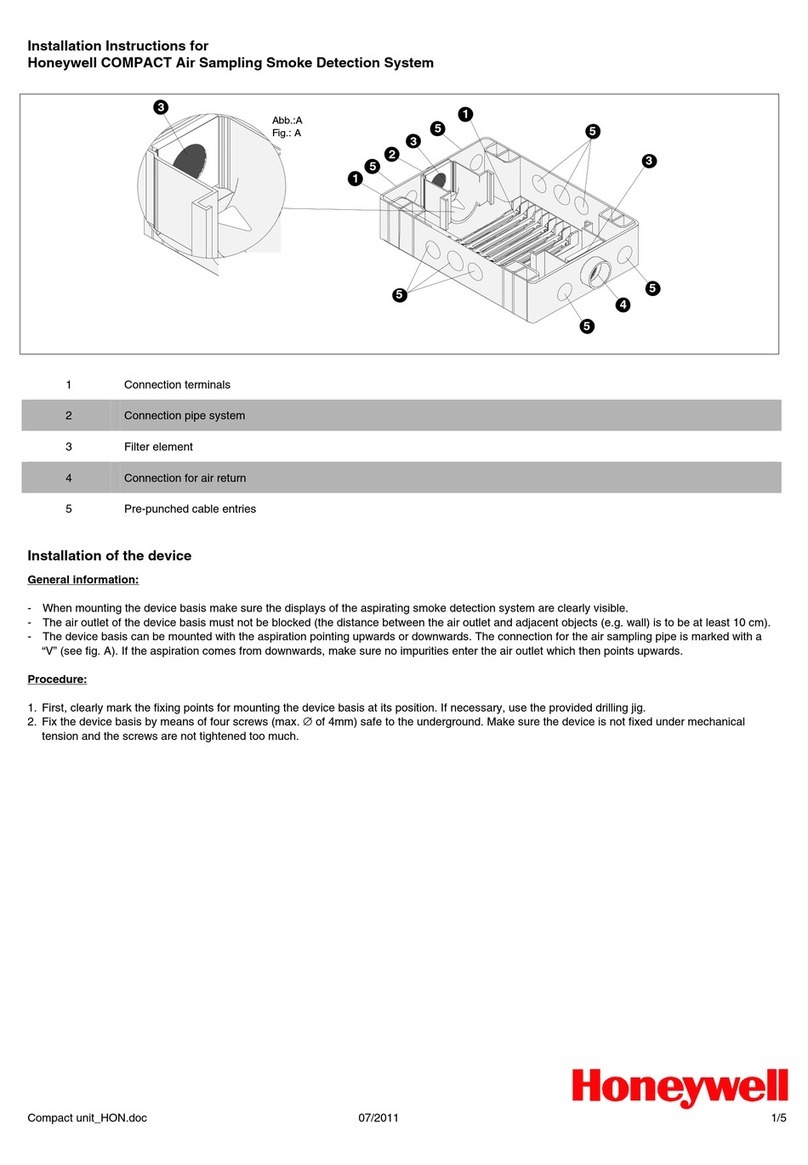

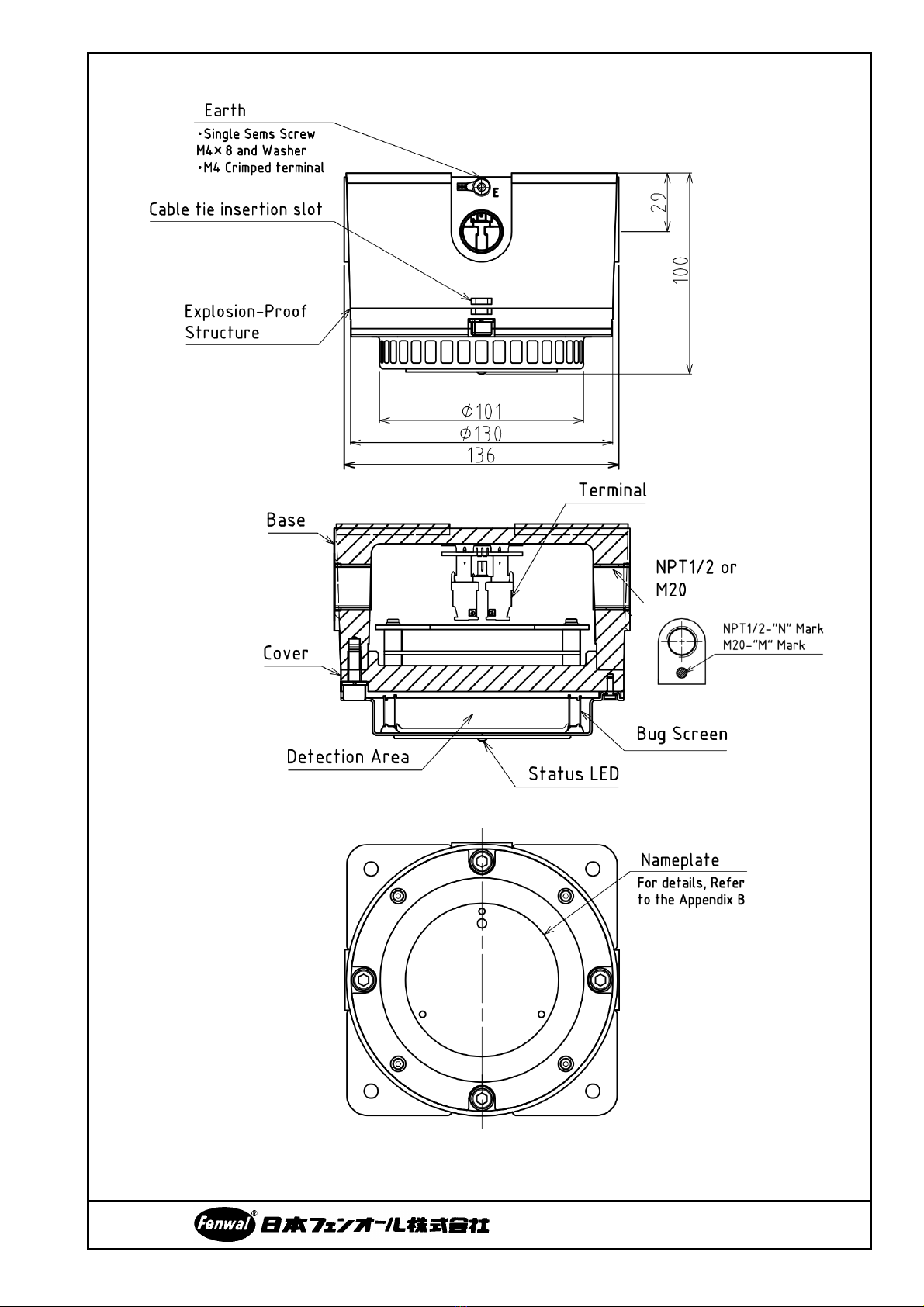

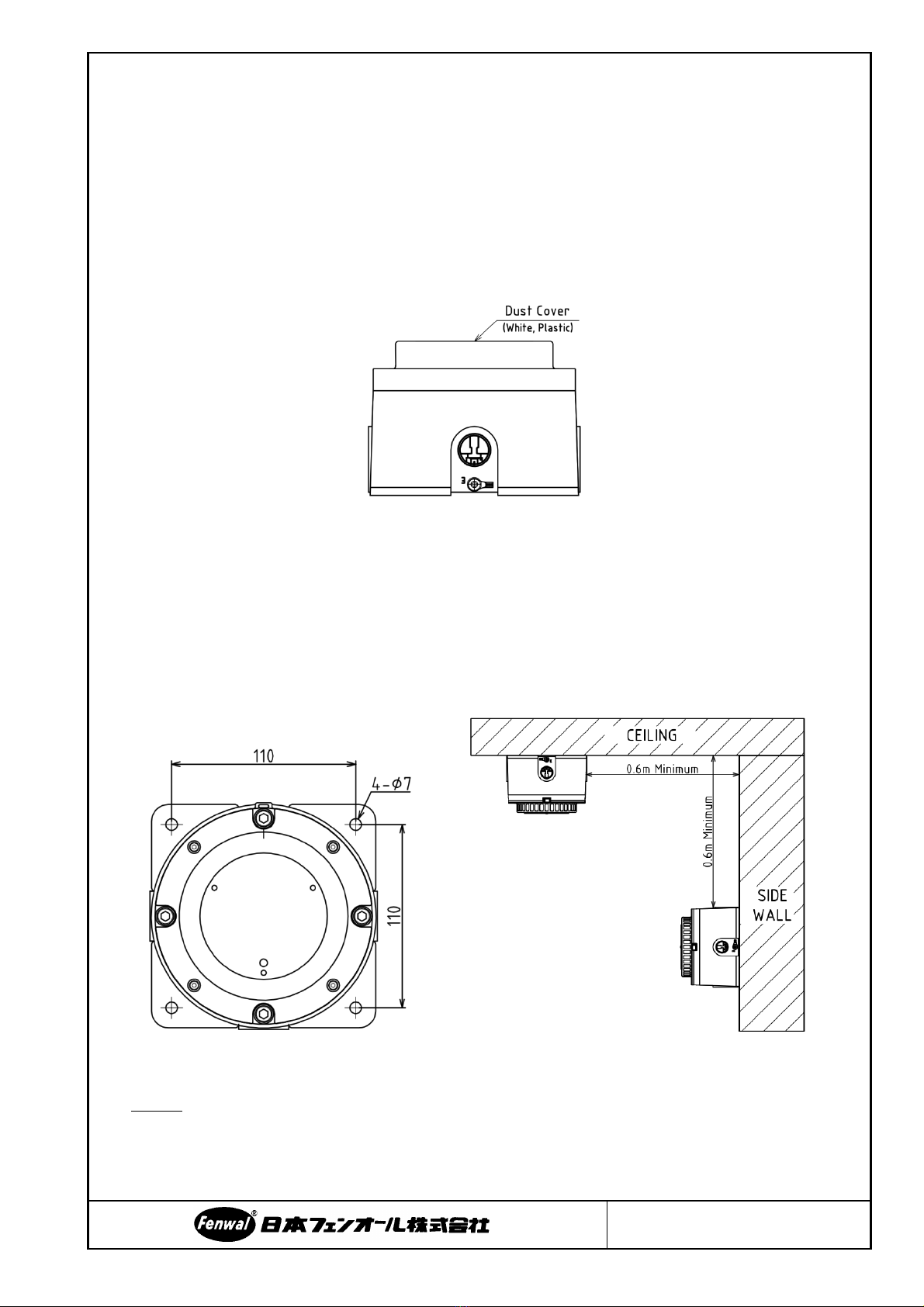

4. STRUCTURE

Figure 1 : FLS-02EC(-H2) Structure

5/13

ES1666

5. OPERATION

5.1. Status LED

Status LED indicates the state of equipment. Table 1 indicates the condition of the LED for each

status. Alarm condition takes priority over trouble condition.

Table 1 - Status LED Operation

Status of detector

LED Indicator

Normal

Blinks once in 10 seconds

Alarm

- Blinks once in 2 seconds

- this indication latching until power-cycle a

system.

Trouble

- Light out

- this indication non-latching.

5.2. Relay

FLS-02EC(-H2) has alarm and trouble relays. All relays are rated to DC24V / 1A. Table 2 indicates

the operation of each relays.

Table 2 - Relays Operation

Relay

Name

Condition

Note

Power

OFF

Normal

Alarm

Trouble

Alarm

Open

Open

Close

Open

this relay latching until

power-cycle a system.

Trouble

Open

Close

Close

Open

this relay non-latching.

5.3. Automatic Test Function

Every hour, detector supervises changes of smoke signal due to aging and dirt of sensor. When

changes of smoke signal reaches to the limit, it will result in Trouble condition.

And, detector supervises the light emission state of detection area every 24 hours (and after 60

seconds since turning on the power). When detection area is light out, it will result in Trouble

condition.

6. INSTALLATION

・FLS-02EC(-H2) must be properly installed and used according to this manual and the

specific approval certificates. Improper installation and use will invalidate warranty and

product certifications.

・Do not disassemble or repair the detector without permission. Detector repair should be

performed only by the manufacturer.

・Be certain that installation complies with all local codes. If you have questions, consult

the authority having jurisdiction before installation the system.

・Please install the detector after turning off the power.

・The FLS-02EC and FLS-02EC-H2 include flameproof joints, consult Fenwal Control of

Japan if repair of the flameproof joints is necessary.

!

WARNING

6/13

ES1666

6.1. Installation Environments

1. Temperature : 0 to +50 degree C

2. Humidity : 30 to 85%RH(However, no condensation)

3. Caution :

・Installed Indoors

・Avoid drops of water, moisture, corrosive gases, and vapors of organic solvents.

・Avoid direct sunlight and radiation by high temperature.

・The Dust Cover (see Figure 2) keeps dust and particles out of the smoke chamber that may

enter. Don't remove it until installation is over.

Figure 2 : Dust Cover

6.2. Mounting

1 ) Fix the FLS-02EC(-H2) to the wall with four M5 or M6 bolts using base 4-φ7 hole (See Figure 3) .

bolt length more than 11 (eleven) mm. It must be mounted on a ceiling or wall of sufficient

strength to support the weight.

2 ) It is normally mounted on the ceiling no less than 0.6 m ( twenty-four inch ) from a side wall, and

vice versa (See Figure 3).

Figure 3 : Mounting

[NOTE] FLS-02EC(-H2) separates the base and cover and packs it

7/13

ES1666

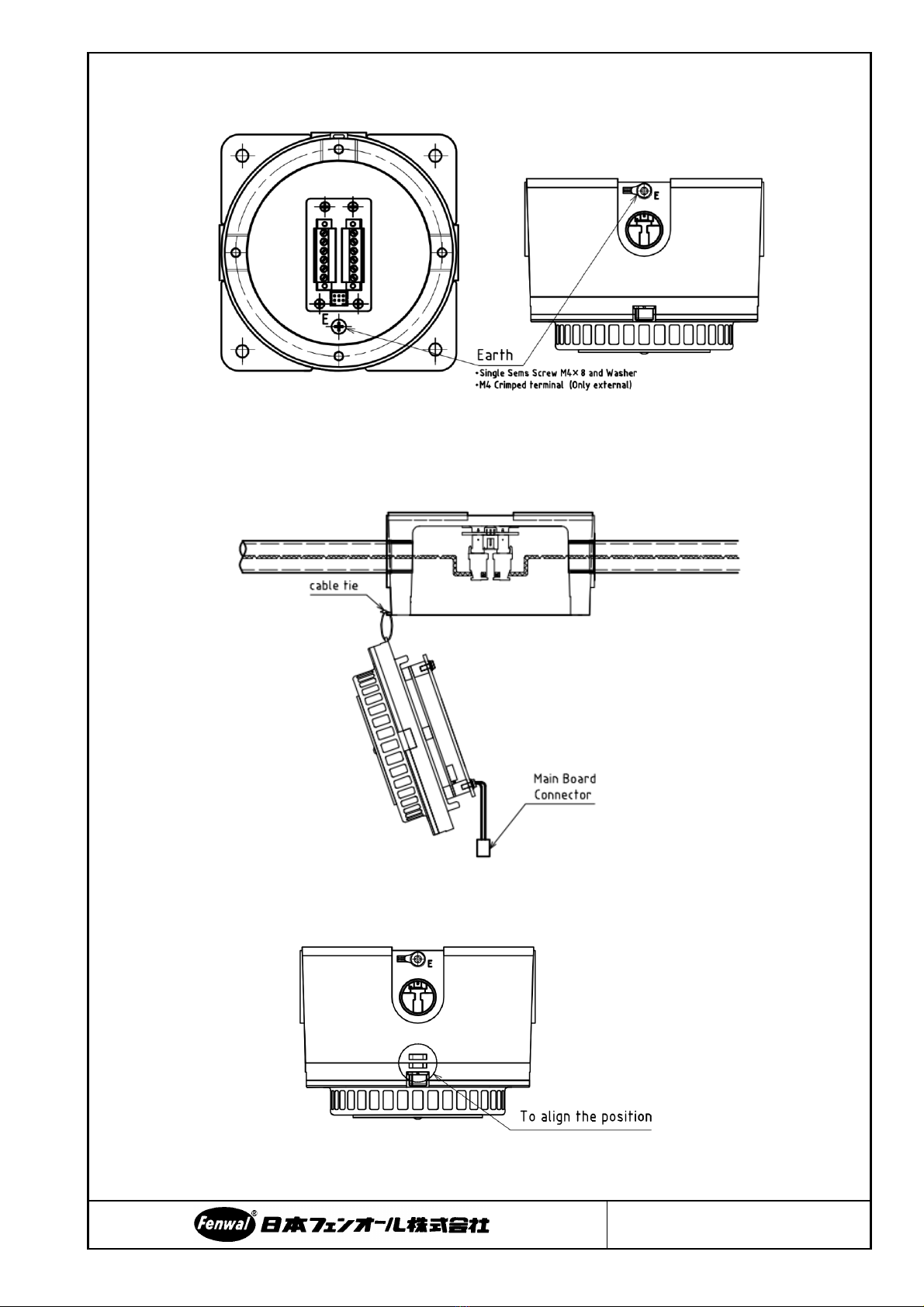

6.3. Wiring

6.3.1. Specification

Table 3 shows the pin assignments of the terminal blocks

CN4 and CN5 (See Figure 4 for exterior view).

Table3 - Pin assignments of Terminal Board

Pin No

Function

1

+24V

2

0V

3

Alarm contact-Normal Open

4

Alarm contact-Common

5

Trouble contact-Normal Close

6

Trouble contact-Common

The diameter of usable wiring is as follows.

Wiring Diameter : (Minimum) 0.2mm2 (Maximum) 2.5mm2

Case of AWG : (Minimum) 24 (Maximum) 12

The screws must be tightened down with a torque 0.5 to 0.6 N•m.

The environmental specification of the cable should be sufficient to withstand the surrounding

environment.

6.3.2. Procedure

1 ) Install the base according to "6.2 Mounting", and complete the installation of the system conduit.

Insert the external cable within the base and close the unused NPT1/2 or M20 entry with the

plug (See Figure 5). Conductor insulation of external wiring should be stripped off with a bare

conductor length of about 0.3 inch (7 mm)

Figure 5 - Install Base

Be certain that wiring complies with all local codes. If you have questions, consult

the authority having jurisdiction before wiring the system.

!

WARNING

Figure 4 - Terminal Board external view

8/13

ES1666

2 ) Connect the external wiring to the appropriate terminals according to "6.3.1 Specification". Refer

to Figure 6 for the earth terminal location and Figure 10 for the wiring diagram.

Figure 6 - Earth terminal

3 ) Hang the cover with a cable tie on the base, and main board connector connect to CN3 of terminal

board (See Figure 7).

Figure 7 - Connection between main board and terminal board

4 ) Attach the cover to the base and align the binding band insertion slot (See Figure 8).

Figure 8 - Attaching the cover

9/13

ES1666

5 ) Fix the 4 places with the attached M6 screw. And, close the unused NPT1/2 or M20 entry with

the plug.

Figure 9 - Fix the cover

Figure 10 - Wiring Diagram

・Please use the plug attached to the detector or one that has been certification to withstand

explosion-proof (Ex d). An example of explosion-proof plug is shown below.

NPT1/2 : CMP-757-D-T1-5 (R.STALL, INC.)

M20×P1.5 : CMP-757-D-M2-5 (R.STALL, INC.)

・Consult with Fenwal Controls of Japan, Ltd. for genuine replacement cover fasteners:

M6X20 hexagon bolts of A2-70 strength class SUS304 stainless steel or better are

acceptable alternatives.

!

WARNING

10/13

ES1666

7. MAINTENANCE AND INSPECTION

In order to check that the system is functioning correctly, it is recommended to perform maintenance

and inspection according to environment (Standard once a year).

FLS-02EC(-H2) can be tested using the same methods employed for any photo-electric detector. For

example, test smoke can be used.

If the detector are in fails condition (do not responding to the operation test, the status indicator

does not light up, etc), please turn off. Then contact us. The detector is not designed to be repaired in

the field.

[Note]

If signal transfer output of an error or alarm to external devices is likely to occur during maintenance,

ensure to inform the Customer’s department in-charge in advance, and then conduct the inspection.

Moreover, when buzzer is going to ring, notify the people in surrounding area beforehand.

Since in many cases it is necessary to move furniture and equipments of customer during

maintenance, discuss closely with the customer in advance and ensure that operators are not injured

and other equipments are not damaged.

11/13

ES1666

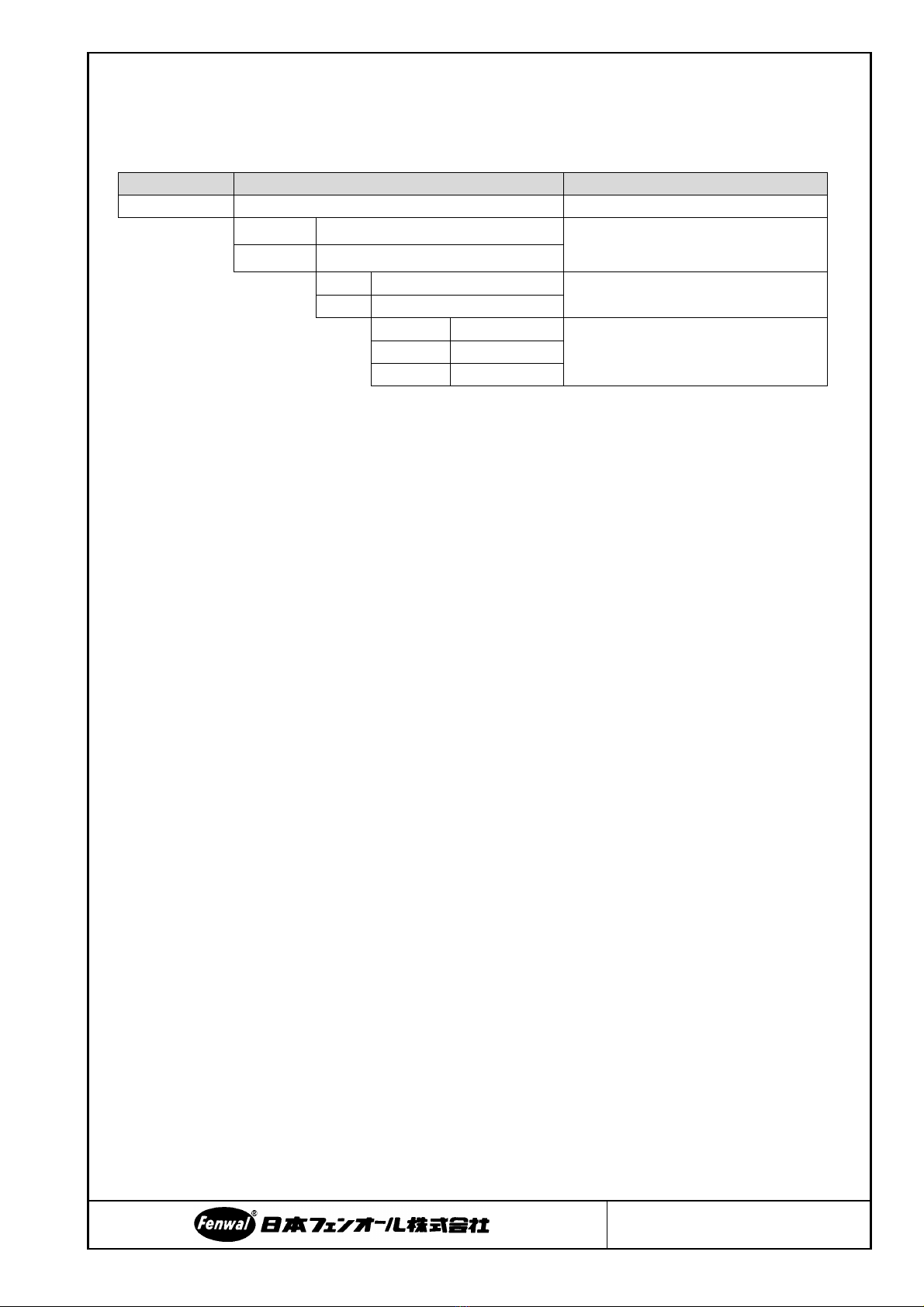

8. ORDERING INFORMATION

When ordering, please specify. Refer to FLS-02EC(-H2) Model Matrix for details.

FLS-02EC(-H2) Model Matrix

MODEL

DESCRIPTION

NOTE

FLS-02EC

Explosion Proof Smoke Detector

-H2

Support to hydrogen gas

See Appendix for details.

-(None)

No support to hydrogen gas

-M

Metric thread (M20)

-N

NPT thread (NPT1/2)

1

Plug:1

Quantity of attached plug

2

Plug:2

3

Plug:3

9. CONTACT US

Please contact our authorized distributors, or the head office or sales offices of the Fenwal Controls

of Japan, Ltd. in inquiring about the product.

Fenwal Controls of Japan, Ltd.

2nd floor, Kyouhan Kudan Bldg., 1-5-10, Iidabashi, Chiyoda-ku, Tokyo, Japan, 102-0072

Tokyo Head Office : (+81)-3-3237-3565

Web Inquiry : http://www.fenwal.co.jp/en/form/

12/13

ES1666

APPENDIX A

FM Certification

FM18US0151X

FLS-02EC Class I, Division 1, Group C,D T6

Class I, Zone 1, AEx db IIB T6 Gb

FLS-02EC-H2 Class I, Division 1, Group B,C,D T6

Class I, Zone 1, AEx db IIB+H2 T6 Gb

Approval Standards

ANSI / ISA 60079-0:2013 Explosive atmospheres - Part 0: Equipment - General Requirements

ANSI / UL 60079-1:2015 Explosive atmospheres - Part 1: Equipment protection by flameproof

enclosures “d”

FM 3600(2018) Electrical Equipment for Use in Hazardous (Classified) Locations -

General Requirements

FM 3615(2018) Explosionproof Electrical Equipment General Requirements

FM 3230(2019) Smoke Actuated Detectors For Automatic Fire Alarm Signaling

IECEx Certification

IECEx FMG 16.0040X

FLS-02EC Ex db IIB T6 Gb

FLS-02EC-H2 Ex db IIB+H2 T6 Gb

Approval Standards

IEC 60079-0:2011 (Ed.6) Explosive atmospheres - Part 0: Equipment - General Requirements

IEC 60079-1:2014 (Ed.7) Explosive atmospheres - Part 1: Equipment protection by flameproof

enclosures “d”

ATEX Certification

FM16ATEX0107X

FLS-02EC II 2 G Ex db IIB T6 Gb

FLS-02EC-H2 II 2 G Ex db IIB+H2 T6 Gb

Approval Standards

EN 60079-0:2012+A11:2013 Explosive atmospheres - Part 0: Equipment - General Requirements

EN 60079-1:2014 Explosive atmospheres - Part 1: Equipment protection by flameproof

enclosures “d”

Special Conditions For Safe Use X:

1. The FLS-02EC and FLS-02EC-H2 include flameproof joints, consult Fenwal Controls of Japan,

Ltd. if repair of the flameproof joints is necessary.

2. Consult with Fenwal Controls of Japan, Ltd. for genuine replacement cover fasteners: M6X20

hexagon bolts of A2-70 strength class SUS304 stainless steel or better are acceptable

alternatives.

13/13

ES1666

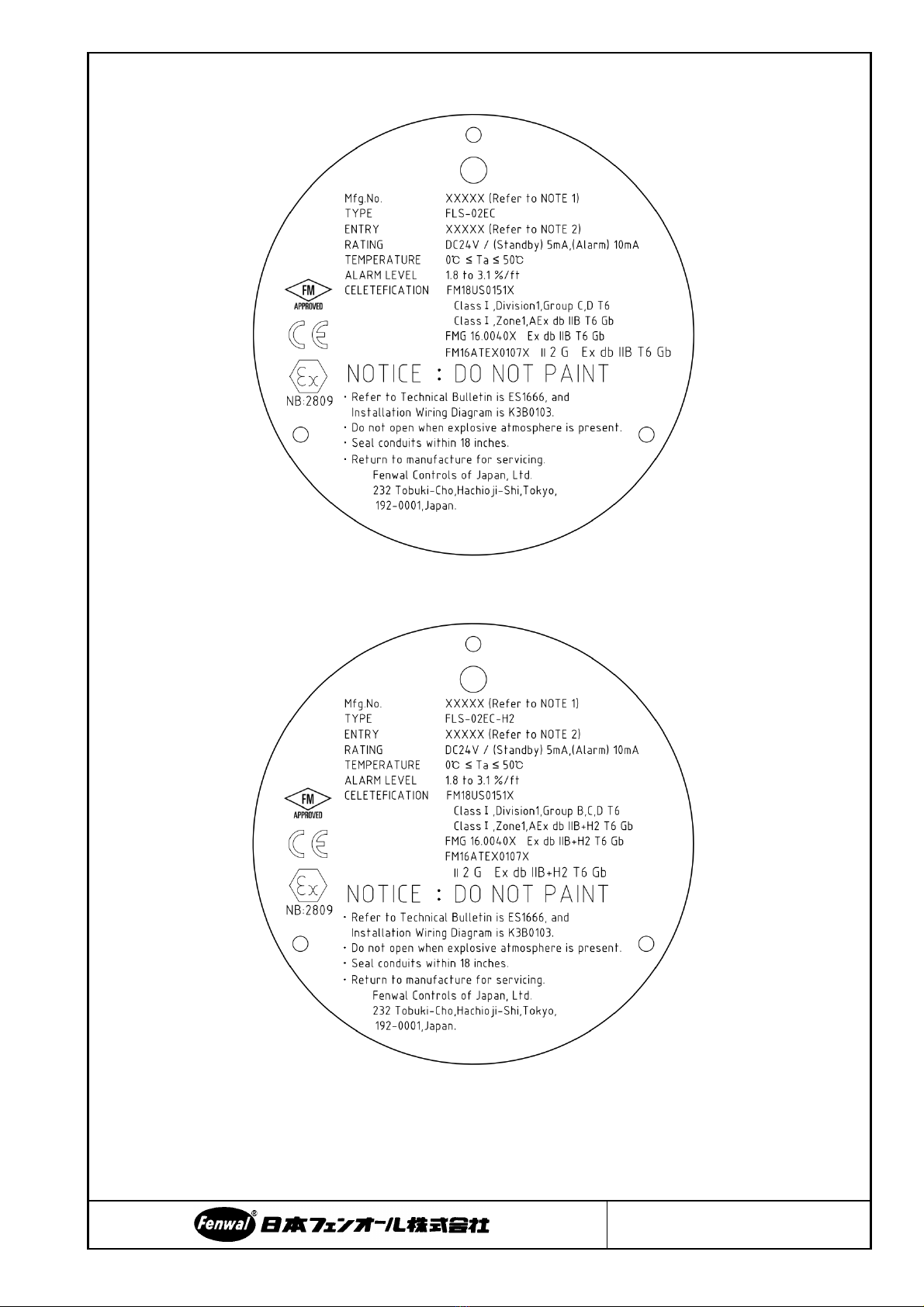

APPENDIX B

FLS-02EC Nameplate

FLS-02EC-H2 Nameplate

NOTE

1. Mfg.No. is unique number of product.

2. ENTRY is thread size (M20×P1.5 or NPT1/2).

This manual suits for next models

1

Table of contents

Other Fenwal Smoke Alarm manuals